Dymo LabelWriter 450 Parts Diagram Explained

The intricacies of modern printing devices often go unnoticed, yet they play a crucial role in ensuring efficiency and reliability. This section aims to explore the components that make up a specific model of a printing machine, providing insights into how each element contributes to its overall functionality.

By examining the layout and arrangement of these essential components, users can gain a clearer understanding of the device’s operation. This knowledge not only enhances troubleshooting skills but also empowers users to make informed decisions regarding maintenance and upgrades.

Ultimately, delving into the structure of this printing technology reveals the sophistication behind what may seem like a simple task of producing labels. A thorough comprehension of its architecture is vital for anyone looking to optimize their printing experience.

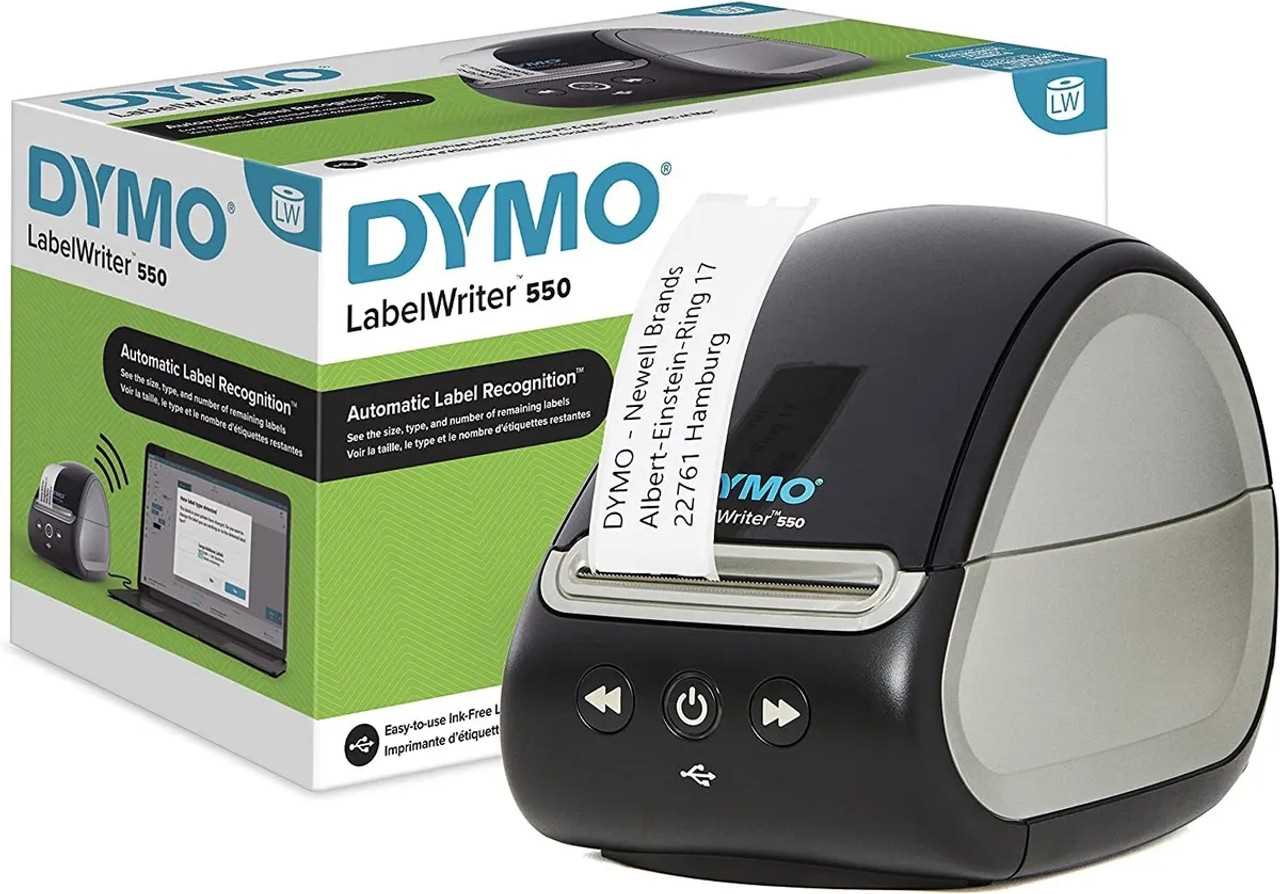

Overview of the Labeling Device

This compact printing solution is designed for efficient and precise label creation, catering to both personal and professional needs. It streamlines the process of organizing and identifying items through easy-to-use technology.

- Compact Design: Ideal for small spaces, making it easy to integrate into any workspace.

- High-Speed Printing: Capable of producing labels quickly, enhancing productivity.

- Versatile Compatibility: Works seamlessly with various operating systems and software.

- User-Friendly Interface: Simple controls allow for quick label design and printing.

Whether for office use or personal projects, this device offers the ultimate convenience in labeling tasks.

Key Features of the Printer

This section explores the essential characteristics that define the efficiency and functionality of this compact printing device. Understanding these features helps users maximize their experience and productivity.

Design and Build

- Compact and lightweight, ideal for office settings.

- Durable construction ensures long-term reliability.

- Sleek design complements various work environments.

Printing Capabilities

- High-resolution output for crisp text and graphics.

- Fast printing speed minimizes waiting time.

- Versatile media compatibility allows for different label sizes.

Understanding Parts and Components

This section aims to explore the various elements that contribute to the overall functionality of a labeling device. Recognizing each component’s role can enhance user experience and improve maintenance practices.

- Main Body: The structure that houses all essential components.

- Responsible for transferring ink onto the material.

- Feed Mechanism: Controls the movement of the media through the machine.

- Control Panel: The interface for user commands and settings adjustments.

- Power Supply: Provides the necessary energy for operation.

Understanding these components allows users to troubleshoot issues and perform maintenance effectively, ultimately leading to improved performance and longevity of the device.

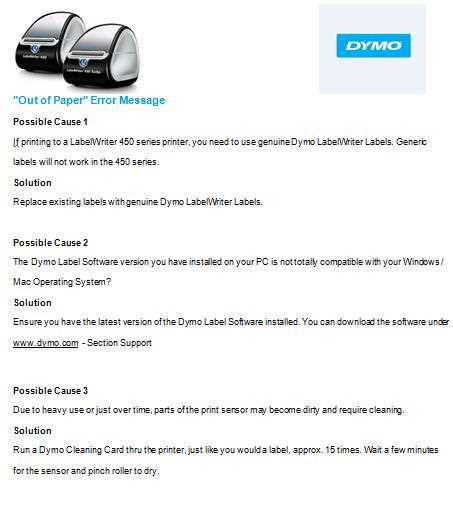

Common Issues and Solutions

In the realm of label printing devices, users often encounter a variety of challenges that can disrupt their workflow. Understanding these common problems and their respective solutions can significantly enhance the overall experience and efficiency.

One frequent issue is paper jams, which can occur due to improper loading or debris in the feed area. To resolve this, carefully remove the stuck material and ensure that the labels are aligned correctly before reloading.

An additional concern is poor print quality, often manifested as faded or uneven text. This can typically be remedied by checking the ink or thermal transfer ribbon, as well as cleaning the print head to remove any residue.

Connectivity problems may also arise, especially when interfacing with computers or networks. To troubleshoot, verify that all cables are securely connected and that the appropriate drivers are installed on the host device.

Lastly, inconsistent label cutting can lead to frustration. Regular maintenance of the cutting mechanism and ensuring it is free from obstructions can help maintain precision in cuts.

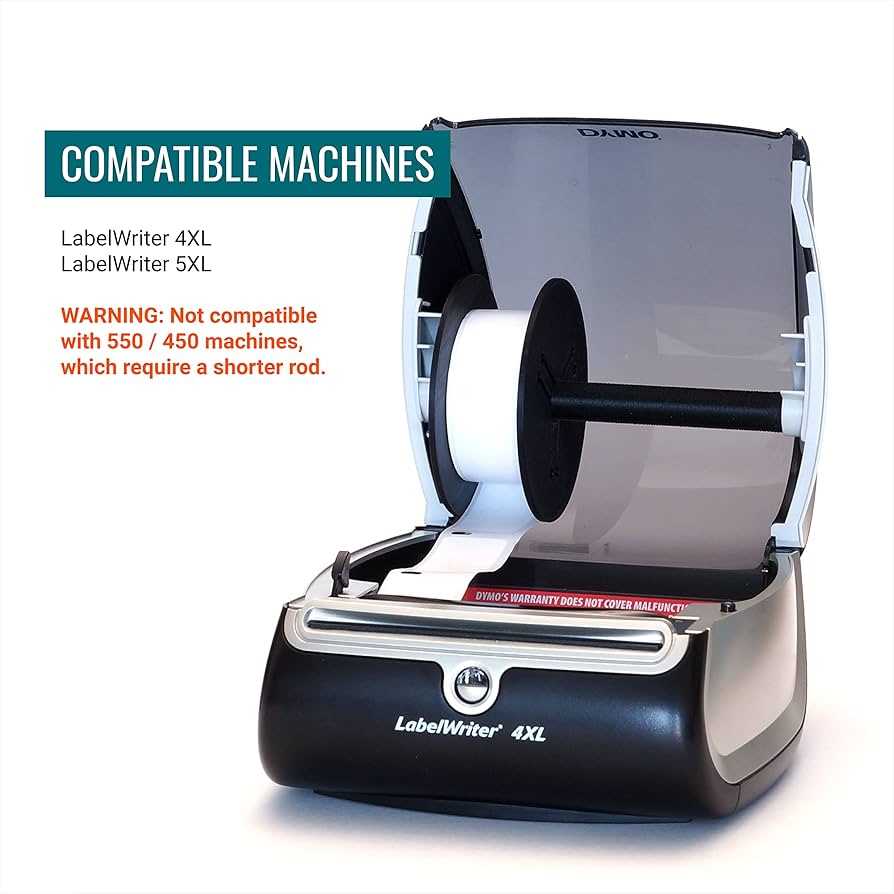

How to Replace Printer Parts

Maintaining the functionality of your printing device often involves replacing certain components. Understanding how to effectively swap out these elements can enhance performance and prolong the lifespan of your machine. This guide will provide you with essential steps to ensure a smooth replacement process.

1. Identify the Component

Before proceeding, it’s crucial to accurately determine which component needs replacement. Common elements include rollers, cartridges, and fusers. Consult your device’s manual for specific guidance on locating the part in question.

2. Gather Necessary Tools

Prepare the tools required for the task. This might include screwdrivers, pliers, or specialized tools depending on the part you are addressing. Having everything on hand will streamline the process.

3. Power Down the Device

Safety should always be a priority. Ensure the device is turned off and unplugged from the electrical source before attempting any replacements. This minimizes the risk of electric shock or damage to the machine.

4. Remove the Faulty Component

Carefully detach the malfunctioning part. Follow the manufacturer’s instructions closely to avoid any accidental damage to surrounding elements. Take note of how the part is connected to assist in installing the new one.

5. Install the New Part

Once the old component is removed, install the new one by reversing the removal process. Ensure that all connections are secure and that the part fits snugly in place.

6. Test the Device

After replacing the component, plug the device back in and power it on. Conduct a test print to verify that everything is functioning correctly. If issues persist, revisit the installation steps to ensure everything is properly connected.

By following these straightforward steps, you can efficiently replace components of your printing device, ensuring it continues to operate at peak performance.

Maintenance Tips for Longevity

Proper care and regular maintenance are essential for ensuring the durability and optimal performance of your printing device. By following a few simple practices, you can extend the lifespan of your equipment and enhance its efficiency.

- Regular Cleaning: Keep the exterior and interior clean. Dust and debris can affect functionality.

- Use Quality Supplies: Opt for high-quality labels and ink. Poor materials can lead to malfunctions.

- Avoid Overheating: Ensure proper ventilation around the device to prevent overheating during prolonged use.

- Check Connections: Regularly inspect cables and connections for wear and tear, replacing any damaged components.

- Update Software: Keep the device’s software up-to-date to ensure compatibility and performance improvements.

By adhering to these maintenance tips, you can significantly enhance the reliability and lifespan of your printing equipment, ensuring it serves you well for years to come.

Using the Software with Dymo

The software designed for label printing devices offers a user-friendly interface that streamlines the creation and management of various label formats. Users can easily navigate through its features to design custom labels, making the process efficient and intuitive.

To get started, ensure that the software is installed on your computer and that the printer is properly connected. The application provides a range of templates and design tools that cater to different labeling needs, from simple text labels to more complex designs with graphics.

| Feature | Description |

|---|---|

| Template Gallery | A collection of pre-designed layouts for various labeling purposes. |

| Text Customization | Options to modify font style, size, and color to match your preferences. |

| Image Import | Ability to add logos or images to enhance your labels. |

| Barcode Generation | Create barcodes for inventory management or pricing purposes. |

| Print Preview | Check the design before printing to avoid errors. |

By utilizing these features, users can maximize the efficiency of their labeling tasks, ensuring a professional appearance and functionality for all printed materials. Regular updates to the software also enhance performance and introduce new features, keeping the user experience fresh and effective.

Label Types Compatible with Device

When considering the various labeling options for your printing device, it is essential to explore the diverse range of materials and formats available. Each type serves specific purposes, ensuring that users can efficiently organize, identify, and communicate information through labels.

Address Labels: These are commonly used for mailing purposes, providing clear information for postal services. They come in various sizes to accommodate different envelope formats.

Shipping Labels: Designed for logistics, these labels often include barcodes or QR codes, making them ideal for tracking packages during transit.

File Folder Labels: Perfect for office organization, these labels help categorize and identify files quickly, improving workspace efficiency.

Clear Labels: Offering a professional look, these labels are perfect for packaging and products where aesthetics matter, allowing the background to show through.

Color-Coded Labels: These labels aid in visual organization by using distinct colors to represent different categories, making it easier to identify items at a glance.

Specialty Labels: This category includes options like water-resistant and thermal labels, tailored for unique applications, ensuring durability and functionality under specific conditions.

Choosing the right type of label enhances the effectiveness of your labeling tasks, making it crucial to consider your specific needs and preferences when selecting compatible materials.

Upgrading to Latest Firmware

Updating your device’s software is essential for optimal performance and access to new features. Regular upgrades can enhance compatibility with various applications, fix bugs, and improve overall functionality. This process ensures that your hardware remains up-to-date with the latest technological advancements.

Before initiating the upgrade, it is crucial to prepare your system adequately. Ensure that you have a stable internet connection and that your device is adequately charged or plugged in. Follow these steps for a smooth update experience:

| Step | Action |

|---|---|

| 1 | Visit the official support website for the latest software version. |

| 2 | Download the upgrade file compatible with your model. |

| 3 | Close all active applications on your system. |

| 4 | Run the downloaded file and follow the on-screen instructions. |

| 5 | Restart your device to complete the installation process. |

By keeping your system updated, you ensure a seamless experience and maximize the utility of your hardware. Always check for updates periodically to benefit from the latest improvements and enhancements.

Benefits of Using LabelWriter 450

Utilizing a high-quality printing device for labels can significantly enhance productivity and organization in various settings. These tools provide a seamless way to produce professional-grade labels, ensuring clarity and efficiency in labeling tasks.

Efficiency and Speed

One of the primary advantages of this printing device is its remarkable speed. Users can quickly generate multiple labels without compromising quality, streamlining workflows and saving valuable time.

Versatility and Customization

This device offers a wide range of label types and sizes, making it suitable for different applications, from shipping to crafting. Additionally, users can easily customize designs to match their branding or personal preferences.

Comparative Analysis with Other Models

This section aims to explore the differences and similarities between a specific printing device and its contemporaries in the market. By examining various features, functionalities, and performance metrics, we can better understand how this device stands in relation to its peers. Such an analysis can aid potential users in making informed choices based on their unique requirements.

Performance Metrics

When evaluating printing efficiency, speed and resolution are paramount. While some devices may excel in print quality, others might prioritize rapid output. Comparing these attributes reveals which model best suits high-volume environments versus those needing finer detail. Additionally, energy consumption and maintenance costs are critical factors that influence long-term usability and overall satisfaction.

Design and Usability

Another vital aspect is the user interface and design. Certain models feature more intuitive controls and a user-friendly setup process, which can greatly enhance the overall experience. Moreover, portability and size play significant roles for users with space constraints or those requiring mobility. Analyzing these design elements helps identify the most convenient options for diverse operational settings.

Where to Find Replacement Parts

Locating components for your printing device can enhance its functionality and longevity. Understanding where to seek these essentials is crucial for maintaining optimal performance.

- Official Website: The manufacturer’s site often provides a dedicated section for ordering components directly.

- Authorized Retailers: Many authorized vendors offer genuine replacements, ensuring compatibility and reliability.

- Online Marketplaces: Platforms like Amazon and eBay frequently list various components, often at competitive prices.

- Local Electronics Stores: Check nearby shops that specialize in office equipment for immediate access to essential parts.

- Repair Shops: Local repair services may have spare components or can help you source them.

By exploring these options, you can efficiently restore your device to its ultimate efficiency.