Comprehensive Parts Diagram for Land Pride FDR1660

In the realm of agricultural machinery, a thorough understanding of the various components is crucial for optimal performance and maintenance. Each element plays a significant role in ensuring that the equipment operates smoothly and efficiently. Familiarity with these individual pieces can greatly enhance your ability to troubleshoot and perform repairs, ultimately extending the lifespan of your investment.

Visual aids are invaluable resources in this process, providing a clear representation of the intricate assembly of components. Such illustrations not only help in identifying each part but also offer insights into how they interact with one another. This knowledge empowers operators and technicians alike, enabling them to tackle issues with confidence and precision.

Whether you are a seasoned professional or a newcomer to the field, having access to detailed guides can streamline maintenance routines and enhance your understanding of the machinery. With the right information, you can ensure that every task is executed effectively, promoting productivity and reducing downtime.

Understanding Land Pride FDR1660

Exploring the intricacies of specialized machinery is essential for effective maintenance and optimal performance. A comprehensive examination reveals how different components function together to enhance efficiency. Knowledge of these elements allows users to maximize utility and ensure longevity.

Familiarity with the configuration and operational mechanics is crucial for anyone working with such equipment. Each segment plays a vital role, contributing to the overall effectiveness of the system. Identifying individual parts and their interactions facilitates troubleshooting and improvements.

In conclusion, grasping the fundamental aspects of this machinery empowers operators to achieve the best results and maintain a smooth workflow.

Key Components of FDR1660

Understanding the essential elements of this machinery is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring the overall efficiency and reliability of the system.

Hydraulic System: This mechanism is pivotal for providing the necessary force to operate various functions. It includes pumps, hoses, and cylinders that work together seamlessly.

Frame Structure: The robust framework supports all other components and is designed for durability under heavy loads. Its construction materials ensure longevity and stability.

Control Mechanism: The intuitive interface allows users to operate the machine effectively. It encompasses levers and buttons that facilitate easy maneuvering and adjustments.

Attachment Points: These are designed for quick and efficient connections to various tools. They enhance versatility and functionality, allowing for a range of applications.

Power Source: The engine or motor is the heart of the equipment, providing the necessary energy for all operations. Its performance directly influences the productivity of the entire unit.

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the extended lifespan and optimal performance of machinery and equipment. Neglecting maintenance can lead to increased wear and tear, resulting in costly repairs and reduced efficiency. By prioritizing systematic care, users can enhance reliability and prevent unexpected breakdowns, ultimately safeguarding their investment.

Preventive Measures

Implementing preventive strategies is essential for maintaining functionality. Routine inspections and timely replacements of worn components can significantly mitigate risks. This proactive approach not only enhances safety but also contributes to smoother operation over time, allowing machinery to perform at its best.

Cost-Effectiveness

Investing in regular maintenance may initially seem like an added expense, but it proves to be cost-effective in the long run. By minimizing the likelihood of major failures, users can avoid hefty repair bills and extend the overall service life of their equipment. This financial prudence ensures that resources are allocated efficiently, maximizing productivity and performance.

Common Issues and Solutions

In the realm of machinery, users often encounter various challenges that can impede performance. Understanding these prevalent concerns and their remedies can greatly enhance operational efficiency and longevity.

Performance Degradation

A frequent issue is a noticeable decline in efficiency. This can stem from factors such as worn components or inadequate lubrication. Regular maintenance checks and timely replacements are crucial in mitigating these problems. Ensure that all moving parts are well-lubricated and inspect for wear to maintain optimal functionality.

Unexpected Failures

Sudden breakdowns can disrupt operations significantly. Such failures may arise from electrical malfunctions or hydraulic leaks. Conducting routine inspections can help identify potential issues before they escalate. Implementing a structured maintenance schedule will ultimately reduce the risk of unexpected downtime.

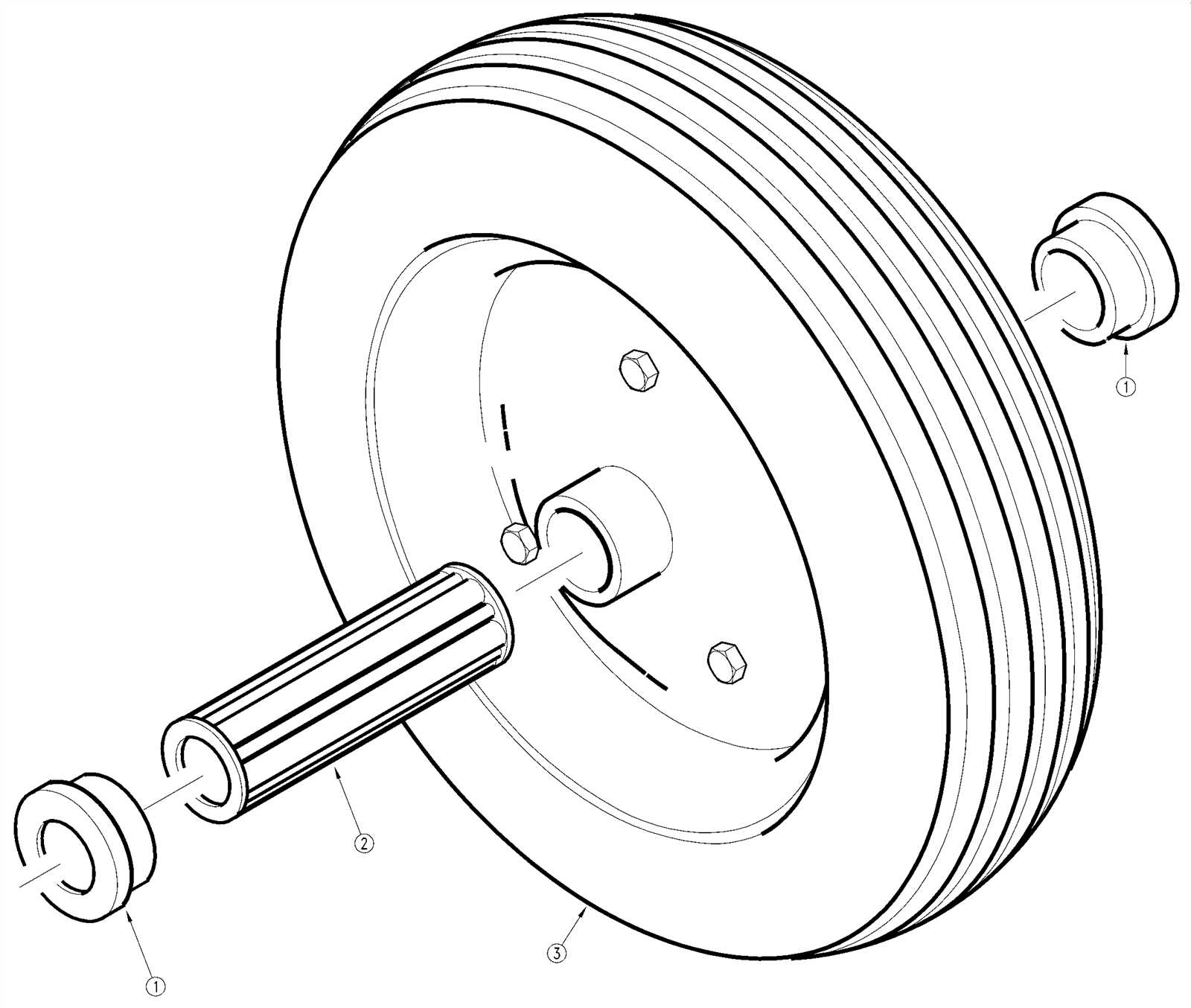

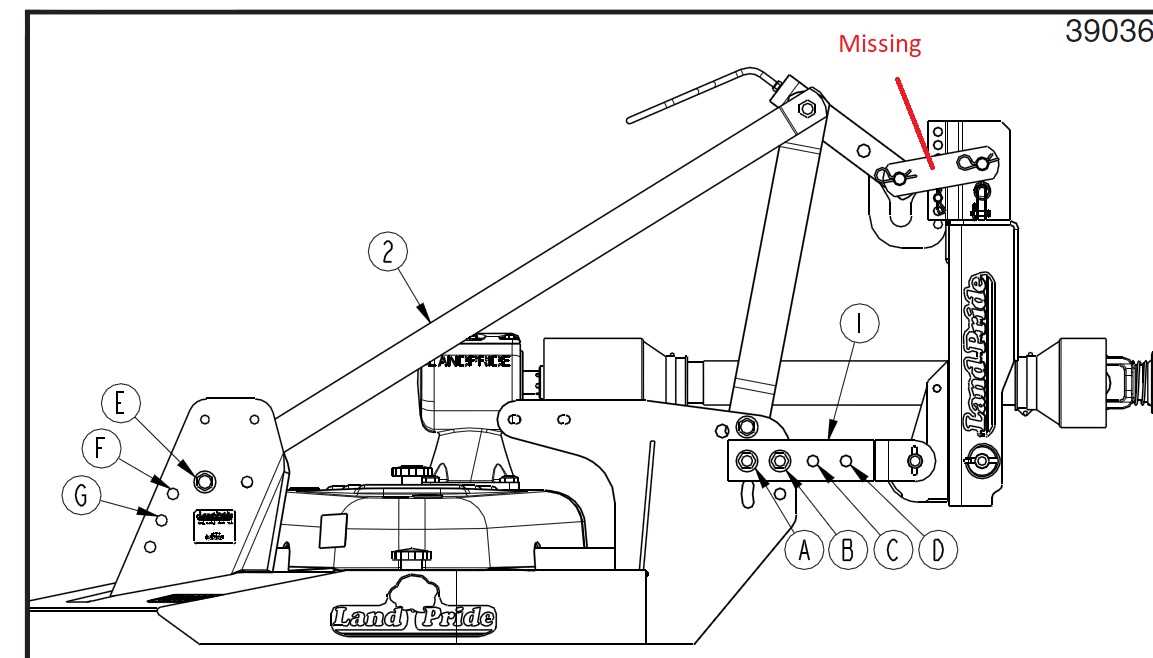

How to Identify Parts on Diagram

Understanding a schematic representation of machinery can be challenging yet rewarding. A well-constructed visual guide helps users navigate through various components, enabling better maintenance and repairs. This section provides insights on how to effectively discern elements within such illustrations.

Familiarizing Yourself with Symbols

Different illustrations use specific symbols to represent various components. Familiarizing yourself with these symbols is crucial for quick identification. Often, manufacturers provide a legend or key alongside the visual representation that outlines what each symbol stands for. Take the time to study this key as it serves as your roadmap to understanding the entire system.

Recognizing Color Coding and Labels

In many cases, color coding and labels provide additional information about components. Colors can signify different functions or materials, while labels may include part numbers or descriptions. Pay close attention to these details as they can greatly aid in accurately identifying specific elements. Additionally, noting the arrangement and proximity of components can offer clues about their interconnections and overall functionality.

Step-by-Step Assembly Instructions

Assembling complex machinery can be a rewarding endeavor when approached methodically. This guide provides a clear, structured pathway to ensure each component is correctly placed and functions seamlessly within the whole system.

- Preparation:

- Gather all necessary tools and components.

- Read through the entire guide before beginning the assembly.

- Base Assembly:

- Start by securing the base frame on a flat surface.

- Attach the support beams to the frame using the specified fasteners.

- Integrating Major Components:

- Position the primary unit onto the assembled base.

- Ensure all connection points align properly before securing.

- Connecting Secondary Parts:

- Install the secondary elements as indicated, checking for compatibility.

- Use the appropriate tools to tighten each connection without over-torquing.

- Final Adjustments:

- Inspect all connections for stability and security.

- Make any necessary adjustments to ensure optimal functionality.

- Testing:

- Conduct a thorough test of the assembled unit.

- Monitor for any irregularities and make adjustments as needed.

By following these detailed steps, you will ensure a successful assembly process that yields a reliable and efficient system.

Replacing Worn-Out Components Effectively

Maintaining the efficiency and longevity of machinery often hinges on timely replacements of deteriorated elements. When components wear down, they can compromise overall performance, leading to increased downtime and repair costs. Therefore, understanding the process of replacing these essential parts is crucial for anyone looking to keep their equipment in optimal condition.

Identifying Components in Need of Replacement

Regular inspections play a vital role in identifying which components require attention. Look for signs of wear, such as unusual noises, decreased performance, or visible damage. Keeping a detailed log of maintenance checks can help you track the condition of various elements over time, allowing for proactive replacements before issues escalate.

Steps for Effective Replacement

Once you’ve identified the components that need to be replaced, follow a systematic approach. Begin by gathering the necessary tools and replacement items. Ensure you have access to the correct specifications to avoid compatibility issues. After removing the old components, carefully install the new ones, adhering to manufacturer guidelines. Finally, conduct a thorough test to verify that everything is functioning correctly. This meticulous approach not only enhances performance but also prolongs the lifespan of your machinery.

Comparing FDR1660 to Other Models

This section explores the distinctions and similarities between various models in the same category. By analyzing key features and performance metrics, we can better understand how one specific model stands out or aligns with its peers.

Performance Metrics

When evaluating different designs, performance metrics such as efficiency, durability, and ease of use are critical. The subject model often demonstrates superior efficiency in specific applications, providing a competitive edge. Understanding these metrics helps users make informed decisions based on their unique requirements.

Design and Features

Design elements play a significant role in user experience. While some alternatives offer a more compact structure, the highlighted model is noted for its robust build quality and user-friendly features. This combination often results in enhanced reliability, appealing to both casual users and professionals alike.

Utilizing the Parts Diagram Efficiently

Understanding the components of a machine can greatly enhance maintenance and repair processes. By effectively using a visual representation, users can identify essential elements and ensure proper functioning.

- Familiarization: Begin by getting to know the layout and labels used in the visual guide.

- Identification: Locate the specific sections that pertain to the issue at hand.

- Cross-reference: Use the visual aid alongside the manual for clearer instructions.

- Organize: Group similar elements for easier access during repairs.

By following these steps, individuals can delve deeper into the intricacies of their equipment and achieve the ultimate efficiency in their maintenance tasks.

Recommended Tools for Repairs

When it comes to maintaining and fixing equipment, having the right tools at your disposal is essential for efficiency and effectiveness. Whether you are a professional technician or a DIY enthusiast, the appropriate instruments can significantly streamline the repair process, ensuring tasks are completed safely and accurately.

Essential Tools List

| Tool | Purpose |

|---|---|

| Socket Wrench Set | For loosening and tightening bolts and nuts |

| Screwdriver Set | To drive screws in various sizes and types |

| Pliers | For gripping, bending, and cutting wires |

| Torque Wrench | To apply a specific torque to fasteners |

| Multimeter | For measuring electrical properties |

Specialized Instruments

In addition to basic tools, certain specialized instruments may be required for more complex repairs. Investing in these can enhance your ability to tackle a variety of challenges effectively.

| Specialized Tool | Function |

|---|---|

| Wrench Set | For working in tight spaces and with different types of fasteners |

| Diagnostic Scanner | To analyze system errors and performance issues |

| Heat Gun | For softening materials and removing adhesives |

| Safety Goggles | To protect eyes during repair tasks |

| Work Gloves | For hand protection while handling tools and materials |

Expert Tips for Optimal Performance

Achieving peak efficiency in machinery requires a blend of maintenance practices, timely interventions, and awareness of operational techniques. By implementing strategic measures, you can ensure longevity and reliability, ultimately maximizing productivity.

Regular Maintenance Checks

Consistent inspections are vital. Schedule routine evaluations to identify wear and tear early, and replace components as needed to prevent costly breakdowns.

Proper Operation Techniques

Adhere to recommended operating procedures. Understanding the machinery’s capabilities and limits will enhance performance and minimize the risk of damage.

FAQs About FDR1660 Parts

This section addresses common inquiries regarding components associated with the FDR1660 model. Understanding these elements can enhance user experience and ensure proper maintenance and functionality.

What are the most frequently replaced components?

Typically, items like belts, filters, and bearings are often substituted due to wear and tear. Regular inspection can help identify when these should be exchanged.

Where can I find high-quality replacements?

Reliable suppliers and authorized dealerships are ideal sources for obtaining superior substitutes. It’s essential to verify authenticity to ensure optimal performance.

Resources for Further Learning

Expanding your knowledge on machinery components and their functionalities is crucial for effective maintenance and operation. A variety of resources can help deepen your understanding, ranging from online platforms to printed materials. Here, you will find a selection of valuable references that cater to different learning preferences.

Online Resources

- YouTube – Explore instructional videos that provide visual demonstrations and expert insights.

- Reddit Mechanics Community – Join discussions and ask questions in a vibrant community of enthusiasts and professionals.

- WikiHow – Access step-by-step guides on various repair and maintenance tasks.

Books and Manuals

- Maintenance Manuals: Look for manufacturer-specific guides that detail operations and care.

- Technical Texts: Invest in books covering general machinery principles and advanced concepts.

- Magazines: Subscribe to industry publications that cover the latest trends and innovations.

Utilizing these resources can greatly enhance your expertise and proficiency, allowing for better handling of equipment and improved problem-solving capabilities.