Understanding the Ferris Lawn Mower Parts Diagram

Maintaining and optimizing outdoor machinery requires a solid understanding of its individual components. Each part plays a crucial role in the overall functionality, and recognizing how they interact can significantly enhance performance. A comprehensive overview of these elements allows users to troubleshoot issues effectively and conduct timely repairs.

In this section, we will delve into the intricacies of various assemblies found in your machinery. By familiarizing yourself with these elements, you empower yourself to not only identify potential problems but also to undertake maintenance tasks with confidence. This knowledge ultimately leads to better longevity and efficiency of your equipment.

Whether you’re a seasoned professional or a passionate hobbyist, knowing the layout and function of each piece is essential. From the simplest components to the more complex assemblies, understanding their roles will aid in maximizing the potential of your machinery and ensuring a smooth operation throughout its lifespan.

Understanding Ferris Lawn Mower Components

Grasping the elements of a cutting machine is essential for effective maintenance and optimal performance. Each component plays a vital role in ensuring that the equipment operates smoothly and efficiently. Recognizing these parts can aid in troubleshooting issues and performing necessary repairs.

Here are the key components that contribute to the functionality of these machines:

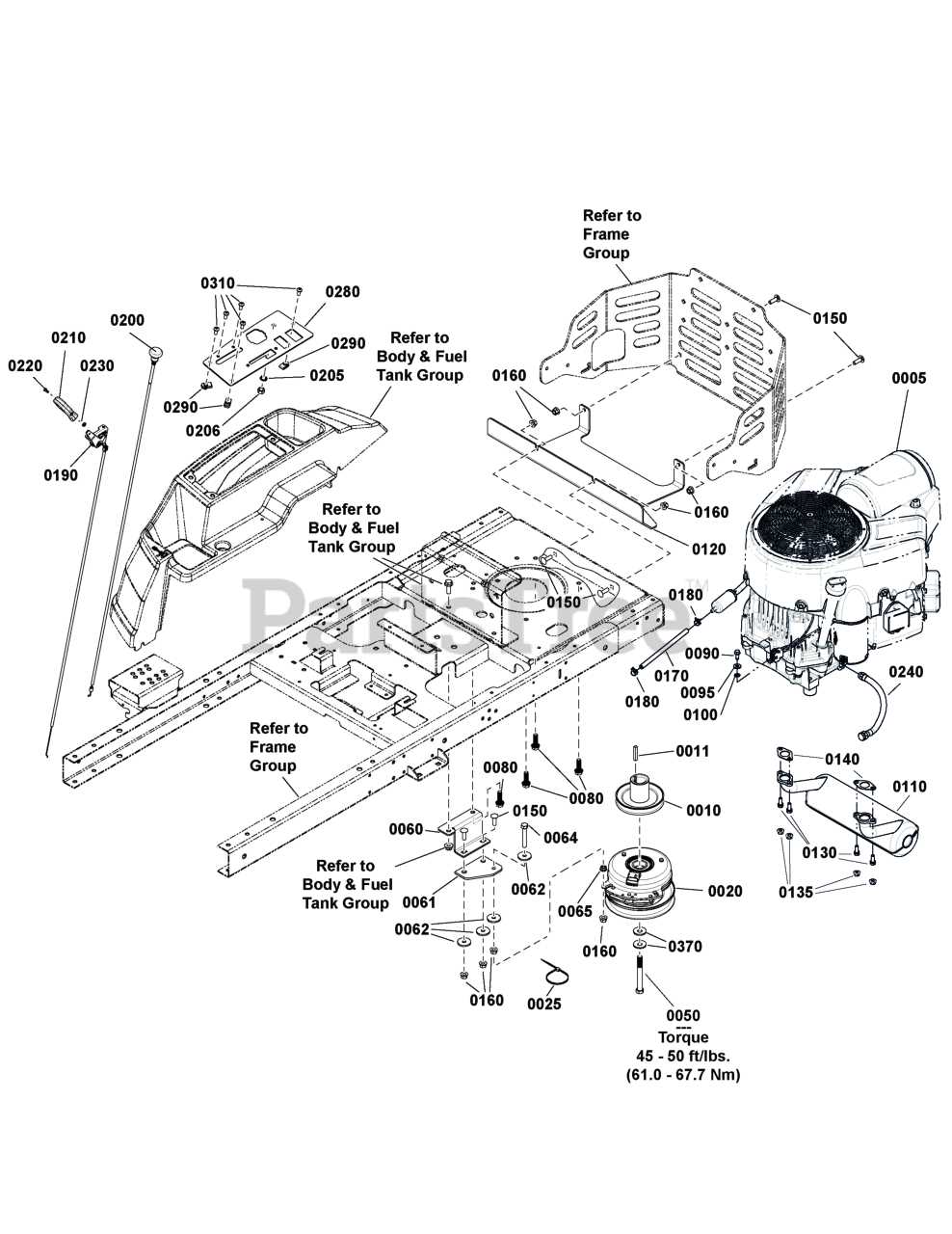

- Engine: The powerhouse that drives the entire system, providing the necessary energy for operation.

- Deck: The housing that contains the cutting blades, designed for efficient grass trimming and collection.

- Blades: Sharp tools that perform the cutting action, crucial for achieving a clean and precise finish.

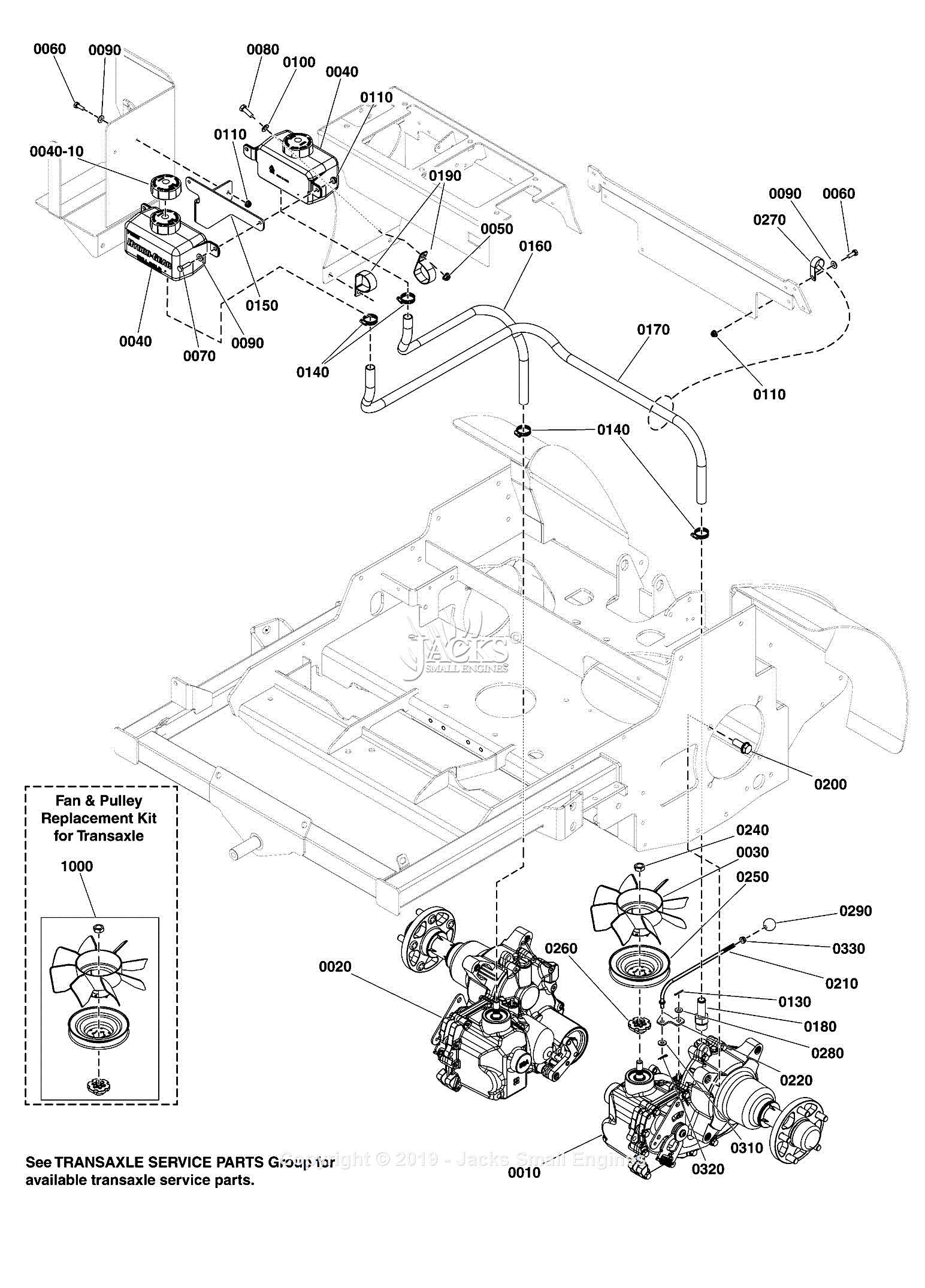

- Transmission: The mechanism that transfers power from the engine to the wheels, enabling movement.

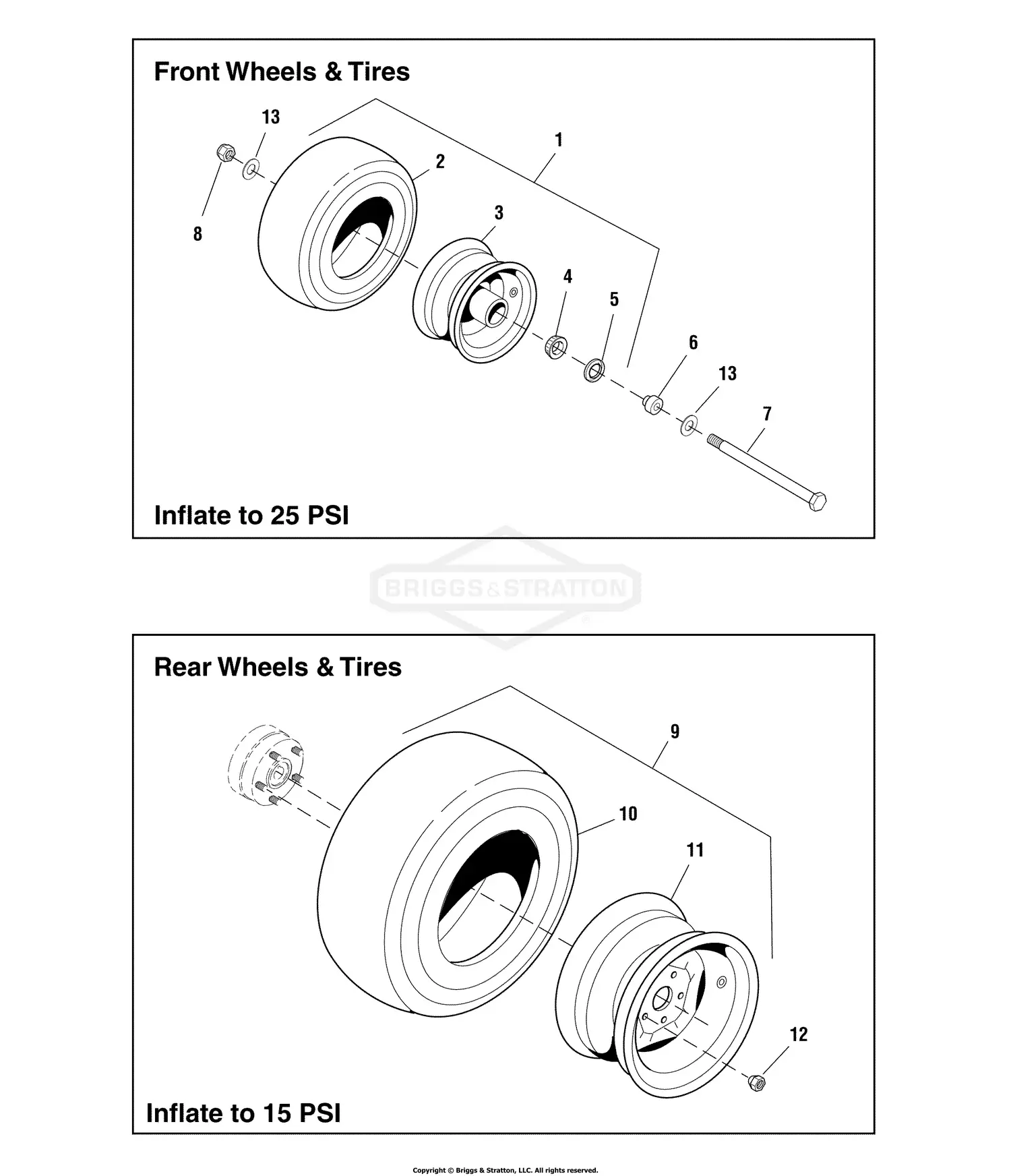

- Wheels: Essential for mobility, these components determine the stability and ease of maneuvering.

Understanding how these parts interact will enhance your ability to maintain the equipment effectively. Regular inspection and awareness of each component’s role can prevent malfunctions and extend the lifespan of your machinery.

Importance of Maintenance for Lawn Mowers

Regular upkeep is essential for ensuring the longevity and efficiency of outdoor equipment. Proper care not only enhances performance but also minimizes the risk of unexpected breakdowns, ultimately saving time and money in the long run. Neglecting routine maintenance can lead to diminished functionality and costly repairs.

One of the primary benefits of consistent service is the improvement in operational efficiency. When machinery is well-maintained, it operates at optimal levels, delivering superior results. This is especially important for tasks that require precision and reliability, making upkeep a critical aspect of ownership.

Additionally, routine inspections and maintenance help identify potential issues before they escalate into major problems. This proactive approach ensures that any necessary repairs can be addressed promptly, preventing disruption in usage. Regular checks on components, such as blades and engines, are vital to maintaining the equipment’s performance.

Lastly, keeping machinery in top condition contributes to safety. Well-maintained equipment is less likely to malfunction during use, reducing the risk of accidents. Ensuring that all parts are functioning correctly not only protects the user but also promotes a safer working environment overall.

Common Issues with Ferris Lawn Mowers

Understanding the typical challenges that can arise with outdoor maintenance equipment is essential for ensuring optimal performance. Whether it’s mechanical failures or operational inefficiencies, recognizing these problems early can lead to effective solutions and prolonged longevity of the machinery.

Frequent Mechanical Problems

Many users encounter various mechanical issues that can hinder functionality. Common concerns include:

- Engine difficulties: Starting problems or stalling can be signs of fuel delivery issues or ignition system failures.

- Blade malfunctions: Dull or damaged blades can affect cutting performance and require regular inspection.

- Transmission troubles: Irregular movement or loss of power might indicate transmission wear or fluid deficiencies.

Operational Challenges

In addition to mechanical issues, operators may face several challenges during usage:

- Uneven cutting: This can result from improperly adjusted cutting heights or worn-out blades.

- Clumping grass: Accumulation of grass clippings can signal clogged discharge areas, impacting efficiency.

- Vibration: Excessive shaking may point to loose components or imbalanced cutting attachments.

Addressing these common issues promptly can enhance the performance and durability of your equipment.

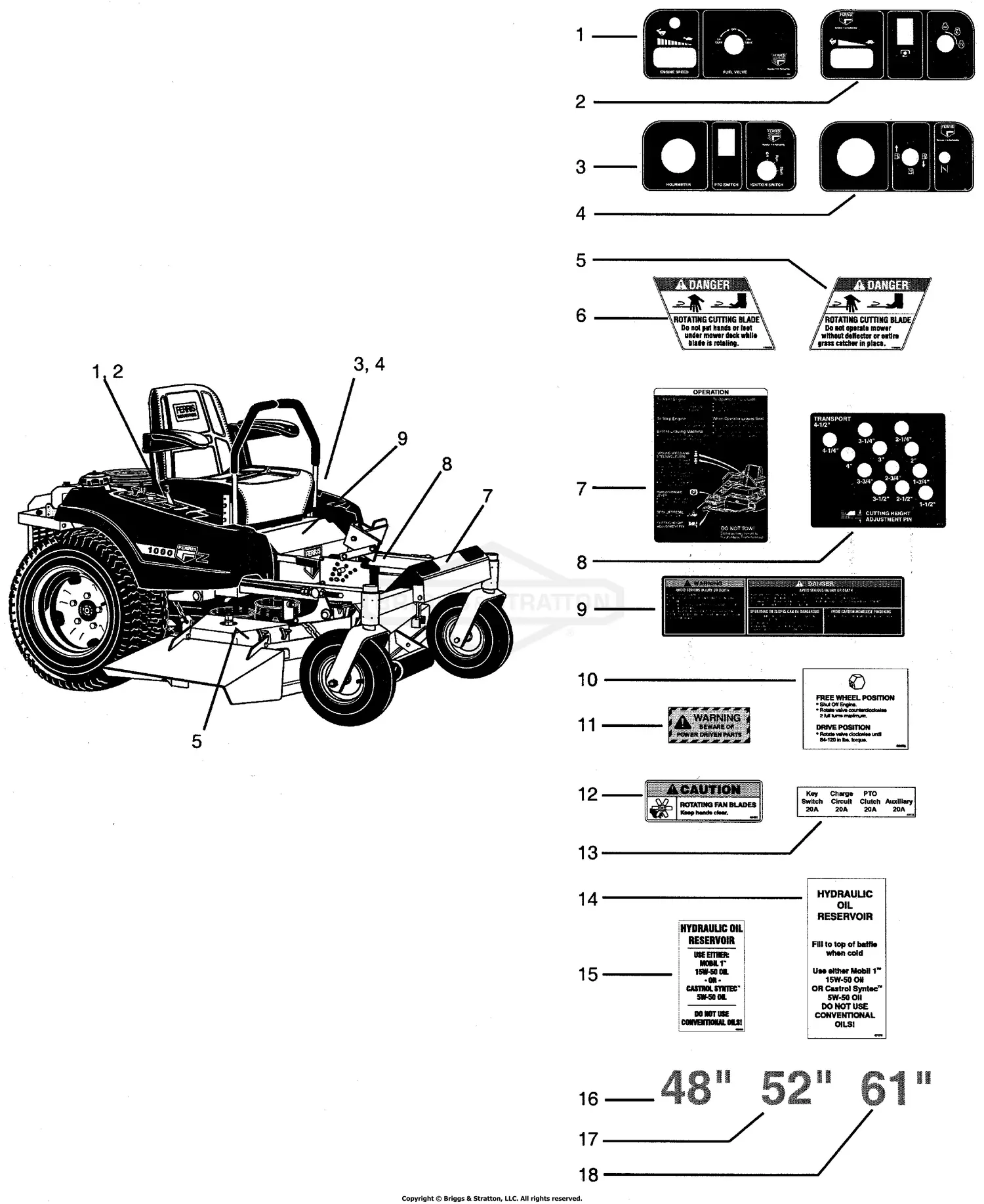

How to Read Parts Diagrams Effectively

Understanding schematic illustrations is essential for anyone involved in equipment maintenance. These visuals serve as a roadmap, guiding users through the intricate relationships and functions of various components. Mastering the art of interpreting these representations can significantly enhance repair efficiency and accuracy.

Key Elements to Identify

- Labels: Familiarize yourself with the terminology used in the illustration. Knowing the names of the components helps in locating and identifying them.

- Numbers: Pay attention to numerical references, as they often correspond to parts lists or catalogs, providing further detail.

- Connections: Observe how elements are linked. Understanding these connections is vital for effective assembly and disassembly.

Steps for Effective Interpretation

- Review the Overview: Start by scanning the entire visual for a general understanding before diving into specifics.

- Match with the List: Use accompanying documentation to correlate numbers and labels, ensuring you know what each item represents.

- Take Notes: Jot down any observations or unclear elements. This will help when seeking additional information or support.

- Consult Resources: Don’t hesitate to refer to manuals or online forums for clarification on complex components.

Key Parts of Ferris Mowers Explained

Understanding the essential components of your equipment is crucial for optimal performance and longevity. Each element plays a significant role in ensuring smooth operation and efficiency, contributing to the overall effectiveness of the machinery.

Here are some of the primary components that deserve attention:

- Engine: The powerhouse that drives the entire system, influencing speed and capability.

- Deck: The housing that contains the cutting mechanism, impacting the quality of the finish.

- Transmission: This element controls power distribution, essential for maneuverability and responsiveness.

- Wheels: Vital for mobility, these components determine traction and stability across various terrains.

- Controls: The interface that allows the operator to manage speed and direction, crucial for ease of use.

Maintaining each of these components is vital for ensuring that your equipment runs smoothly and efficiently. Regular inspections and timely replacements can prevent issues and extend the lifespan of your machinery.

Where to Find Official Diagrams

When seeking detailed illustrations for machinery components, it’s essential to know the right sources. Accurate and official guides are crucial for effective repairs and maintenance. Here, we outline the most reliable places to locate these valuable resources.

Manufacturer Websites

The primary source for accurate schematics is the official website of the manufacturer. Most brands provide comprehensive resources for their products, including downloadable guides and online support. Navigate to the support or resources section of the site to find specific documents.

Authorized Dealers and Service Centers

Visiting authorized dealers can be another excellent way to obtain genuine diagrams. Many dealerships offer printed manuals and can provide assistance with any inquiries regarding the components of the equipment.

| Source Type | Description | Benefits |

|---|---|---|

| Manufacturer Website | Official online platform for accessing manuals and diagrams. | Up-to-date information, direct from the source. |

| Authorized Dealers | Physical locations that sell and service equipment. | Personal assistance and access to printed materials. |

| Online Forums | Community-driven platforms where users share information. | Real-world insights and tips from fellow users. |

Ordering Replacement Parts Made Easy

Maintaining your equipment can often seem like a daunting task, especially when it comes to sourcing necessary components. However, streamlining the process of acquiring replacements is simpler than you might think. With the right approach, you can efficiently obtain the items you need to keep your machinery running smoothly.

Start with Identification: The first step is accurately identifying the specific components required for your machine. Utilize available resources such as manuals or online databases to ensure you know the exact specifications of what you need. This will prevent any confusion during the ordering process.

Utilize Trusted Retailers: Choose reputable suppliers who specialize in these components. Online platforms often provide user-friendly interfaces, enabling you to search for items by model or category. Make sure to read reviews and check for reliability before making a purchase.

Check for Compatibility: Always verify that the replacements you are considering are compatible with your equipment. Many retailers offer compatibility filters on their websites, making it easier to find suitable options that match your model.

Review Return Policies: Before completing your order, take a moment to read the return policies. Understanding the terms of returns and exchanges can save you time and hassle in case the items do not meet your expectations.

Keep Track of Your Orders: Once you’ve placed your order, keep a record of your purchases. This will help you track shipments and manage future needs more effectively. Additionally, maintaining a list of components can simplify future maintenance tasks.

By following these steps, you can make the process of obtaining replacements not only easier but also more efficient, ensuring your machinery stays in top condition.

Tools Needed for Basic Repairs

Performing basic maintenance and repairs on equipment requires a selection of essential tools to ensure efficiency and effectiveness. Having the right instruments at hand can make the process smoother and more enjoyable, allowing for a better understanding of the machinery involved.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for loosening and tightening various screws.

- Wrenches: Adjustable wrenches and socket sets are necessary for tackling nuts and bolts of different sizes.

- Pliers: Needle-nose and standard pliers can assist in gripping, twisting, and cutting wires or components.

- Safety Gear: Protective eyewear and gloves should always be worn to prevent injuries during repairs.

Additionally, having the following tools can enhance your repair experience:

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

- Multimeter: Useful for diagnosing electrical issues within the machinery.

- Jack or Stands: Provides stability and height when working underneath or around heavy components.

- Cleaning Tools: Brushes, cloths, and solvents help maintain cleanliness during repairs.

Equipping yourself with these tools will not only simplify the repair process but also extend the lifespan of your equipment through proper maintenance.

Identifying Worn Parts on Your Mower

Maintaining the efficiency of your equipment requires vigilance in recognizing components that may be showing signs of deterioration. Addressing wear and tear promptly can prevent more significant issues and ensure optimal performance during operation.

Common Signs of Wear

One of the most noticeable indicators of aging components is irregular performance. If your machine struggles to operate smoothly or produces unusual sounds, it may be time to inspect specific elements closely. Cracks, discoloration, and fraying are also critical signs that parts are no longer functioning as intended. Regular checks can help in spotting these issues before they escalate.

Inspecting Key Components

Focus on crucial areas such as the cutting mechanism and drive systems. Sharpness is vital; dull blades not only hinder efficiency but can also lead to other damages. Additionally, check belts and cables for fraying or looseness. By being proactive and regularly assessing these key areas, you can extend the lifespan of your equipment significantly.

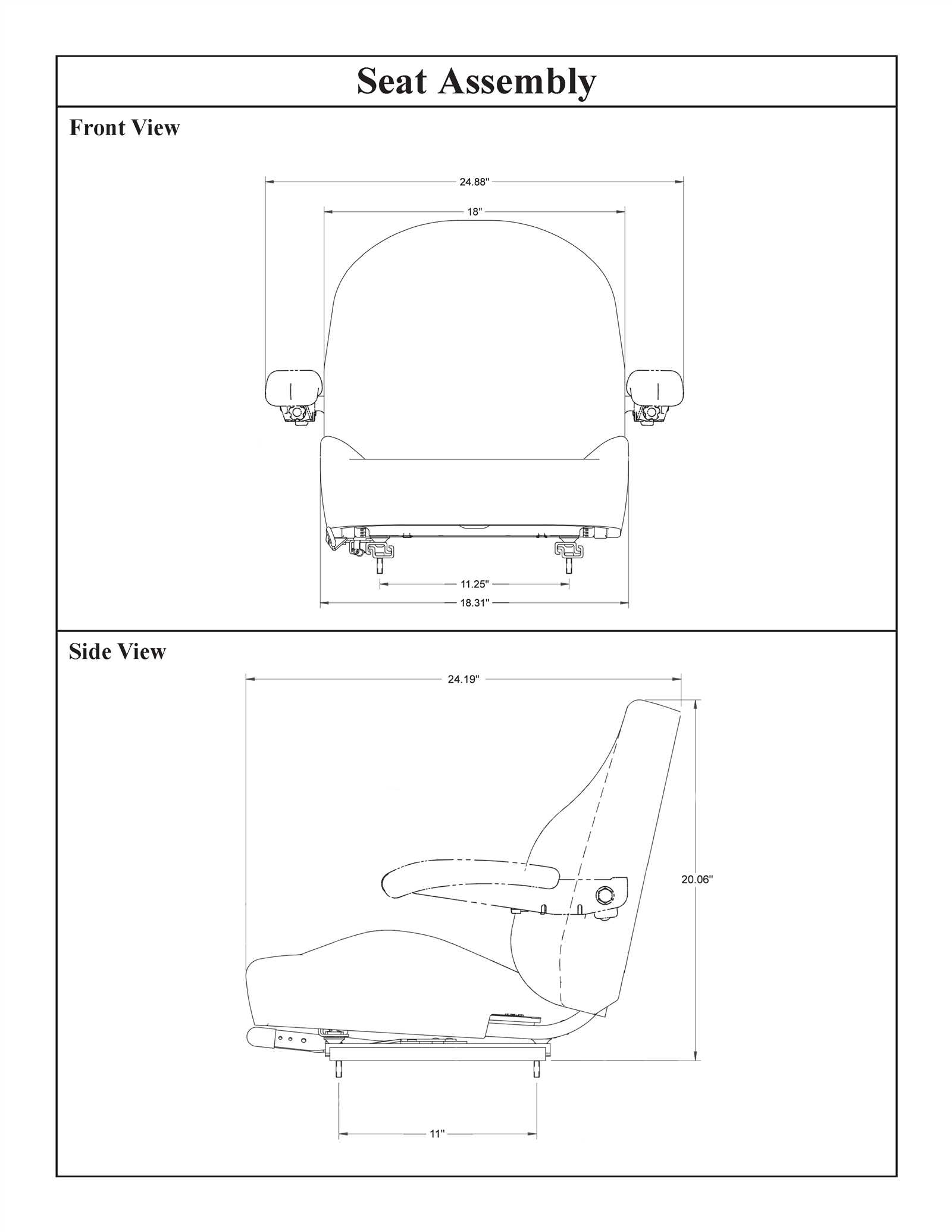

Comparing Ferris Models and Their Components

This section explores the various models available in the marketplace, highlighting their distinctive features and functionalities. By examining the differences and similarities among these designs, users can make informed choices based on their specific needs and preferences.

Model Features and Capabilities

Different variants come equipped with unique attributes that cater to various tasks. Some units prioritize speed and efficiency, while others focus on maneuverability and precision. Understanding these functionalities allows users to select equipment that aligns with their operational requirements.

Essential Components and Maintenance

Each design comprises critical elements that contribute to overall performance. Engine type, deck design, and transmission systems are among the main components that vary across models. Regular upkeep of these parts ensures longevity and optimal functionality. Familiarizing oneself with the specifics of each unit helps in maintaining efficiency and preventing breakdowns.

DIY vs. Professional Repairs: Pros and Cons

When it comes to maintenance and repair tasks, individuals often face a decision: should they tackle the job themselves or hire a professional? Each approach has its unique advantages and disadvantages, influencing both time investment and overall cost. Understanding these factors can help in making an informed choice that aligns with one’s skills and budget.

DIY Repairs: One of the main benefits of handling repairs personally is the potential for significant savings. By avoiding labor costs, you can allocate your budget toward quality materials. Moreover, the satisfaction of completing a task on your own can be incredibly rewarding. However, this approach requires a certain level of expertise and tools. Mistakes made during the process can lead to further damage, ultimately resulting in higher expenses and more time spent fixing the initial error.

Professional Repairs: Opting for a specialist often guarantees a level of expertise and efficiency that can be hard to match. Professionals usually possess the right tools and knowledge, which can lead to quicker and more effective repairs. This can provide peace of mind, especially for complex issues. On the downside, hiring a technician can be expensive, and it may require waiting for an appointment, which could delay the restoration process.

Ultimately, the decision between DIY and professional assistance depends on your comfort level with the task, the complexity of the issue, and your budget. Weighing the pros and cons of each approach is crucial in determining the best path forward.

Tips for Prolonging Lawn Mower Lifespan

Ensuring the longevity of your grass cutting equipment requires a combination of proper care, regular maintenance, and mindful usage. Implementing the right practices can significantly enhance performance and durability over time.

Regular Maintenance Practices

- Change the oil regularly to keep the engine running smoothly.

- Sharpen the blades consistently for cleaner cuts and reduced strain on the motor.

- Clean the underside to prevent grass build-up that can lead to rust and corrosion.

- Check and replace air filters to ensure optimal airflow.

- Inspect and tighten loose bolts and screws to avoid operational issues.

Seasonal Preparations

- Before winter storage, drain fuel to prevent degradation and engine problems.

- Consider covering the equipment to protect it from dust and moisture.

- In spring, perform a thorough inspection to address any issues before the cutting season begins.

By adopting these practices, you can enhance the functionality and lifespan of your equipment, ensuring it serves you well for years to come.

Community Resources for Mower Owners

For enthusiasts and caretakers of outdoor equipment, finding reliable resources can greatly enhance maintenance and repair experiences. Community-driven initiatives offer a wealth of information, support, and camaraderie, making the journey of ownership more enjoyable and less daunting.

Online Forums and Groups

Numerous online platforms allow individuals to connect with fellow enthusiasts. These forums provide a space for sharing experiences, troubleshooting issues, and exchanging tips. Engaging in these communities can lead to discovering valuable insights and best practices that enhance the overall experience of equipment management.

Local Workshops and Classes

Many communities host workshops aimed at teaching basic maintenance skills. Participating in these sessions not only equips owners with practical knowledge but also fosters relationships with local experts and other enthusiasts. Learning together can make the process of upkeep much more approachable and enjoyable.