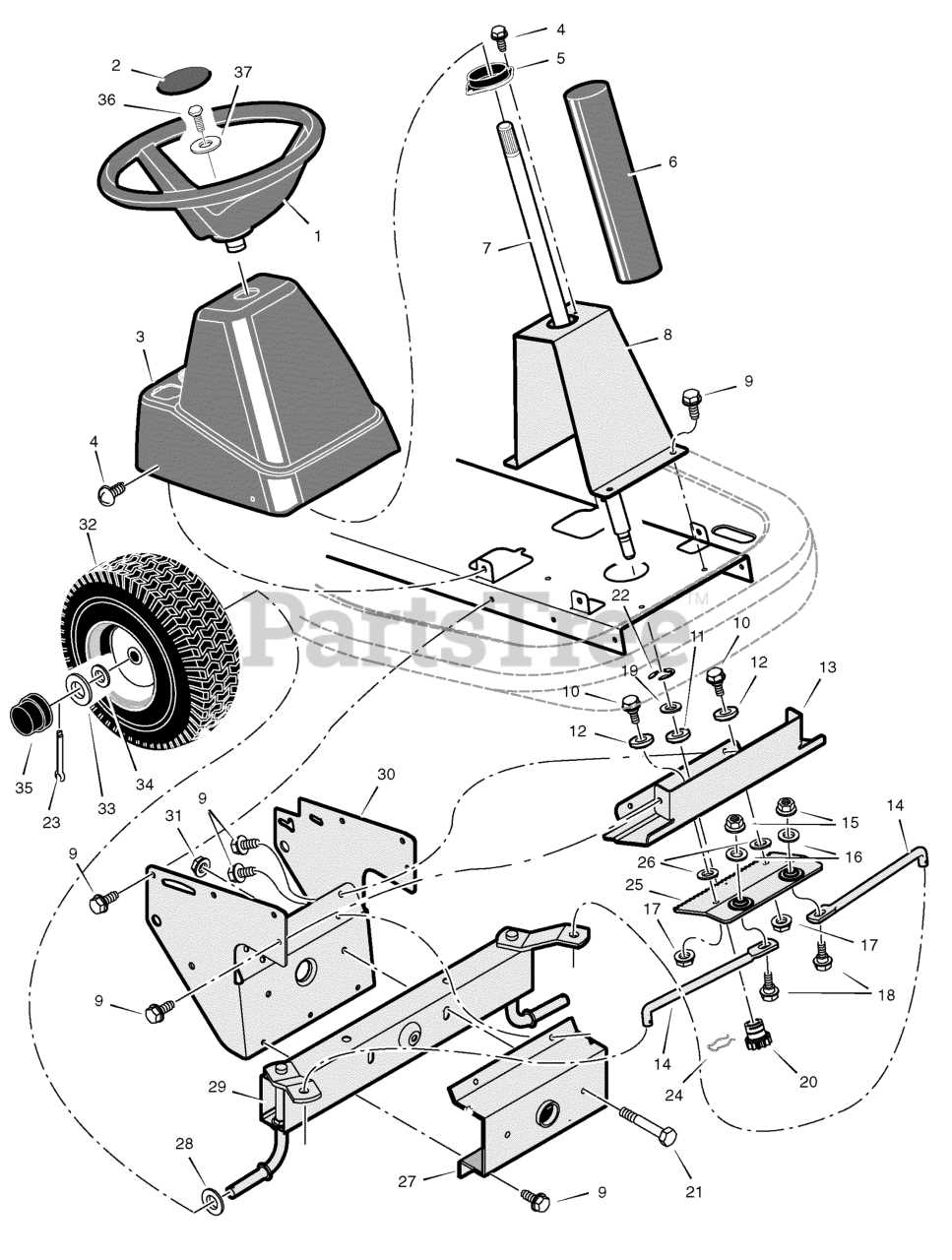

Murray 21 Lawn Mower Parts Breakdown

Every machine consists of various elements working together in harmony, and outdoor equipment is no exception. Having a clear overview of the various mechanical connections is crucial for ensuring smooth operation and maintenance. Whether you’re a seasoned expert or a casual user, familiarizing yourself with the internal workings can prevent unnecessary breakdowns and extend the life of your equipment.

Each section of the machine plays a vital role in its functionality, from the power source to the cutting mechanism. Knowing where each component is located and how it interacts with others allows for quicker troubleshooting and replacement when necessary. This knowledge not only simplifies repairs but also enhances safety during use, providing a better overall experience.

This guide will take you through the essential mechanical structures of a common outdoor tool, helping you navigate the different sections and understand how they contribute to its efficient performance. With a well

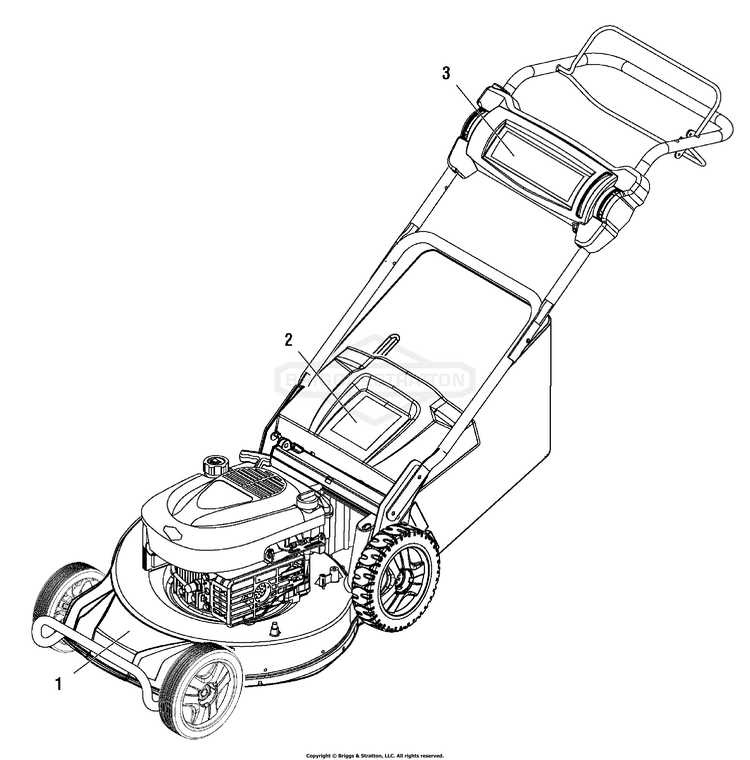

Overview of the Murray 21 Lawn Mower

This machine offers a practical and efficient solution for maintaining outdoor spaces, designed to provide smooth operation and reliable performance. Its construction allows for easy maneuverability, ensuring an even and clean trim across varied terrains.

- Compact and user-friendly design for easy handling

- Equipped with a powerful cutting system to ensure precision

- Multiple cutting height options to accommodate different grass types

- Durable build quality for long-lasting use

- Optimized for minimal maintenance and easy upkeep

Whether for small yards or larger spaces, this equipment ensures efficient trimming with adjustable settings, making it adaptable to various conditions. The blend of ergonomic design and advanced features supports a hassle-free experience for users of all skill levels.

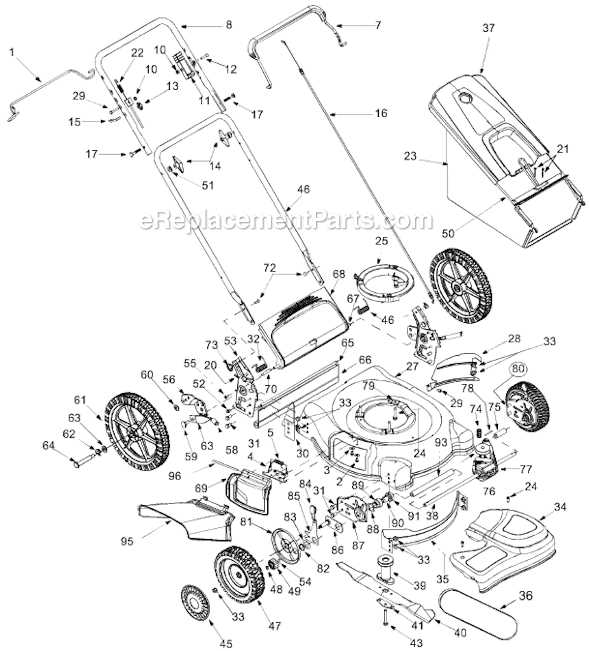

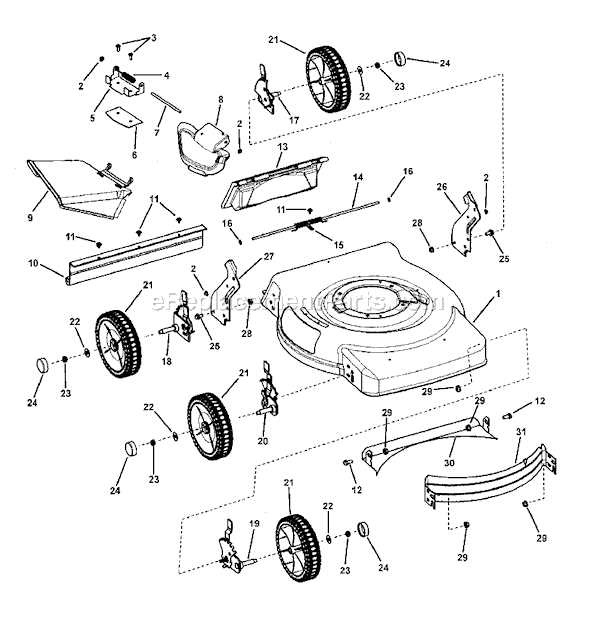

Key Components of the Mower Deck

The cutting assembly is a crucial system that ensures effective and efficient trimming of outdoor surfaces. It contains various mechanical elements designed to work together seamlessly, allowing smooth operation and reliable performance. Understanding the layout and individual roles of these parts is essential for maintaining peak functionality.

Blade Mechanism

The blade setup is central to the entire cutting process. Positioned beneath the unit, the blade rotates at high speeds to provide precision cutting. It is connected to the drive shaft, which powers the blade rotation.

- Blades: These sharp edges are responsible for trimming and should be regularly inspected for wear.

- Spindle Assembly: This component holds the blades in place and ensures they remain properly aligned during rotation.

- Deck Belt: The belt transfers power from the engine to the spindle, driving the blades.

Deck Frame and Support

Understanding the Engine Assembly

The mechanical core is the heart of the entire system, driving its essential operations. This section will guide you through the crucial components that make up this vital assembly. Each element within the mechanism has a specific role, ensuring smooth performance and functionality. By gaining a deeper understanding of how these elements work together, you’ll be better equipped to maintain or troubleshoot issues that may arise.

The engine structure includes several key sections, such as the combustion chamber, crankshaft, and exhaust system. These components work in harmony to convert fuel into motion. The ignition process, air intake, and exhaust expulsion all occur in a finely-tuned sequence, contributing to the overall efficiency. Understanding how each part interacts is critical for ensuring peak performance and longevity of the system.

How to Replace the Cutting Blade

Maintaining sharp and well-balanced cutting tools is crucial for efficient operation and a clean finish. Regular inspection and timely replacement of worn or damaged components can improve the overall performance and prolong the life of the machine. Below, we’ll guide you through the steps to safely and correctly replace this essential part of your outdoor equipment.

Step 1: Safety First

Before starting any maintenance, ensure the engine is turned off and any power source is disconnected to prevent accidents. Wear protective gloves to shield your hands from potential injury when handling sharp tools.

Step 2: Removing the Old Blade

Position the machine on a stable surface and carefully tilt it for easier access to the underside. Secure the cutting tool in place by using a block of wood or a similar object to prevent it from rotating. Use a wrench

Wheels and Axle Mechanism Explained

The function of the wheel and axle system plays a critical role in ensuring smooth movement and stability across different surfaces. Understanding how these components work together can help maintain efficient operation and prolong the lifespan of your equipment. The mechanism involves more than just the circular elements; it integrates a combination of parts designed for support, rotation, and load distribution.

The wheels are crafted to provide adequate traction and handle various terrains, while the axle is responsible for connecting these elements and allowing them to rotate freely. This connection enables controlled motion, ensuring the equipment moves with minimal friction. Proper alignment and maintenance of the axle are essential to prevent uneven wear and ensure consistent performance.

In many designs, the axle mechanism also includes additional components like bearings and bushings. These elements help reduce friction between moving parts and ensure a smoother operation, particularly under heavy loads. Keeping these parts clean and properly lubricated is crucial for preventing premature damage and ensuring long-term functionality

Fuel Tank Layout and Connections

This section explores the arrangement and linkages associated with the fuel reservoir. Understanding these elements is crucial for ensuring optimal performance and maintenance of the equipment. The layout typically includes various components that work together to facilitate the efficient flow of fuel to the engine.

Components of the Fuel Reservoir

The primary elements of the fuel reservoir include the tank itself, the cap, and the associated tubing. Each of these components plays a vital role in maintaining the integrity of the fuel system and preventing leaks or blockages.

Connection Overview

The connections to the fuel reservoir are essential for the proper functioning of the equipment. The arrangement may involve different fittings and hoses that need to be inspected regularly to ensure they are secure and in good condition.

| Component | Description |

|---|---|

| Fuel Tank | The main storage unit for the fuel. |

| Fuel Cap | Seals the tank and prevents fuel evaporation. |

| Fuel Lines | Hoses that transport fuel to the engine. |

| Fuel Filter | Traps contaminants before they reach the engine. |

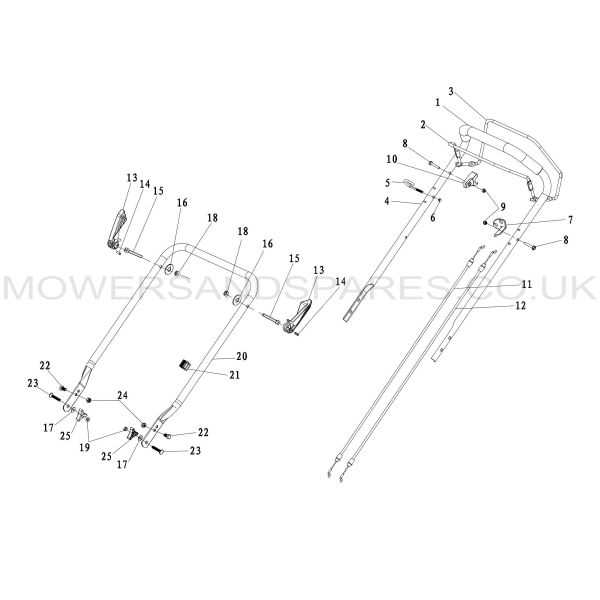

Handle and Control Panel Overview

This section provides insight into the structure and functionality of the grip assembly and the interface utilized for operation. Understanding these components is essential for effective handling and maneuverability, ensuring a seamless experience while managing the equipment.

Grip Assembly Features

The grip assembly is designed to offer comfort and stability during use. It typically includes ergonomic features that reduce fatigue, allowing for extended periods of operation without discomfort. The material used is often selected for its durability and ability to withstand outdoor conditions, ensuring a reliable grip in various weather scenarios.

Control Interface Functionality

The control panel serves as the primary interface for managing various functions of the device. It includes switches and levers that enable the operator to adjust speed, start the engine, and engage different modes of operation. Familiarity with the layout and function of these controls is crucial for efficient handling and optimal performance.

Exploring the Drive System Components

The drive mechanism of a cutting machine is essential for its efficient operation. Understanding the various elements involved in this system can enhance performance and maintenance. Each component plays a vital role in ensuring smooth movement and functionality.

Key components of the drive system include:

- Engine: The power source that drives the entire mechanism.

- Transmission: A crucial part that transfers power from the engine to the wheels, allowing for controlled speed and torque.

- Drive Belt: Connects the engine to the transmission, ensuring the transfer of energy efficiently.

- Wheels: Provide mobility, allowing the machine to navigate various terrains.

- Axles: Support the wheels and help maintain balance while enabling rotation.

Understanding these components not only aids in troubleshooting but also in optimizing the overall efficiency of the device. Regular maintenance of each part can lead to improved performance and longevity.

Air Filter Housing and Function

The air filter housing plays a crucial role in the overall efficiency and performance of an engine. Its primary function is to protect the internal components by filtering out contaminants and debris from the air entering the combustion chamber. By ensuring a clean airflow, the housing contributes to optimal engine operation and longevity.

Structure and Design

This enclosure is typically constructed from durable materials, designed to withstand various environmental conditions. It houses the air filter, which captures particles like dust, dirt, and pollen. A well-designed air filter housing facilitates easy access for maintenance, allowing for straightforward filter replacement and inspection.

Importance of Clean Air Supply

A proper airflow is essential for achieving efficient combustion. Impurities in the air can lead to reduced performance and increased wear on engine components. Regular maintenance of the air filter and its housing ensures that the engine receives a sufficient supply of clean air, promoting better fuel efficiency and reducing emissions.

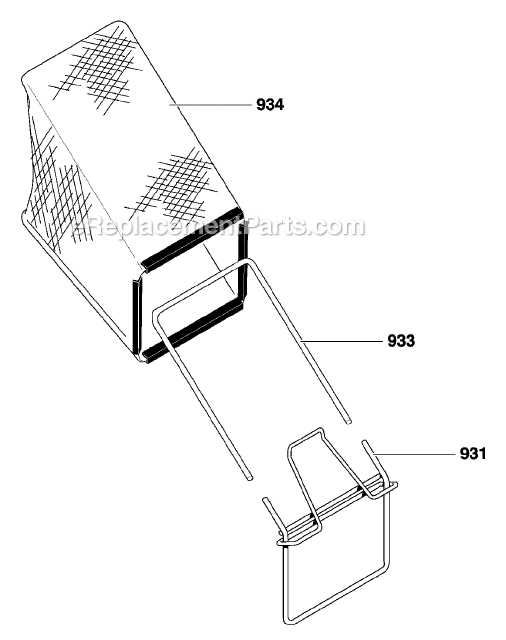

Guide to the Grass Catcher System

The grass catcher system is an essential feature designed to enhance the efficiency of cutting operations. By collecting clippings as you work, it helps maintain a tidy appearance in the yard while reducing the need for post-cutting clean-up. Understanding the components and functionality of this system can significantly improve your overall experience and performance.

Key Components of the Collection System

This system typically consists of several integral elements, including the catcher bag, frame, and attachment mechanism. The catcher bag is responsible for collecting the cut grass, while the frame supports the bag and keeps it securely in place during use. The attachment mechanism allows for easy installation and removal, making it convenient for users to switch between different functionalities.

Maintenance Tips for Optimal Performance

Regular maintenance is crucial to ensure the grass catcher system operates effectively. It is advisable to check the catcher bag for tears or blockages periodically. Cleaning the frame and attachment points can prevent dirt buildup, which may hinder performance. Additionally, ensuring that all components fit snugly together will enhance the efficiency of the collection process.

Throttle and Speed Adjustment Parts

This section focuses on components essential for regulating engine power and operational speed. Understanding these elements is crucial for maintaining optimal performance and efficiency in various outdoor equipment.

Key Components

At the heart of speed regulation are the throttle lever and cable, which connect the operator’s control to the engine’s carburetor. These components work together to modulate airflow, influencing the rate at which fuel is delivered and ultimately controlling the machinery’s pace.

Maintenance Considerations

Regular inspection and maintenance of these elements are vital for ensuring smooth operation. Lubrication of moving parts and checking for wear and tear can prevent potential issues, allowing for a seamless adjustment of speed during use.

Inspecting the Ignition and Electrical System

Maintaining the ignition and electrical components of your equipment is crucial for optimal performance. Regular inspections help ensure reliable operation, enhance longevity, and prevent unexpected breakdowns. By understanding the key elements involved, you can effectively troubleshoot and address any issues that may arise.

Key Components to Check

- Ignition Coil: Verify that the ignition coil is functioning properly, as it generates the high voltage needed to ignite the fuel-air mixture.

- Spark Plug: Inspect the spark plug for wear and carbon buildup. A clean and properly gapped plug is essential for efficient combustion.

- Wiring Harness: Examine the wiring harness for any signs of damage, corrosion, or loose connections that could disrupt electrical flow.

- Battery: If applicable, ensure the battery is charged and the terminals are clean and securely connected.

Steps for Effective Inspection

- Begin by disconnecting the power source to ensure safety during the inspection.

- Carefully examine each component, looking for signs of wear, damage, or corrosion.

- Clean connections and replace any faulty parts as needed to maintain a reliable ignition system.

- Reassemble all components and reconnect the power source, then perform a test to ensure proper functionality.

Maintaining the Oil and Lubrication Parts

Regular upkeep of the oil and lubrication components is essential for ensuring optimal performance and longevity of your equipment. Proper maintenance not only enhances efficiency but also prevents costly repairs and replacements. This section outlines the key practices for maintaining these critical systems.

Firstly, it is crucial to regularly check and change the lubricant, as it plays a vital role in reducing friction and wear between moving components. Ensuring that the oil level is adequate can prevent overheating and mechanical failures.

In addition, consider the following maintenance tasks:

| Task | Frequency | Description |

|---|---|---|

| Check Oil Level | Weekly | Inspect the oil level to ensure it meets the manufacturer’s specifications. |

| Change Oil | Every 25 hours | Replace the oil to keep the system clean and efficient. |

| Inspect Filters | Every 50 hours | Examine and clean or replace filters to maintain proper flow and function. |

| Grease Fittings | Every 10 hours | Apply grease to fittings to reduce wear on moving parts. |

By adhering to these maintenance guidelines, you will promote the reliability and performance of your machinery, ultimately extending its service life.