Comprehensive Guide to Husqvarna Lawn Mower Parts Diagram

When it comes to maintaining a pristine outdoor space, familiarity with the essential elements of your machinery is crucial. Knowing how different sections work together not only enhances performance but also simplifies troubleshooting and repairs. A visual representation of these components can serve as a valuable guide for enthusiasts and professionals alike.

By exploring the intricate relationships between various sections, users can gain insights into their functionality and maintenance requirements. This knowledge empowers individuals to optimize their tools, ensuring they operate at peak efficiency throughout the seasons. Whether you’re preparing for the growing season or performing routine checks, understanding these key elements will greatly enhance your gardening experience.

Furthermore, a comprehensive overview of each component allows for better planning when it comes to replacements or upgrades. This not only saves time and money but also fosters a deeper appreciation for the technology that supports our green endeavors. Thus, diving into the specifics of these vital tools becomes an enlightening journey for any gardening aficionado.

Understanding Husqvarna Mower Components

Familiarizing oneself with the various elements of outdoor equipment is essential for efficient operation and maintenance. Each component plays a vital role in the overall functionality, influencing performance and longevity. By understanding these essential parts, users can make informed decisions regarding upkeep and troubleshooting.

Key Elements of Outdoor Equipment

- Engine: The heart of the machine, responsible for providing the necessary power.

- Blade Assembly: Crucial for achieving a clean cut, consisting of sharp edges designed for optimal performance.

- Chassis: The frame that houses various components, ensuring stability and durability.

- Transmission: Facilitates the movement, allowing for adjustments in speed and direction.

- Fuel System: Essential for delivering energy to the engine, influencing efficiency and reliability.

Maintenance Tips

- Regularly inspect the engine for any signs of wear or damage.

- Keep the blade assembly sharp to ensure effective cutting.

- Check the chassis for rust or corrosion to prolong lifespan.

- Monitor the transmission fluid levels to maintain smooth operation.

- Ensure the fuel system is clean and free from debris for optimal performance.

Essential Parts of Husqvarna Lawn Mowers

Understanding the key components of a grass-cutting machine is crucial for maintaining its efficiency and performance. Each element plays a significant role in ensuring that the equipment operates smoothly and effectively. Familiarity with these vital elements can aid in troubleshooting and regular upkeep.

- Engine: The heart of the machine, providing the necessary power for operation.

- Blades: Sharp and durable, these are responsible for cutting the grass to the desired length.

- Deck: The housing that holds the blades and protects other components from debris.

- Wheels: Essential for mobility, allowing easy navigation across various terrains.

- Fuel System: Includes the tank and lines, ensuring a steady supply of energy to the engine.

Proper knowledge of these fundamental components not only enhances user experience but also prolongs the lifespan of the equipment.

- Regular inspections and cleaning.

- Timely replacement of worn or damaged elements.

- Ensuring proper lubrication of moving parts.

By prioritizing these practices, users can enjoy a reliable and efficient machine throughout its service life.

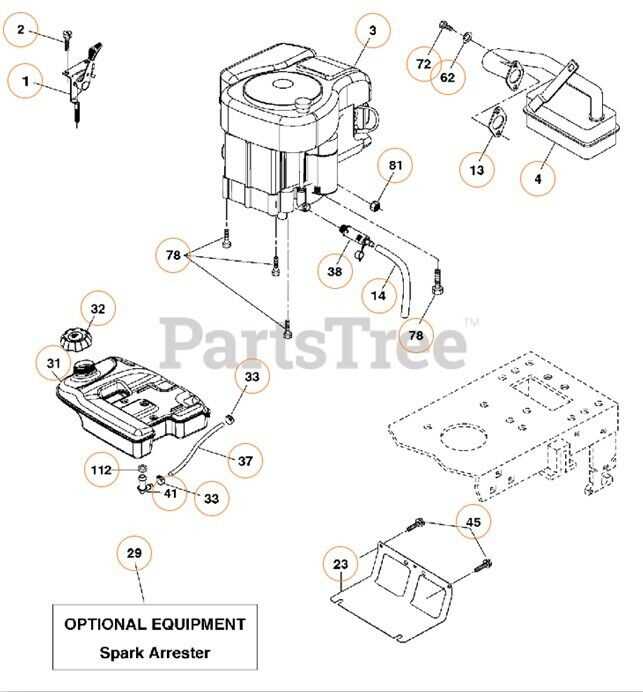

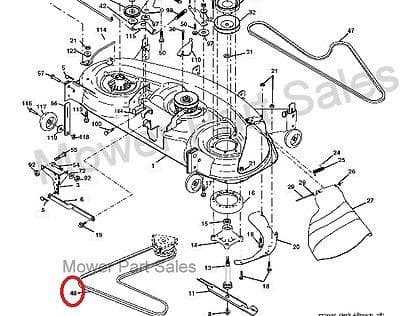

How to Read Mower Diagrams

Understanding technical illustrations is essential for anyone looking to maintain or repair their outdoor equipment. These visual aids provide a detailed view of components and their interrelations, enabling users to identify parts and understand their functions. Grasping how to interpret these graphics can significantly simplify troubleshooting and replacement processes.

1. Familiarize Yourself with Symbols: Technical illustrations often utilize specific symbols to represent various elements. Take time to learn what each symbol signifies, as this will help you navigate the illustration more effectively.

2. Identify Key Components: Start by locating the primary sections of the illustration. Understanding the main parts will allow you to follow the flow of the entire mechanism and grasp how each element interacts with others.

3. Follow the Lines: Lines connecting different elements indicate relationships and pathways. By tracing these lines, you can determine how power flows or how components are assembled.

4. Refer to the Legend: Many illustrations come with a legend that explains symbols and numbering. Consult this guide frequently to ensure accurate interpretation of the visual information.

5. Cross-Reference with Manuals: Pair the illustration with your equipment’s manual for comprehensive understanding. The manual will provide context and additional details that enhance your grasp of the components’ roles.

By mastering the skill of reading these technical visuals, you will empower yourself to conduct repairs with confidence and efficiency.

Common Issues with Mower Parts

Understanding the frequent challenges that can arise with various components of garden equipment is essential for effective maintenance and operation. Identifying these issues early can save time and resources, ensuring optimal performance and longevity of the machinery.

Frequent Problems

Some of the most common troubles encountered include wear and tear, improper assembly, and insufficient lubrication. Each of these issues can lead to decreased efficiency and potential damage if not addressed promptly.

Symptoms and Solutions

| Issue | Symptoms | Possible Solutions |

|---|---|---|

| Worn Blades | Poor cutting performance, uneven grass height | Sharpen or replace blades |

| Loose Belts | Slipping noise, reduced power | Tighten or replace belts |

| Clogged Air Filter | Engine stalling, difficulty starting | Clean or replace air filter |

| Faulty Spark Plug | Engine misfiring, starting issues | Inspect and replace spark plug |

Finding Replacement Parts Easily

Locating suitable components for your outdoor equipment can be a straightforward task if you know where to look and what to consider. Understanding the specific requirements of your machine and utilizing available resources will save you time and ensure you find the right fit for maintenance or repairs.

Utilizing Online Resources

Numerous websites specialize in offering a wide range of components for various types of outdoor machinery. These platforms often provide comprehensive catalogs that include detailed descriptions, specifications, and compatibility information. By inputting your model number or other identifiers, you can quickly narrow down your search.

Consulting Manufacturer Documentation

Accessing the original documentation or user manuals for your equipment can provide invaluable insights. These resources typically include diagrams and lists of components, which can guide you in identifying what you need for replacement. This approach also helps ensure compatibility with your specific model.

| Resource Type | Description |

|---|---|

| Online Retailers | Specialized websites that offer various components for purchase. |

| User Manuals | Official documentation providing detailed information about parts and maintenance. |

| Forums and Communities | Online groups where enthusiasts share experiences and recommendations. |

| Local Dealers | Physical stores that may carry or can order specific components for you. |

Maintenance Tips for Lawn Mowers

Proper upkeep is essential for ensuring optimal performance and longevity of your gardening equipment. Regular maintenance not only enhances efficiency but also prevents costly repairs and prolongs the lifespan of the machine. Following a systematic routine will help you keep your tool in excellent condition, allowing it to tackle tasks with ease.

Regular Inspection

Consistent checks are vital for identifying any wear and tear before it leads to significant issues. Inspect the engine, blades, and belts for signs of damage. Make sure to clean the air filter and spark plug periodically to maintain smooth operation. Additionally, keep an eye on the fuel system to ensure there are no leaks or clogs that could hinder performance.

Seasonal Maintenance

Different seasons require specific care. Before the onset of the growing season, sharpen the cutting edges to ensure clean cuts and promote healthy growth. At the end of the season, drain fuel and clean the entire unit to prevent rust and deterioration during storage. Following these seasonal tips will ensure that your equipment is always ready for use when needed.

Using Diagrams for Troubleshooting

Visual representations play a crucial role in identifying issues within mechanical systems. They provide a clear overview of components and their relationships, making it easier to pinpoint potential malfunctions. When faced with a challenge, consulting these illustrations can streamline the diagnostic process.

Understanding Component Layouts

Diagrams typically display the arrangement of elements, allowing users to familiarize themselves with the overall configuration. This knowledge aids in recognizing which parts may be contributing to the problem, facilitating a more efficient troubleshooting approach.

Identifying Common Issues

By analyzing visual guides, one can quickly reference typical failure points. Recognizing these areas can save time and reduce frustration, as it narrows down the focus to specific components that are known to cause trouble.

Enhancing Repair Accuracy

Using detailed illustrations ensures that repairs are conducted with precision. Technicians can verify the correct placement and orientation of elements, minimizing the risk of errors during reassembly. This attention to detail ultimately leads to more reliable performance.

In summary, leveraging visual aids not only simplifies the troubleshooting process but also empowers users to approach repairs with greater confidence and clarity.

Where to Buy Genuine Parts

Finding authentic components for your equipment is crucial for maintaining performance and longevity. Quality items ensure that your machinery operates efficiently and safely. Whether you’re a professional or a DIY enthusiast, knowing where to source reliable replacements can save time and money.

One of the best places to purchase genuine components is through official retailers or authorized dealers. These sources guarantee that the items you acquire meet the manufacturer’s specifications. Additionally, many of these outlets provide customer support and guidance to help you identify the correct components for your needs.

Online platforms also offer a vast selection of genuine components. Websites dedicated to machinery and equipment often feature a comprehensive inventory, complete with detailed descriptions and compatibility information. Be sure to check for customer reviews and ratings to ensure that the site is reputable.

Local hardware stores may carry a range of authentic items as well. It’s advisable to call ahead or check their inventory online to confirm availability. Building relationships with local suppliers can also be beneficial, as they can provide insights and recommendations based on your specific requirements.

Lastly, consider joining forums or community groups related to your equipment. Enthusiasts often share resources and suggestions for purchasing genuine components, helping you find the best options available.

DIY Repairs: Step-by-Step Guide

Performing your own repairs can save time and money, allowing you to maintain your equipment efficiently. This guide will provide clear instructions to help you tackle common issues with your machinery. By following these steps, you can troubleshoot effectively and ensure your devices operate smoothly.

- Gather Necessary Tools and Materials

- Screwdrivers (flathead and Phillips)

- Wrenches and pliers

- Replacement components

- Safety gear (gloves, goggles)

- Identify the Problem

Carefully observe the equipment for any signs of malfunction. Common indicators include unusual noises, leaks, or failure to start.

- Refer to the Manual

Consult the user manual to understand the assembly and components. This will help you identify the specific parts that may need attention.

- Disassemble the Equipment

Using your tools, carefully take apart the necessary sections. Keep track of screws and small parts to avoid losing them.

- Inspect Components

Look for wear and tear, cracks, or any other damage on the components. Replace any faulty items as needed.

- Reassemble with Care

Once you have replaced or repaired the damaged parts, carefully put everything back together. Ensure that all screws and fasteners are secure.

- Test the Equipment

After reassembly, test your machine to ensure everything is functioning correctly. Monitor for any unusual behavior during operation.

By following this structured approach, you can effectively manage repairs and extend the lifespan of your equipment. Regular maintenance and timely fixes will contribute to optimal performance and reliability.

Safety Precautions During Maintenance

Proper upkeep of equipment is essential not only for performance but also for the safety of the operator. Adhering to safety measures can significantly reduce the risk of accidents and injuries while handling machinery. Understanding the necessary precautions before beginning maintenance tasks is crucial for a safe working environment.

Personal Protective Equipment

Before starting any maintenance activities, ensure you are equipped with appropriate personal protective equipment (PPE). This may include gloves to protect your hands, safety goggles to shield your eyes from debris, and sturdy footwear to prevent injuries from falling objects. Additionally, consider wearing ear protection if the machinery operates at high noise levels.

Proper Procedures

Always consult the manufacturer’s guidelines for specific maintenance protocols. Disconnecting the power source is essential before attempting any repairs or adjustments to avoid unintended activation. Maintain a tidy workspace to minimize tripping hazards, and use tools appropriately to prevent accidents. Following these procedures will help ensure a safe and efficient maintenance experience.

Upgrading Components for Better Performance

Enhancing the functionality of your gardening equipment can significantly improve its efficiency and lifespan. By investing in superior elements, you can achieve a more robust performance and ensure a smoother operation, whether for regular maintenance or more demanding tasks.

One of the primary upgrades to consider is the engine. A high-performance engine can provide increased power, leading to quicker cutting and reduced fuel consumption. Opting for a more efficient model may also minimize emissions, making your equipment more environmentally friendly.

Another crucial aspect is the cutting blade. Upgrading to a sharper, high-quality blade can enhance the quality of the cut, resulting in healthier grass. Moreover, using specialized blades designed for specific conditions can optimize performance across various terrains.

Don’t overlook the importance of the drive system. Investing in a more reliable transmission can improve maneuverability and control, allowing for smoother navigation around obstacles. This can make a significant difference in achieving a neat and tidy finish in your outdoor spaces.

Finally, maintaining and upgrading accessories such as filters and belts is essential. Regularly replacing these components can prevent breakdowns and ensure that your equipment operates at peak efficiency. This proactive approach not only extends the lifespan of your tools but also enhances their overall effectiveness.