Kubota M8200 Parts Diagram Overview

In the realm of agricultural machinery, a thorough comprehension of the individual elements that comprise these robust machines is crucial for effective maintenance and operation. Each component plays a significant role in ensuring optimal performance, and familiarity with their arrangement can greatly aid in troubleshooting and repairs.

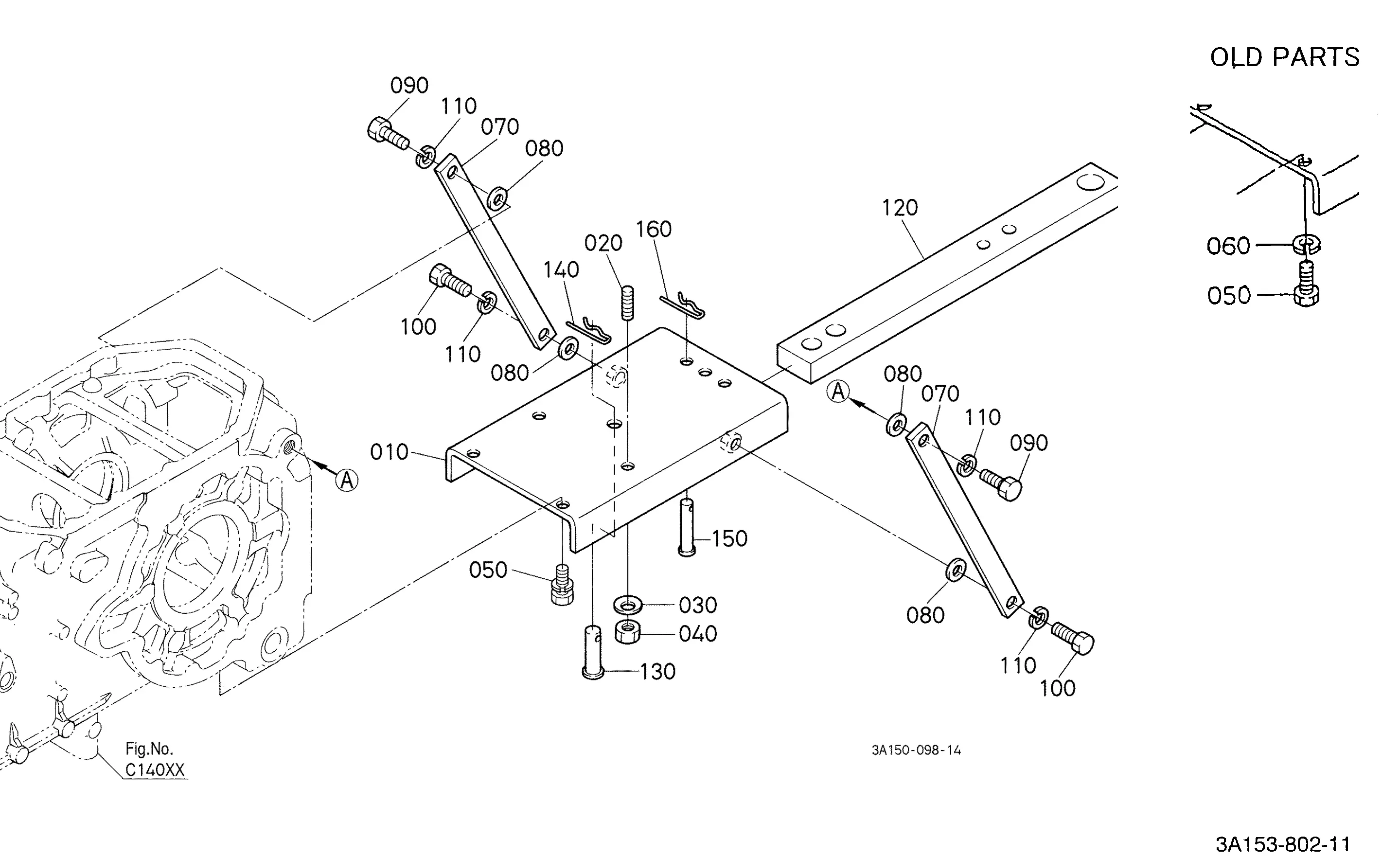

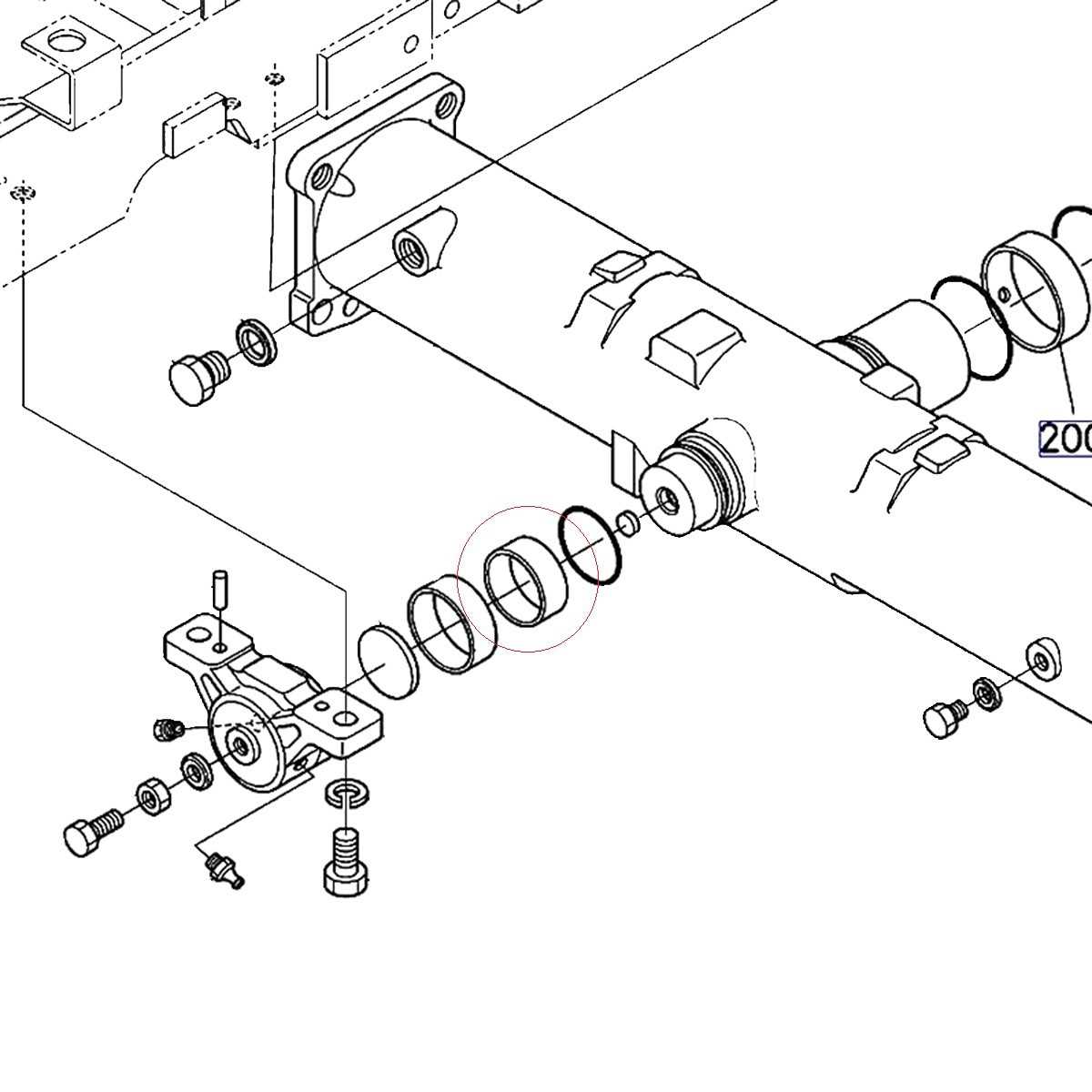

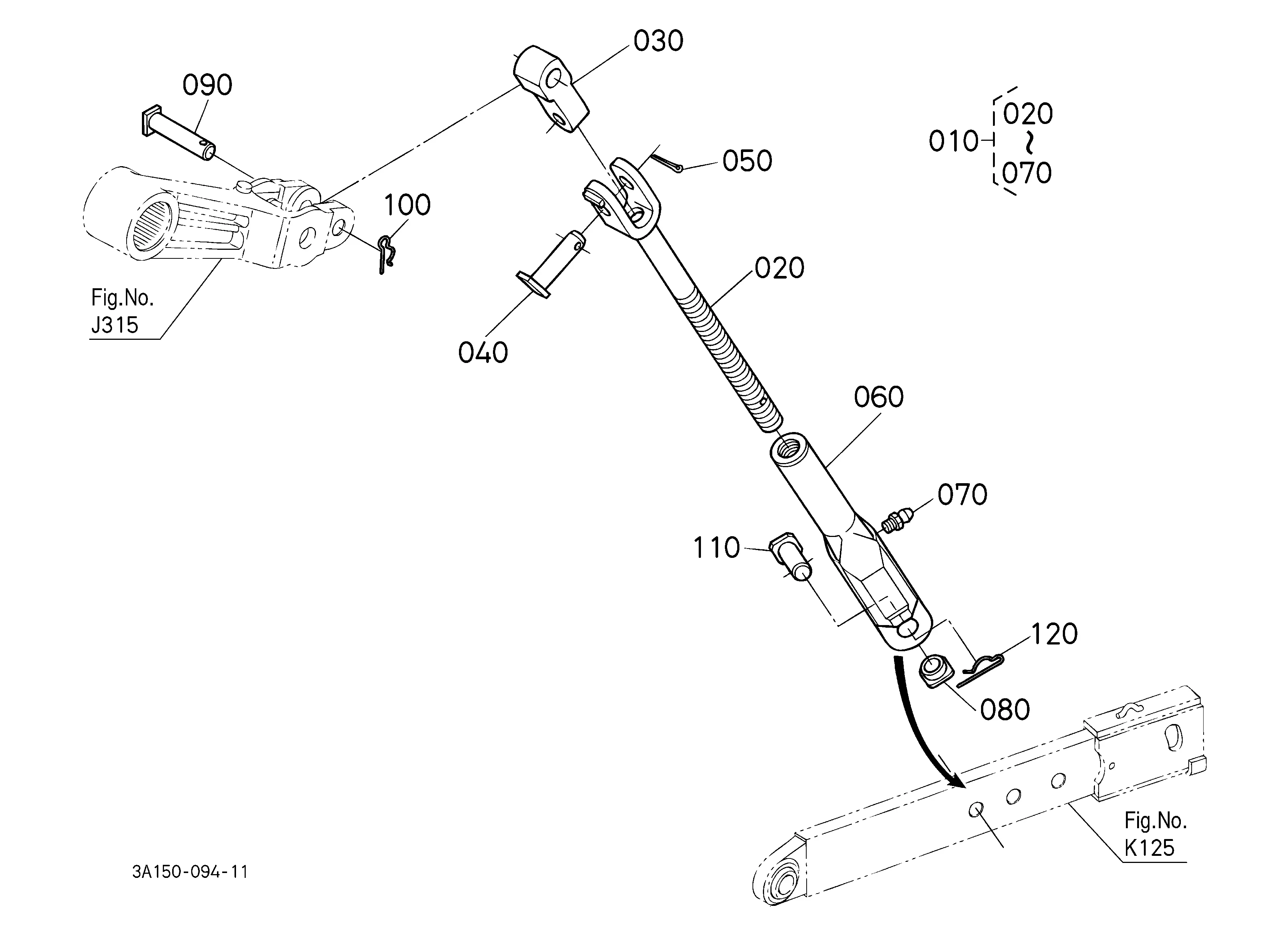

Visual representations of these mechanical assemblies provide valuable insights, illustrating the intricate relationships between various sections. Such illustrations not only enhance understanding but also streamline the identification of specific units when issues arise. By exploring these schematics, operators and technicians can quickly navigate the complexities of their equipment.

Equipped with this knowledge, users can make informed decisions regarding repairs and replacements. A clear grasp of how different parts interact fosters confidence in handling machinery, ultimately leading to improved efficiency and longevity in operation. Understanding these connections is an indispensable skill for anyone involved in the care and upkeep of agricultural implements.

Kubota M8200 Overview

This section provides a comprehensive look at a robust agricultural machine designed for efficiency and reliability in various farming tasks. Known for its powerful performance and durability, this equipment has become a staple in many agricultural operations, ensuring that farmers can tackle their work with confidence.

Key Features

Equipped with a high-performance engine, this model offers impressive horsepower, enabling it to handle heavy loads and challenging terrain. Its advanced hydraulic system enhances productivity, allowing seamless operation of various implements and attachments. Additionally, the intuitive controls ensure ease of use, making it accessible for operators of all skill levels.

Applications

Ideal for a wide range of agricultural activities, this machine excels in tasks such as plowing, tilling, and hauling. Its versatility makes it suitable for both small farms and larger agricultural enterprises. With its reliable construction and efficient design, it stands out as a crucial asset for anyone looking to improve their farming operations.

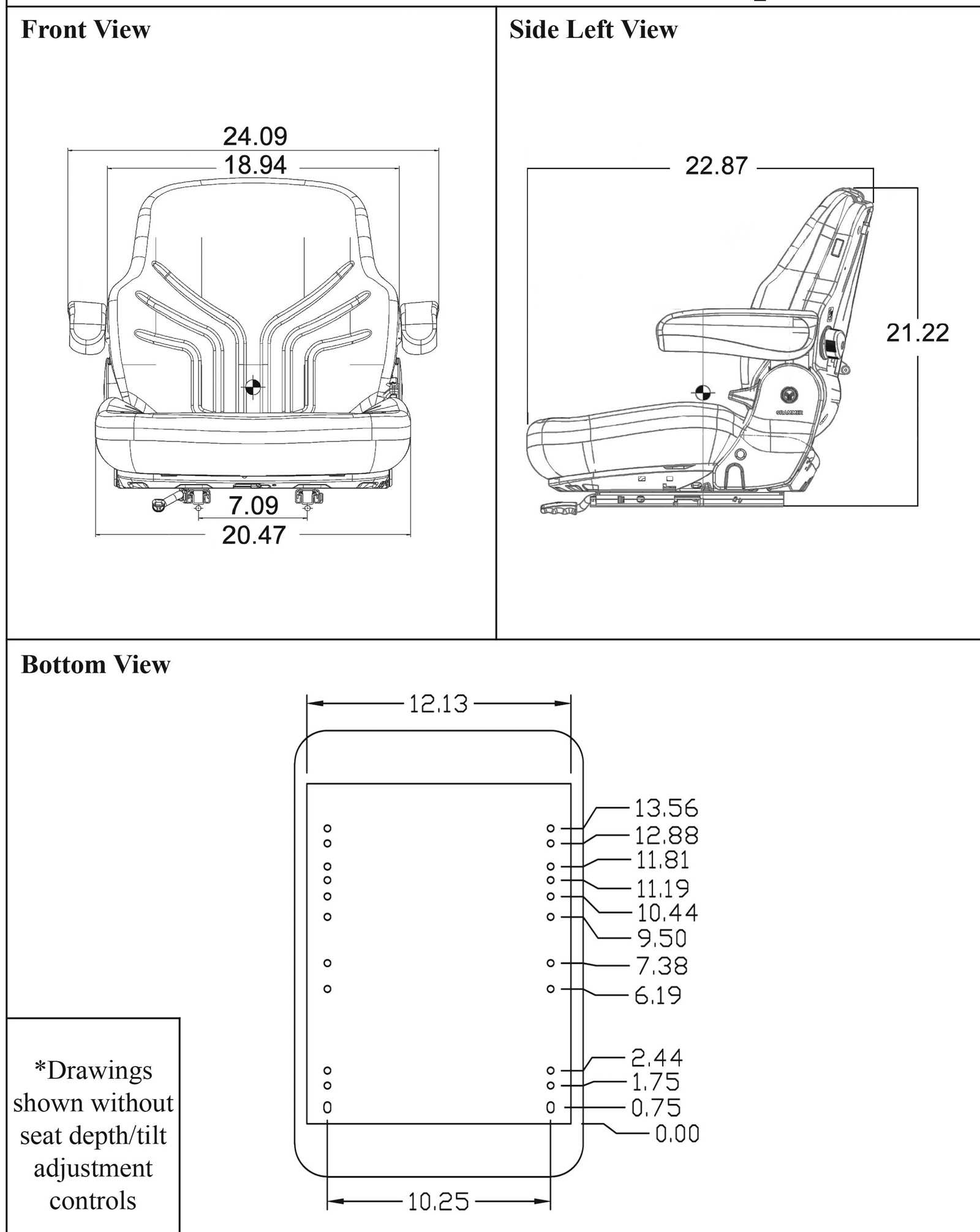

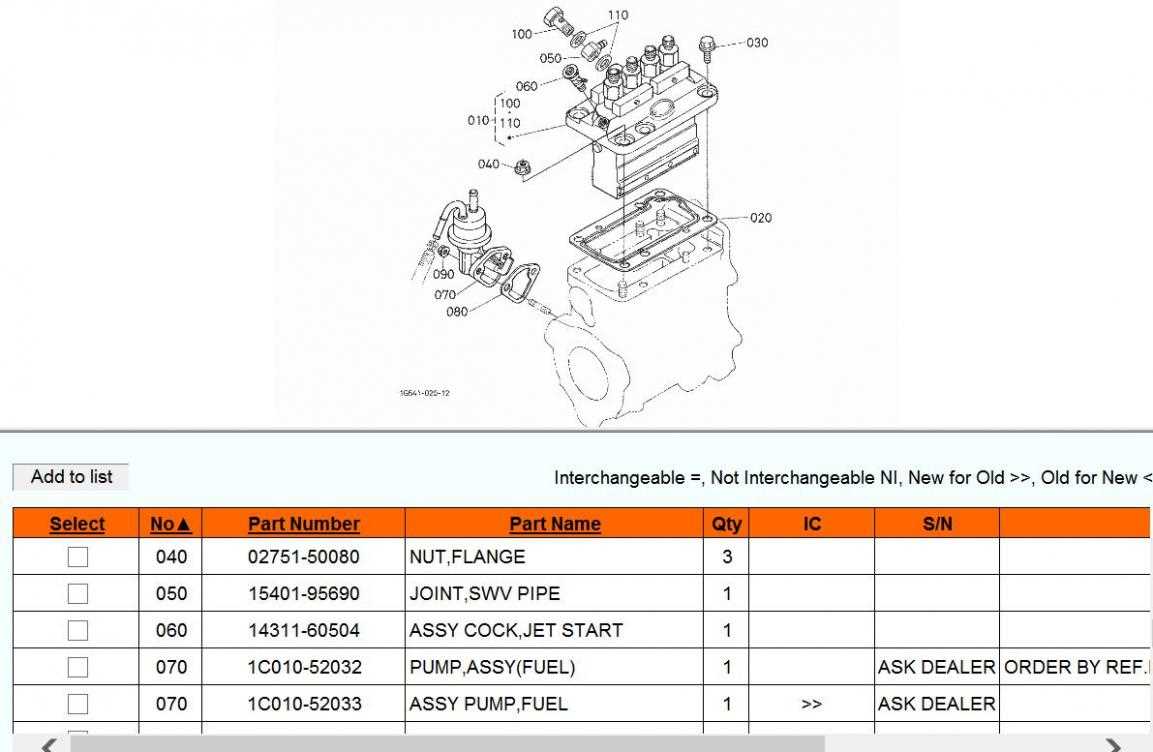

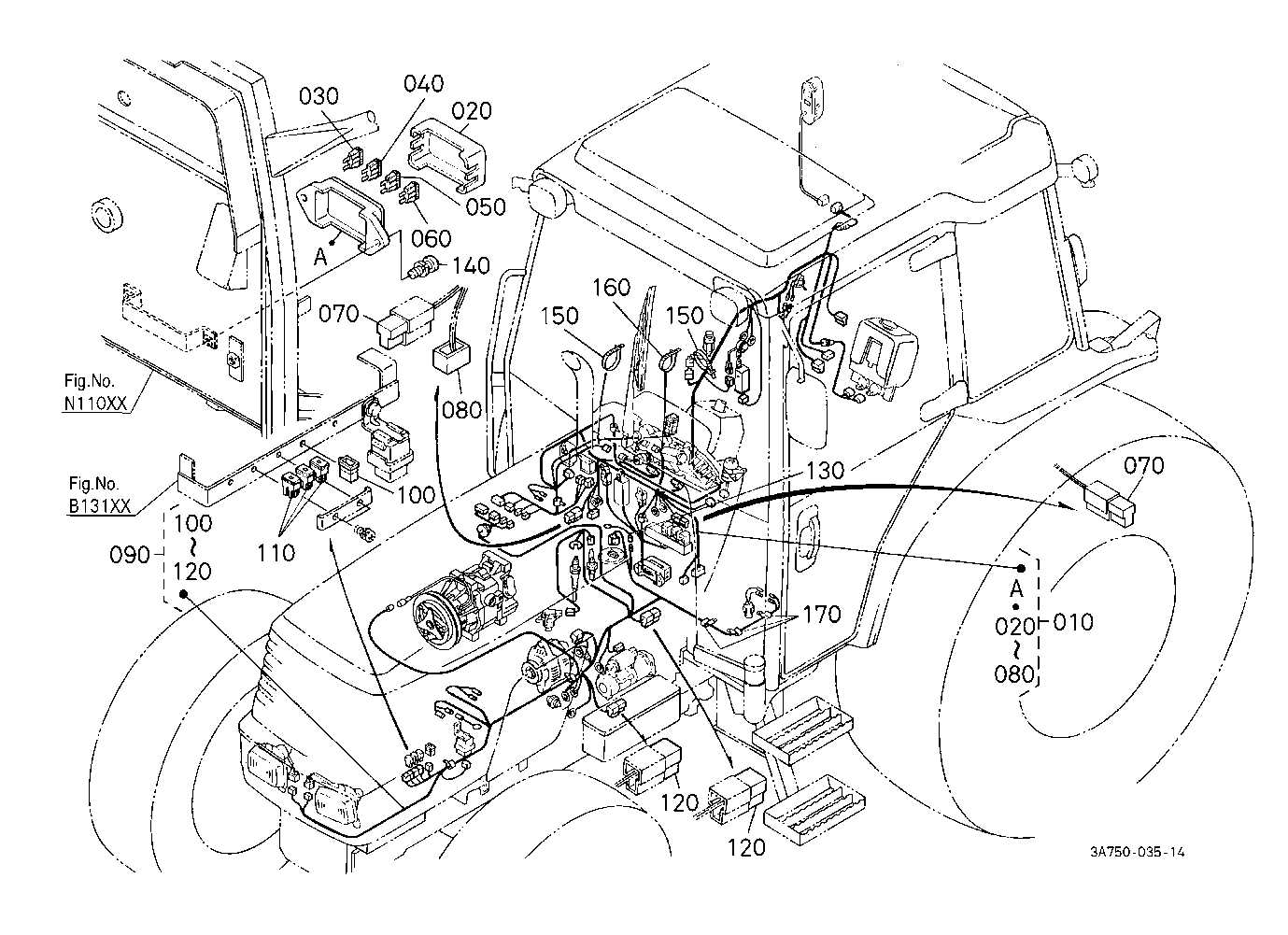

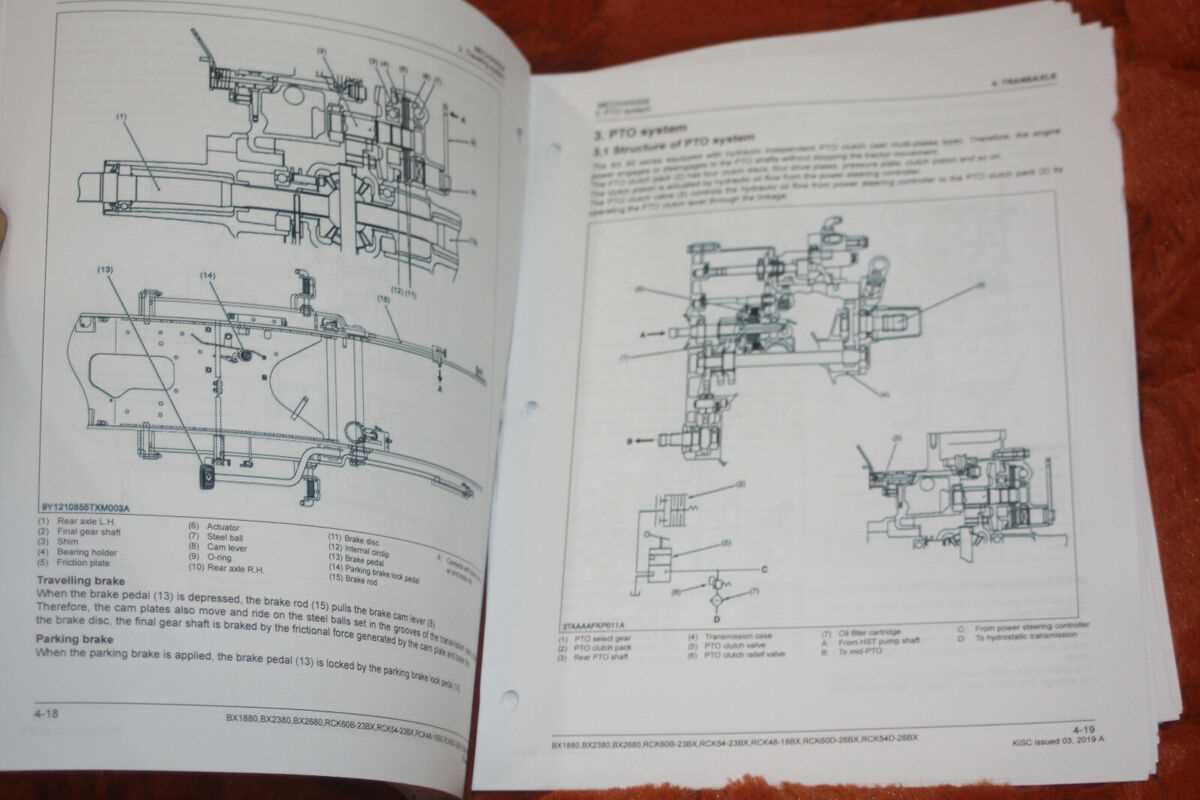

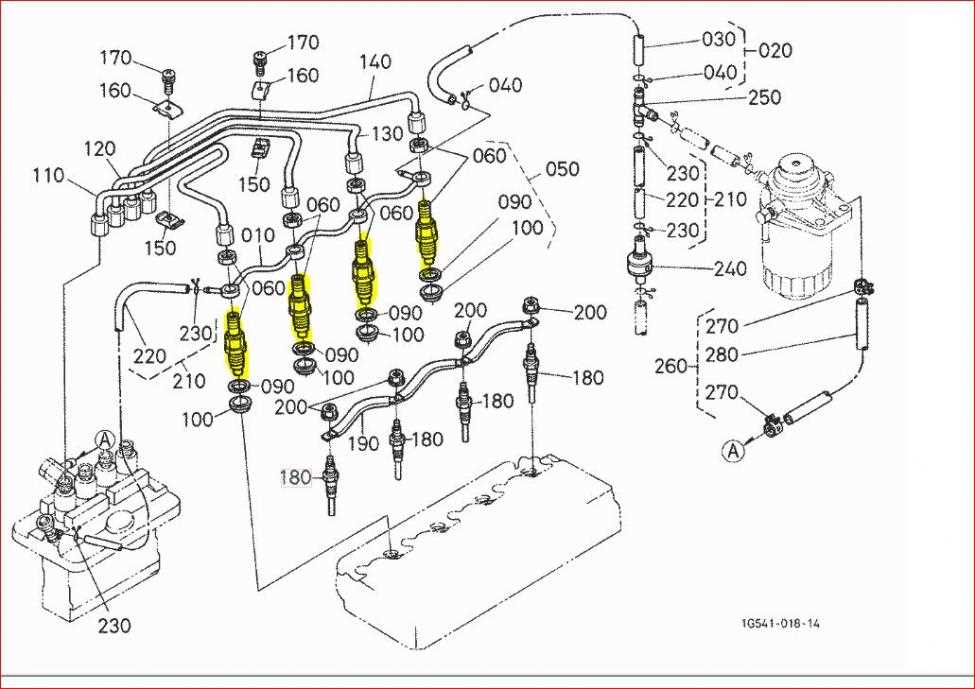

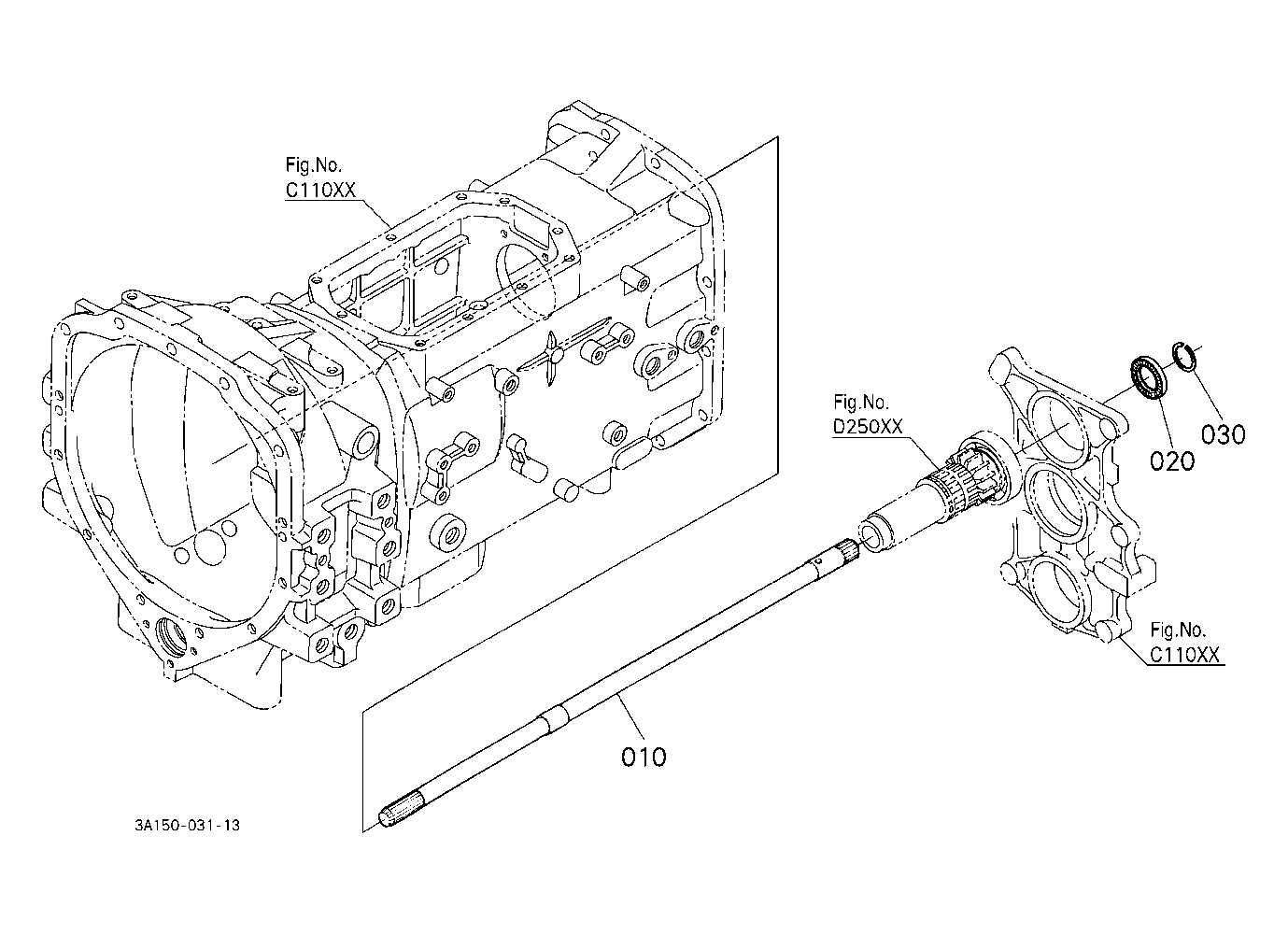

Understanding the Parts Diagram

Grasping the layout of components in machinery is essential for effective maintenance and repair. Such visual representations not only aid in identifying individual elements but also illustrate how they interact within the overall system. Familiarity with this schematic can streamline troubleshooting and enhance the efficiency of service tasks.

Importance of Visualization

A clear visual guide enables users to pinpoint specific elements quickly, minimizing downtime during repairs. By understanding the arrangement and connection of various parts, technicians can more efficiently assess issues and execute necessary adjustments. This clarity promotes a more systematic approach to upkeep.

Utilizing the Guide Effectively

To make the most of these visual aids, it is crucial to familiarize oneself with the symbols and notations used. Each element is often labeled, providing insights into function and compatibility. A thorough comprehension of the layout will empower users to navigate repairs with confidence, ensuring that every component is addressed appropriately.

Importance of Accurate Parts Identification

Correct identification of components is crucial in ensuring the efficient functioning and longevity of machinery. Misidentifying any element can lead to a cascade of issues, affecting performance and increasing the risk of breakdowns. Recognizing the precise specifications and compatibility of each piece is essential for maintenance and repair processes.

Impact on Performance

Using the right components directly influences the operational efficiency of equipment. When all elements are correctly matched, machinery operates smoothly, leading to enhanced productivity and reduced wear and tear. Conversely, incorrect parts can cause malfunctions, resulting in costly repairs and downtime.

Cost Efficiency

Investing in accurate component identification can significantly save costs in the long run. While it may seem economical to use generic or mismatched elements, the potential for failures and repairs far outweighs the initial savings. A focus on proper identification fosters reliability and minimizes unnecessary expenses.

| Benefit | Description |

|---|---|

| Improved Performance | Ensures machinery operates at peak efficiency. |

| Reduced Downtime | Minimizes interruptions due to equipment failures. |

| Cost Savings | Limits unnecessary repair and replacement costs. |

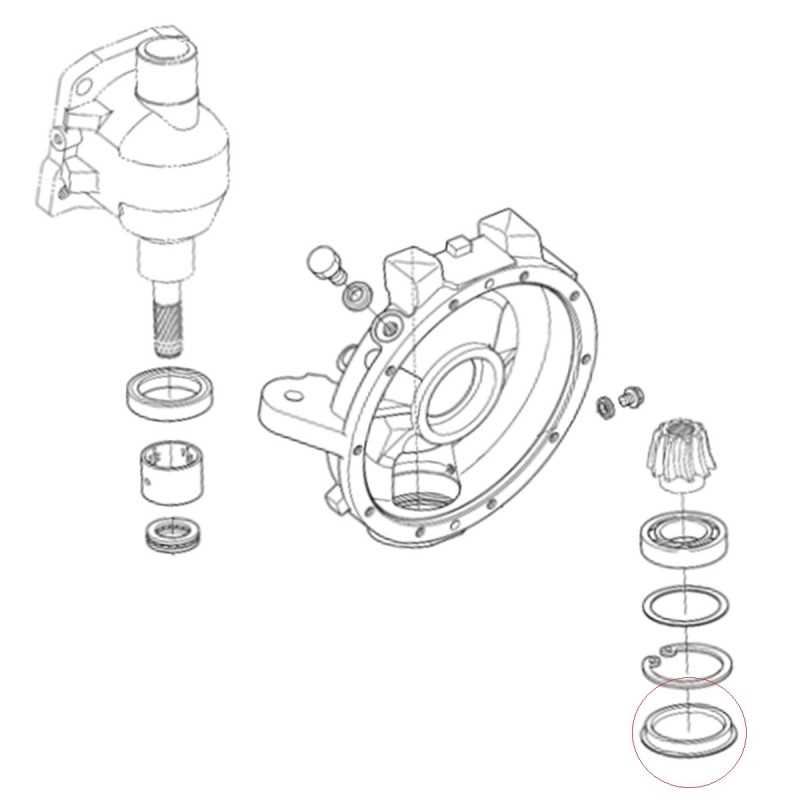

Common Issues with M8200 Components

Understanding the frequent challenges associated with specific machinery elements is crucial for effective maintenance and longevity. Various components can exhibit problems that may lead to operational inefficiencies, requiring attention and repair to ensure optimal performance.

| Component | Common Issue | Possible Solution |

|---|---|---|

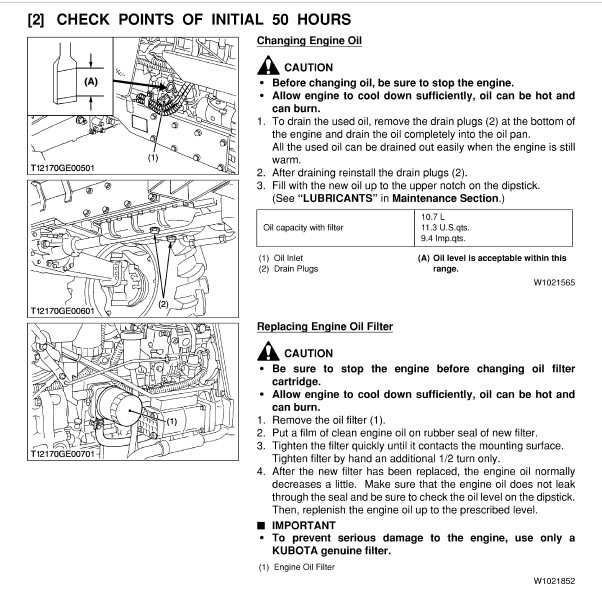

| Engine | Overheating | Check coolant levels and inspect for leaks. |

| Transmission | Slipping gears | Examine fluid levels and replace worn-out seals. |

| Hydraulic System | Fluid leaks | Inspect hoses and fittings for wear or damage. |

| Electrical System | Faulty connections | Clean terminals and ensure proper wiring. |

| Cooling System | Clogged radiator | Flush the radiator and clean debris. |

By proactively addressing these common issues, operators can significantly enhance the reliability and efficiency of their machinery, ultimately leading to improved productivity and reduced downtime.

Where to Find Genuine Parts

When it comes to maintaining the performance and longevity of your machinery, sourcing authentic components is essential. Genuine replacements ensure compatibility, durability, and reliability, ultimately enhancing the operational efficiency of your equipment.

Authorized Dealers

One of the most reliable sources for authentic components is through authorized dealers. These establishments typically offer:

- Expert guidance from knowledgeable staff.

- A comprehensive inventory of genuine components.

- Warranty coverage for purchased items.

Online Marketplaces

Another option is to explore online marketplaces that specialize in machinery components. When selecting this route, consider:

- Verifying the seller’s reputation and reviews.

- Ensuring the authenticity of the offered products.

- Checking return policies and customer support availability.

By choosing these avenues, you can ensure that you are acquiring quality components that will keep your machinery running smoothly.

How to Read the Diagram Effectively

Understanding a technical illustration is essential for effective maintenance and repair tasks. It allows users to identify components, comprehend their relationships, and execute procedures with greater accuracy. By mastering the key aspects of these visuals, one can streamline their workflow and enhance overall efficiency.

Familiarize Yourself with the Key Symbols

Every illustration utilizes specific symbols and notations to represent different elements. Familiarizing yourself with these can significantly improve your comprehension. Typically, you will encounter various shapes and lines indicating components, connections, and functionalities. Take the time to reference a legend or key, if available, to ensure you interpret these elements correctly.

Analyze the Layout and Flow

Another critical aspect is understanding the layout of the visual. Observing the arrangement of elements helps in recognizing how parts interact with one another. Start from the primary section and follow the pathways indicated. This will provide a clear picture of the operational flow, making it easier to troubleshoot issues or assemble components.

| Symbol | Description |

|---|---|

| ◼️ | Component |

| ➔ | Connection |

| Functionality Indicator |

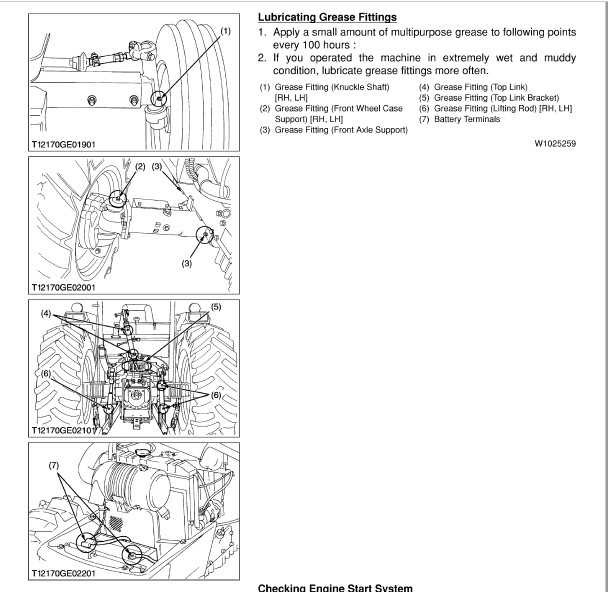

Maintenance Tips for M8200 Owners

Proper upkeep is essential for ensuring the longevity and efficiency of your machinery. Regular maintenance not only helps in preventing unexpected breakdowns but also enhances performance and reliability. By following a structured maintenance routine, you can keep your equipment in optimal condition and extend its lifespan.

Regular Inspection

Conduct routine checks on critical components to identify any signs of wear or damage. Pay attention to the fluid levels, filters, and belts. A proactive approach can save you from costly repairs in the long run. Additionally, always refer to the owner’s manual for specific inspection intervals.

Fluid Maintenance

Maintaining proper fluid levels is vital for smooth operation. Regularly check and change engine oil, coolant, and hydraulic fluids according to the manufacturer’s recommendations. Using high-quality fluids will enhance performance and protect internal components. Don’t forget to inspect the filters; clean or replace them as necessary to ensure efficient operation.

Comparing M8200 with Other Models

When evaluating different agricultural machines, it’s essential to assess how various models stack up against each other. Each model brings unique features and specifications that cater to diverse farming needs. This comparison helps in making informed decisions based on performance, efficiency, and versatility.

Key factors to consider include:

- Engine Power: Different models may offer varying horsepower, influencing their capacity for heavy-duty tasks.

- Transmission Types: Options like manual or hydrostatic can affect ease of use and control.

- Size and Weight: The dimensions of the machine can determine its suitability for specific environments and tasks.

- Fuel Efficiency: Comparing fuel consumption rates can lead to significant cost savings over time.

Here are a few popular alternatives to consider:

- Model A: Known for its superior maneuverability and lightweight design, making it ideal for smaller farms.

- Model B: Offers higher horsepower and advanced technology, suitable for larger agricultural operations.

- Model C: Features enhanced fuel efficiency, appealing for those looking to reduce operating costs.

Ultimately, the choice of machinery should align with specific agricultural practices and objectives. Each option has its strengths, making thorough comparison critical for optimal productivity.

Cost of Replacement Parts

Understanding the expenses associated with essential components for machinery is crucial for maintenance and repair planning. Costs can vary significantly based on factors such as brand, availability, and type of replacement needed. This section provides insights into various financial aspects related to acquiring these necessary items.

Here are some key factors influencing the cost of components:

- Brand Quality: Premium manufacturers often charge more, reflecting higher reliability and durability.

- Component Type: Some parts are inherently more expensive due to complexity, such as electronic systems compared to mechanical items.

- Market Demand: Fluctuations in demand can impact prices, particularly for popular or high-use items.

- Geographic Location: Costs may differ depending on regional availability and shipping expenses.

To make informed decisions, consider the following strategies:

- Research various suppliers for competitive pricing.

- Assess the longevity of different components to determine overall value.

- Evaluate the benefits of aftermarket versus OEM options.

- Budget for potential additional costs such as shipping or installation.

By analyzing these factors and strategies, users can better manage their expenses and ensure their machinery operates efficiently.

DIY Repairs: Is It Worth It?

Engaging in do-it-yourself repairs can be a rewarding experience, offering both satisfaction and potential savings. However, the decision to tackle maintenance tasks independently requires careful consideration of various factors, including skill level, time commitment, and the cost of materials. This section explores whether the effort put into self-repair is truly beneficial.

Benefits of DIY Repairs

Taking on repairs yourself can lead to significant advantages. Not only can you save money on labor costs, but you also gain valuable skills that can be applied to future projects. Furthermore, the sense of accomplishment from successfully completing a task can enhance your confidence and motivate you to take on more complex challenges.

Potential Drawbacks

On the flip side, do-it-yourself projects can sometimes lead to unexpected issues. Mistakes made during repairs can result in additional expenses, especially if professional help becomes necessary later on. Additionally, the time invested in learning and executing repairs can be substantial, potentially outweighing the savings achieved.

| Factors | Pros | Cons |

|---|---|---|

| Cost | Lower expenses | Possible additional costs if mistakes are made |

| Skill Development | Gain new abilities | Learning curve may be steep |

| Time Investment | Flexible scheduling | Time-consuming tasks |

| Sense of Accomplishment | Boosts confidence | Frustration if things go wrong |

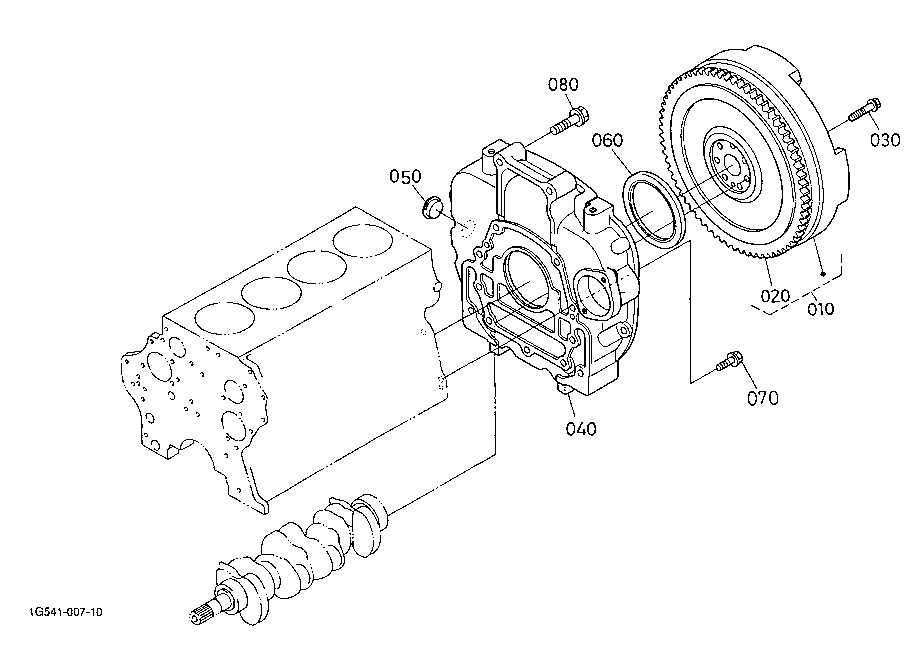

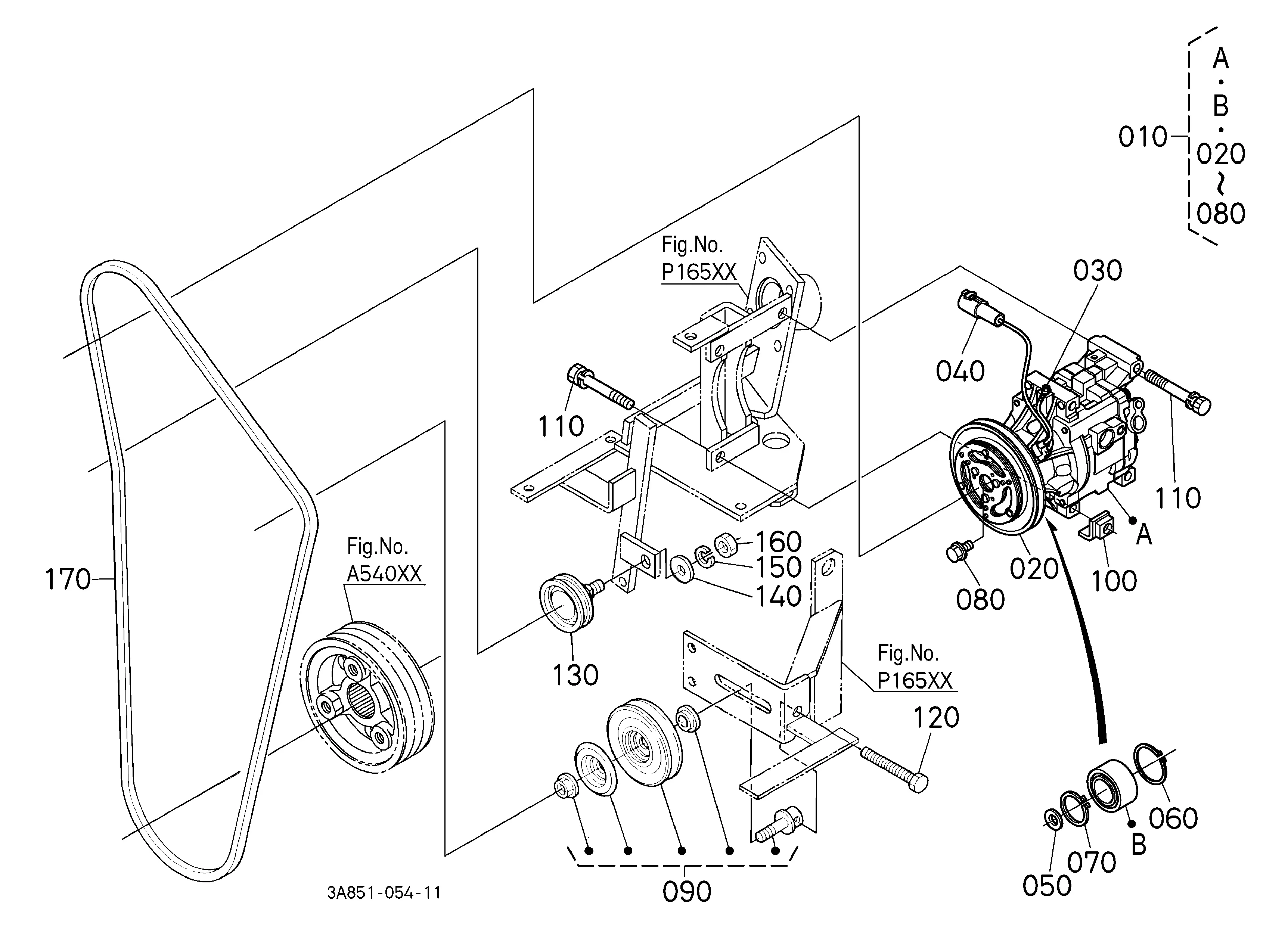

Upgrading Components for Better Performance

Enhancing machinery performance is a strategic approach that can yield significant benefits in productivity and efficiency. By focusing on upgrading specific elements, operators can ensure that their equipment not only meets but exceeds operational demands.

Key areas for improvement often include:

- Engine Enhancements: Upgrading the engine can lead to increased power and efficiency, allowing for heavier loads and faster operation.

- Transmission Modifications: Improving the transmission system can facilitate smoother shifts and better control, ultimately enhancing maneuverability.

- Hydraulic Systems: Enhancing hydraulic components can boost lifting capacity and responsiveness, making tasks easier and more efficient.

- Electrical Upgrades: Implementing advanced electrical systems can improve reliability and reduce downtime, enabling better management of operations.

When considering upgrades, it’s essential to assess compatibility and ensure that new components integrate seamlessly with existing systems. This not only maximizes performance but also extends the lifespan of the machinery.

In conclusion, investing in component upgrades is a proactive strategy that can lead to substantial performance improvements, ultimately driving greater efficiency and productivity in operations.