Kubota Z726X Parts Diagram Overview

In the realm of machinery maintenance, a comprehensive understanding of the various components is essential for optimal performance. This section delves into the intricacies of a specific model, shedding light on how each part interconnects and functions harmoniously. By familiarizing oneself with these intricate details, operators can ensure longevity and efficiency in their equipment.

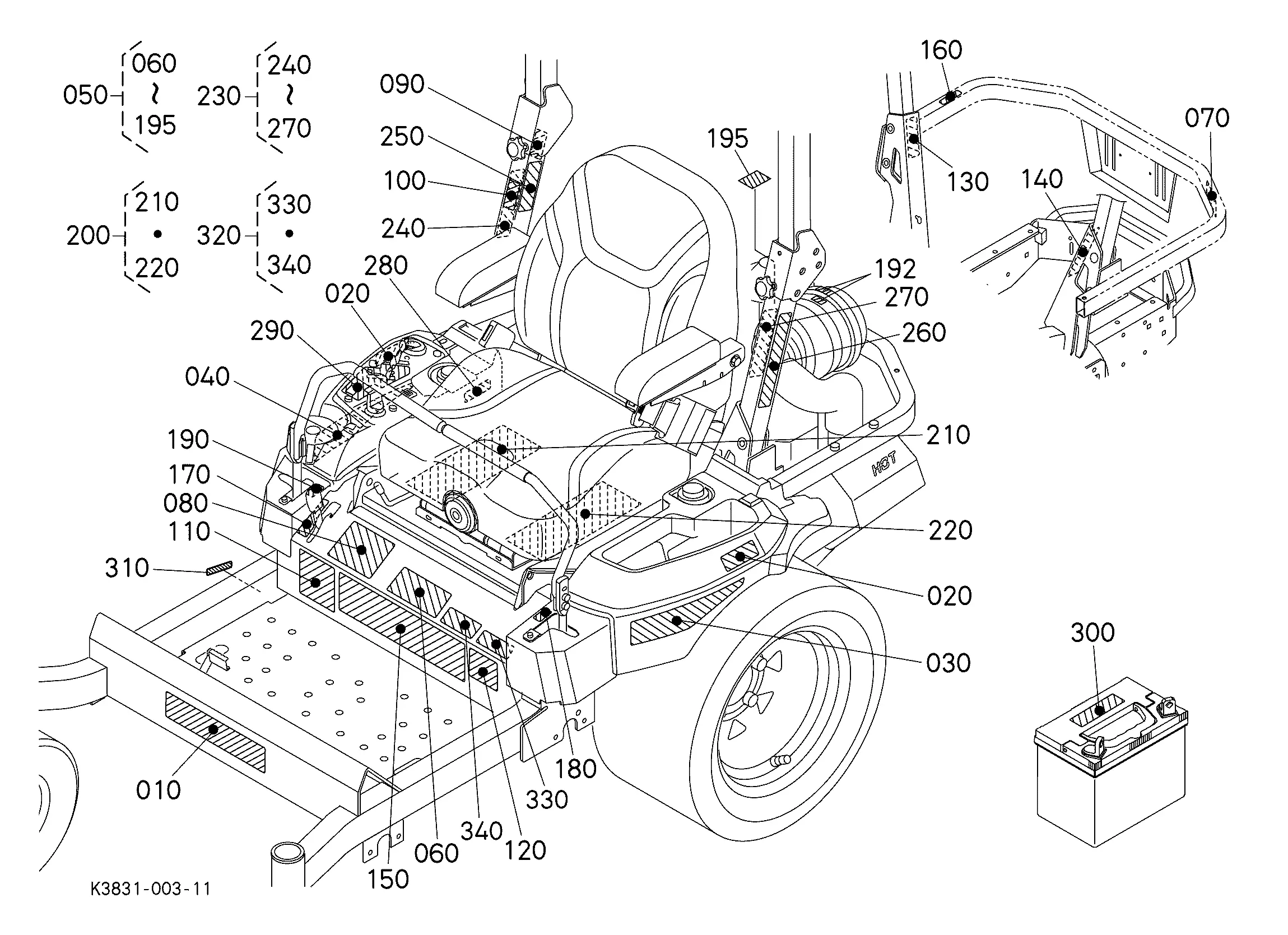

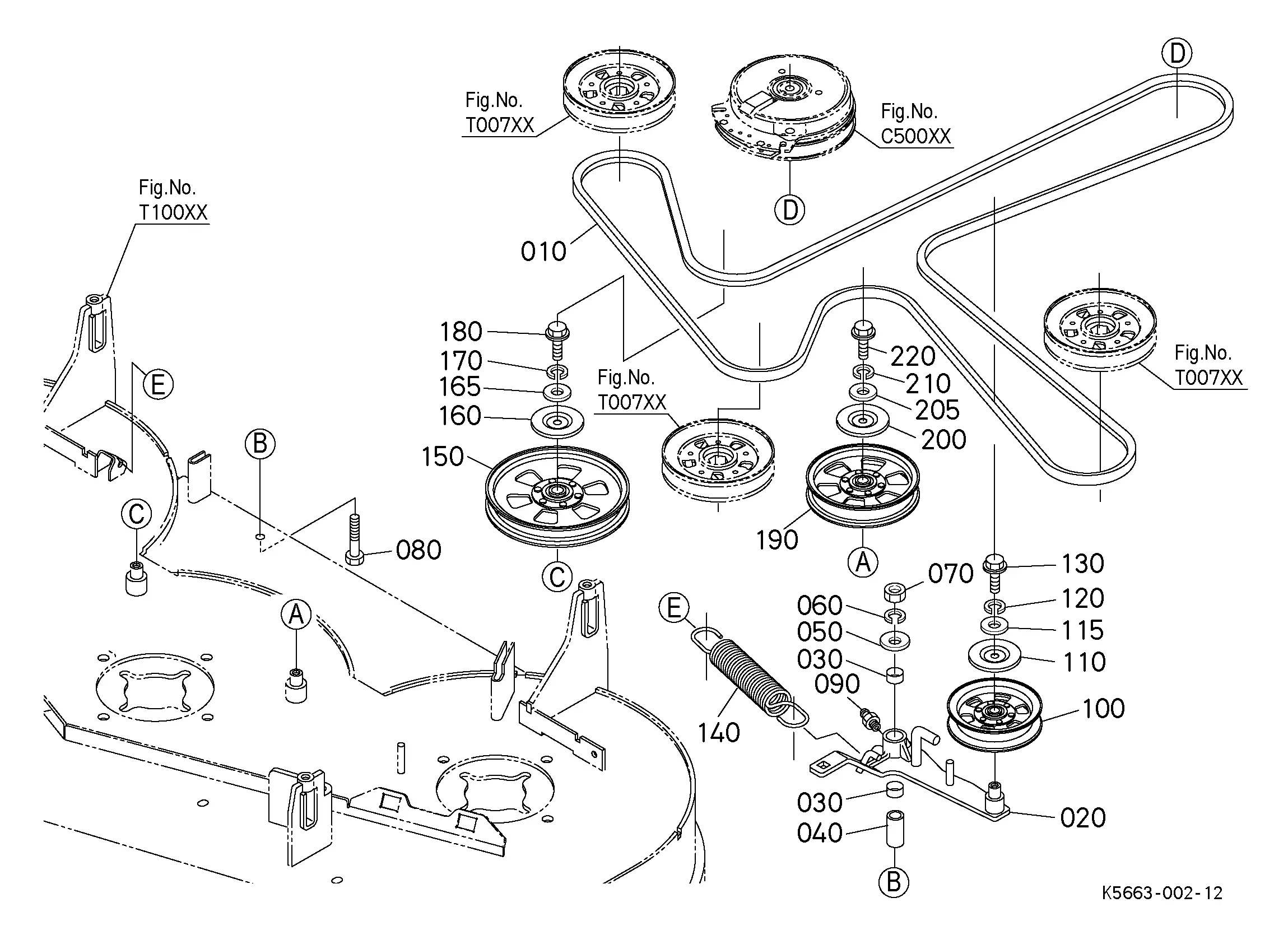

Illustrations of the various elements provide invaluable insights, highlighting the relationships and arrangements that facilitate seamless operation. This exploration not only aids in troubleshooting but also empowers users to undertake preventive measures, minimizing potential issues before they arise. With a clear visual representation, maintenance tasks become more manageable and intuitive.

For enthusiasts and professionals alike, having access to a detailed overview of component placement and specifications enhances the overall understanding of the machinery’s capabilities. Whether for repairs, upgrades, or routine inspections, such knowledge is indispensable in ensuring that every aspect of the equipment is functioning at its best.

Kubota Z726X Overview

This section provides an insight into a robust and efficient piece of outdoor machinery designed for landscape maintenance. With a focus on performance and user-friendliness, this model is suitable for both commercial and residential applications.

Key features include:

- Powerful engine for enhanced productivity

- Ergonomic design for operator comfort

- Advanced cutting technology for superior results

- Durable construction for longevity

When considering this machine, it’s important to note the following advantages:

- High maneuverability in various terrains

- Efficient fuel consumption, leading to cost savings

- Ease of maintenance, ensuring minimal downtime

- Variety of attachments for versatile functionality

This outdoor equipment stands out in its class, combining innovative features with reliability, making it a popular choice among professionals and enthusiasts alike.

Importance of Parts Diagrams

Understanding the intricate components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools for technicians and operators, allowing them to identify individual elements and their relationships within the overall system. This clarity not only enhances troubleshooting efficiency but also streamlines the process of ordering replacements or performing upgrades.

Moreover, these visual guides facilitate training and knowledge transfer among team members. New employees can quickly familiarize themselves with the machine’s architecture, promoting a safer and more efficient working environment. As a result, the reliance on accurate visual references contributes to reducing downtime and ensuring optimal performance.

In addition, these resources empower users to undertake repairs with confidence. When faced with a malfunction, having access to a detailed illustration can eliminate guesswork, guiding individuals to the precise area of concern. This not only aids in executing repairs accurately but also fosters a sense of autonomy among operators, encouraging them to engage more deeply with the equipment they use.

Key Components of Kubota Z726X

This section highlights the essential elements that contribute to the overall functionality and efficiency of this model. Understanding these key components is crucial for maintenance and optimal performance.

| Component | Description |

|---|---|

| Engine | Powers the machine, ensuring reliable operation under various conditions. |

| Transmission | Facilitates smooth gear shifting and efficient power transfer to the wheels. |

| Deck | Designed for durability and precision cutting, it is integral to the mowing process. |

| Wheels | Provide stability and maneuverability, enabling effective navigation on different terrains. |

| Control Panel | Houses the controls for operation, allowing the user to manage various functions with ease. |

Familiarity with these components enhances understanding and facilitates better care of the equipment, ensuring longevity and peak performance.

Understanding the Parts Layout

Grasping the arrangement of components is crucial for effective maintenance and troubleshooting. A well-structured layout provides clarity on how each element interacts within the system, facilitating easier identification of issues and ensuring efficient repairs.

Comprehending the configuration allows users to navigate through the various sections with confidence. Each segment is designed with specific functionalities in mind, and understanding these roles helps in recognizing the significance of every individual piece.

Additionally, visual references serve as valuable tools for technicians and enthusiasts alike, aiding in the localization of parts during inspections or replacements. A clear understanding of the overall layout promotes a more systematic approach, enhancing the overall repair experience.

Common Issues and Solutions

Machinery often encounters operational challenges that can hinder performance. Understanding typical problems and how to address them efficiently ensures long-term reliability and optimal functionality. Early detection and maintenance are key to preventing these complications.

Starting Problems: Frequent difficulties with starting equipment can be traced to battery health or ignition system faults. Ensure regular checks of electrical components and clean connections to prevent power-related failures.

Uneven Performance: If the equipment is not operating smoothly, it could indicate issues with the fuel system or air intake. Inspect filters and fuel lines for blockages or wear, ensuring unobstructed flow for optimal operation.

Overheating: Consistent overheating typically points to cooling system inefficiencies. Regularly check the radiator, coolant levels, and ensure proper airflow to avoid damage to internal components.

Noise and Vibrations: Unusual sounds or vibrations often signal mechanical wear. Routine inspections of belts, bearings, and fasteners can prevent minor issues from escalating into major malfunctions.

Where to Find Replacement Parts

Locating the appropriate components for your equipment is essential for maintaining its functionality and ensuring long-term reliability. By knowing where to source high-quality replacements, you can extend the lifespan of your machinery and minimize downtime.

Authorized Suppliers

One of the best ways to secure reliable components is through official retailers or certified distributors. These outlets offer genuine, manufacturer-approved solutions, ensuring compatibility and durability.

- Manufacturer-certified stores

- Online platforms with official partnerships

- Local dealerships

Online Marketplaces

If you’re looking for convenience and wider selection, various online platforms can be a valuable resource. They often provide detailed specifications, reviews, and shipping options, making it easier to compare and choose the right components.

- Trusted e-commerce websites

- Specialized equipment forums

Maintenance Tips for Longevity

Ensuring the longevity and optimal performance of your equipment requires consistent care and attention. Regular upkeep helps to prevent major issues, minimizes downtime, and extends the life of your machine. By following a few key practices, you can keep your machinery running smoothly for years to come.

Routine Inspections

Frequent visual checks are essential to catch any signs of wear or damage early. Look for loose connections, leaks, or unusual noises, and address them promptly to avoid more extensive repairs. Keeping track of these inspections helps to maintain the overall health of your equipment.

Lubrication and Cleaning

Keeping moving parts properly lubricated reduces friction and prevents premature wear. Additionally, regular cleaning prevents the buildup of

Comparison with Other Models

When analyzing different equipment types, it’s important to understand how one machine stands against its alternatives. Each model presents unique advantages and design differences that may influence a buyer’s decision. This section highlights key factors such as performance, efficiency, and durability, offering a clear comparison between various options available on the market.

Performance: One of the primary distinctions between machines lies in their operational power and reliability. While some models excel in speed and handling, others are designed for heavy-duty tasks requiring more torque and endurance.

Efficiency: Fuel consumption and maintenance frequency are critical considerations. Some alternatives offer more economical solutions, reducing long-term operational costs, while others may prioritize maximum output over efficiency.

Durability: Construction quality and component longevity vary significantly. Certain machines are built with reinforced materials, ensuring longer service life, while others may offer lighter designs that require more frequent part replacements.

Tools Needed for Repairs

When it comes to maintaining or fixing complex machinery, having the right equipment at hand is crucial. Proper tools ensure that tasks are completed efficiently and with minimal risk of damage to mechanical components. Selecting the appropriate instruments not only saves time but also helps maintain the longevity of the machine.

Among the essential tools, you will need various wrenches, screwdrivers, and pliers of different sizes to tackle bolts, nuts, and fittings. A socket set with different heads is particularly useful for working with hard-to-reach areas. For more precise adjustments, torque wrenches will help apply the correct amount of pressure to fasteners, preventing over-tightening.

Other handy equipment includes a sturdy jack or lifting mechanism to access the undercarriage, as well as a set of wire cutters for any electrical adjustments. Depending on the nature of the repairs, you might also require specialized instruments such as bearing pullers, belt

Visual References for Assembly

Effective assembly relies on accurate visual guides that facilitate understanding and execution. Utilizing detailed illustrations enhances the clarity of complex structures, enabling users to identify each component’s placement and function within the assembly process.

Illustrative Guides

Illustrative guides serve as essential tools in assembly, providing clear depictions of components in relation to one another. These visuals can simplify the understanding of how parts interact and are arranged, ultimately improving the efficiency of the assembly process.

Importance of Clear Visuals

Clear visuals not only aid in identifying parts but also reduce the risk of errors during assembly. Utilizing well-designed illustrations allows for a smoother workflow and ensures that all components are assembled correctly and securely.