Kubota Mower Parts Diagram for Ultimate Maintenance and Repair

Maintaining outdoor machinery is crucial for optimal performance and longevity. Familiarizing oneself with the various elements that constitute these machines can significantly enhance their upkeep. A clear representation of these components allows users to quickly identify and address any issues that may arise during operation.

In this section, we delve into the intricate layout of essential machine elements, highlighting their specific roles and interconnections. By grasping the function of each piece, operators can ensure more effective troubleshooting and maintenance practices. This knowledge is invaluable for both novice users and seasoned professionals looking to optimize their equipment’s efficiency.

Moreover, having access to a visual guide can simplify the process of ordering replacements or upgrades. Understanding where each component fits into the broader system not only streamlines repairs but also empowers users to engage more confidently with their machinery. Embracing this knowledge fosters a deeper connection to the tools we rely on for our outdoor tasks.

Kubota Mower Parts Overview

This section provides a comprehensive look at the essential components that contribute to the efficiency and performance of your outdoor equipment. Understanding these elements is crucial for maintenance, troubleshooting, and enhancing the overall functionality of your machine.

Key Components

Familiarity with various sections can significantly impact performance. Here are the primary categories to consider:

| Category | Description |

|---|---|

| Engine | The powerhouse that drives the entire system. |

| Transmission | Facilitates the movement and speed adjustments. |

| Deck | The housing that protects and supports the cutting mechanism. |

| Blades | Critical for achieving a clean cut and maintaining grass health. |

Maintenance Tips

Regular inspection and timely replacements of these crucial components can lead to the ultimate performance and longevity of your equipment. Always consult a professional for complex repairs to ensure optimal functionality.

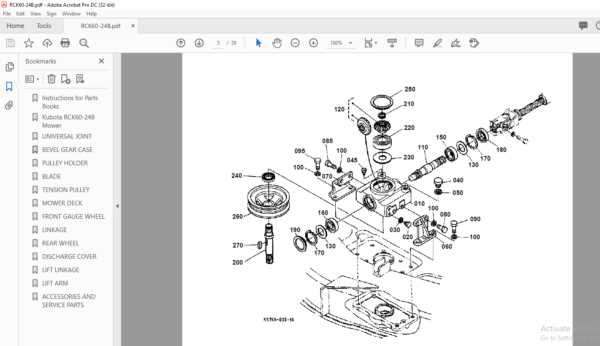

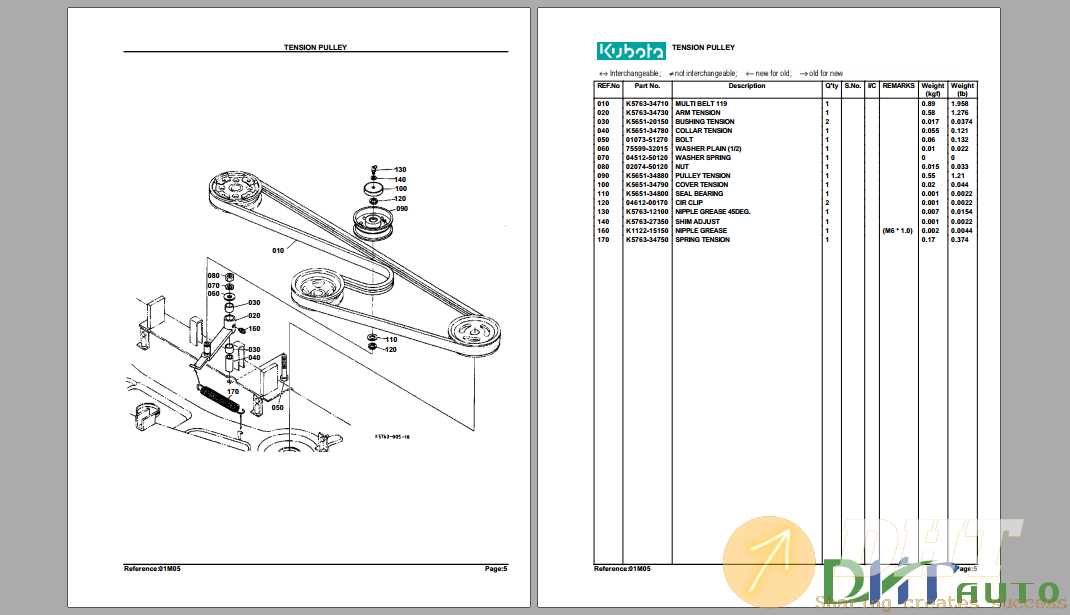

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of various machinery. They serve as essential tools for technicians and enthusiasts alike, allowing for a clearer understanding of the intricate relationships between different elements. This understanding is vital for ensuring optimal performance and longevity of the equipment.

Facilitating Accurate Repairs

Having access to visual schematics enables users to identify and locate specific components quickly. This accuracy significantly reduces the time spent troubleshooting and enhances the efficiency of repairs. Furthermore, a detailed overview assists in determining the exact nature of any issues, enabling more informed decision-making regarding repairs and replacements.

Enhancing User Knowledge

Studying these visual guides can deepen one’s comprehension of the machinery’s overall structure and function. This knowledge empowers users to perform maintenance tasks with confidence, promoting proactive care rather than reactive fixes. As a result, individuals become more self-sufficient, saving both time and resources in the long run.

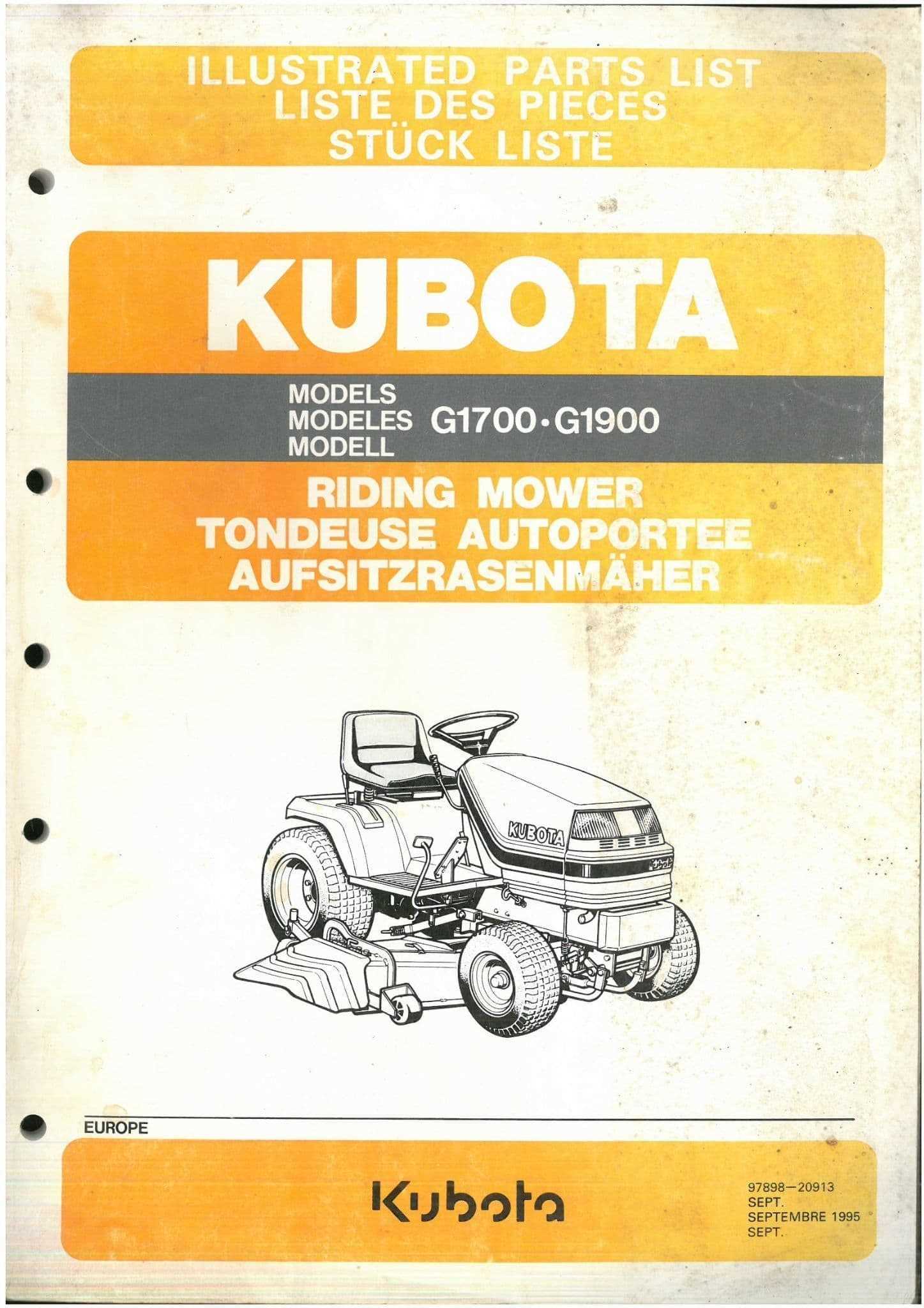

Understanding Your Kubota Mower Model

Gaining insight into your agricultural machine is essential for optimal performance and longevity. Each model possesses unique features and specifications that contribute to its functionality. By familiarizing yourself with these attributes, you can ensure efficient operation and timely maintenance.

Identifying Key Features

Every model comes equipped with distinctive characteristics that enhance its usability. From engine specifications to cutting mechanisms, recognizing these elements allows for better handling and care. Always refer to your user manual to delve into specific functionalities.

Maintenance Essentials

Regular upkeep is crucial for any agricultural equipment. Understanding the necessary maintenance tasks, such as oil changes and blade sharpening, ensures your machine remains in top condition. Adopting a proactive approach will lead to the ultimate performance and reliability over time.

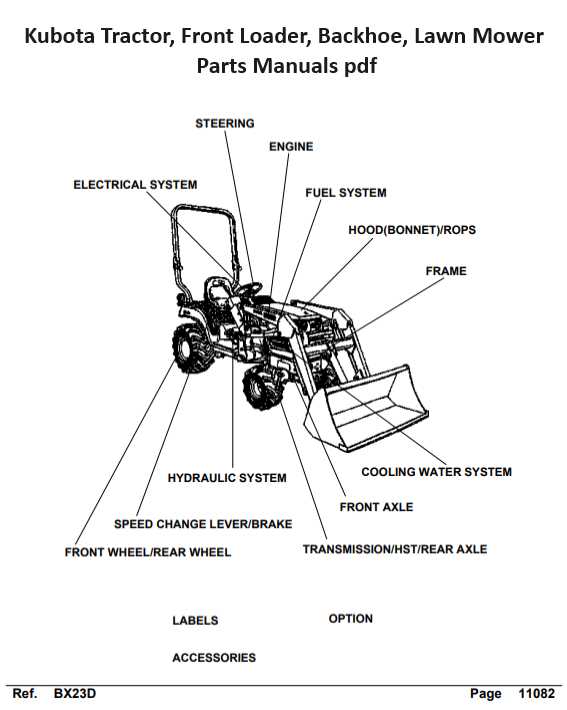

Main Components of a Kubota Mower

The essential elements of a cutting machine play a crucial role in its performance and efficiency. Understanding these key components can enhance maintenance and ensure optimal functionality.

| Component | Description |

|---|---|

| Engine | Provides the necessary power for operation, influencing speed and cutting ability. |

| Deck | The structure that houses the cutting blades, affecting the quality of the cut. |

| Blades | Sharp instruments responsible for cutting grass, available in various styles for different needs. |

| Transmission | Transfers power from the engine to the wheels, affecting movement and maneuverability. |

| Wheels | Support mobility and stability, essential for navigating uneven terrain. |

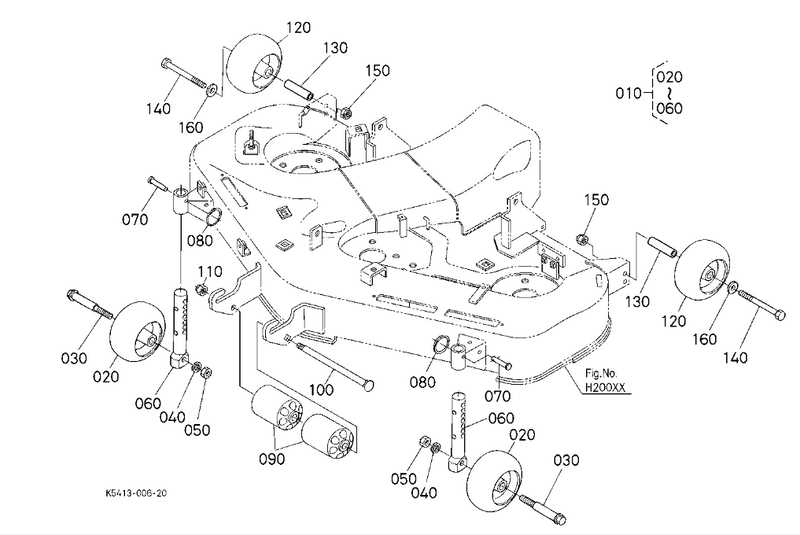

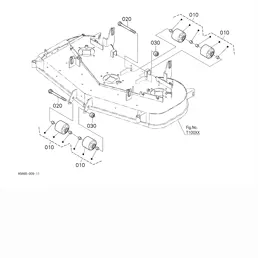

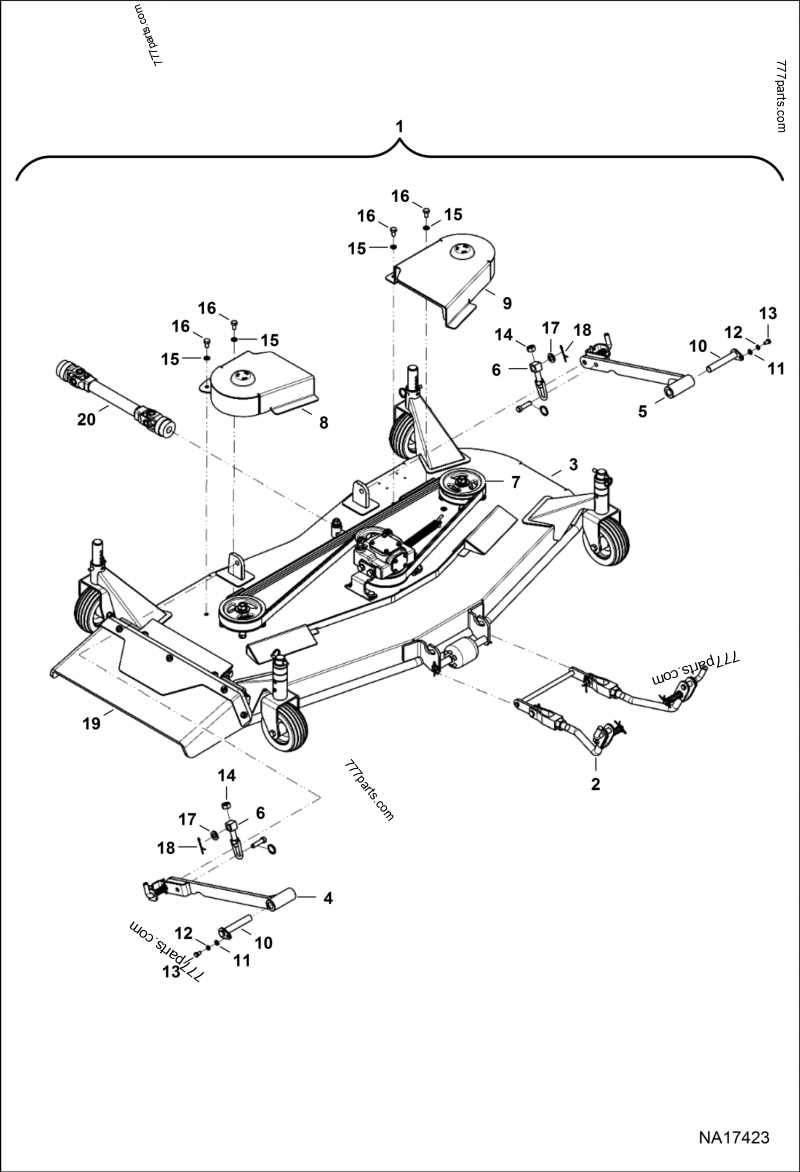

How to Read a Parts Diagram

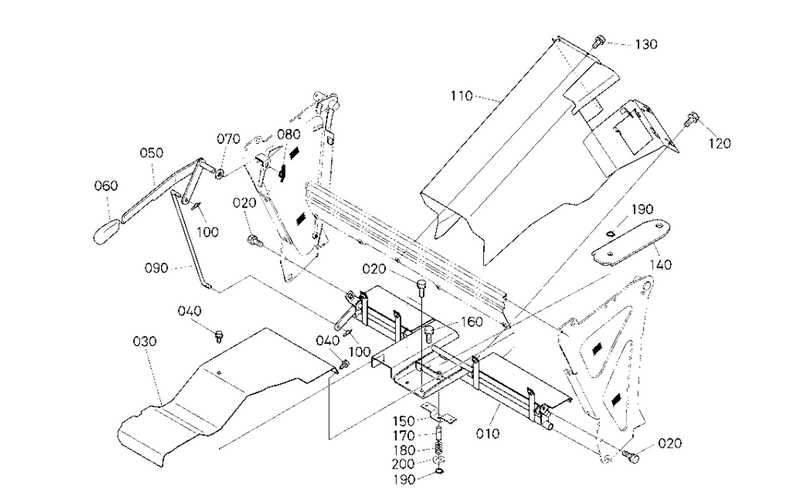

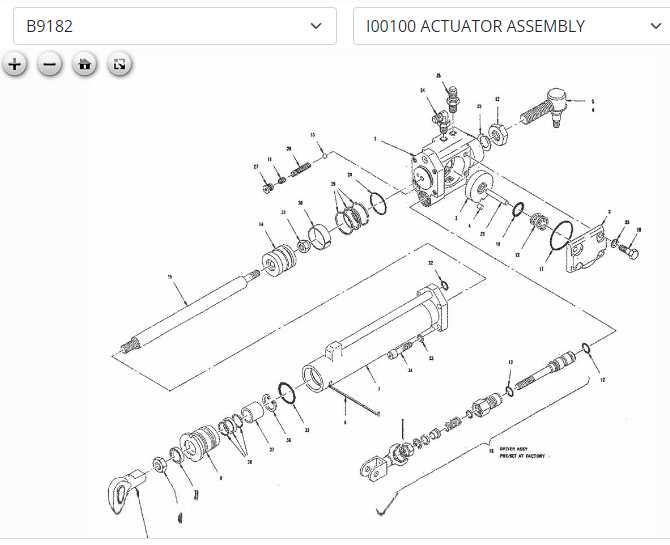

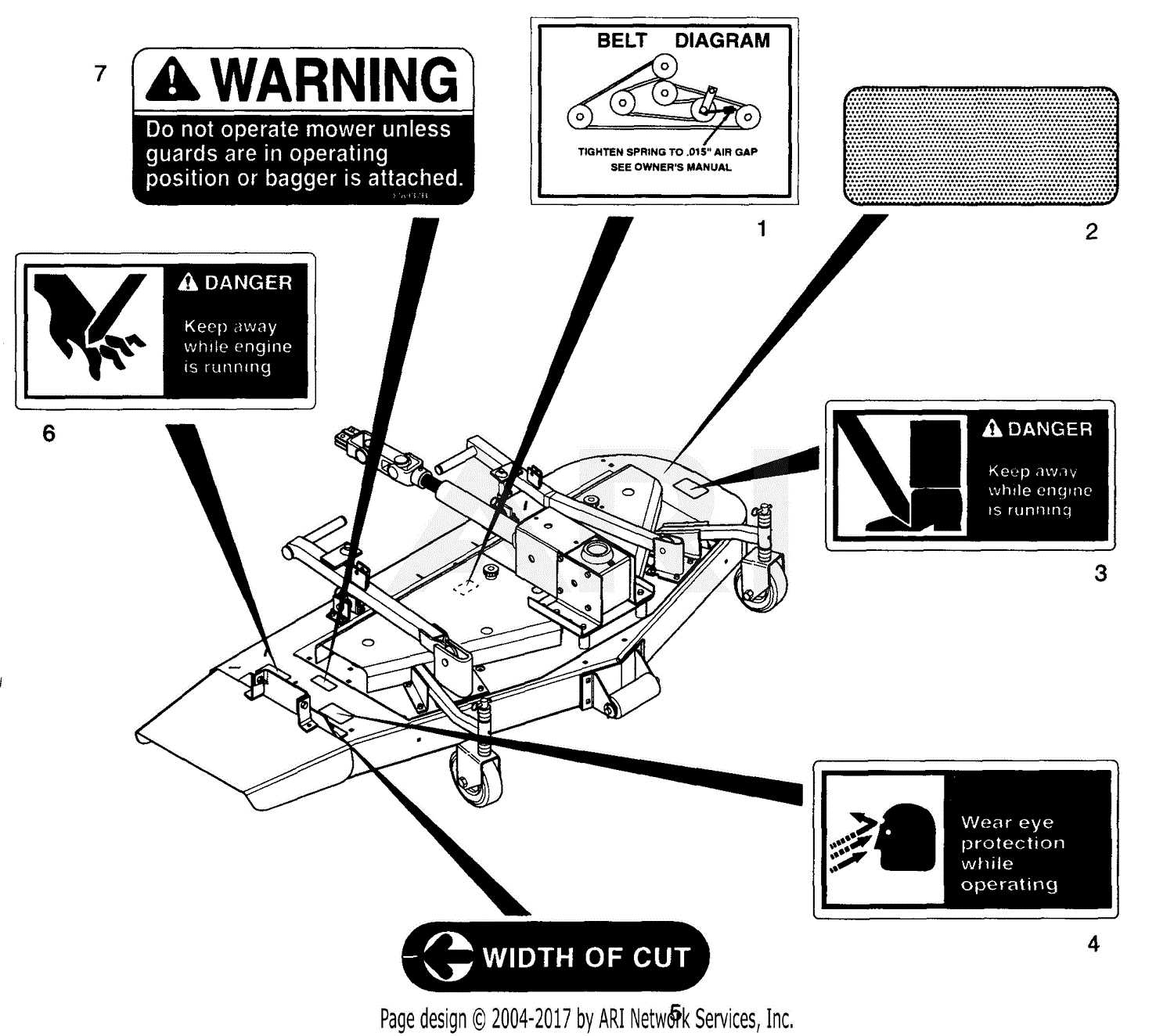

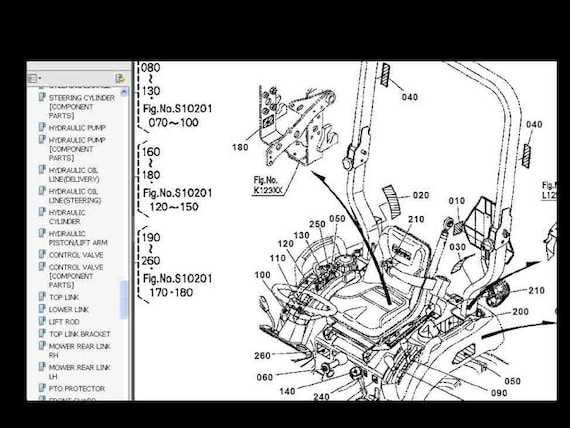

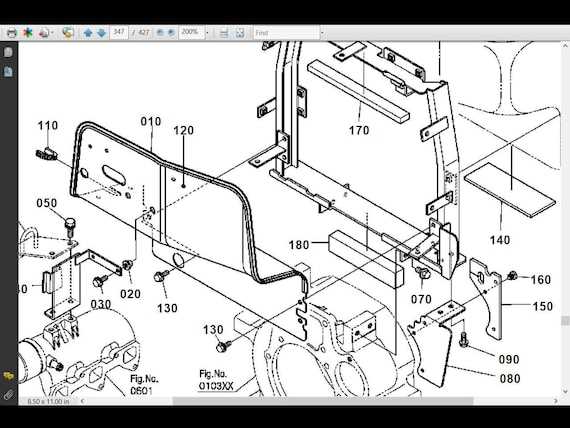

Understanding an illustration of components is essential for anyone looking to maintain or repair machinery. These visuals serve as a roadmap, providing a clear representation of how various elements fit together and function in harmony. Mastering the art of interpreting these graphics can significantly simplify the repair process, ensuring that you select the correct pieces and execute tasks with confidence.

Key Elements to Identify

When examining an illustration of components, pay attention to several critical aspects. First, look for labels that identify each item. These are often numbered or marked with letters for easy reference. Additionally, familiarize yourself with legend sections that explain symbols or specific notes, as they can provide valuable insights into the function or positioning of each part.

Understanding the Layout

The arrangement of the elements within the illustration is also important. Groupings may indicate how parts are assembled or related to one another. Notice how some components may overlap or connect, highlighting their interdependence. A clear grasp of this layout will allow you to visualize how to approach any maintenance or repair tasks effectively.

Common Replacement Parts Explained

Understanding essential components is crucial for maintaining the performance and longevity of outdoor machinery. This section highlights frequently needed elements, ensuring optimal functionality and efficiency.

- Blades: Sharp edges are vital for effective cutting. Regular inspection and timely replacement enhance performance.

- Filters: Air and fuel filters play a significant role in maintaining cleanliness and efficiency. Clogged filters can lead to poor performance.

- Batteries: Reliable power sources are essential for starting and operation. Periodic checks can prevent unexpected failures.

- Belts: These components are critical for transferring power. Wear and tear can cause slippage and affect performance.

- Wheels: Durable wheels ensure smooth movement and stability. Check for wear to maintain traction and control.

- Springs: Often overlooked, these elements are vital for various mechanical functions, contributing to overall performance.

Regularly assessing and replacing these key components can lead to a smoother and more efficient experience, reducing downtime and enhancing productivity.

Locating OEM Kubota Parts

Finding original equipment manufacturer components is essential for maintaining the efficiency and longevity of your machinery. Understanding where to source these items can save time and ensure you are using high-quality replacements.

Key Sources for OEM Components

- Authorized Dealers: Visit local dealerships that specialize in your machinery brand.

- Online Retailers: Explore reputable websites that focus on genuine components.

- Manufacturer’s Website: Check the official site for a parts locator tool or catalog.

- Repair Shops: Consult with local mechanics who might have access to original parts.

Tips for Ensuring Authenticity

- Always verify the part number against the manufacturer’s specifications.

- Look for certifications or seals of authenticity when purchasing.

- Read customer reviews to gauge the reliability of the source.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires consistent care and attention. By following a few essential maintenance practices, you can significantly enhance performance and reliability. Regular upkeep not only improves functionality but also prevents costly repairs and replacements.

Regular Cleaning

Keeping your machinery clean is crucial for optimal operation. Dirt and debris can accumulate and cause wear over time. Here are some tips for effective cleaning:

- Use a soft brush or cloth to remove dust and grass clippings.

- Clean air filters regularly to ensure proper airflow.

- Inspect and wash undercarriages to prevent rust and corrosion.

Routine Inspections

Performing periodic checks can help identify potential issues before they escalate. Consider these inspection tips:

- Examine belts and cables for signs of wear or fraying.

- Check fluid levels and top off as necessary.

- Inspect blades for sharpness and damage, replacing them when needed.

By adhering to these maintenance tips, you can ensure your equipment remains in excellent condition, providing reliable performance for years to come.

DIY Repairs: Tools You Need

Engaging in home repairs can be rewarding, especially when equipped with the right tools. Having a proper toolkit not only simplifies tasks but also ensures that repairs are completed efficiently and effectively.

- Wrenches: Essential for loosening or tightening bolts and nuts.

- Screwdrivers: A variety of types, including flathead and Phillips, will cover most fastening needs.

- Pliers: Useful for gripping, bending, and cutting wires.

- Socket Set: Ideal for quick adjustments on fasteners in tight spaces.

- Utility Knife: Handy for cutting materials or stripping insulation.

Each tool serves a specific purpose, making it crucial to have the right ones at your disposal for successful maintenance.

Where to Find Service Manuals

Accessing reliable service documentation is essential for effective maintenance and repairs of your equipment. These manuals provide detailed instructions, diagrams, and specifications that can help users troubleshoot issues and perform necessary upkeep. Knowing where to locate these resources can save both time and money, ensuring your machinery operates smoothly and efficiently.

One of the best places to start your search is the official website of the manufacturer, which often offers downloadable versions of service manuals. Additionally, authorized dealerships frequently have physical and digital copies available for customers. Online forums and communities dedicated to equipment enthusiasts can also be valuable resources, as members often share links to manuals and personal insights.

For those seeking a broader range of materials, online marketplaces and specialty websites dedicated to equipment support might provide access to manuals, including rare or older models. Libraries or local technical colleges sometimes carry resources for equipment maintenance as well, providing another avenue to obtain necessary documentation.

Identifying Issues with Diagrams

When working with technical illustrations, understanding the potential pitfalls is essential for effective troubleshooting. These visual aids are designed to simplify complex information, yet misinterpretation can lead to errors in assembly or repair processes. Recognizing common issues allows for better navigation and utilization of these resources.

One frequent challenge is the lack of clarity in the visuals. Sometimes, the details may be too small or poorly labeled, making it difficult to discern the specific components or their relationships. In such cases, it’s vital to use magnification tools or refer to supplementary documentation to gain a clearer perspective.

Another issue might arise from outdated illustrations. As models evolve, older representations may not accurately reflect current designs, leading to confusion. Always ensure that the reference material corresponds to the specific model in question to avoid misguidance.

Ambiguity in instructions can also create problems. Diagrams may assume a certain level of prior knowledge or familiarity, which can alienate less experienced users. It’s crucial to seek additional explanations or resources that can provide the necessary context to navigate these visual guides effectively.

Finally, consider the orientation of the diagram. Viewing angles can significantly impact the understanding of the layout. If a diagram appears confusing, try to visualize the components in a three-dimensional space to better grasp their arrangement and functionality.

Benefits of Regular Parts Inspection

Conducting routine evaluations of essential components is vital for maintaining optimal performance and longevity of equipment. Regular checks can prevent unexpected breakdowns, ensuring that machinery operates smoothly and efficiently.

Enhanced Reliability: By consistently inspecting critical elements, users can identify wear and tear before it escalates into significant issues. This proactive approach fosters greater trust in the equipment’s reliability, reducing the risk of unexpected failures.

Cost Efficiency: Regular assessments can lead to substantial savings over time. Addressing minor problems early prevents them from developing into costly repairs, ultimately extending the lifespan of the machinery and minimizing downtime.

Improved Safety: A thorough inspection of crucial components contributes to a safer working environment. Identifying and rectifying potential hazards not only protects the operator but also safeguards those nearby.

Optimal Performance: Ensuring that all elements are functioning correctly allows equipment to perform at its best. Regular maintenance leads to better fuel efficiency and higher productivity, making operations more effective overall.

Informed Decision-Making: Keeping detailed records of inspections aids in making informed choices regarding replacements or upgrades. This data-driven approach can enhance strategic planning and resource allocation.