Understanding Milwaukee Lawn Mower Parts Diagram for Efficient Maintenance

Maintaining any machinery requires a clear understanding of its structure and components. Knowing how each element interacts can enhance performance and longevity. This section aims to provide insights into the intricate layout of your device, helping you navigate its essential features.

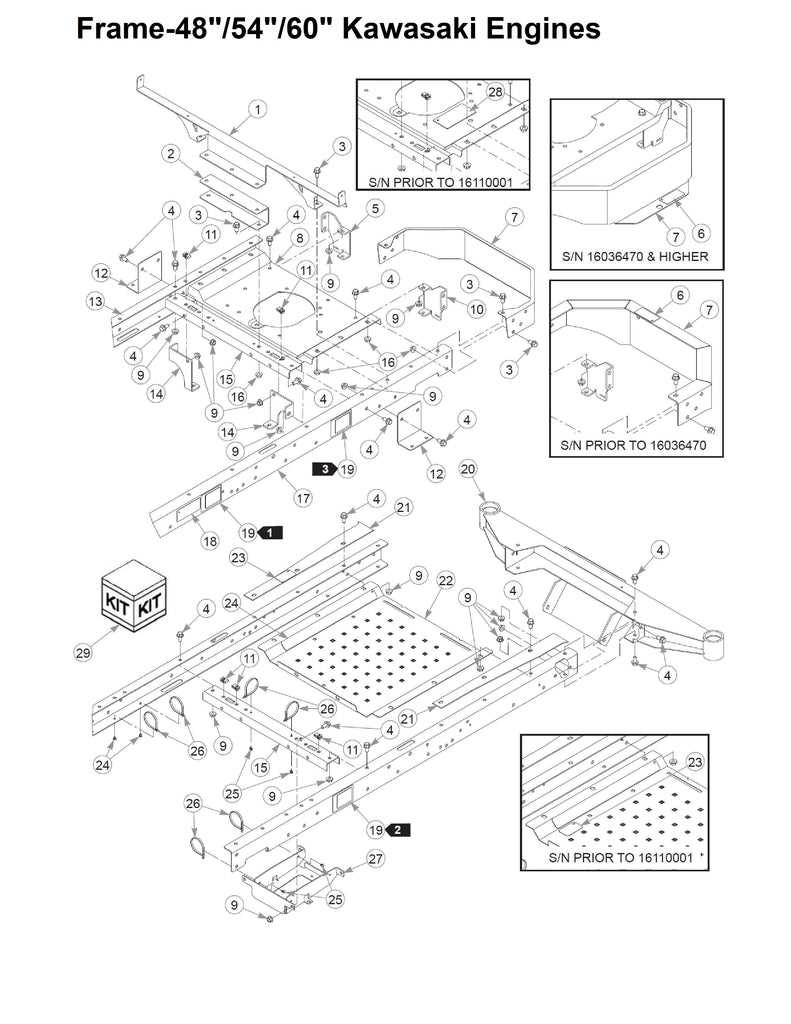

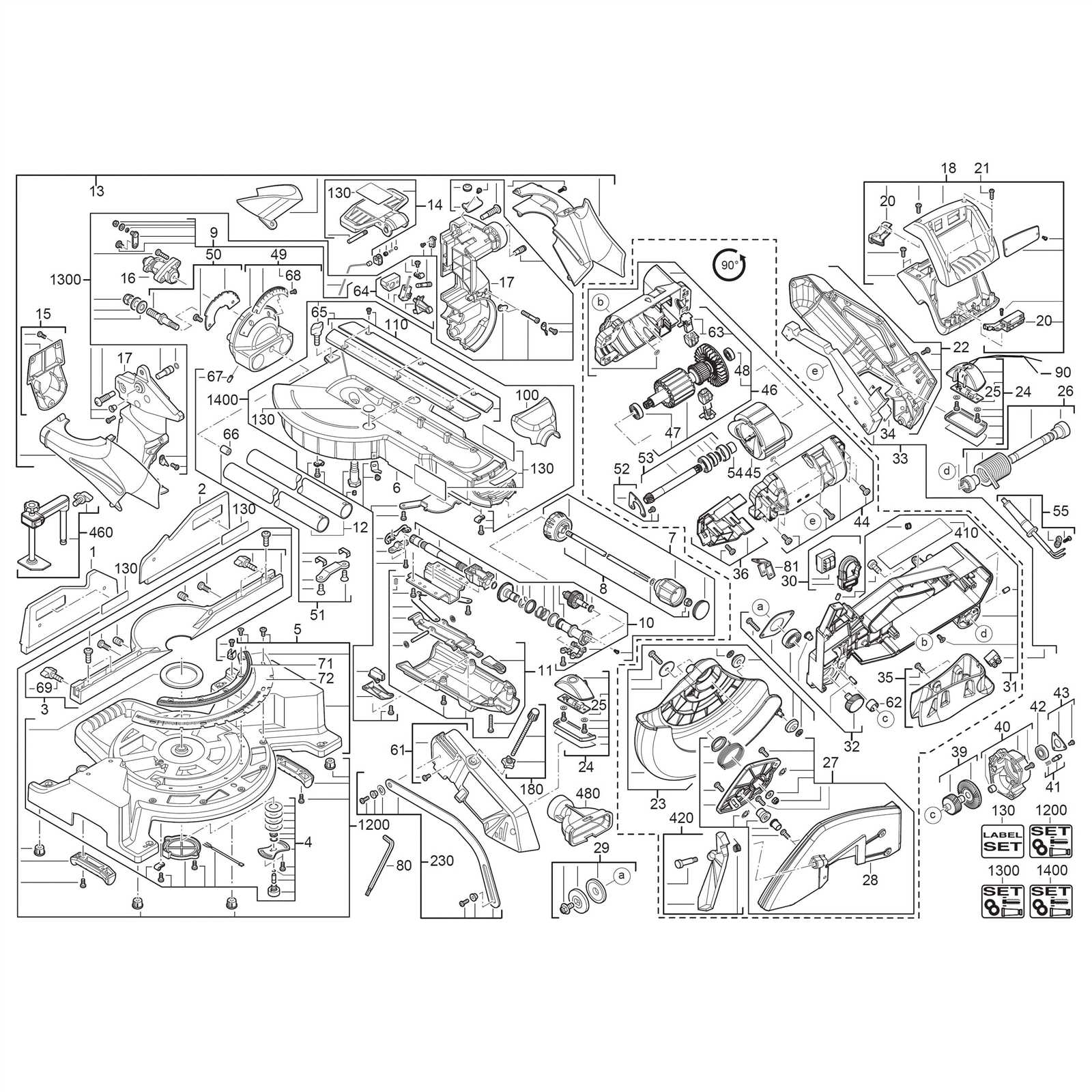

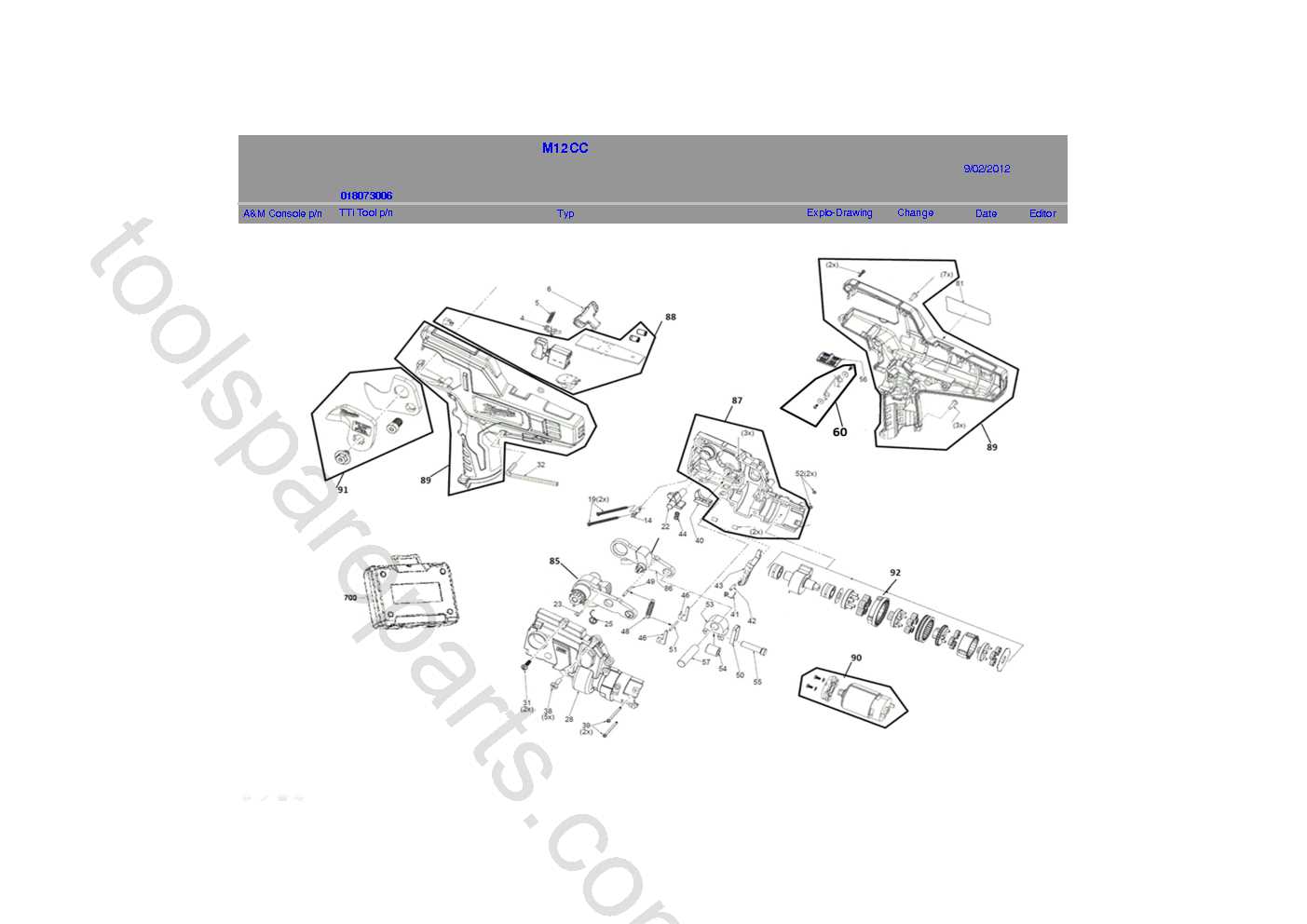

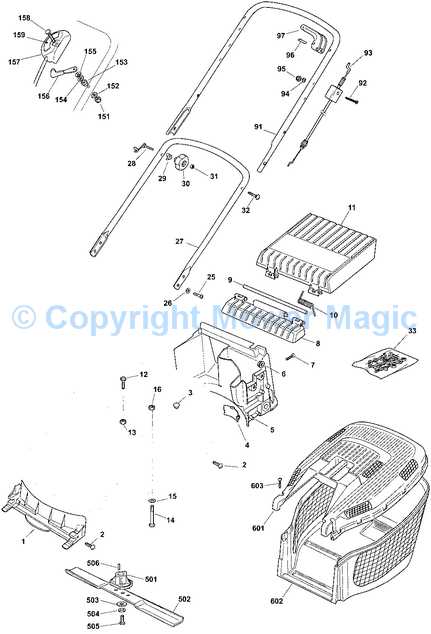

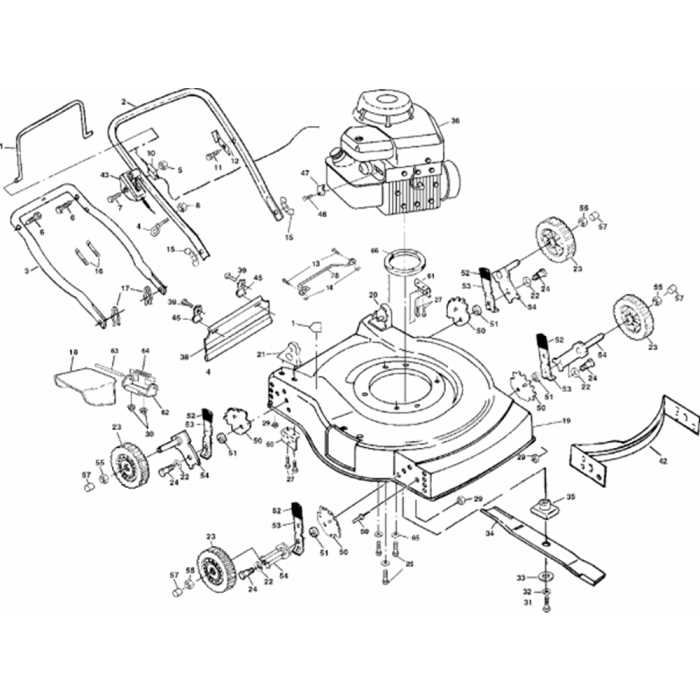

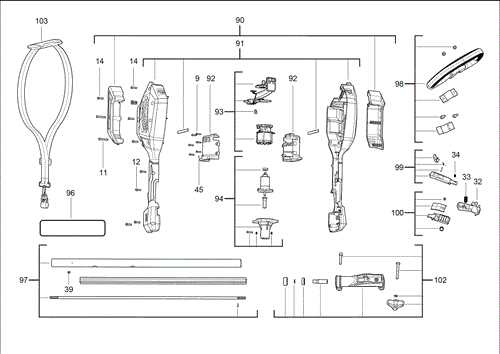

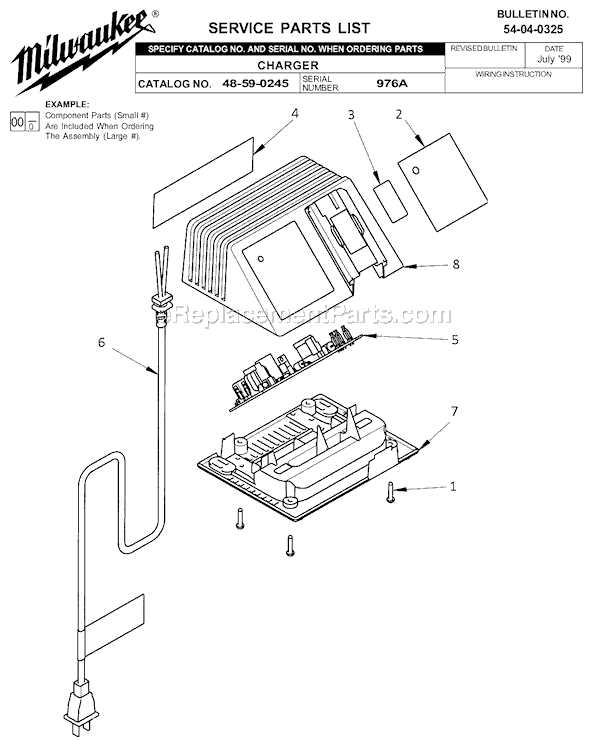

Visual representations can be invaluable when troubleshooting or replacing components. By familiarizing yourself with the layout, you can quickly identify issues and streamline repairs. Such knowledge not only saves time but also ensures efficient operation.

Delving into the specifics of the various sections and their functionalities will empower you as an operator. You’ll be better equipped to make informed decisions and ultimately achieve optimal results with your equipment.

Understanding Milwaukee Lawn Mower Diagrams

Gaining insight into the schematics of outdoor equipment is essential for effective maintenance and repair. By familiarizing yourself with these illustrations, you can enhance your knowledge of the components involved, ensuring optimal functionality and longevity of your machinery.

Importance of Familiarization

Recognizing each element within the visual representations allows users to identify issues swiftly. This understanding ultimately leads to more efficient troubleshooting and the ability to source replacements accurately.

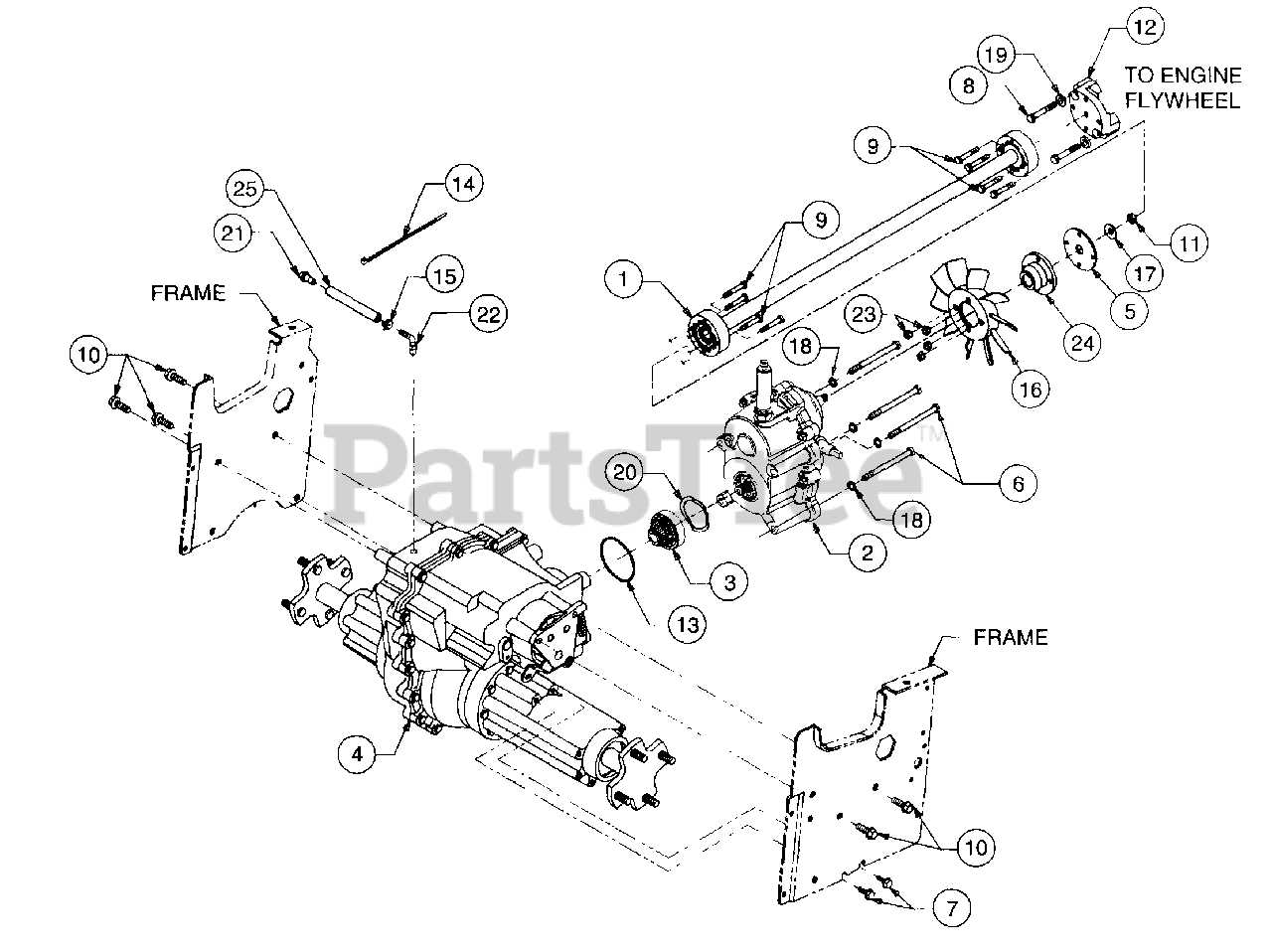

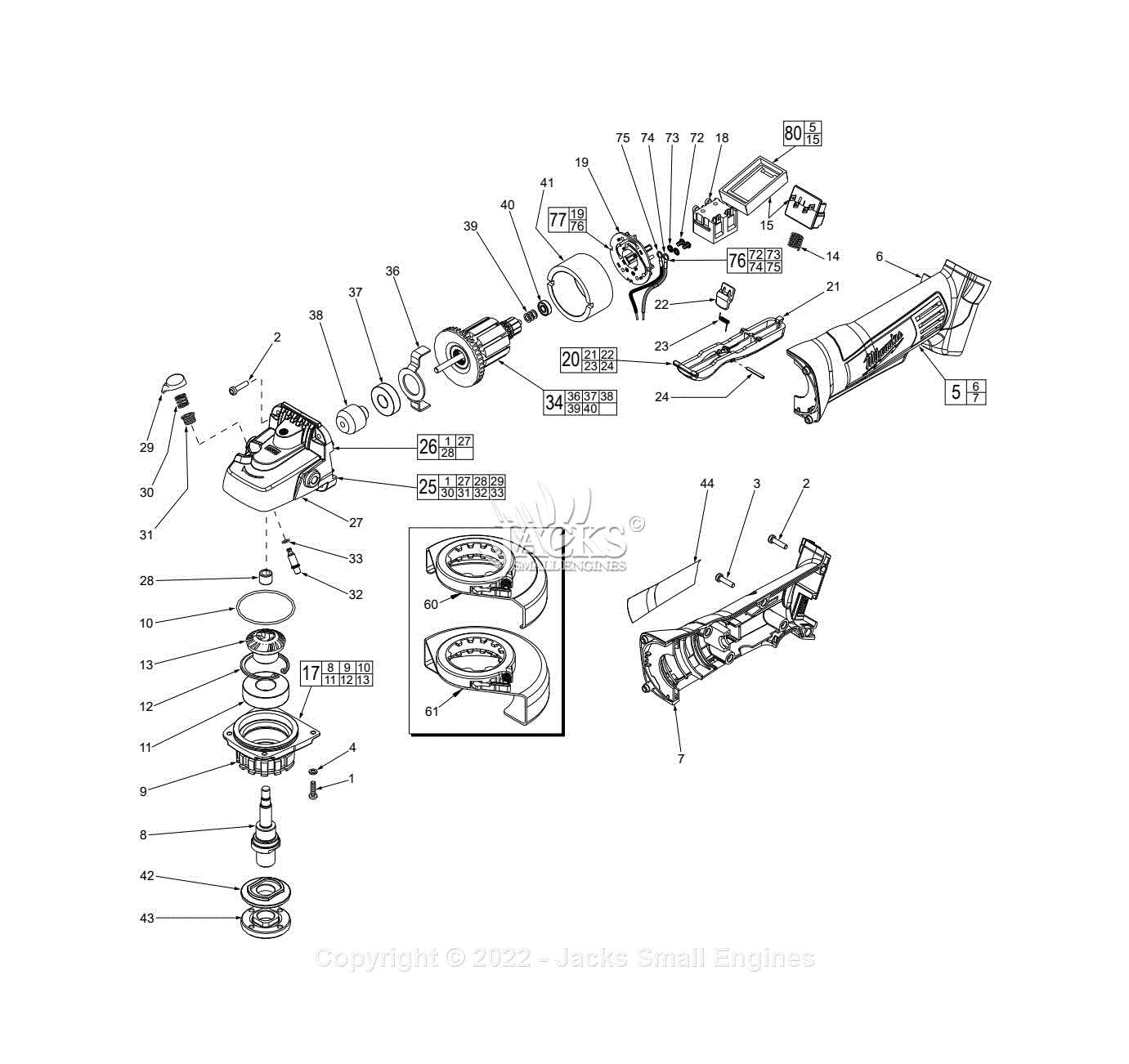

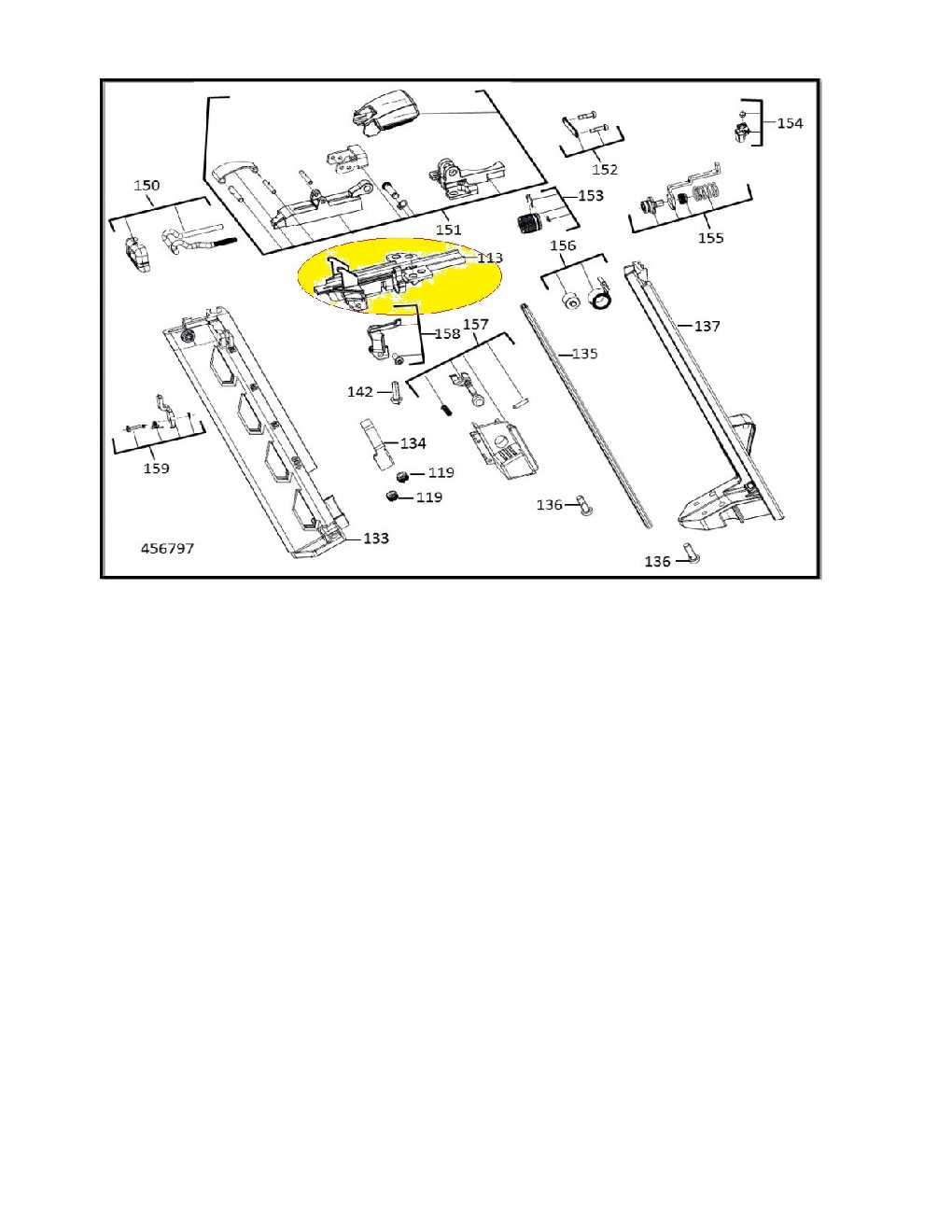

Interpreting Symbols and Connections

Delving into the specific symbols and connections illustrated in these diagrams is crucial. It not only aids in comprehending the assembly but also highlights the relationship between various components, empowering users to undertake maintenance with confidence.

Key Components of Lawn Mowers

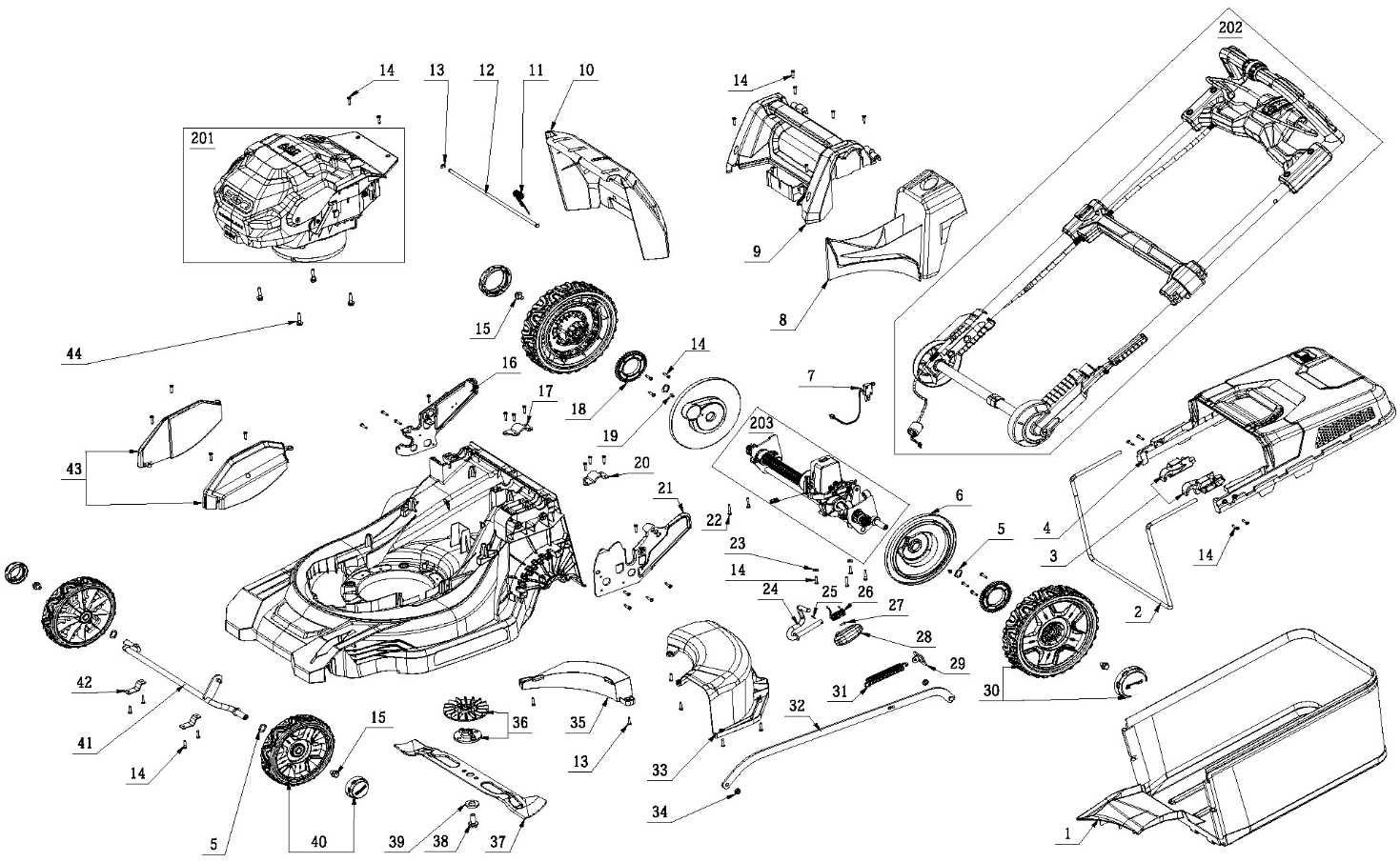

Understanding the essential elements of grass-cutting machines is crucial for effective maintenance and optimal performance. Each component plays a significant role in ensuring that the equipment operates smoothly and efficiently. Familiarity with these parts can help users troubleshoot issues and enhance their machine’s longevity.

1. Engine: The heart of the machine, responsible for generating power. Different types of engines offer varying levels of efficiency and performance, impacting how well the device performs its task.

2. Cutting Blade: This sharp tool is essential for achieving a clean and precise cut. Blade design and sharpness directly influence the quality of the trimming process.

3. Chassis: The frame provides structural integrity and supports all components. A robust chassis ensures stability during operation and can affect maneuverability.

4. Fuel System: Responsible for delivering energy to the engine, this system includes the fuel tank, lines, and filter. Proper maintenance of this system is vital for smooth operation.

5. Drive System: This includes mechanisms that propel the machine forward. Whether manual or automatic, the drive system significantly affects ease of use.

6. Wheels: The size and design of the wheels influence mobility and the machine’s ability to navigate various terrains. Quality wheels contribute to overall handling and performance.

7. Controls: User interfaces, such as levers and buttons, allow for easy operation. Well-designed controls enhance user experience and safety.

In summary, each of these elements plays a vital role in the functionality and effectiveness of grass-cutting devices. Understanding their importance can lead to better care and improved performance.

Importance of Accurate Parts Identification

Understanding the specific components of any machinery is crucial for effective maintenance and repair. Proper identification ensures that the right elements are used, which can significantly enhance performance and longevity. When the correct pieces are employed, it minimizes the risk of damage and optimizes functionality.

Accurate identification not only facilitates smoother repairs but also aids in avoiding costly errors. For instance, using an incorrect component can lead to mechanical failures or even safety hazards. Moreover, having a clear understanding of each element involved allows for better planning and resource allocation, ultimately saving time and effort.

Furthermore, familiarity with the correct components fosters confidence in handling machinery. This knowledge empowers users to make informed decisions when sourcing replacements, ensuring compatibility and quality. Thus, emphasizing precise identification is key to maintaining operational efficiency and safety.

How to Read Lawn Mower Schematics

Understanding technical illustrations can significantly enhance your ability to maintain and repair garden equipment. These visuals provide a clear representation of components and their interconnections, enabling users to identify issues and perform necessary tasks with confidence. Grasping the conventions used in these schematics is essential for efficient troubleshooting.

Familiarize Yourself with Symbols

Each illustration employs specific symbols to denote various elements such as engines, electrical systems, and cutting mechanisms. Familiarize yourself with these icons, as they serve as the foundation for interpreting the overall design. A legend is often included, explaining each symbol’s meaning, making it easier to navigate the schematic.

Follow the Flow of Information

To effectively interpret the illustration, trace the connections between components. Pay attention to lines that represent pathways for energy or motion. These lines often indicate how parts interact and are crucial for diagnosing problems. Understanding the flow of information helps pinpoint malfunctioning sections and ensures a comprehensive approach to repairs.

Common Parts in Milwaukee Models

Understanding the essential components of these machines can greatly enhance maintenance and repair efficiency. Various elements contribute to the overall functionality, ensuring optimal performance and longevity.

Engines serve as the powerhouse, providing the necessary energy for operation. Blades are critical for achieving clean cuts, with different designs tailored for specific tasks. Additionally, chassis structures support the overall design, ensuring stability and ease of maneuverability.

Wheels facilitate movement across various terrains, while handles offer comfort and control during use. Finally, fuel systems are vital for delivering energy efficiently, making them crucial for the machine’s performance.

Finding Replacement Parts Easily

Locating the right components for your outdoor equipment can be a straightforward process when you know where to look. Understanding the various resources available to you will streamline your search and ensure you get what you need quickly and efficiently.

Start by consulting the manufacturer’s website, which often provides detailed information on compatible components. Additionally, online retailers and specialized suppliers can offer a wide selection, often with user-friendly search tools to narrow down options. Don’t overlook the importance of user manuals, which can provide critical insights into part numbers and compatibility.

Forums and community groups dedicated to outdoor equipment can also be invaluable. Engaging with fellow enthusiasts can yield recommendations on where to find specific items, as well as tips on installation and maintenance. By leveraging these resources, you’ll ultimately save time and frustration in sourcing your necessary replacements.

Tools Needed for Maintenance Tasks

Proper upkeep of your equipment requires a selection of essential instruments to ensure efficiency and longevity. Having the right tools on hand can streamline various maintenance activities, enabling you to address issues effectively and maintain optimal performance.

For basic maintenance, you will need a screwdriver set to tighten or adjust components, along with a wrench for bolt adjustments. A socket set is also beneficial for more intricate tasks. Additionally, pliers can aid in gripping and manipulating small parts.

Cleaning your equipment is vital; thus, a brush and compressed air can help remove debris. For lubricating moving parts, keep a lubricant spray handy, as it minimizes friction and wear. Finally, a safety kit, including gloves and goggles, is crucial for protecting yourself during maintenance tasks.

Comparing Parts Across Different Models

This section explores the similarities and differences in components across various designs. Understanding these variations can enhance user experience and facilitate better maintenance and upgrades.

Key Components to Analyze

- Engines

- Blades

- Wheels

- Handles

- Decks

Benefits of Comparison

- Improved compatibility with accessories.

- Enhanced performance insights.

- Cost-effective maintenance solutions.

- Better understanding of durability factors.

Where to Purchase Original Parts

Finding authentic components for your equipment is essential for maintaining its performance and longevity. Genuine items ensure compatibility and reliability, reducing the risk of malfunctions. This section highlights the best avenues for acquiring these essential elements to keep your machinery operating smoothly.

Authorized Dealers

One of the most reliable sources for original components is through authorized dealers. These retailers are certified to sell genuine items and often provide expert advice on installation and maintenance. Here are some benefits of purchasing from authorized dealers:

| Benefit | Description |

|---|---|

| Quality Assurance | Guaranteed authenticity and reliability of components. |

| Expert Support | Access to knowledgeable staff for guidance and recommendations. |

| Warranty Coverage | Potential for warranty on items, offering peace of mind. |

Online Retailers

Another convenient option for sourcing original components is through reputable online platforms. These websites often provide a vast selection of items, allowing you to compare prices and features easily. When purchasing online, consider the following:

| Consideration | Details |

|---|---|

| Reputation | Ensure the retailer has positive reviews and ratings. |

| Return Policy | Check the return policy in case the item does not meet expectations. |

| Shipping Options | Look for reliable shipping methods and estimated delivery times. |

DIY Repairs for Common Issues

Addressing minor malfunctions in outdoor equipment can save time and money while enhancing the lifespan of your machine. Many users can tackle these repairs themselves with a bit of guidance and the right tools. Below are some common problems and simple solutions that can help restore functionality without needing professional assistance.

1. Difficulty Starting

If your device refuses to start, first check the fuel supply. Ensure there’s enough fuel, and inspect for any signs of contamination. Additionally, examine the spark plug; if it’s worn or dirty, cleaning or replacing it can make a significant difference.

2. Uneven Cutting

An uneven cutting pattern may indicate dull blades. Regularly sharpen the blades to maintain a clean cut. Also, inspect the height settings; adjusting them can improve performance and consistency.

3. Overheating

Overheating often stems from a clogged cooling system. Regularly clean air filters and vents to ensure proper airflow. If the device continues to overheat, check for oil levels and consider a change if it appears dirty or low.

4. Excessive Vibration

Vibration issues can be caused by loose components or unbalanced blades. Tighten any loose bolts and ensure blades are properly installed. If the problem persists, inspect for any damage or wear in the components.

5. Leaking Fluids

Fluid leaks can be alarming. Identify the source of the leak, which may be due to worn seals or loose fittings. Tightening connections or replacing seals can often resolve these issues effectively.

By following these straightforward tips, users can perform essential maintenance and repairs on their equipment, ensuring optimal performance throughout the season.

Understanding Warranty and Parts Coverage

When investing in outdoor equipment, it’s essential to grasp the nuances of protection and component support offered by manufacturers. Such guarantees not only safeguard your investment but also ensure the longevity and efficiency of the machinery.

Warranties typically cover defects in materials and workmanship, providing peace of mind that you won’t incur unexpected costs due to manufacturing flaws. It’s important to familiarize yourself with the duration of these protections and any specific conditions that might apply.

Parts coverage varies significantly between brands, often influencing the ease of obtaining replacements or repairs. Understanding what is included can help you maintain your equipment effectively and avoid future inconveniences.

Always read the fine print to ensure you know your rights and responsibilities, as well as the limitations of the coverage offered. This knowledge is crucial for making informed decisions regarding maintenance and repairs.

Upgrading Your Lawn Mower Components

Enhancing the efficiency and performance of your outdoor cutting equipment can significantly improve your gardening experience. By investing in superior components, you not only extend the lifespan of your machinery but also achieve better results in maintaining your green spaces. Understanding which elements to upgrade can make all the difference.

Identifying Key Components for Improvement

Begin by evaluating the critical aspects of your equipment. Focus on the blades, as sharper and more durable options can lead to cleaner cuts and healthier grass. Additionally, consider the engine; upgrading to a more powerful model can enhance speed and reduce the time spent on maintenance tasks. Lastly, check the wheels and drive system, as improved traction and mobility can transform your overall experience.

Benefits of Upgrading

Investing in high-quality replacements not only boosts performance but also improves safety. Enhanced components reduce the likelihood of malfunctions, ensuring a smoother operation. Furthermore, an upgrade can result in lower fuel consumption, which is both economical and environmentally friendly. By prioritizing these enhancements, you can create a more effective and enjoyable gardening tool.

Tips for Long-lasting Mower Performance

Ensuring the longevity of your cutting equipment requires a combination of regular maintenance, proper usage, and awareness of essential components. By focusing on these key areas, you can maximize efficiency and extend the life of your device.

Regular Maintenance: Schedule consistent inspections to clean and replace worn-out components. This practice prevents buildup that can lead to decreased functionality.

Optimal Usage: Always follow manufacturer guidelines for operation. Avoid pushing the equipment beyond its limits, as this can cause unnecessary strain.

Seasonal Preparation: Before storing, prepare your tool for the off-season by emptying the fuel and cleaning all surfaces. This helps avoid corrosion and ensures a smooth start in the future.

Quality Fuel: Use high-quality fuel to prevent clogs and other issues. Consider adding a fuel stabilizer for long-term storage to keep the engine running smoothly.

Sharpen Blades: Keep blades sharp for optimal cutting performance. Dull blades can damage grass and reduce the overall efficiency of your equipment.

Check Filters: Regularly inspect and replace air and fuel filters. Clean filters enhance airflow and fuel delivery, contributing to better performance.

By incorporating these practices into your routine, you can achieve the ultimate durability and efficiency for your equipment.