Kubota Z724 Parts Breakdown and Diagrams

Understanding the internal configuration and connections of various elements in any machinery is crucial for efficient maintenance and repair. By analyzing the intricate details of how individual sections come together, it becomes easier to identify potential issues and ensure smooth operation.

This section delves into the detailed breakdown of the machine’s assembly, offering insights into how different mechanisms work in unison. Each section of the system is carefully designed to interact with others, forming a well-coordinated and reliable structure.

For those engaged in technical servicing, having a clear view of how everything fits together can significantly simplify troubleshooting and ensure optimal performance. Whether you’re maintaining or repairing, understanding these connections is key to ensuring a long-lasting and efficient system.

Understanding the Key Components

The equipment in question is a powerful machine built for performance and efficiency. Each element plays a critical role in ensuring smooth operation and reliability over time. In this section, we will explore the primary systems and parts that work together to deliver optimal functionality.

Engine and Powertrain

The core of the machine is its engine, designed to provide robust power while maintaining fuel efficiency. This, combined with a well-engineered powertrain, allows for seamless transitions between tasks and enhances the overall durability of the machine.

Chassis and Steering Mechanism

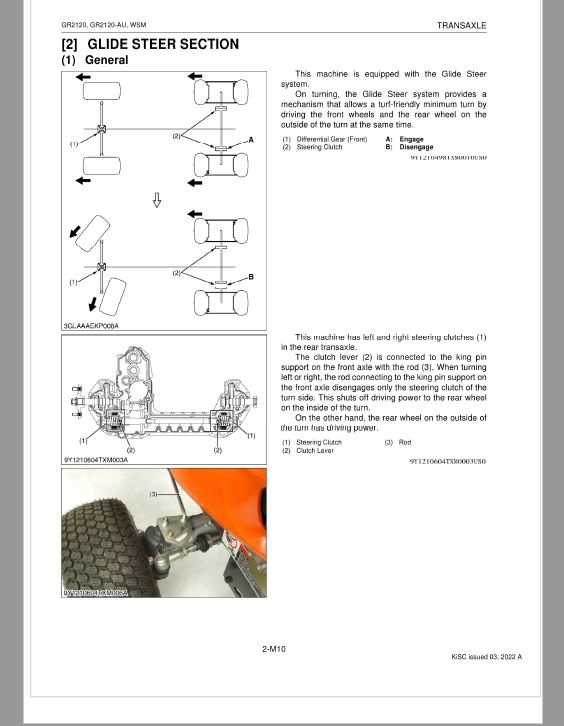

The sturdy frame and advanced steering system ensure stability and maneuverability. These components allow the operator to maintain control, even in challenging conditions, improving the safety and handling of the equipment.

Key Parts of the Kubota Z724

This section explores the essential components that contribute to the functionality and performance of this powerful machinery. Each element plays a crucial role, ensuring that the overall operation is efficient and reliable. Understanding these core parts is vital for maintenance and optimal performance.

One of the main elements is the engine, which provides the necessary power for operation. This unit is designed for efficiency and durability, ensuring longevity even under heavy usage. Another critical component is the transmission system, responsible for transferring power from the engine to the wheels, allowing for smooth maneuverability.

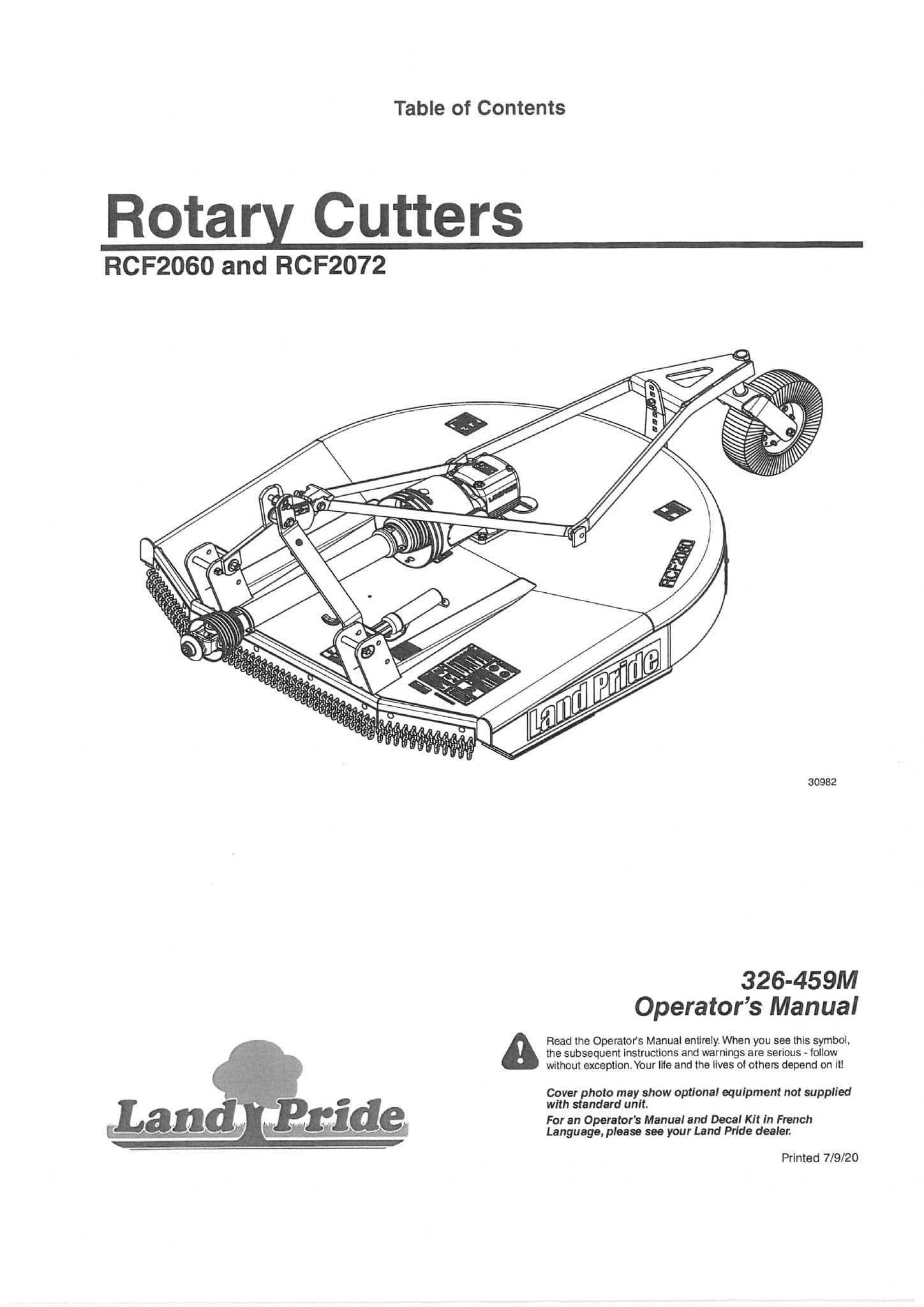

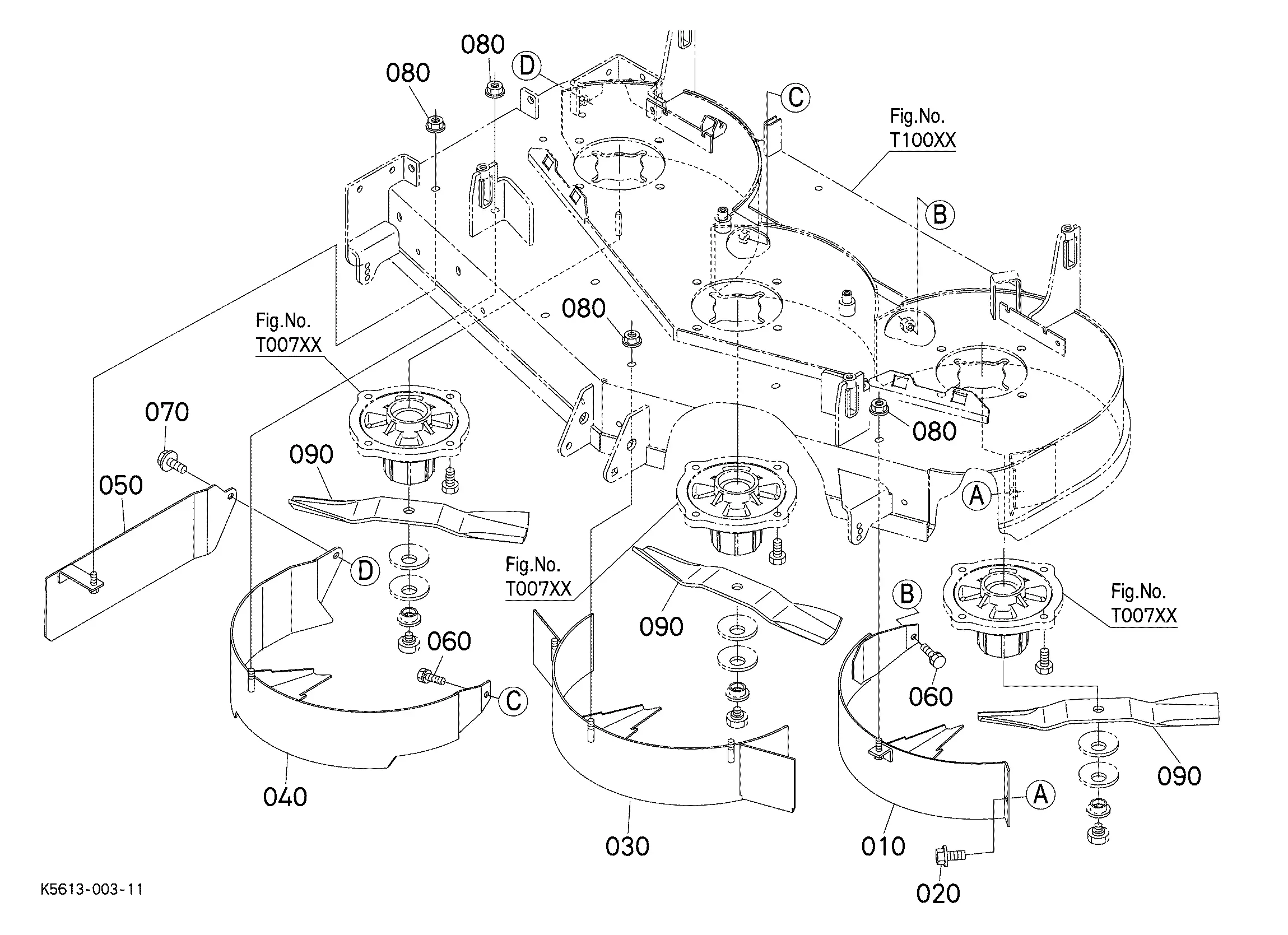

The cutting deck is also a significant feature, designed to deliver precision and effectiveness in mowing. Its design allows for an even cut, enhancing the overall aesthetic of the area being maintained. Additionally, the steering system is engineered for ease of use, offering operators the ability to navigate through tight spaces effortlessly.

Moreover, the hydraulic system plays a vital role in various functions, from lifting attachments to controlling movement, enhancing the machine’s versatility. Finally, the safety features integrated into the design ensure that operators can work confidently, minimizing risks while maximizing productivity.

Maintenance Tips for Kubota Z724

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a structured maintenance routine, you can prevent potential issues and enhance efficiency. This section provides key recommendations to keep your machine in top condition.

Routine Inspections

Performing frequent checks on vital components is crucial. Inspect the fluid levels, including oil and coolant, and look for any signs of leaks. Regularly examine the filters and replace them as needed. Pay attention to the tires, ensuring they are properly inflated and free of damage. These small steps can significantly impact overall functionality.

Cleaning and Storage

Keeping your machinery clean is vital for preventing rust and wear. After each use, remove debris and dirt from surfaces, particularly around the engine and undercarriage. When storing, ensure the equipment is in a dry, sheltered location to protect it from harsh weather. Using covers can further safeguard against dust and moisture, extending the lifespan of your investment.

Replacing Worn-Out Kubota Z724 Parts

Maintaining optimal performance in machinery requires regular assessment and replacement of components that have suffered wear and tear. Addressing these issues promptly not only enhances efficiency but also prolongs the lifespan of the equipment. Understanding which elements need replacement and how to go about it is crucial for any operator.

Here are some key steps to follow when replacing worn components:

- Identify the Problem: Regularly inspect your machine for signs of wear. Common indicators include unusual noises, decreased performance, or visible damage.

- Consult the Manual: Reference the equipment manual for specific details on the components in question. This will provide guidance on replacement procedures and compatible replacements.

- Gather Necessary Tools: Ensure you have all required tools before starting the replacement process. This may include wrenches, screwdrivers, and safety gear.

- Order New Components: Once you know what needs replacing, procure the appropriate parts from a reliable supplier to guarantee quality and compatibility.

- Follow Proper Replacement Procedures: Adhere to the manufacturer’s instructions during installation. This minimizes the risk of improper assembly and ensures functionality.

- Test the Equipment: After replacing the worn elements, conduct a thorough test to confirm that everything is functioning as expected.

By regularly monitoring and replacing worn components, you can maintain high performance and reliability in your machinery, ultimately saving time and costs associated with major repairs.

Common Issues with Kubota Z724 Components

Understanding the frequent problems associated with machinery components is essential for maintaining optimal performance and longevity. Many operators encounter similar challenges that can arise due to wear and tear, improper maintenance, or environmental factors. Identifying these issues early can help mitigate costly repairs and downtime.

Worn Belts and Cables

One of the most prevalent concerns involves belts and cables that experience wear over time. These parts are crucial for the proper functioning of various systems, and deterioration can lead to decreased efficiency or even complete failure. Regular inspections and timely replacements are key to preventing unexpected breakdowns.

Hydraulic System Leaks

Another common problem is leaks within the hydraulic system. These can occur due to degraded seals or connections that have become loose. Prompt detection and repair of leaks are vital, as they can severely affect the machine’s operation and lead to significant fluid loss, compromising overall performance.

How to Identify Kubota Z724 Parts

Understanding the components of your machinery is crucial for effective maintenance and repair. Proper identification of each element ensures that you can find the right replacements or upgrades, thus enhancing the overall performance of your equipment. This guide will walk you through the essential steps to recognize and categorize the various elements of your model.

Step-by-Step Identification

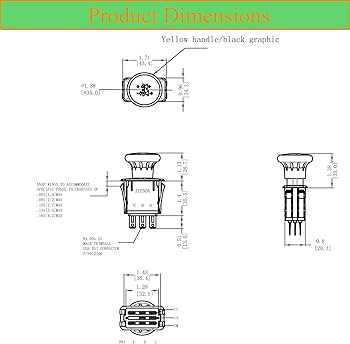

Start by examining the machinery closely. Take note of any labels or numbers imprinted on the components, as these often provide valuable information regarding specifications. Additionally, referencing the user manual can offer insights into each section of the equipment, helping you to pinpoint specific features and their corresponding functions.

Utilizing Online Resources

The internet is a treasure trove of information. Numerous websites and forums specialize in detailing machinery components, complete with images and descriptions. Engaging with these communities can yield practical advice and firsthand experiences from other users, making your identification process smoother and more informed.

Upgrading Your Kubota Z724 Equipment

Enhancing your outdoor machinery can significantly improve performance and efficiency. Upgrading specific components can lead to better functionality, increased longevity, and a more enjoyable user experience. Whether you’re looking to boost power, improve handling, or simply modernize your equipment, strategic enhancements can make a substantial difference.

Key Areas for Improvement

- Engine Performance: Consider upgrading to a high-efficiency air filter or performance exhaust system. These enhancements can optimize airflow and improve fuel efficiency.

- Hydraulic System: Evaluate the hydraulic components for possible upgrades. Enhanced pumps or cylinders can increase lifting capacity and speed.

- Transmission: Upgrading the transmission system can lead to smoother operation and better torque delivery, making your tasks easier.

- Control Systems: Implementing modern electronic controls can provide better precision and responsiveness during operation.

Steps for Effective Upgrades

- Research compatible upgrades that enhance the specific features you want to improve.

- Consult with professionals or experienced users to gather insights and recommendations.

- Carefully review installation procedures to ensure proper fitting and functionality.

- Test the equipment post-upgrade to ensure all enhancements work as intended.

By taking the time to upgrade your machinery thoughtfully, you can ensure that it meets your needs more effectively while extending its overall life and performance.

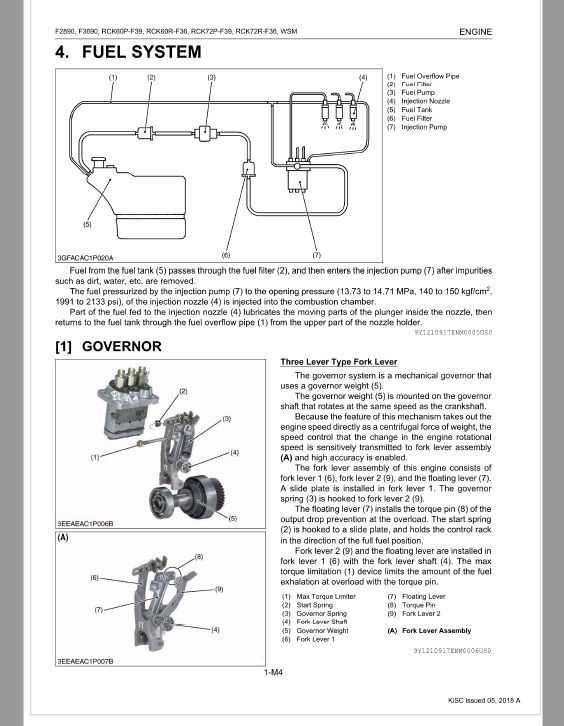

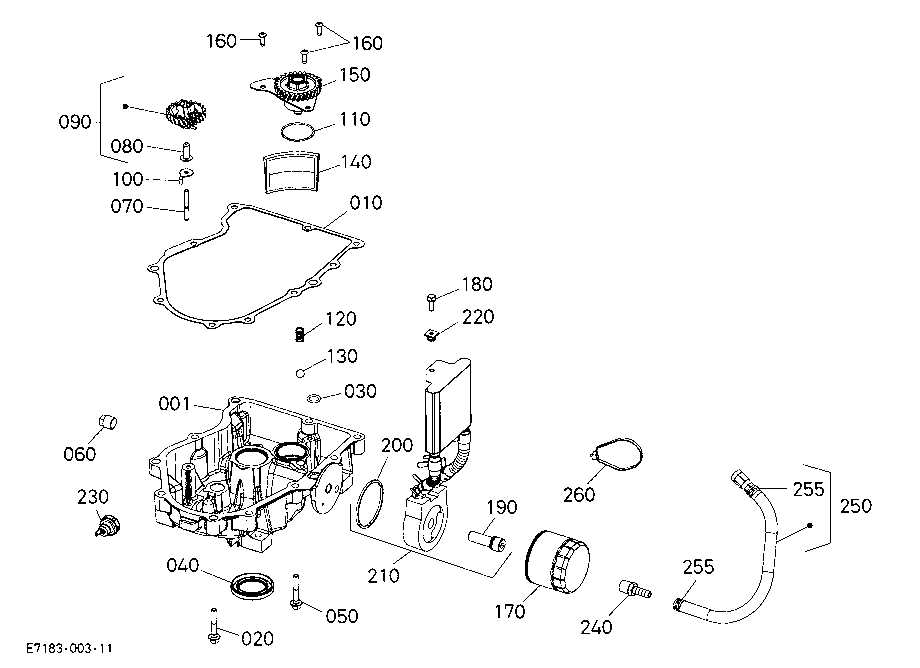

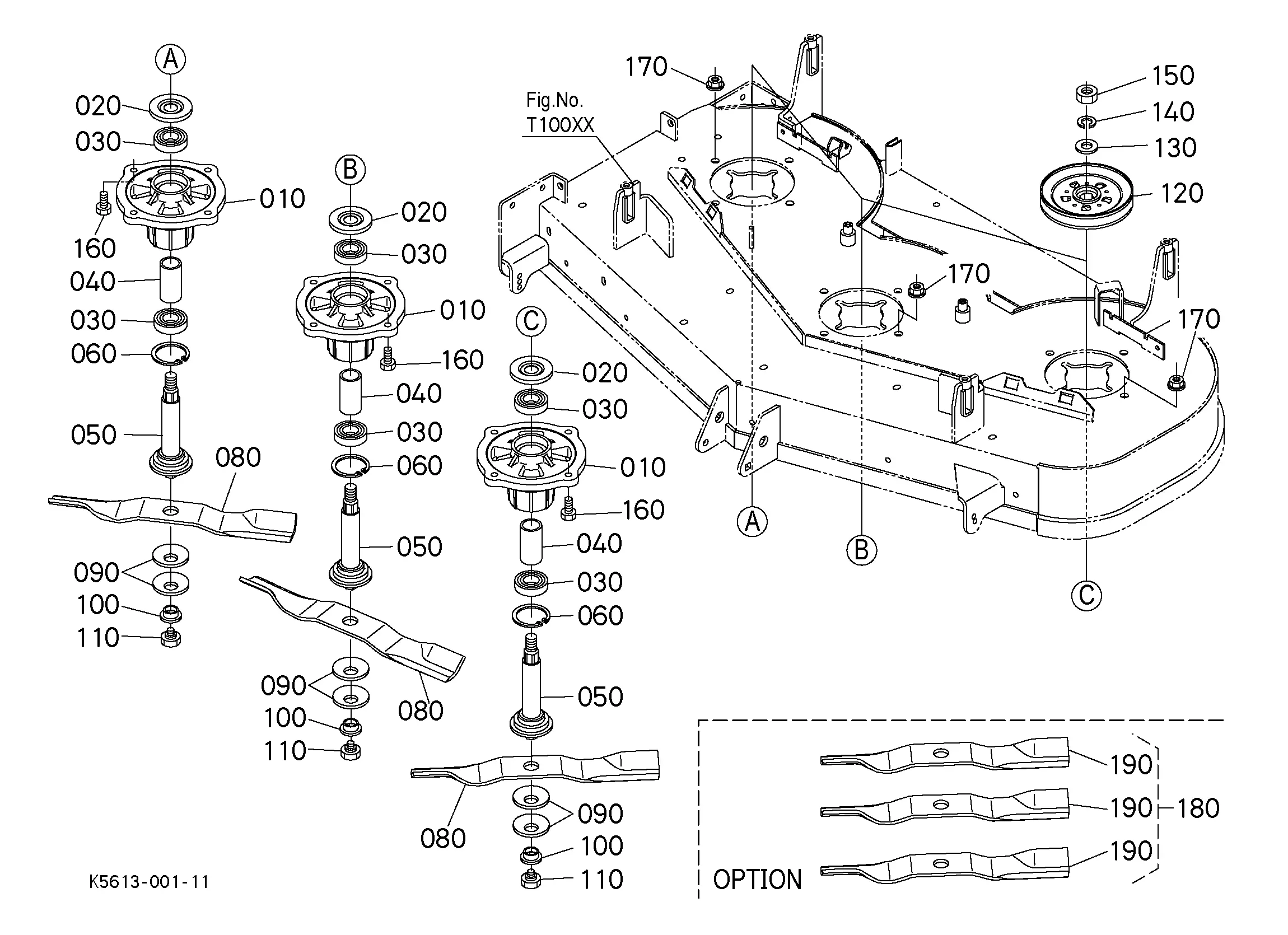

Diagram Guide for Kubota Z724 Maintenance

Understanding the intricate layout of machinery components is essential for effective upkeep and repair. A well-organized visual representation can significantly simplify maintenance tasks, allowing operators to identify parts quickly and address issues efficiently. This guide provides insights into maintaining your equipment by highlighting essential elements for optimal performance.

Understanding Component Locations

Familiarizing yourself with the arrangement of key elements is crucial. Each section of the equipment serves a specific function, and knowing where to find them can streamline troubleshooting and servicing. For instance, the engine assembly, hydraulic systems, and drive mechanisms are all interconnected. Recognizing their placements can enhance your ability to perform routine checks and repairs.

Regular Maintenance Practices

Consistent upkeep ensures longevity and reliability. It is important to regularly inspect vital components, such as filters, belts, and fluids. Establishing a maintenance routine based on the visual guide can help you stay ahead of potential issues. Furthermore, keeping a record of maintenance activities will allow you to track performance over time, ensuring your equipment operates smoothly.

In summary, utilizing a clear representation of your machinery can aid in effective maintenance practices, promoting both efficiency and durability.

Essential Tools for Kubota Z724 Repairs

When it comes to maintaining and fixing outdoor equipment, having the right instruments is crucial for efficiency and effectiveness. Whether you are a professional mechanic or a DIY enthusiast, the selection of tools you choose can significantly impact the quality of your work. Understanding which tools are essential for specific tasks can save time and enhance the repair process.

| Tool | Purpose |

|---|---|

| Socket Set | Used for loosening and tightening bolts and nuts, ensuring proper assembly. |

| Wrenches | Ideal for accessing tight spaces and adjusting components. |

| Torque Wrench | Ensures fasteners are tightened to manufacturer specifications, preventing damage. |

| Screwdriver Set | Essential for various screws, providing versatility in repairs. |

| Pliers | Useful for gripping, twisting, and cutting wires or small parts. |

| Jack Stands | Provides stability and safety when lifting equipment for undercarriage work. |

| Grease Gun | Facilitates lubrication of moving parts, ensuring optimal performance. |

Equipping yourself with these fundamental tools will prepare you for a variety of maintenance tasks, enhancing your ability to keep your machinery in top condition. Proper maintenance not only prolongs the life of your equipment but also improves its performance and reliability.

Proper Care of Critical Parts

Ensuring the longevity and efficiency of essential components is crucial for any machinery. Regular maintenance not only extends the lifespan of individual elements but also enhances overall performance. Understanding how to care for these vital segments is key to avoiding costly repairs and ensuring smooth operation.

Maintenance Tips

To maintain the integrity of critical elements, consider the following recommendations:

| Component | Maintenance Action | Frequency |

|---|---|---|

| Engine | Change oil and filter | Every 100 hours |

| Air Filter | Inspect and clean/replacement | Every 50 hours |

| Hydraulic System | Check fluid levels | Weekly |

| Batteries | Inspect terminals and charge | Monthly |

Importance of Regular Inspections

Conducting routine assessments of crucial components prevents potential failures and ensures optimal functionality. Identifying wear and tear early allows for timely interventions, which can save time and resources. Establishing a maintenance schedule tailored to your machine’s requirements is vital for achieving sustained performance.

Troubleshooting Kubota Z724: Parts Overview

When addressing issues with your machine, understanding the components involved is crucial for effective resolution. A comprehensive overview of the essential elements can aid in identifying the root cause of any malfunction, ensuring smoother operation and longevity.

Common Components to Inspect

- Engine: Check for any signs of wear or leaks.

- Transmission: Look for fluid levels and shifting performance.

- Electrical System: Inspect wiring and battery connections for corrosion.

- Hydraulic System: Ensure there are no leaks and that fluid levels are adequate.

- Cuts and Blades: Assess sharpness and any physical damage.

Steps for Effective Troubleshooting

- Start with a visual inspection of all components.

- Refer to the user manual for specific guidance on each part.

- Test functionalities systematically to isolate issues.

- Replace or repair damaged elements as necessary.

- Conduct routine maintenance to prevent future problems.