Complete Guide to Kubota M4700 Parts Diagram

In the realm of agricultural machinery, a comprehensive grasp of the various elements that make up these powerful machines is essential for optimal performance and maintenance. Knowing how different components interact can enhance the longevity and efficiency of the equipment.

Farm equipment often consists of a myriad of parts, each with a specific function and purpose. A clear visual representation of these elements can aid operators and technicians in identifying issues and performing necessary repairs with confidence.

In this discussion, we will explore detailed representations that showcase the configuration of critical components within a particular model. Such resources are invaluable for anyone looking to improve their understanding of machinery functionality, facilitating both troubleshooting and effective upkeep.

Kubota M4700 Overview

This section provides a comprehensive look at a specific agricultural machine renowned for its reliability and efficiency in various farming tasks. Designed to cater to the needs of modern agriculture, it combines power with versatility, making it an essential tool for farmers.

| Feature | Description |

|---|---|

| Engine Power | Offers robust horsepower suitable for heavy-duty tasks. |

| Transmission | Equipped with a reliable transmission system for smooth operation. |

| Hydraulic System | Features a strong hydraulic system for effective implement handling. |

| Design | Engineered for user comfort and ease of maintenance. |

Importance of Parts Diagrams

Understanding the layout and composition of machinery components is crucial for effective maintenance and repair. Visual representations serve as essential guides, allowing users to identify each element’s role and placement within the system. This clarity not only aids in troubleshooting but also enhances overall operational efficiency.

Facilitating Maintenance

Having a clear visual reference simplifies the upkeep process. Technicians can quickly locate specific pieces, ensuring timely replacements and adjustments, which ultimately extends the lifespan of the equipment.

Enhancing Training and Support

For new operators and technicians, these visuals serve as valuable educational tools. They provide a foundational understanding of complex machinery, enabling faster learning and reducing errors during hands-on tasks.

Common Parts of M4700 Model

This section provides an overview of frequently used components in a specific agricultural machine. Understanding these elements is essential for maintenance and repair, ensuring optimal performance and longevity of the equipment. Various crucial pieces work in harmony to facilitate functionality and efficiency in operations.

Engine Components

The engine is the heart of the machine, responsible for providing the necessary power for various tasks. Key elements include the cylinder head, which houses critical parts such as valves and spark plugs, and the fuel pump, essential for delivering fuel to the engine. Regular inspection of these components can prevent operational issues and enhance overall performance.

Transmission Elements

Another vital aspect involves the transmission system, which transfers power from the engine to the wheels. Important components include the gearbox, which regulates speed and torque, and the clutch assembly, allowing smooth engagement and disengagement of gears. Maintaining these parts is crucial for ensuring seamless operation and improving the machine’s efficiency.

Identifying Parts by Diagram

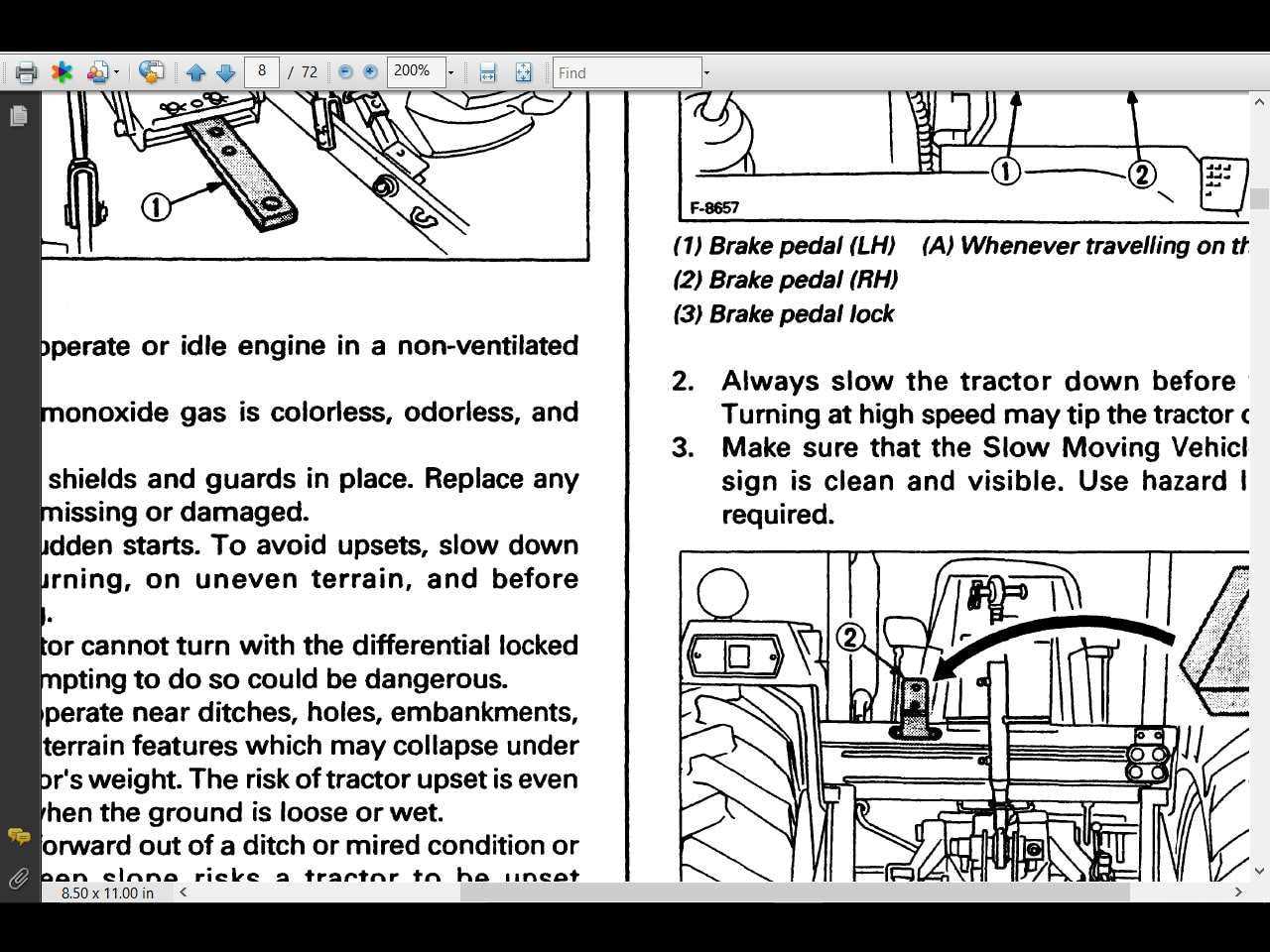

Understanding the components of machinery through visual representations is essential for effective maintenance and repair. By utilizing these illustrations, users can quickly pinpoint specific elements, ensuring efficient troubleshooting and restoration processes. This method not only enhances clarity but also streamlines workflow, making it easier to manage various tasks.

Benefits of Visual Identification

Using illustrations to recognize components offers numerous advantages. First, it simplifies the identification process, allowing users to match parts with their corresponding numbers or labels. This can significantly reduce the time spent searching for specific items. Additionally, having a clear visual guide minimizes the risk of errors during reassembly or replacement, contributing to overall operational efficiency.

How to Effectively Use Illustrations

To make the most of these visual aids, start by familiarizing yourself with the layout. Identify key sections and familiarize yourself with the symbols used to represent different elements. This knowledge will help in quickly locating parts when needed. Always keep a reference handy while working, ensuring that you can easily verify information as you progress through tasks.

Maintenance Tips for Kubota M4700

Regular upkeep is essential to ensure longevity and optimal performance of your agricultural machinery. Adopting a systematic approach to maintenance can significantly reduce downtime and enhance efficiency. This section outlines key strategies to keep your equipment in peak condition.

Routine Inspections

Conducting frequent assessments helps identify potential issues before they escalate. Check fluid levels, inspect belts and hoses for wear, and monitor tire pressure. Addressing small problems early can prevent costly repairs later.

Lubrication and Cleaning

Proper lubrication is crucial for reducing friction and preventing wear on moving parts. Use the recommended lubricants and ensure all joints and bearings are well-greased. Additionally, regularly cleaning the machine helps avoid build-up that can impair functionality.

Where to Find Genuine Parts

Finding authentic components for machinery is crucial for maintaining optimal performance and longevity. Reliable sources ensure that you receive high-quality replacements that fit perfectly and operate efficiently.

Here are some recommended avenues to explore when seeking genuine components:

- Authorized Dealers: Visiting a certified distributor guarantees access to official merchandise. They often have a comprehensive inventory and can provide expert guidance.

- Manufacturer Websites: Official online platforms frequently offer the latest information on available products, along with detailed specifications and support resources.

- Trade Shows and Expos: Industry events are excellent opportunities to connect with vendors and discover new offerings, often including exclusive promotions.

- Online Marketplaces: Reputable e-commerce sites can provide a wide selection of items. Be sure to check seller ratings and reviews to ensure authenticity.

When searching for replacements, always verify that the components meet quality standards to protect your investment and ensure seamless operation.

Common Repairs and Parts Needed

Understanding the typical maintenance tasks and components required for efficient operation is crucial for any machinery. This section outlines frequent issues encountered and the essential items necessary for repairs, ensuring optimal performance and longevity.

Frequent Issues

Common problems include engine overheating, transmission failures, and hydraulic system leaks. Addressing these issues promptly helps maintain productivity and prevent further damage.

Essential Components

| Repair Type | Required Items |

|---|---|

| Engine Overhaul | Piston rings, gaskets, oil filters |

| Transmission Repair | Seals, bearings, fluid |

| Hydraulic System Service | Hoses, pumps, filters |

Understanding Part Numbers and Codes

In the realm of machinery, identifying the correct components is crucial for efficient maintenance and repairs. Each item is assigned a unique identifier, often a combination of letters and numbers, which serves as a key to unlock information about its specifications and compatibility. Understanding these identifiers can significantly streamline the repair process and ensure the right items are sourced for any given task.

Part codes typically reflect specific attributes of the item, including size, function, and design revisions. They may include prefixes that indicate the category of the component or its application, providing immediate context to the user. For example, a certain prefix might denote a part suitable for agricultural equipment, while another could signify compatibility with construction machinery.

Deciphering these codes requires familiarity with the numbering system employed by manufacturers. Often, a series of numbers follows the prefix, representing the actual component. Additionally, suffixes may indicate variations or updates to the design, helping users distinguish between similar items. Understanding this structure is essential for accurately ordering replacements and maintaining the efficiency of machinery.

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components offers numerous advantages that can enhance the performance and longevity of machinery. These high-quality elements are designed specifically for compatibility, ensuring optimal operation and minimizing the risk of malfunctions.

Reliability is one of the primary benefits. Components made by the original manufacturer are subjected to rigorous testing, which guarantees their durability and effectiveness. This leads to fewer repairs and maintenance issues over time.

Additionally, using these parts often results in better resale value. Buyers typically prefer machinery with authentic components, as this reflects care and maintenance. Furthermore, OEM elements frequently come with warranties that provide added security for your investment.

Finally, opting for original components promotes sustainability. Quality parts reduce waste, as they last longer and operate more efficiently. By choosing OEM, you’re making a smart choice for both your equipment and the environment.

Upgrading vs. Replacing Components

When it comes to enhancing machinery performance, the decision often boils down to whether to upgrade existing elements or replace them entirely. Each approach has its merits and potential drawbacks, making it essential to evaluate the specific needs and conditions of the equipment.

Upgrading involves improving parts without full replacement, allowing for enhanced functionality and longevity. This method can often be more cost-effective, as it focuses on integrating new technologies or materials into existing frameworks. However, it may require careful consideration of compatibility and overall impact on performance.

On the other hand, replacement entails removing old components and installing new ones, which can lead to significant performance improvements and reliability. While this option may come with higher upfront costs, it can ultimately ensure that the equipment meets modern standards and efficiency levels. Assessing the balance between these two strategies is crucial for optimal machinery operation.

Community Resources and Forums

Engaging with online communities offers valuable insights and support for enthusiasts and operators alike. These platforms serve as hubs for exchanging information, troubleshooting issues, and sharing experiences related to machinery maintenance and operation.

Forums are particularly useful, as they foster discussions among individuals who share similar interests. Members can delve into topics ranging from common repairs to upgrades, providing a wealth of knowledge for both novice and experienced users.

Additionally, social media groups often host vibrant conversations, where users can post questions and receive timely responses. This sense of community enhances the learning experience and helps users find the ultimate solutions to their challenges.

Whether you seek advice or simply want to connect with others, these resources are indispensable for anyone involved in the machinery sector.