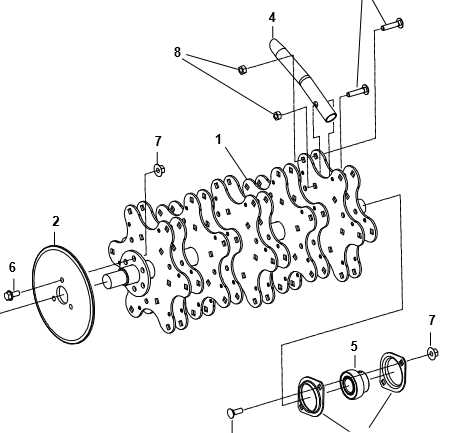

Comprehensive Parts Diagram for Ryan Lawnaire 28

In the world of outdoor maintenance, grasping the intricate makeup of machinery is vital for optimal performance. This knowledge not only enhances the efficiency of your tools but also extends their lifespan. A comprehensive overview of essential elements provides insight into how each piece contributes to the overall functionality.

Mastering the layout of these vital elements can lead to more effective troubleshooting and maintenance practices. By delving into the specific roles each component plays, users can navigate repairs with greater confidence and understanding. This ultimate familiarity fosters a deeper appreciation for the equipment’s design and purpose.

Whether you are a seasoned expert or a newcomer to the realm of lawn care, recognizing the significance of these mechanical parts will undoubtedly elevate your maintenance game. Embracing this knowledge transforms the way you interact with your tools, ensuring a more productive and satisfying experience.

Understanding the Ryan Lawnaire 28

Exploring the mechanics of this turf maintenance equipment reveals its essential role in ensuring optimal lawn care. A thorough grasp of its components and functionality enhances efficiency and effectiveness in various landscaping tasks.

| Component | Description |

|---|---|

| Engine | Provides the power needed for operation. |

| Blades | Designed for precise cutting and aeration. |

| Handle | Ensures user comfort and control during use. |

| Deck | Houses the cutting mechanism and aids in grass collection. |

| Wheels | Facilitates mobility across various terrains. |

Key Features of the Lawnaire 28

This innovative machine is designed to optimize lawn care with a blend of efficiency and functionality. Its robust construction and user-friendly interface ensure that it meets the demands of both professional landscapers and homeowners alike.

Powerful Engine: Equipped with a high-performance engine, this model provides exceptional reliability and speed, enabling users to tackle extensive areas quickly.

Ergonomic Design: The thoughtfully crafted handle and controls reduce operator fatigue, allowing for longer working sessions without discomfort.

Durable Build: Made from high-quality materials, this equipment offers longevity and resilience against wear and tear, making it a worthwhile investment.

Versatile Functionality: Capable of performing various tasks, this machine adapts seamlessly to different lawn care needs, from aerating to dethatching.

Easy Maintenance: Designed with accessibility in mind, routine upkeep is straightforward, ensuring optimal performance throughout its lifespan.

Importance of Parts Diagrams

Understanding the various components of a machine is crucial for efficient maintenance and repair. Visual representations of these elements offer significant advantages, helping users identify and manage each section effectively. Such illustrations serve as a key resource for technicians and operators alike, facilitating quicker problem-solving and enhancing overall operational efficiency.

Benefits of Visual Representations

Utilizing graphical layouts allows for improved clarity and communication among team members. These visuals simplify complex structures, making it easier for individuals to comprehend the relationships between different components. By providing a clear reference point, users can quickly locate specific elements and determine their functionality within the system.

Streamlining Maintenance Processes

Effective maintenance is essential for any operational equipment. Graphical guides assist technicians in identifying wear and tear or other issues. This proactive approach reduces downtime and minimizes repair costs, ultimately leading to increased productivity. Moreover, having a reliable reference enhances the training of new personnel, allowing them to become proficient in handling the equipment more swiftly.

| Advantage | Description |

|---|---|

| Enhanced Understanding | Clarifies the relationships between various components. |

| Quick Reference | Provides immediate access to essential information. |

| Improved Efficiency | Reduces the time needed for troubleshooting and repairs. |

| Training Aid | Helps onboard new employees with visual guidance. |

Common Issues with the Lawnaire 28

In any specialized equipment, certain recurring problems can arise that impact performance and efficiency. Understanding these challenges is essential for effective maintenance and troubleshooting. This section explores typical concerns encountered with this specific model, offering insights into their causes and potential solutions.

1. Engine Performance Issues

Many users report a decline in engine efficiency over time. This can stem from clogged filters or stale fuel. Regular inspection and maintenance of fuel components are crucial to ensure optimal operation.

2. Drive Belt Wear

The drive belt is a vital component that can experience wear and tear due to continuous use. Signs of fraying or cracking should prompt immediate replacement to prevent further mechanical failures.

3. Uneven Aeration

A common problem involves inconsistent soil aeration, which may be attributed to improper adjustment of the equipment or worn tines. Ensuring the tines are in good condition and correctly calibrated can enhance aeration effectiveness.

4. Electrical Failures

Electrical components, such as ignition systems, may occasionally malfunction, leading to starting issues. Regular checks of the electrical wiring and connections can help identify potential problems before they escalate.

5. Tire Wear and Pressure

Maintaining proper tire pressure is essential for stability and performance. Uneven wear can affect handling, making it important to regularly inspect and rotate tires as needed.

By addressing these common issues proactively, operators can extend the lifespan of their equipment and maintain its efficiency for various landscaping tasks.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan and optimal performance of any equipment. Implementing a few strategic practices can greatly enhance durability and efficiency over time.

- Clean the unit frequently to prevent debris buildup.

- Inspect components regularly for signs of wear or damage.

- Lubricate moving parts as recommended to reduce friction.

- Check and replace filters to maintain air quality and flow.

- Store the equipment properly during off-seasons to prevent deterioration.

By adhering to these guidelines, users can significantly extend the useful life of their machinery and ensure it operates at its ultimate potential.

Replacing Worn Out Components

Maintaining equipment in optimal condition is crucial for ensuring efficient performance. Over time, certain elements may deteriorate, leading to decreased functionality and potential failures. Identifying and replacing these components can significantly enhance the lifespan of your machinery.

Here are key signs that indicate a need for replacement:

- Unusual noises during operation

- Reduced efficiency or performance

- Visible wear or damage

- Frequent breakdowns or malfunctions

When considering replacements, follow these essential steps:

- Assess the condition of each component.

- Source high-quality replacements from reliable suppliers.

- Carefully remove the worn parts, ensuring no further damage occurs.

- Install the new components following manufacturer guidelines.

- Test the machinery to confirm proper function.

By regularly evaluating and updating your equipment, you can prevent costly repairs and enhance overall performance.

Tools Needed for Repairs

When it comes to maintenance tasks, having the right equipment is essential for achieving optimal results. Proper tools not only streamline the repair process but also enhance efficiency and safety.

Essential tools for any repair project typically include wrenches, screwdrivers, and pliers. Each item plays a crucial role in handling various components effectively.

Additionally, having a reliable set of measuring instruments ensures accuracy, which is vital for successful outcomes. Don’t forget safety gear, such as gloves and goggles, to protect yourself during the process.

By equipping yourself with the necessary tools, you can delve deeper into repairs with confidence, ultimately achieving a more satisfying experience.

Identifying Each Part’s Function

Understanding the role of each component in a system is crucial for effective maintenance and operation. Each element serves a specific purpose, contributing to the overall efficiency and performance. Recognizing these functions not only aids in troubleshooting but also enhances the user experience.

Power Source: This element provides the necessary energy to operate the machinery. Its reliability ensures consistent performance and prevents interruptions.

Control Mechanism: This component regulates the operation, allowing the user to manage settings and adapt the performance according to specific needs. A well-designed control system enhances usability and precision.

Cutting Mechanism: Essential for executing tasks, this part performs the actual work, whether it involves trimming, cutting, or shaping. Its design affects the quality of the output and overall effectiveness.

Support Structure: Providing stability, this framework holds the various elements in place, ensuring that everything operates smoothly. Its robustness is vital for the longevity of the equipment.

Safety Features: These components are critical for protecting the user and the equipment from potential hazards. Proper functioning of safety mechanisms is imperative for maintaining a secure working environment.

By familiarizing oneself with these functions, users can ensure optimal operation and longevity of their equipment, leading to improved results and satisfaction.

Best Practices for Assembly

Ensuring optimal performance during the assembly process is crucial for longevity and functionality. Adhering to specific guidelines can significantly enhance the overall effectiveness of the assembled unit.

Preparation Steps

Before beginning the assembly, gather all necessary tools and components. Organizing the workspace helps minimize errors and increases efficiency. Additionally, reviewing the manual or guide beforehand can provide valuable insights into the assembly process.

Assembly Techniques

Employ systematic techniques to ensure proper fitting and alignment. Always tighten connections securely but avoid overtightening, which can lead to damage. Regularly check for proper alignment throughout the process to ensure a smooth operation.

| Step | Action |

|---|---|

| 1 | Gather all tools and components. |

| 2 | Organize your workspace. |

| 3 | Review the assembly guide. |

| 4 | Assemble systematically. |

| 5 | Check for alignment regularly. |

Where to Find Replacement Parts

Finding components for maintenance or repair can be a daunting task, but it is essential for ensuring optimal performance. Whether you’re looking for specific elements to fix a malfunctioning machine or upgrade its functionality, knowing where to look can save time and money. This section will guide you through various resources and strategies to help you locate the items you need.

Online Retailers

The internet offers a plethora of options for sourcing the necessary components. Numerous e-commerce platforms specialize in providing a wide range of equipment and accessories. Utilizing search engines to identify reputable online stores can lead you to various suppliers, often featuring customer reviews and ratings to assist in your decision-making process.

Local Dealers and Repair Shops

Visiting local dealerships or repair shops can also be beneficial. These establishments typically carry a selection of components or can order specific items for you. Additionally, staff members often possess valuable expertise and can recommend suitable alternatives or compatible options that might enhance your equipment’s performance.

Upgrading Components for Performance

Enhancing the functionality of your equipment often involves replacing certain elements with superior alternatives. By selecting components that offer improved efficiency, durability, or adaptability, you can significantly boost overall performance. This process not only maximizes the operational capacity but also extends the lifespan of the machinery.

Key Components to Consider

When planning an upgrade, it is essential to identify which parts can benefit from enhancement. Focus on elements that contribute to performance, such as the engine, transmission, and control systems. Below is a table summarizing potential upgrades and their expected benefits:

| Component | Upgrade Option | Benefits |

|---|---|---|

| Engine | High-Performance Filter | Increased airflow, improved efficiency |

| Transmission | Enhanced Gear Ratio | Better torque management, smoother shifting |

| Control System | Advanced ECU | Optimized fuel management, increased responsiveness |

Conclusion

Investing in upgraded components can yield significant improvements in performance. By making informed choices and focusing on critical areas, you can achieve a noticeable enhancement in your equipment’s capabilities, ensuring it meets the demands of any task with greater efficiency.

Expert Insights on Troubleshooting

Effective troubleshooting is an essential skill that enables operators to identify and resolve issues efficiently. By understanding the underlying mechanisms and employing a systematic approach, one can minimize downtime and enhance performance. This section offers practical insights and techniques to assist in diagnosing common challenges.

Common Issues and Solutions

- Engine Performance: If the engine is running poorly, check the fuel supply and air filters. Ensure that all connections are secure.

- Electrical Failures: Inspect wiring and connections for signs of wear or damage. Use a multimeter to test for continuity.

- Mechanical Problems: Look for unusual noises or vibrations that may indicate wear. Lubricate moving parts regularly to prevent friction-related issues.

Steps for Effective Diagnosis

- Gather information: Review operational manuals and maintenance logs for prior issues.

- Perform visual inspections: Check for visible damage or loose components.

- Conduct systematic tests: Isolate each system or component to pinpoint the source of the problem.

- Document findings: Keep detailed records of issues and resolutions for future reference.

By following these guidelines, operators can streamline the troubleshooting process, leading to quicker resolutions and improved operational efficiency.

Benefits of Regular Inspections

Conducting routine evaluations of equipment and machinery is essential for maintaining optimal performance and longevity. These assessments help identify potential issues before they escalate, ensuring that operations run smoothly and efficiently.

One of the primary advantages of regular inspections is the prevention of costly breakdowns. By detecting wear and tear early, businesses can avoid emergency repairs that not only disrupt workflows but also strain budgets. Furthermore, consistent check-ups contribute to enhanced safety standards, reducing the risk of accidents and ensuring a secure environment for workers.

Another significant benefit is improved efficiency. Regular evaluations allow for fine-tuning of equipment, leading to better performance and energy savings. This not only enhances productivity but also contributes to environmental sustainability by minimizing unnecessary energy consumption.

Lastly, these inspections foster a culture of proactive maintenance within an organization. Employees become more aware of the importance of equipment care, leading to a more responsible approach to operational practices. This shift not only enhances team morale but also aligns with long-term organizational goals.