Understanding Weed Eater Lawn Mower Parts Diagrams

When it comes to maintaining a pristine garden or yard, the intricacies of various machinery play a crucial role. Familiarity with the components and their interconnections enhances efficiency and prolongs the lifespan of these tools. A thorough comprehension of how each element functions can empower users to tackle repairs and improvements with confidence.

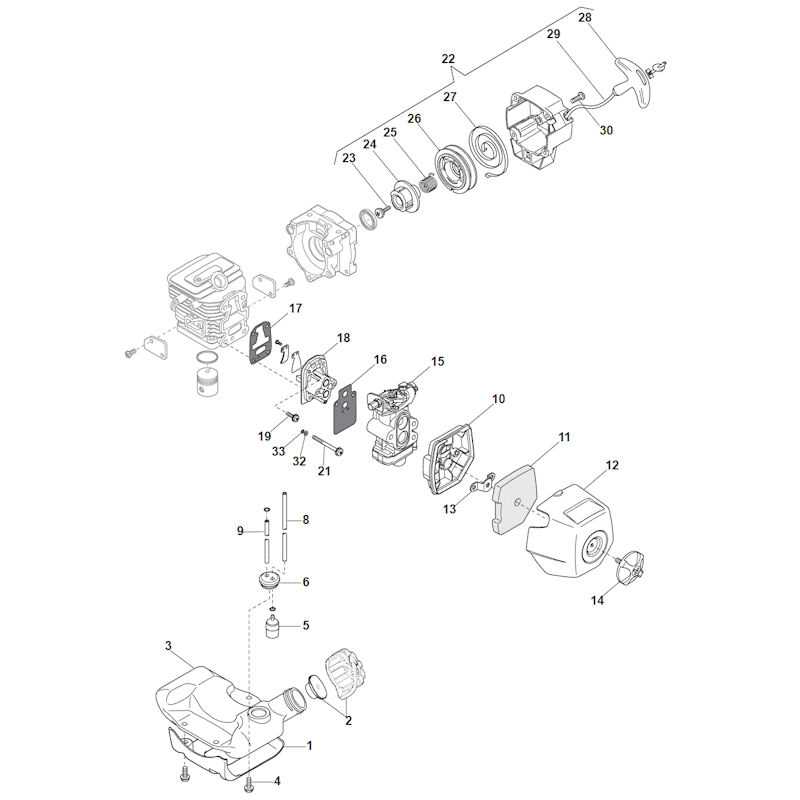

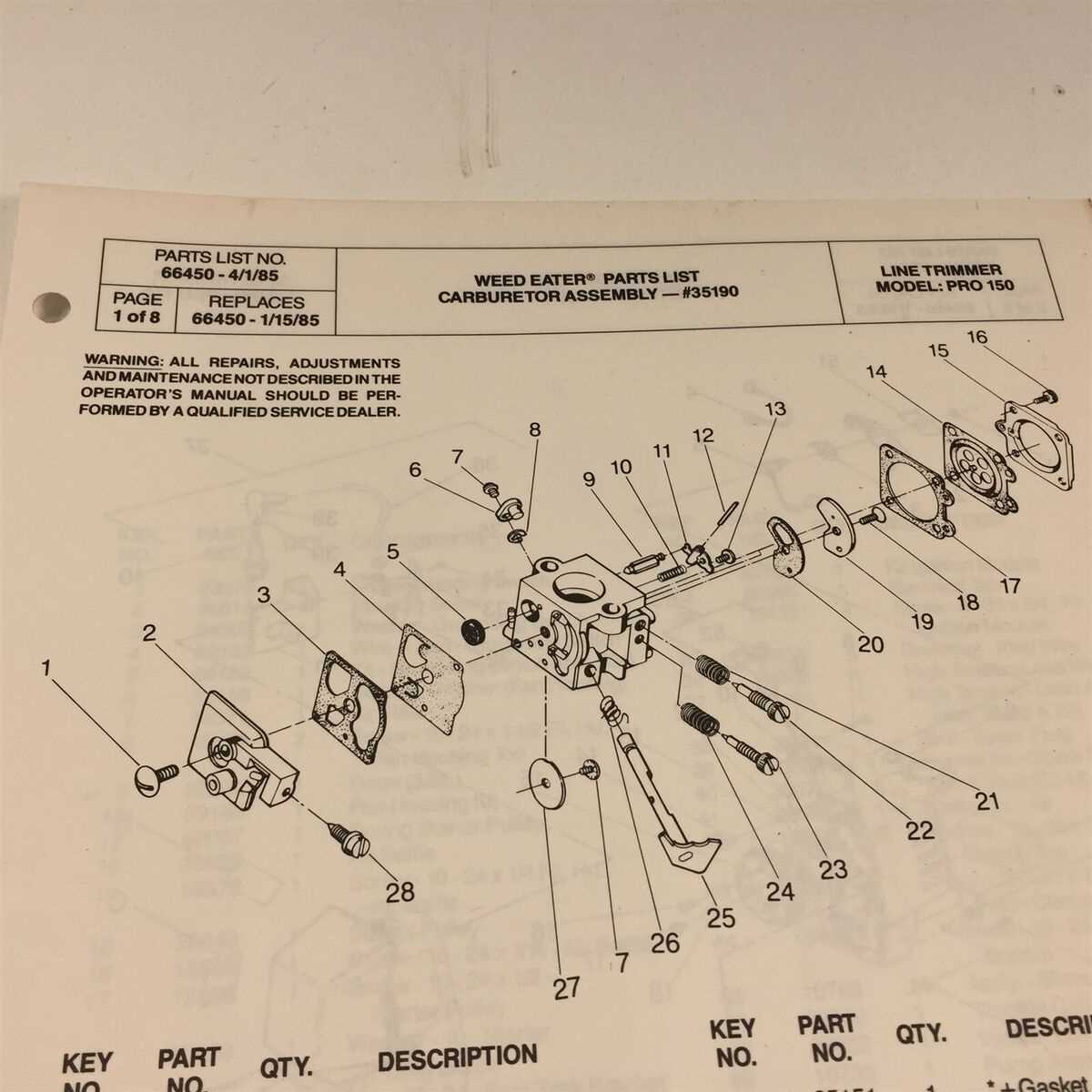

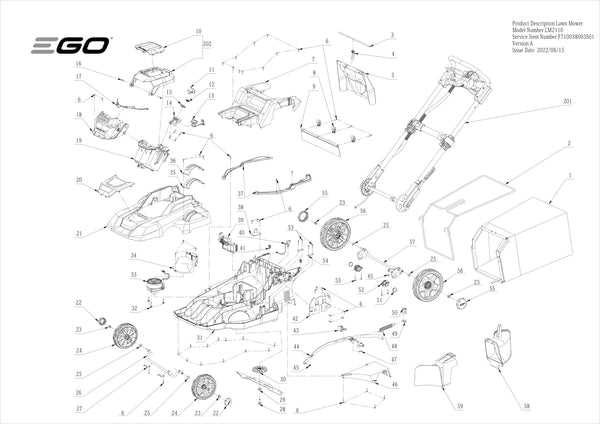

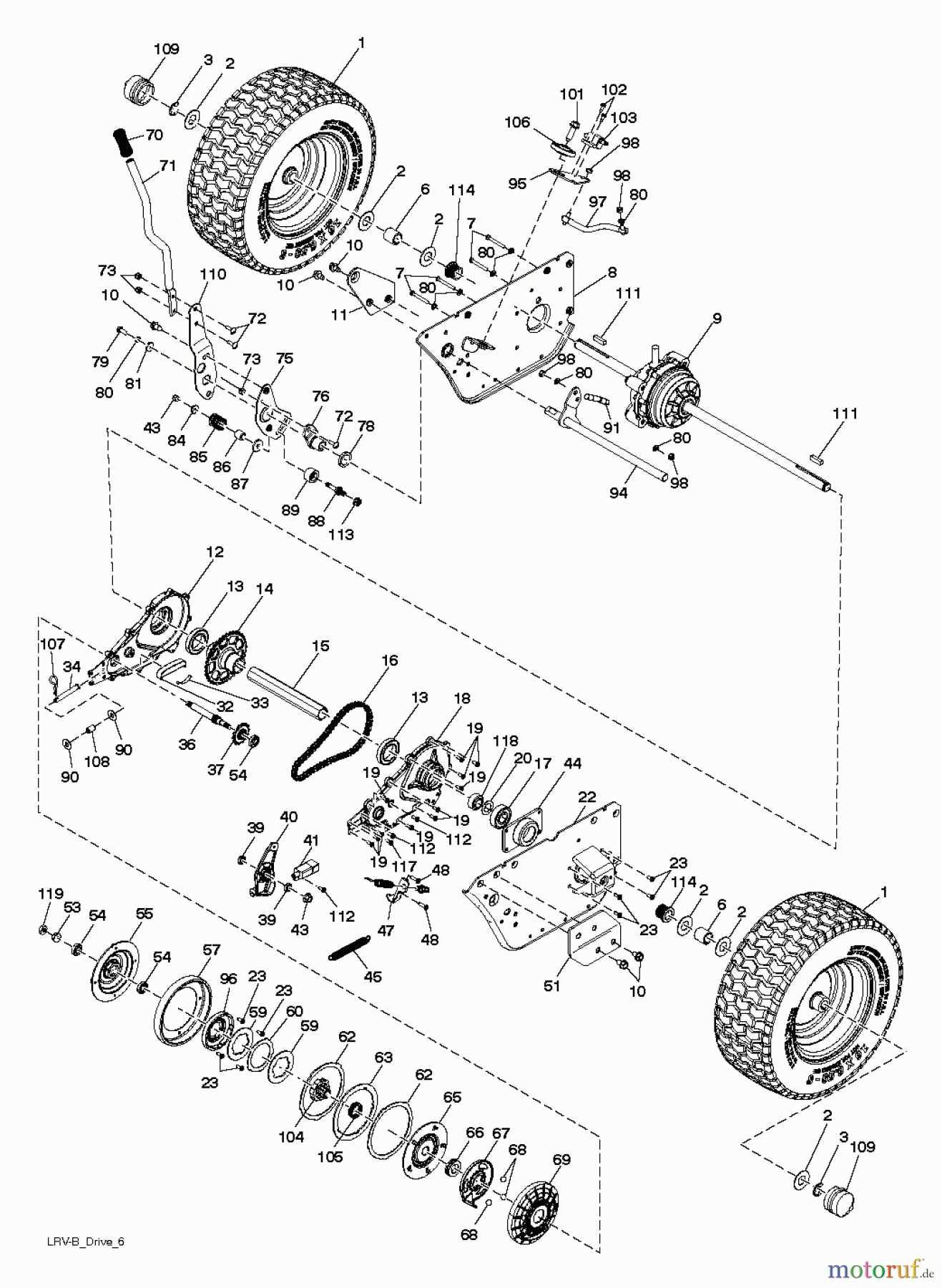

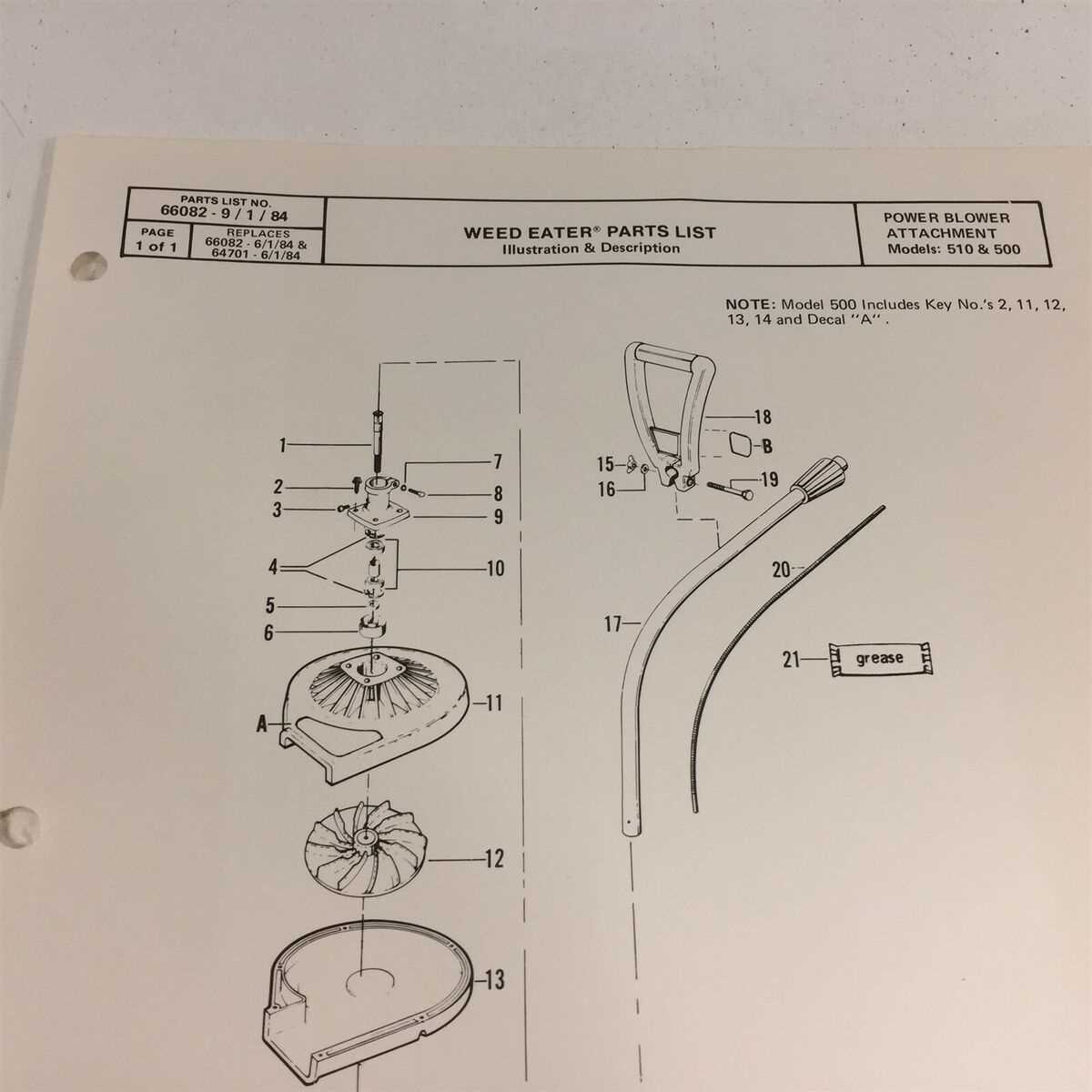

Detailed visual representations serve as invaluable resources for both novice and experienced operators. These illustrations illuminate the relationships between different elements, enabling better troubleshooting and facilitating routine maintenance. By diving into these visual aids, one can develop a more profound appreciation for the mechanics at play.

Moreover, an understanding of these designs fosters a more proactive approach to upkeep. Recognizing potential issues before they escalate can save time and resources. Equipped with this knowledge, enthusiasts can ensure their equipment remains in optimal condition, ready to tackle the challenges of outdoor upkeep.

Understanding Weed Eater Lawn Mowers

This section delves into the functionality and components of specialized outdoor cutting equipment. These machines are essential for maintaining a neat and tidy landscape, allowing users to efficiently trim overgrown areas. Familiarity with their mechanisms enhances operational efficiency and prolongs the lifespan of the equipment.

Key Components

Each machine comprises several critical elements that work together to achieve optimal performance. The engine provides the necessary power, while the cutting mechanism is designed for precision and effectiveness. Additionally, the handle and support structures ensure comfort and control during operation.

Maintenance Tips

Regular upkeep is vital for sustaining the functionality of these devices. Cleaning the cutting mechanism, checking the fuel system, and inspecting the overall condition can prevent malfunctions. Understanding these maintenance practices not only improves performance but also enhances safety during use.

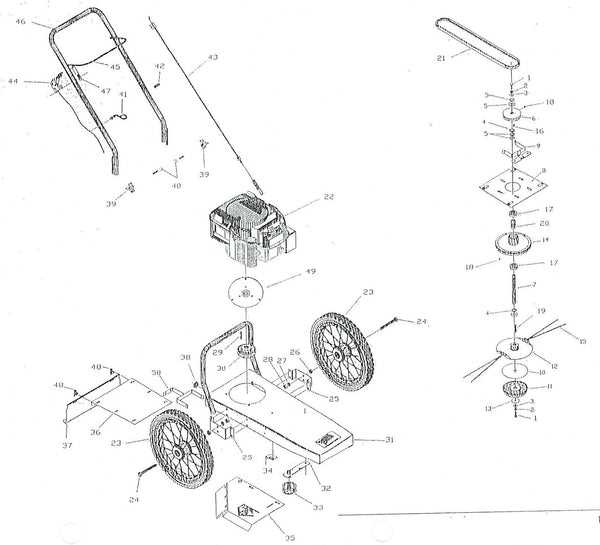

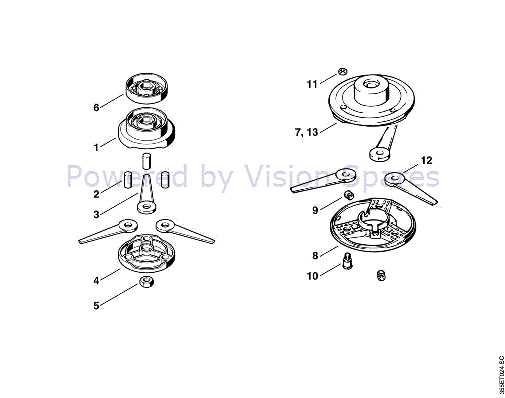

Common Parts of Lawn Mowers

This section explores the essential components that contribute to the functionality and efficiency of grass cutting machines. Understanding these elements can aid in maintenance and repairs, ensuring optimal performance during operation.

| Component | Description |

|---|---|

| Blade | The cutting tool that trims grass and vegetation to the desired height. |

| Engine | The power source that drives the machine, typically fueled by gasoline or electricity. |

| Deck | The housing that encases the cutting blade, providing a streamlined design for grass collection. |

| Handle | The part used for maneuvering the machine, often adjustable for comfort. |

| Wheels | The components that allow for mobility across different terrains. |

| Grass Collector | A bag or container that collects cut grass for easy disposal. |

| Throttle | The control mechanism for regulating the engine speed and cutting intensity. |

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair processes of various equipment. These illustrations provide a clear understanding of the assembly and function of each segment, enabling users to efficiently identify and address issues that may arise.

By utilizing these schematics, individuals can streamline their repair efforts, ensuring that the correct components are targeted during troubleshooting. This not only saves time but also minimizes the risk of errors that could lead to further complications.

Moreover, having access to these visuals enhances the learning experience for those unfamiliar with the machinery. They serve as a valuable resource, fostering confidence and skill development in both novice and experienced users.

Ultimately, comprehensive visual guides are indispensable for anyone looking to maintain equipment effectively, ensuring longevity and optimal performance through informed decision-making.

How to Read Diagrams Effectively

Understanding schematics can significantly enhance your ability to perform repairs and maintenance on various equipment. Familiarizing yourself with these visual representations will allow you to quickly identify components and their functions, leading to more efficient troubleshooting.

Here are some strategies to improve your diagram-reading skills:

- Familiarize with Symbols: Different diagrams utilize specific symbols to represent various elements. Take time to learn what these symbols mean.

- Study the Layout: Notice how components are arranged. This can provide insights into their relationships and interactions.

- Follow Flow Directions: Many diagrams illustrate the flow of energy or materials. Pay attention to arrows and lines that indicate movement.

To further enhance your comprehension, consider the following steps:

- Take Notes: Jot down any unfamiliar terms or symbols as you study the schematic.

- Cross-Reference: Use manufacturer manuals or online resources to validate your understanding of the components.

- Practice: Regularly engage with different types of schematics to build confidence and proficiency.

By applying these techniques, you can navigate complex visuals with ease, leading to more successful repairs and maintenance tasks.

Identifying Worn Components

Recognizing deteriorated elements in your garden maintenance equipment is crucial for optimal performance. Over time, certain components can become less effective, impacting the overall efficiency of the machine. Understanding how to spot these signs of wear can save you both time and resources in the long run.

Visual Inspection is the first step. Look for any visible signs of damage, such as cracks, breaks, or excessive wear on various components. Pay close attention to those areas that experience the most stress during operation, as these are likely to show the earliest signs of fatigue.

Functional Testing is equally important. If you notice any decrease in performance, such as reduced power or difficulty in operation, it may indicate that certain parts have worn down. Conducting regular tests can help identify these issues before they escalate.

Maintenance Logs can also provide valuable insights. Keeping track of when components were last replaced or serviced can highlight patterns in wear and help predict when replacements might be necessary. This proactive approach can enhance the longevity of your equipment.

Lastly, consulting the manufacturer’s guidelines can offer specific indicators of component lifespan. Many manufacturers provide recommendations on when to inspect or replace parts, ensuring your equipment remains in peak condition.

Replacement Parts: What to Know

When it comes to maintaining outdoor equipment, understanding how to source and replace essential components is crucial. Ensuring that each element functions optimally not only prolongs the life of your machine but also enhances its performance. This section provides guidance on key considerations for acquiring substitutes that suit your specific model.

Compatibility is the first aspect to examine. Not all components are interchangeable, so it is vital to verify that the replacements align with your equipment’s specifications. Refer to the user manual or manufacturer’s website for precise details about the required elements.

Quality is another critical factor. Opting for high-grade materials can significantly affect the durability and efficiency of your machine. While it may be tempting to choose cheaper alternatives, investing in reputable brands often yields better long-term results.

Availability is also important. Check various retailers, both online and offline, to find the best options. Some parts may be readily available, while others could require special ordering, which might impact your maintenance schedule.

Lastly, installation should be considered. While some components can be easily replaced by the owner, others may require professional assistance. Assess your skills and tools before attempting any replacements to avoid unnecessary complications.

Tools for Lawn Mower Repair

Maintaining and fixing outdoor machinery requires the right equipment to ensure efficiency and precision. A variety of instruments are essential for performing various tasks, from minor adjustments to major overhauls. Understanding which tools to use can significantly simplify the repair process and enhance the lifespan of your equipment.

Essential Instruments

To tackle repairs effectively, having a selection of basic tools is crucial. A reliable wrench set allows for the tightening and loosening of bolts, while a good screwdriver set can handle various fasteners found in the machinery. Additionally, a socket set is invaluable for reaching difficult spots and ensuring a secure fit on nuts and bolts.

Advanced Equipment

For more complex repairs, specialized tools may be necessary. A multimeter is essential for diagnosing electrical issues, while a spark plug wrench ensures proper ignition system maintenance. Investing in a toolbox organizer can help keep your instruments neatly arranged, making it easier to find what you need when it matters most.

Maintaining Your Mower’s Performance

Ensuring optimal functionality of your cutting equipment is essential for achieving a pristine outdoor space. Regular upkeep not only extends the life of your machinery but also enhances its efficiency. Understanding the components and their care will significantly contribute to the overall performance.

Key Maintenance Tips

To keep your device in peak condition, consider the following recommendations:

| Task | Frequency | Description |

|---|---|---|

| Inspect Blades | Every Use | Check for sharpness and damage; sharpen or replace as needed. |

| Clean Air Filter | Monthly | Remove debris to ensure optimal airflow and engine performance. |

| Check Fuel Level | Every Use | Ensure proper fuel quality and fill levels to avoid engine issues. |

| Change Oil | Every 25 Hours | Replace oil to maintain engine health and efficiency. |

| Tighten Fasteners | Monthly | Inspect and secure all nuts and bolts to prevent vibrations and damage. |

Seasonal Considerations

Adjust your maintenance schedule based on seasonal changes. In the spring, thorough cleaning and blade sharpening prepare your equipment for the busy months ahead. Conversely, autumn should focus on storage and winterization to protect against environmental factors.

Safety Tips for Lawn Mower Repair

When undertaking repairs on outdoor equipment, it is crucial to prioritize safety to prevent accidents and injuries. Following proper guidelines ensures a secure working environment, allowing for effective and efficient maintenance of your machinery.

Preparation and Inspection

Before beginning any repair work, ensure you are wearing appropriate personal protective equipment, such as gloves and safety goggles. Inspect the equipment for any potential hazards, including leaks or frayed wires. Always disconnect the power source to avoid unintended activation during the repair process.

Tool Usage and Maintenance

Utilize the correct tools for each task, as this minimizes the risk of injury and damage to components. Keep your tools in good condition, ensuring they are sharp and functioning properly. Always read the manufacturer’s guidelines before attempting repairs, and when in doubt, consult a professional.

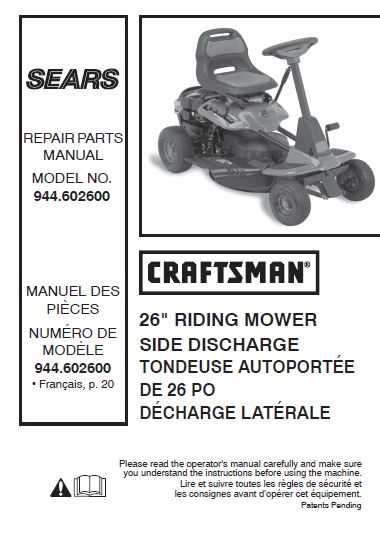

Where to Find Diagrams Online

Locating detailed illustrations and schematics for your gardening equipment can greatly enhance your understanding of how to maintain and repair it. There are numerous resources available online that cater to those seeking visual guides for their machinery.

Online Resources

- Manufacturer Websites: Many companies provide comprehensive resources, including schematics, user manuals, and maintenance guides directly on their official sites.

- Repair Forums: Community-driven forums often feature shared experiences and diagrams from other users, making them invaluable for troubleshooting.

- Parts Retailers: Websites specializing in equipment components frequently offer diagrams to assist customers in identifying the correct parts for their needs.

- Instructional Videos: Platforms like YouTube host numerous tutorials that visually break down the components of various machines, often accompanied by diagrams in the video descriptions.

Search Tips

- Use specific terms related to your equipment when searching to find more relevant resources.

- Combine terms with “manual” or “schematic” for more precise results.

- Check multiple sources to compare illustrations and ensure accuracy.

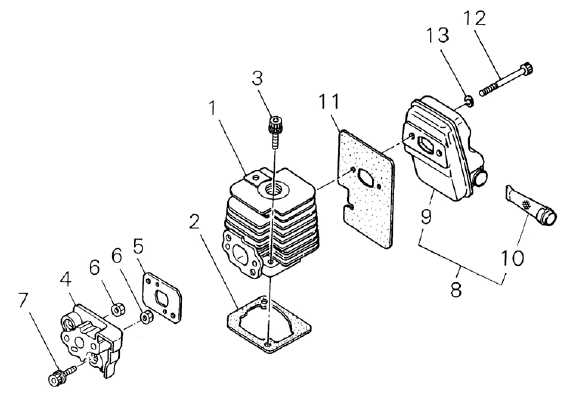

Understanding Engine Components

Engines are intricate systems that convert fuel into mechanical energy, driving various equipment and vehicles. To comprehend how these mechanisms function, it’s essential to familiarize oneself with the primary elements that constitute their structure. Each component plays a vital role in ensuring optimal performance and efficiency.

Key Components of an Engine

- Crankshaft: Transforms linear motion into rotational movement.

- Piston: Moves up and down within the cylinder, creating pressure for combustion.

- Cylinder: Houses the piston and is where the fuel-air mixture ignites.

- Camshaft: Regulates the opening and closing of valves.

- Valves: Control the flow of air and fuel into the cylinder and exhaust out.

- Spark Plug: Ignites the fuel-air mixture to initiate combustion.

The Role of Each Component

- Crankshaft: Converts energy generated by combustion into usable mechanical power.

- Piston: Compresses the fuel-air mixture, enhancing efficiency and power output.

- Cylinder: Ensures a controlled environment for combustion, affecting engine performance.

- Camshaft: Synchronizes the timing of valve movements with the piston’s position.

- Valves: Optimize the intake and exhaust process, impacting engine responsiveness.

- Spark Plug: Essential for ignition, influencing starting and running efficiency.

Understanding these components is crucial for diagnosing issues and performing maintenance, ultimately leading to enhanced longevity and functionality of the machinery involved.

Seasonal Maintenance Checklist

Regular upkeep of your outdoor equipment ensures optimal performance and longevity. Following a seasonal maintenance checklist can help you identify any issues early and keep your tools in peak condition throughout the year.

Spring Preparation

- Inspect all components for wear and tear.

- Clean the exterior and interior to remove debris.

- Change the oil and replace the filter if applicable.

- Sharpen blades to ensure clean cutting.

- Check fuel lines for cracks and leaks.

Fall Wrap-Up

- Thoroughly clean equipment after use.

- Drain fuel or add a stabilizer to prevent degradation.

- Inspect and tighten any loose fasteners.

- Store in a dry, sheltered area to avoid moisture damage.

- Review and plan for any needed replacements before the next season.

Upgrading Your Mower’s Features

Enhancing the capabilities of your machine can significantly improve its performance and efficiency. By incorporating modern upgrades, you can ensure that your equipment meets current standards and provides a better user experience.

Here are some features to consider when looking to enhance your device:

- Engine Power: Upgrading to a more powerful engine can enhance cutting performance and reduce operational time.

- Blade Technology: Consider swapping out blades for higher-quality options that provide a cleaner cut and better durability.

- Ergonomic Handles: Improving handle design can enhance comfort during use, reducing fatigue.

- Mulching Capabilities: Adding or upgrading to a mulching kit can allow for better grass recycling, improving soil health.

- Bagging Systems: An efficient bagging system can help maintain a tidy area by collecting clippings and debris.

When upgrading, ensure compatibility with your existing model. Research options and choose upgrades that align with your specific needs and preferences. A well-equipped machine not only saves time but also enhances the overall experience.