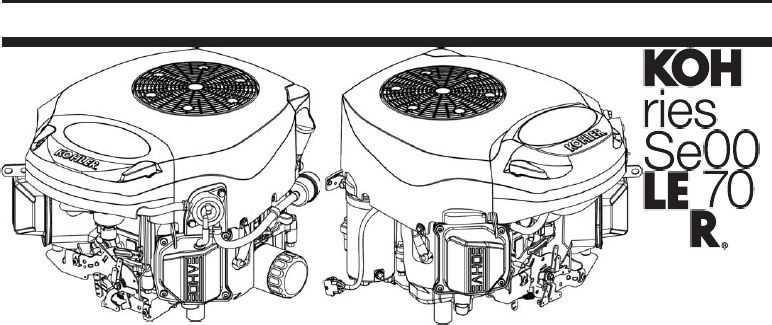

Kohler Lawn Mower Parts Diagram Explained

When maintaining and repairing outdoor machinery, having a clear representation of its internal elements can significantly enhance the process. A detailed illustration can serve as an essential tool for both novice and experienced users, providing insight into the various functions and interconnections of each component.

In this section, we will delve into the intricacies of a specific engine model, focusing on the layout and functionality of its essential pieces. By examining these elements, users can gain a comprehensive understanding of how to troubleshoot and efficiently manage their equipment.

Utilizing visual aids not only simplifies complex tasks but also contributes to the ultimate effectiveness of maintenance efforts. Whether you’re replacing a worn-out component or performing routine checks, familiarity with the engine’s architecture will undoubtedly streamline your workflow.

Kohler Lawn Mower Parts Overview

This section provides a comprehensive look at the essential components that contribute to the efficient operation of outdoor machinery. Understanding these elements is crucial for maintenance and repair, ensuring longevity and optimal performance.

| Component | Description |

|---|---|

| Engine | The power source that drives the entire system. |

| Blade | The cutting element that interacts with the grass. |

| Deck | The housing that encloses the cutting mechanism. |

| Wheels | Facilitate mobility across various terrains. |

| Fuel System | Supplies energy to the engine for operation. |

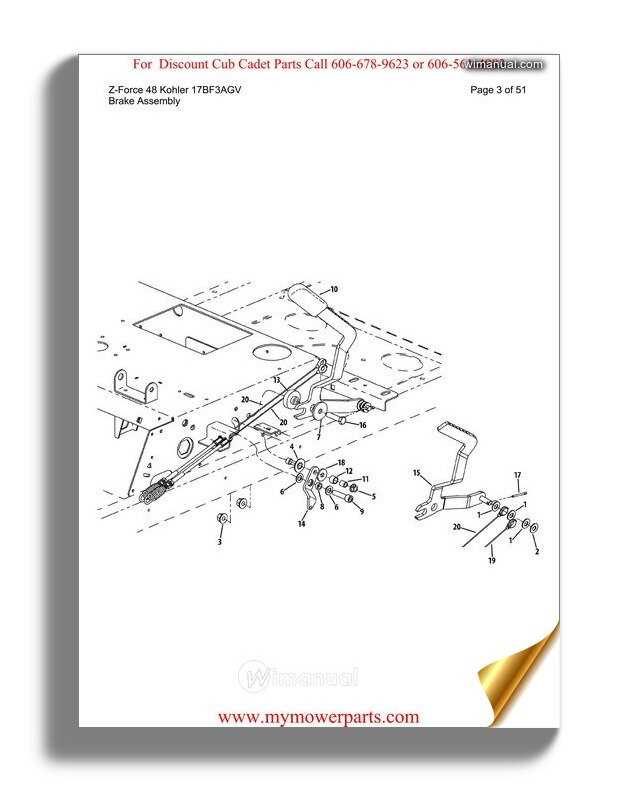

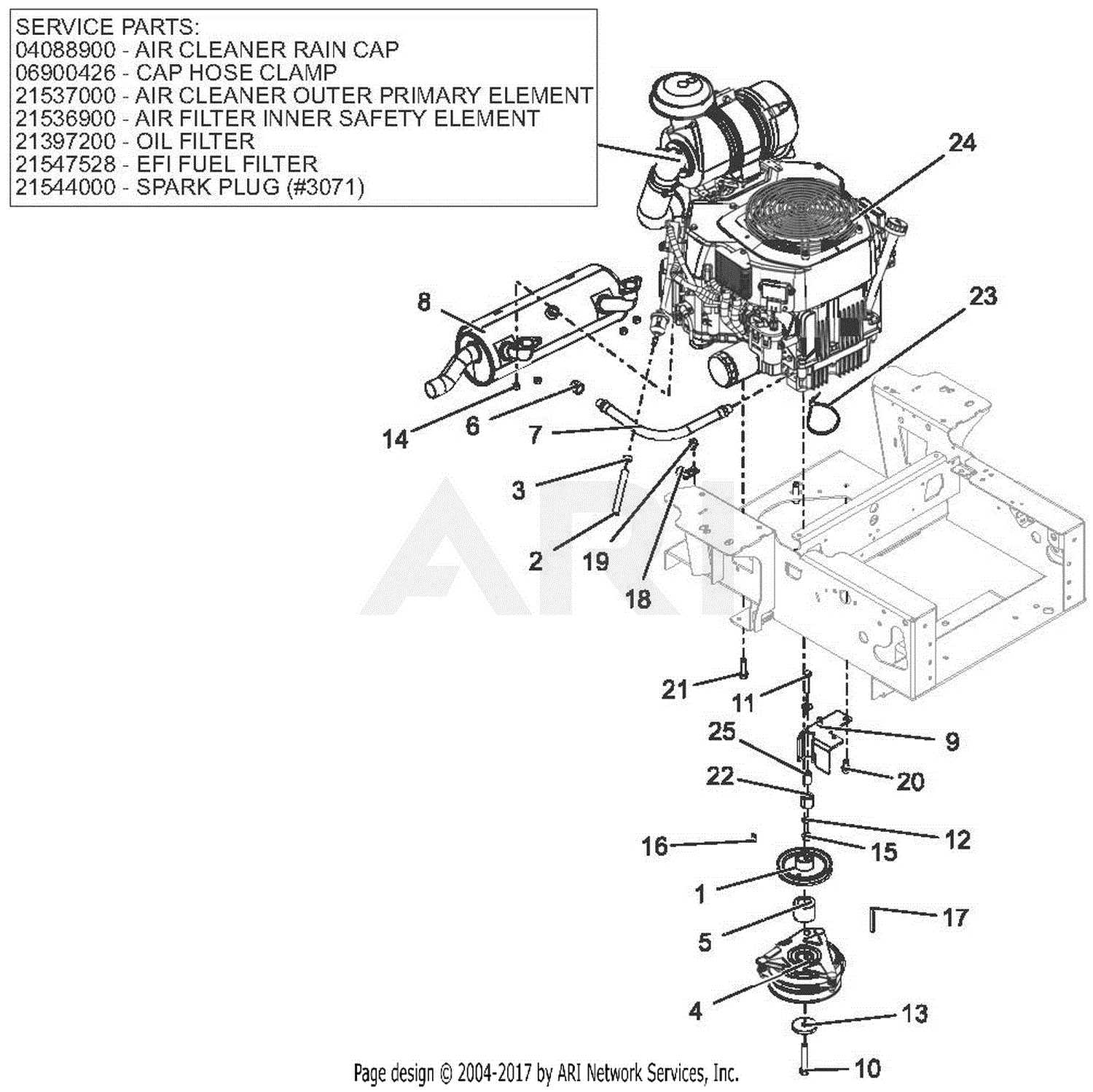

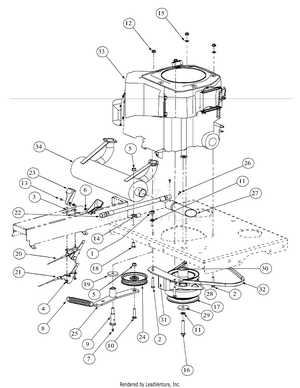

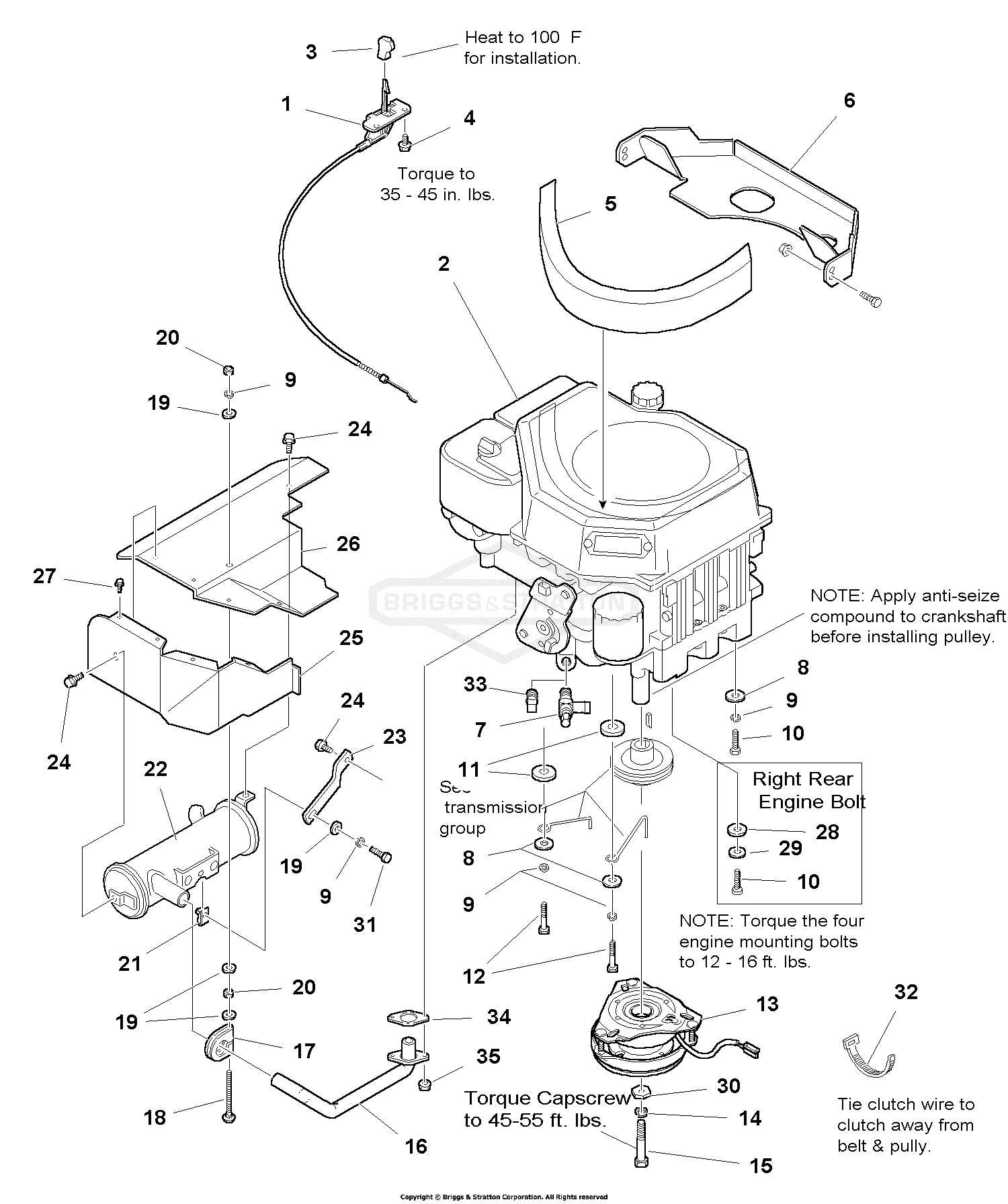

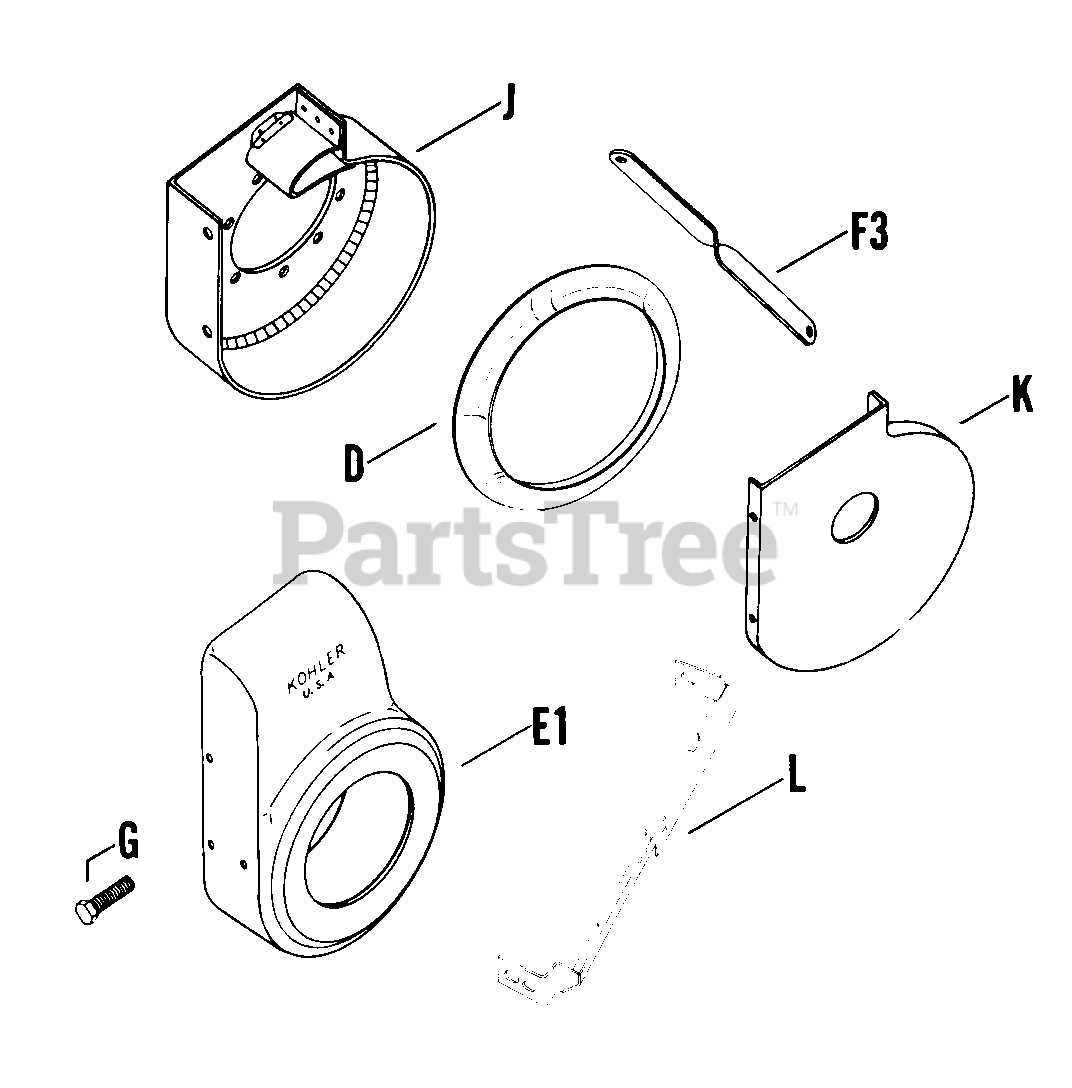

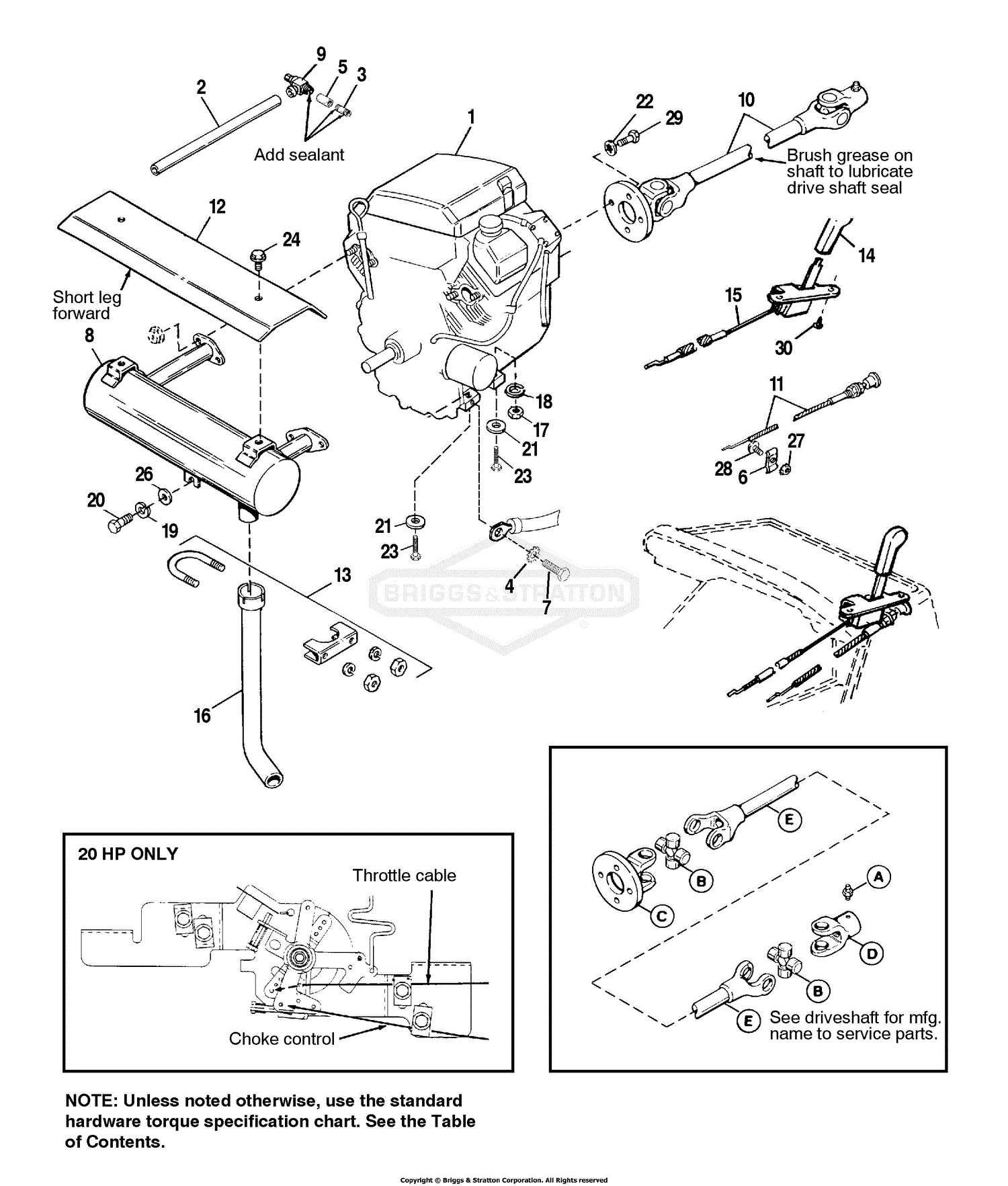

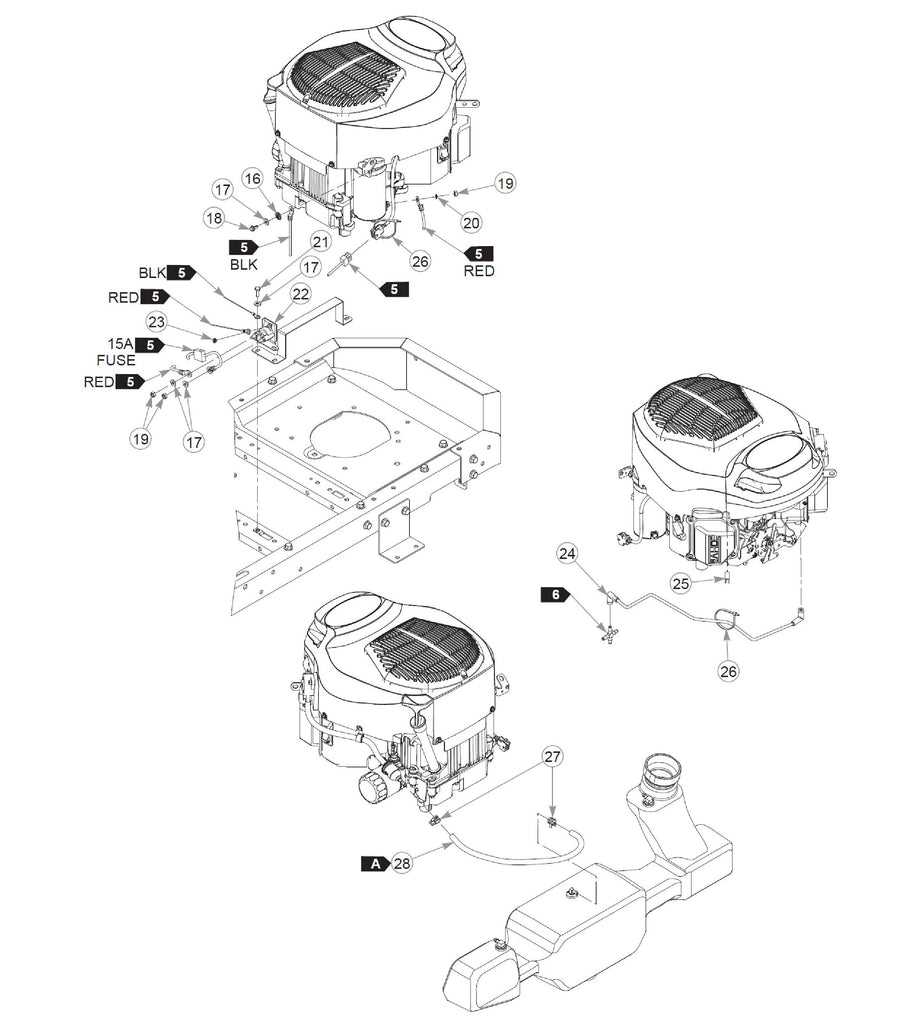

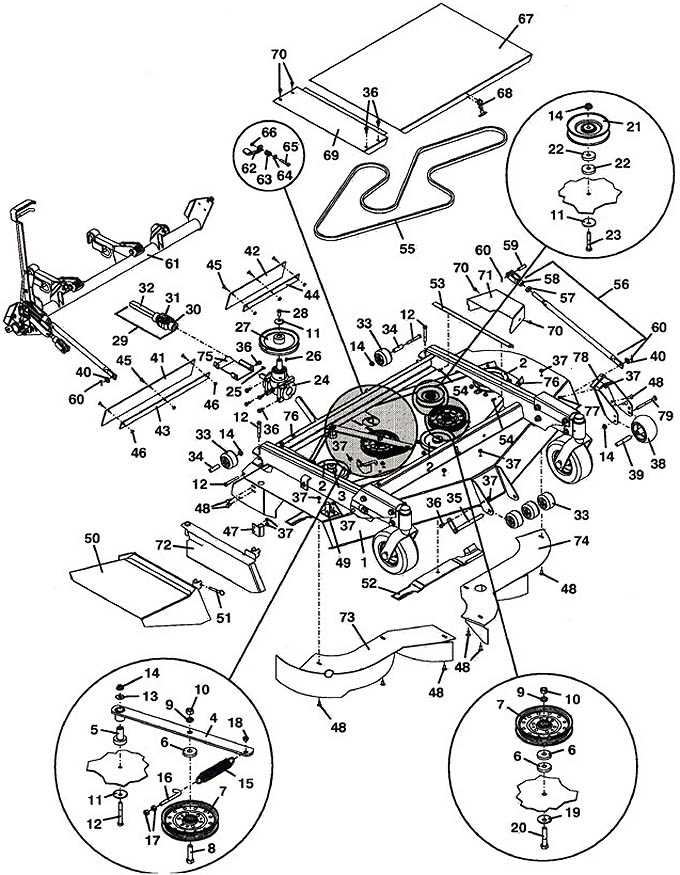

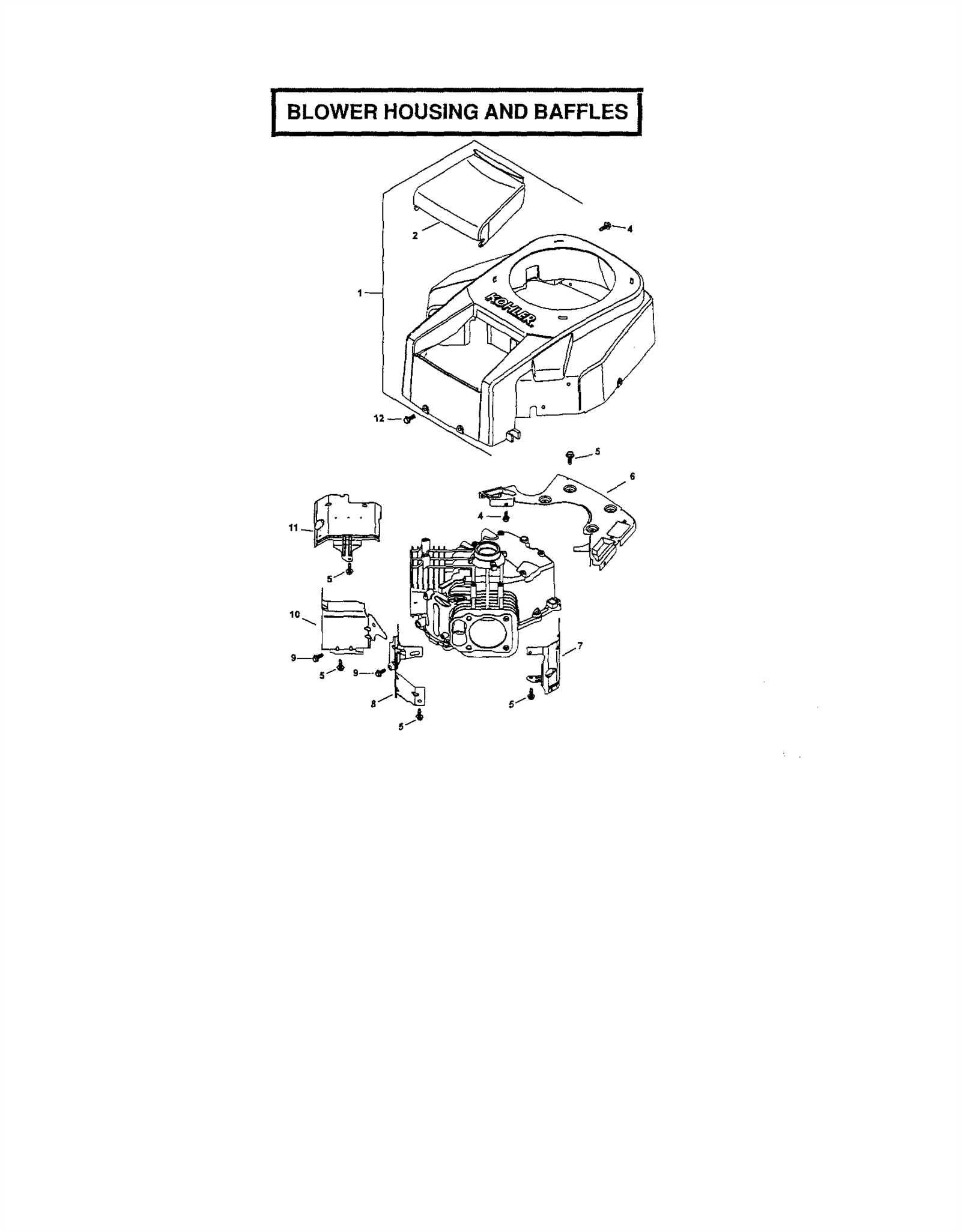

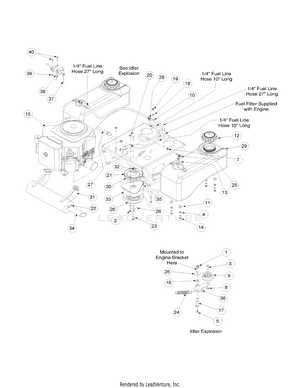

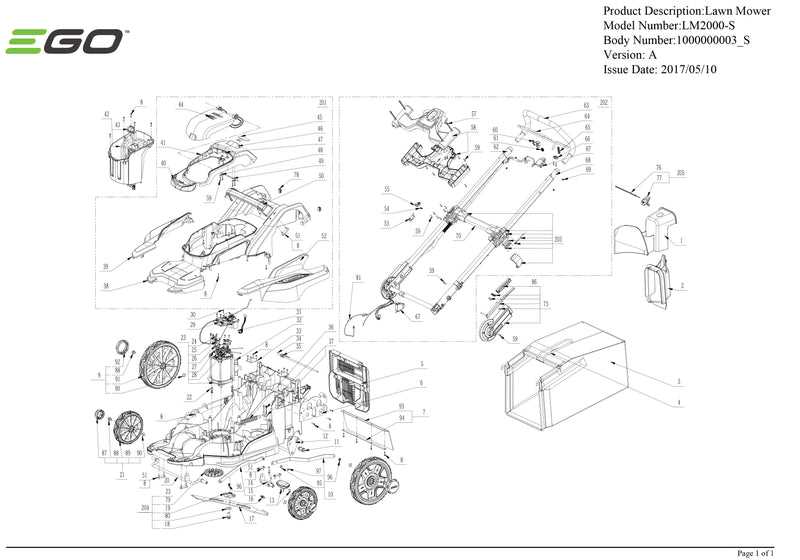

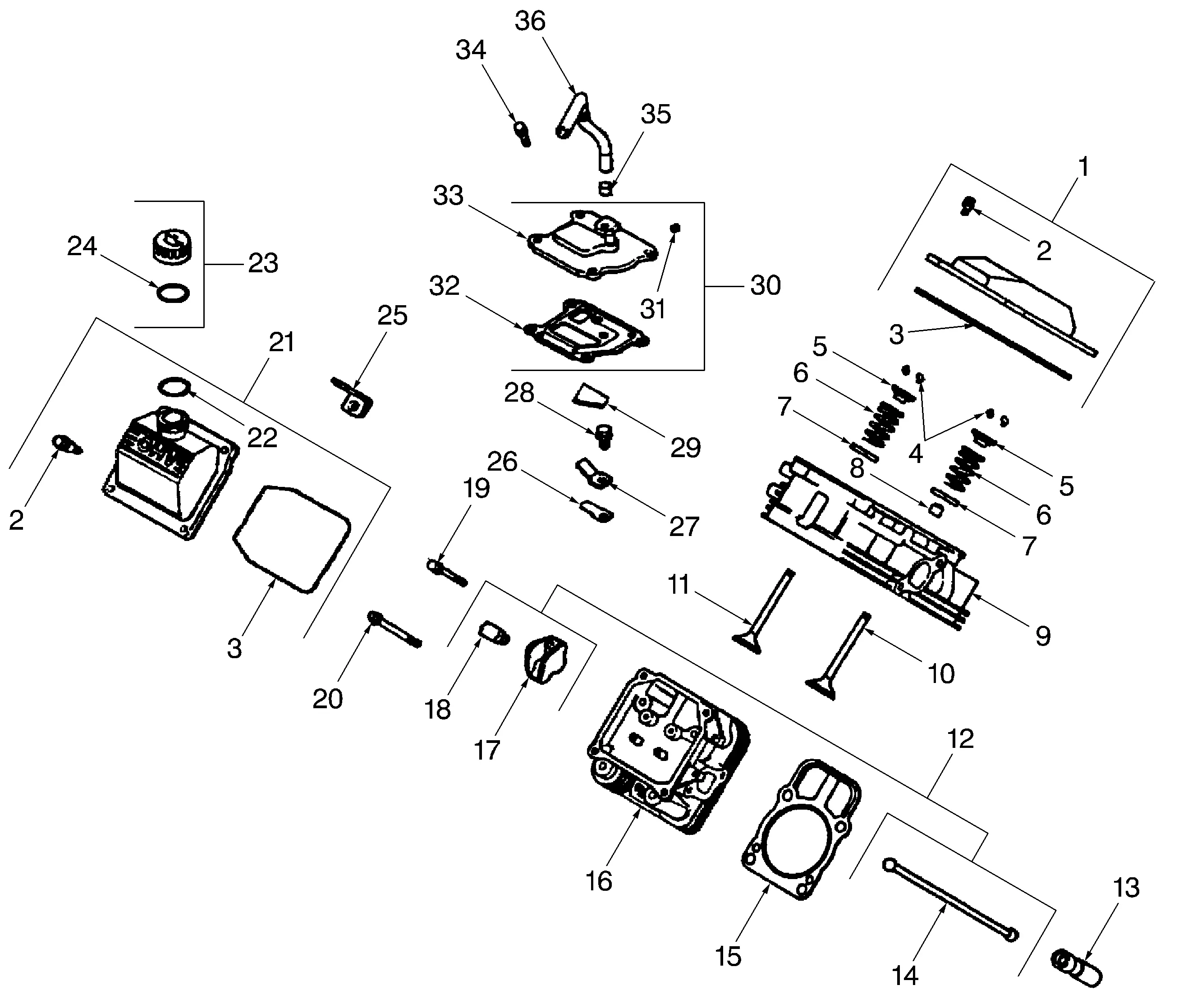

Understanding the Diagram Components

Interpreting visual representations of mechanical assemblies is crucial for effective maintenance and repair. These illustrations serve as a roadmap, highlighting various elements and their relationships within a machine, enabling users to identify and locate specific components efficiently.

Key Elements of the Illustration

Each visual representation typically includes symbols and labels that denote different parts. Understanding these symbols is essential for users to navigate the assembly accurately. Each component is often accompanied by a reference number that corresponds to a detailed description, providing clarity on function and maintenance tips.

Interrelationships and Functionality

The layout usually shows how various parts interact with one another. Recognizing these interconnections can lead to a deeper understanding of the overall functionality, ensuring that repairs or replacements are conducted with precision and efficiency.

Importance of Genuine Parts

Using authentic components is crucial for maintaining the performance and longevity of your equipment. These original elements are designed specifically to fit and function seamlessly within your machinery, ensuring optimal efficiency and reliability.

Quality Assurance: Genuine items undergo rigorous testing and quality control, which helps to prevent failures and reduce the risk of accidents during operation.

Cost-Effectiveness: Although they may be priced higher initially, authentic components can save you money in the long run by minimizing the need for frequent replacements and repairs.

Performance: When you choose original components, you enhance the overall functionality and effectiveness of your equipment, leading to better results and smoother operation.

Warranty Protection: Many manufacturers offer warranties on their products, which often require the use of genuine components to remain valid, providing additional peace of mind.

Common Replacement Parts Explained

Understanding the essential components of outdoor machinery is crucial for maintenance and efficiency. This section explores frequently replaced elements, highlighting their functions and importance in ensuring optimal performance.

Blades: The cutting instruments play a vital role in achieving a clean and precise trim. Regular inspection and replacement help maintain effectiveness and prevent damage to the surrounding area.

Filters: Air and fuel filters are essential for keeping contaminants out of the engine. Replacing them regularly ensures smooth operation and extends the lifespan of the equipment.

Spark Plugs: These components are responsible for igniting the fuel-air mixture in the engine. A worn or fouled spark plug can lead to starting issues and reduced power.

Batteries: The power source for electric starters, batteries require periodic replacement to ensure reliable starting and performance, especially in colder climates.

Belts: These transfer power between various parts, facilitating movement. Frayed or worn belts can hinder functionality, making timely replacement essential.

How to Read the Diagram

Understanding a schematic representation is essential for effective maintenance and repair of machinery. These visual guides illustrate various components and their interconnections, providing a clear roadmap for troubleshooting and assembly. Familiarity with these representations enhances your ability to identify specific elements and their functions.

Begin by examining the overall layout. Each section typically corresponds to a particular area of the equipment. Look for labeled parts that indicate their names and functions. Colors and symbols often differentiate between types of components, helping you quickly locate what you need.

Next, pay attention to the numbering system. Many schematics use a sequential numbering method to reference individual parts. This system allows you to cross-reference with the accompanying list or manual, ensuring that you can identify and order the correct items.

Additionally, notice any arrows or lines connecting components. These indicate relationships and directions of flow, whether it’s electrical signals, fuel, or air. Understanding these connections is crucial for diagnosing issues effectively.

Finally, don’t hesitate to consult supplementary materials or guides that accompany the schematic. They can provide valuable context and clarify any uncertainties. With practice, interpreting these visual tools will become a straightforward task, empowering you to maintain and enhance your equipment with confidence.

Troubleshooting Common Issues

When operating outdoor machinery, encountering difficulties can be frustrating. This section aims to guide users through typical problems, offering solutions to enhance functionality and performance. Understanding the signs of malfunction is crucial for efficient repairs.

Engine Won’t Start: If the engine fails to ignite, check the fuel supply and ensure the ignition system is operational. Additionally, inspect the battery connections for corrosion.

Uneven Cutting: If the cutting results are inconsistent, it may indicate dull blades or uneven wheel height. Sharpening the blades and adjusting the wheels can significantly improve performance.

Excessive Vibration: Excessive shaking during operation might be caused by loose or damaged components. Tightening bolts and inspecting for wear can help restore stability.

Overheating: If the machine overheats, verify the air filter’s cleanliness and ensure proper airflow. Additionally, check coolant levels if applicable.

Addressing these common issues can lead to smoother operation and extended lifespan of the equipment, ultimately enhancing user satisfaction.

Maintaining Your Lawn Mower

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By implementing a consistent maintenance routine, you can prevent potential issues and enhance efficiency. This process includes a variety of tasks that contribute to the smooth operation and reliability of your machine.

Routine Inspections

Performing periodic checks on your device is crucial. Look for wear and tear, especially in the blades and engine components. Keeping everything clean and free of debris can significantly improve performance and reduce the risk of damage.

Essential Maintenance Tasks

Changing the oil regularly and replacing filters can greatly enhance functionality. Additionally, ensuring that all moving parts are lubricated will help minimize friction and extend the life of your equipment. Never underestimate the importance of a well-maintained tool; it’s the ultimate key to achieving outstanding results in your outdoor tasks.

Where to Find Replacement Parts

Finding the right components for your machinery can be crucial for maintaining its performance and longevity. Whether you are looking for specific elements or general supplies, there are several reliable sources to explore. Below are some options to consider when searching for essential replacements.

| Source | Description |

|---|---|

| Official Manufacturer Website | The most reliable source for original components, offering detailed information and specifications. |

| Local Hardware Stores | Many neighborhood stores stock a variety of necessary supplies and can offer personalized assistance. |

| Online Retailers | Websites like Amazon and eBay provide a wide selection and often competitive prices. |

| Specialty Shops | Stores dedicated to outdoor equipment may have unique or hard-to-find items available. |

| Salvage Yards | Used parts can be sourced here, often at a fraction of the cost of new items. |

Comparing OEM vs. Aftermarket Parts

When considering components for equipment maintenance, the choice between original and alternative options plays a crucial role. Understanding the distinctions can lead to more informed decisions, potentially impacting performance, longevity, and cost.

Advantages of OEM Components

- Designed specifically for compatibility.

- Often backed by warranties.

- Consistent quality assurance from manufacturers.

Benefits of Aftermarket Alternatives

- Typically more affordable options.

- A wider variety of products available.

- Potential for enhanced performance features.

Ultimately, weighing the pros and cons of each type can help you delve deeper into what best suits your needs and budget.

Assembly Instructions for Key Parts

This section provides a comprehensive guide for assembling essential components of your equipment. Following these instructions will ensure a smooth assembly process, enhancing the overall functionality and longevity of the machine.

Step-by-Step Assembly

Begin by gathering all necessary components and tools. Ensure that you have a clean workspace to facilitate an organized assembly process. Start with the main frame and secure it to the base. Use the appropriate fasteners to prevent any instability. Once the frame is in place, proceed to attach the drive system, ensuring all connections are tight and aligned properly.

Final Checks

After assembling the main components, perform a thorough inspection. Check for any loose fittings and ensure that all moving parts operate smoothly. It’s crucial to refer back to your assembly guide to confirm that every piece is correctly positioned. Once satisfied with your work, proceed to test the equipment to verify its performance.

Identifying Model-Specific Components

Understanding the unique elements of each model is crucial for effective maintenance and repair. Every design may include specialized features that enhance performance and longevity.

To accurately identify components, consider the following steps:

- Check the model number: Locate it on the unit for reference.

- Consult the user manual: This document often provides detailed information about specific features.

- Use manufacturer resources: Official websites often have searchable databases.

- Join community forums: Engage with other users to share insights and experiences.

By following these guidelines, you can ensure a thorough understanding of your equipment’s unique requirements.

Tips for Long-lasting Performance

Ensuring optimal functionality and longevity of your outdoor equipment requires a combination of regular maintenance and mindful usage. By adopting best practices, you can significantly enhance the lifespan of your machinery, allowing it to operate at peak efficiency for years to come.

1. Regular Maintenance: Consistent upkeep is crucial. Clean and inspect components regularly to prevent build-up that can hinder performance.

2. Quality Fuel: Always use high-quality fuel to minimize deposits in the engine, promoting smoother operation and reducing wear.

3. Proper Storage: Store equipment in a dry, sheltered location to protect it from environmental factors that can cause damage.

4. Timely Repairs: Address any issues promptly. Delaying repairs can lead to more significant problems down the line.

5. Follow Manufacturer Guidelines: Adhering to the recommended procedures for operation and care can significantly extend the life of your equipment.

By implementing these strategies, you can achieve the ultimate performance from your machinery while minimizing the need for replacements or extensive repairs.