Kubota U35-4 Parts Diagram Explained

In the world of compact machinery, the intricate design and functionality of each unit play a vital role in its performance. A thorough comprehension of how different elements interact can significantly enhance operational efficiency and maintenance practices.

Having access to a visual representation of these components allows operators and technicians to identify parts easily, facilitating repairs and replacements. This knowledge is essential for maximizing the lifespan of the equipment and ensuring it operates at its ultimate capacity.

Whether you’re a seasoned professional or a newcomer, delving into the structure of your excavator provides invaluable insights. This understanding not only aids in troubleshooting but also empowers users to make informed decisions regarding upgrades and enhancements.

Kubota U35-4 Overview

This section provides a comprehensive look at a compact excavator designed for versatility and efficiency in various applications. Ideal for construction, landscaping, and agricultural tasks, this machine combines powerful performance with user-friendly features, making it a preferred choice for operators seeking reliability and ease of use.

Key Features

The equipment boasts an impressive array of attributes that enhance its functionality. With a robust engine and advanced hydraulic systems, it ensures optimal digging and lifting capabilities. Its compact size allows for maneuverability in tight spaces, while ergonomic controls provide comfort during prolonged operation. Additionally, the machine’s durability and low maintenance requirements contribute to long-term value.

Applications

This excavator is well-suited for a variety of tasks, from digging trenches to lifting heavy materials. Its adaptability makes it an excellent choice for both urban and rural environments, catering to projects ranging from utility installation to landscaping. The combination of power and precision ensures that operators can achieve their goals efficiently and effectively.

Importance of Parts Diagrams

Understanding the intricate layout of components within machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that simplify the identification and organization of various elements. By providing a clear overview, these illustrations enhance the efficiency of service tasks and facilitate troubleshooting processes.

Enhanced Efficiency in Repairs

When technicians have access to visual aids, they can quickly locate and assess individual components. This expedites the repair process, minimizing downtime and reducing the likelihood of errors. A comprehensive visual guide can also assist in planning the necessary actions and resources required for effective interventions.

Facilitating Communication and Training

Such visuals play a significant role in communication among team members, enabling clearer discussions regarding repairs and maintenance. Additionally, they serve as valuable training resources for new staff, helping them to familiarize themselves with the machinery more rapidly. By illustrating the connections and functions of different elements, these tools foster a deeper understanding of operational mechanics.

Key Components of U35-4

Understanding the essential elements of this compact excavator is crucial for effective operation and maintenance. Each part plays a vital role in ensuring the machine functions optimally and efficiently, contributing to overall performance and longevity.

- Engine: The powerhouse of the equipment, responsible for generating the necessary force for all operations.

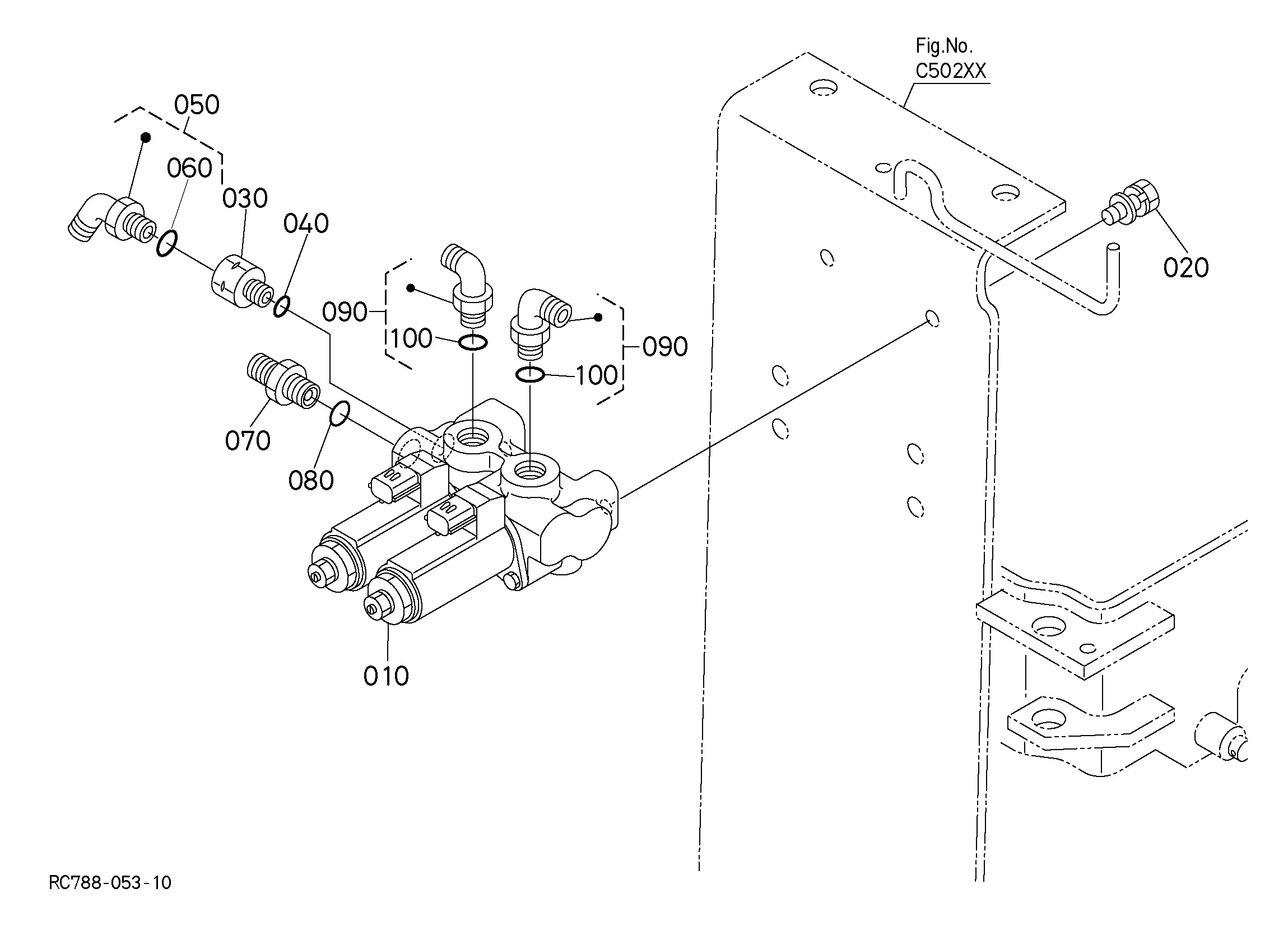

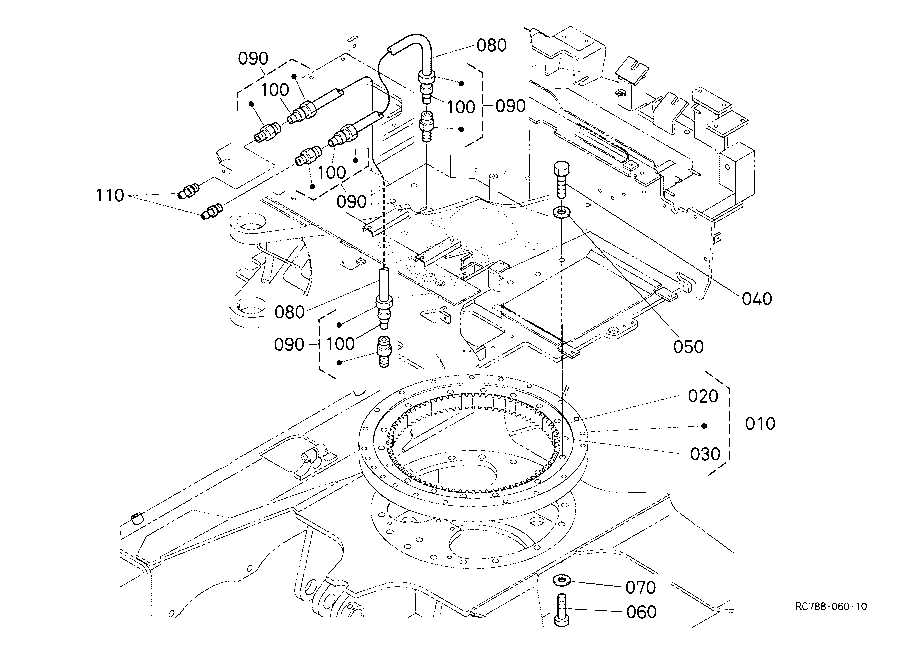

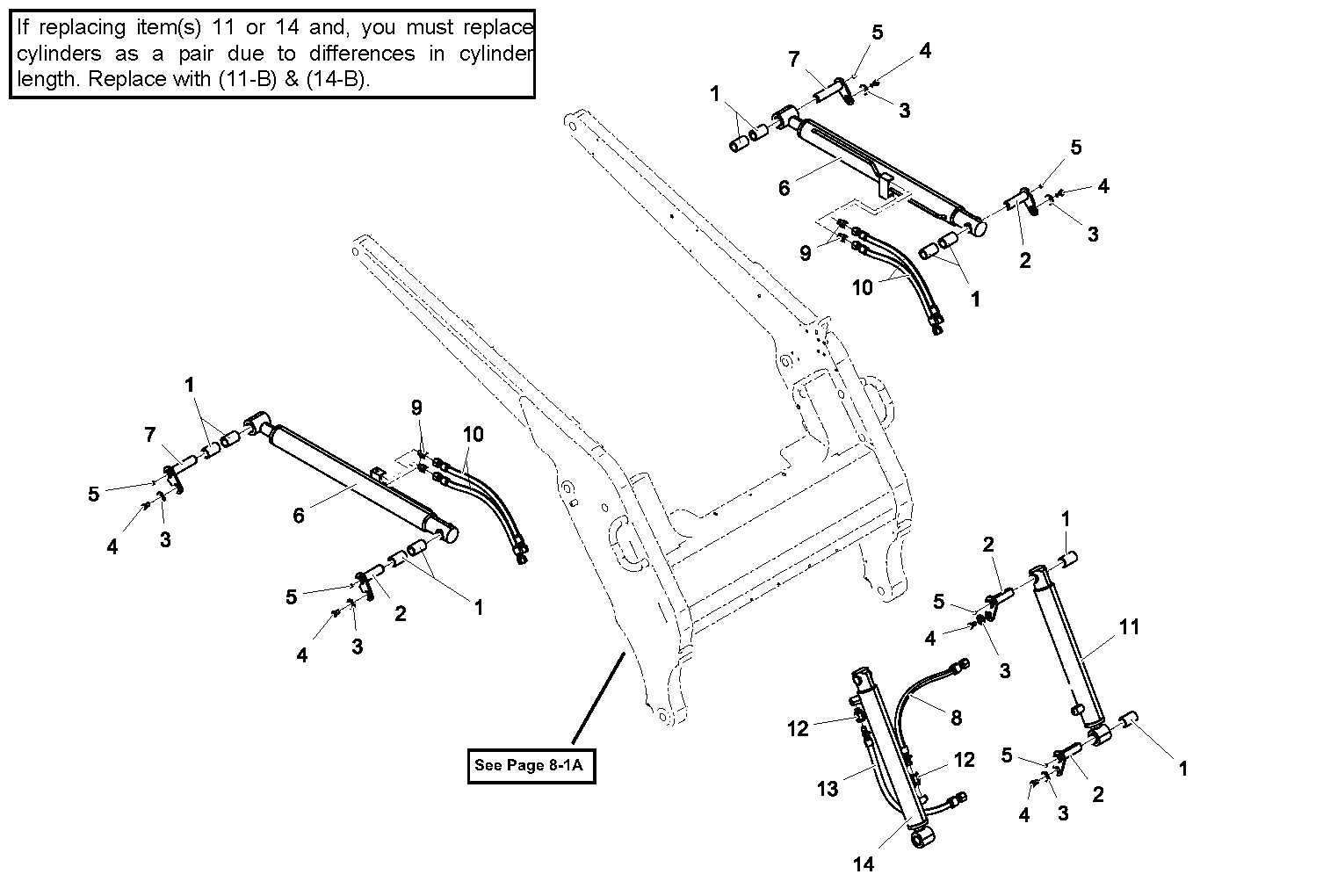

- Hydraulic System: A complex network that controls movement and power distribution, enabling precise actions.

- Track Assembly: Provides stability and mobility, allowing the excavator to navigate various terrains.

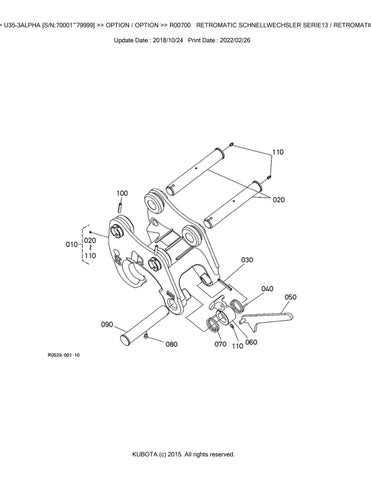

- Boom and Arm: Key components for digging and lifting, designed for strength and flexibility.

- Cab: The operator’s workspace, equipped with controls for managing functions and ensuring comfort.

- Attachments: Various tools that can be mounted for specific tasks, enhancing versatility.

Familiarity with these fundamental components not only aids in troubleshooting but also enhances the overall effectiveness of the equipment in diverse applications.

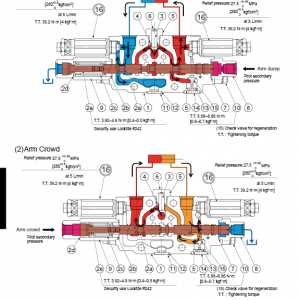

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in many machinery applications, utilizing fluid power to facilitate movement and control. By harnessing the principles of fluid dynamics, these systems enable the transmission of force and motion with remarkable efficiency and precision. Understanding their components and functions is essential for optimal performance and maintenance.

The core of a hydraulic system includes a pump, reservoir, valves, and actuators. The pump generates hydraulic pressure, drawing fluid from the reservoir and delivering it to the system. Valves regulate the flow and direction of the fluid, while actuators convert hydraulic energy into mechanical work, driving various machinery functions. This interplay allows for smooth and responsive operation across diverse applications.

Efficiency and safety are paramount in hydraulic design. Proper maintenance, including regular checks of fluid levels and component integrity, is vital to prevent failures and ensure longevity. By delving into the intricacies of hydraulic systems, operators can achieve the ultimate performance and reliability needed for demanding tasks.

Maintenance Tips for U35-4

Proper upkeep of your machinery is essential for ensuring optimal performance and longevity. Regular maintenance not only prevents unexpected breakdowns but also enhances efficiency and reduces operational costs. This section provides valuable insights into maintaining your equipment effectively.

Regular Inspections

Conducting frequent inspections is crucial. Check all critical components, such as the hydraulic system, engine, and undercarriage, for signs of wear or damage. Early detection of issues can prevent costly repairs and extend the lifespan of the machinery.

Fluid Levels and Quality

Maintaining appropriate fluid levels is vital for proper functioning. Regularly check and change the engine oil, hydraulic fluid, and coolant as per the manufacturer’s guidelines. Clean and replace filters to ensure optimal fluid quality, which will contribute to smoother operations.

Common Issues and Solutions

Machines often encounter various challenges during operation, which can affect their performance and efficiency. Understanding these issues and knowing how to address them is essential for maintaining optimal functionality.

Overheating: A frequent problem, overheating can result from inadequate coolant levels or a blocked radiator. Regularly check fluid levels and ensure that cooling components are free from debris.

Hydraulic System Failures: Leaks in hydraulic lines or worn seals can lead to decreased performance. Inspecting and replacing damaged components promptly can prevent further complications.

Electrical Issues: Faulty wiring or blown fuses may disrupt operation. Routine inspections of electrical connections and replacing worn parts can help maintain consistent functionality.

Engine Performance: Poor engine performance may stem from fuel quality or air filter blockages. Regularly changing filters and using high-quality fuel can enhance engine efficiency.

By addressing these common issues proactively, operators can ensure their machines remain reliable and effective in the long run.

Where to Find Replacement Parts

Locating quality components for machinery can significantly enhance its performance and longevity. There are several avenues to explore when seeking these essential items, each with its own benefits and potential challenges.

Online Resources

- Manufacturer’s Website: Directly accessing the official site ensures authenticity and comprehensive listings.

- Third-Party Retailers: Numerous websites specialize in machinery components, offering competitive prices.

- Marketplaces: Platforms like eBay and Amazon feature a range of options, often including used items.

Local Options

- Authorized Dealers: These outlets provide genuine components and professional advice.

- Repair Shops: Local service providers often have access to suppliers and may offer parts for sale.

- Salvage Yards: Used machinery can be a treasure trove of usable components at a fraction of the cost.

Cost Considerations for Repairs

When it comes to maintaining heavy machinery, understanding the financial implications of repairs is crucial for efficient operation and budgeting. Various factors influence the overall cost, ranging from the complexity of the repair to the quality of the components required. Planning ahead can help mitigate unexpected expenses and ensure the longevity of the equipment.

Assessment of Damage

Before initiating any repair work, a thorough assessment of the machinery’s condition is essential. This evaluation not only identifies the extent of damage but also determines the most effective repair strategies. Engaging professionals for a detailed inspection may incur initial costs but can save money in the long run by preventing further issues.

Parts and Labor Costs

The expenses associated with components and labor can vary significantly. High-quality components often come at a premium but can enhance the performance and durability of the machinery. Additionally, labor costs can fluctuate based on the expertise required for specific repairs. Investing in skilled technicians may increase upfront costs but can lead to better outcomes and reduced frequency of future repairs.

DIY Repair vs. Professional Help

When it comes to maintaining and fixing machinery, enthusiasts often face the decision of whether to tackle repairs themselves or seek assistance from experts. This choice can significantly impact both the time invested and the outcome of the repair process. Understanding the pros and cons of each approach is essential for making an informed decision.

Benefits of DIY Repairs

Taking on repairs personally can be incredibly rewarding. Cost savings is a major advantage, as you can avoid labor fees that professionals typically charge. Additionally, performing repairs yourself allows for a deeper understanding of the equipment, enhancing your skills and knowledge. Moreover, the flexibility to work at your own pace can be appealing, especially for those who enjoy hands-on projects.

Advantages of Professional Assistance

On the other hand, enlisting the help of professionals can save time and provide peace of mind. Experts bring experience and specialized knowledge, often leading to quicker and more reliable outcomes. Furthermore, professional repairs often come with warranties, ensuring that the work is protected against future issues. For complex problems, the expertise of trained technicians may be indispensable, reducing the risk of further damage during the repair process.

Ultimately, the choice between DIY repairs and professional help depends on individual skills, the complexity of the issue, and the resources available. Weighing these factors carefully can lead to a more satisfactory resolution.

Upgrading Parts for Better Performance

Enhancing machinery efficiency often hinges on the careful selection of superior components. By investing in high-quality upgrades, operators can significantly improve functionality, reliability, and overall output. These enhancements not only optimize the equipment’s performance but also extend its lifespan, ensuring a worthwhile return on investment.

Identifying Key Areas for Improvement

To achieve optimal results, it’s essential to analyze which specific elements can benefit from modernization. Common areas include hydraulic systems, engine components, and undercarriage elements. Upgrading these vital sections can lead to smoother operation, greater power, and enhanced fuel efficiency.

Selecting Quality Alternatives

When considering replacements, it’s crucial to source options that meet or exceed original specifications. Researching reputable manufacturers and reading user reviews can guide you toward choices that provide the best performance gains. Moreover, collaborating with knowledgeable professionals can help in making informed decisions that align with operational goals.