Comprehensive Lincoln 180 Parts Diagram Guide

In the world of vintage machinery, understanding the intricate arrangements of various elements is crucial for enthusiasts and restorers alike. The layout of these components not only enhances functionality but also plays a significant role in the overall maintenance and longevity of the equipment. By delving into the specifics of how different pieces interact, users can gain insights into optimizing performance and ensuring reliable operation.

Accurate representation of each segment serves as a valuable resource for anyone engaged in restoration or repair tasks. These visual aids facilitate a deeper comprehension of how individual elements fit together, making troubleshooting more intuitive. With a well-structured overview, both novice and experienced operators can navigate the complexities of their machinery with greater confidence.

Additionally, exploring these layouts promotes a sense of community among enthusiasts, as sharing knowledge about assembly and functionality fosters collaboration. By connecting with others who share similar interests, individuals can enhance their understanding and appreciation of these remarkable machines. This journey into the heart of classic equipment not only preserves history but also cultivates a passion for craftsmanship.

Understanding Lincoln 180 Parts Diagram

This section explores the intricacies of mechanical components for a specific welding machine, providing insights into their arrangement and functionality. Understanding the layout of these elements is essential for effective maintenance and operation.

Key Components Overview

Familiarity with each element enhances troubleshooting skills and improves the overall efficiency of the equipment. Below is a brief description of the major components:

| Component | Description |

|---|---|

| Electrode Holder | Used to grip the electrode securely during welding. |

| Ground Clamp | Provides a stable electrical connection to the workpiece. |

| Power Source | Supplies the necessary voltage and current for welding. |

| Cooling Fan | Prevents overheating of internal components during operation. |

Importance of Understanding Layout

Grasping the configuration of these components allows users to perform more efficient repairs and adjustments. It ultimately contributes to better performance and longevity of the welding apparatus.

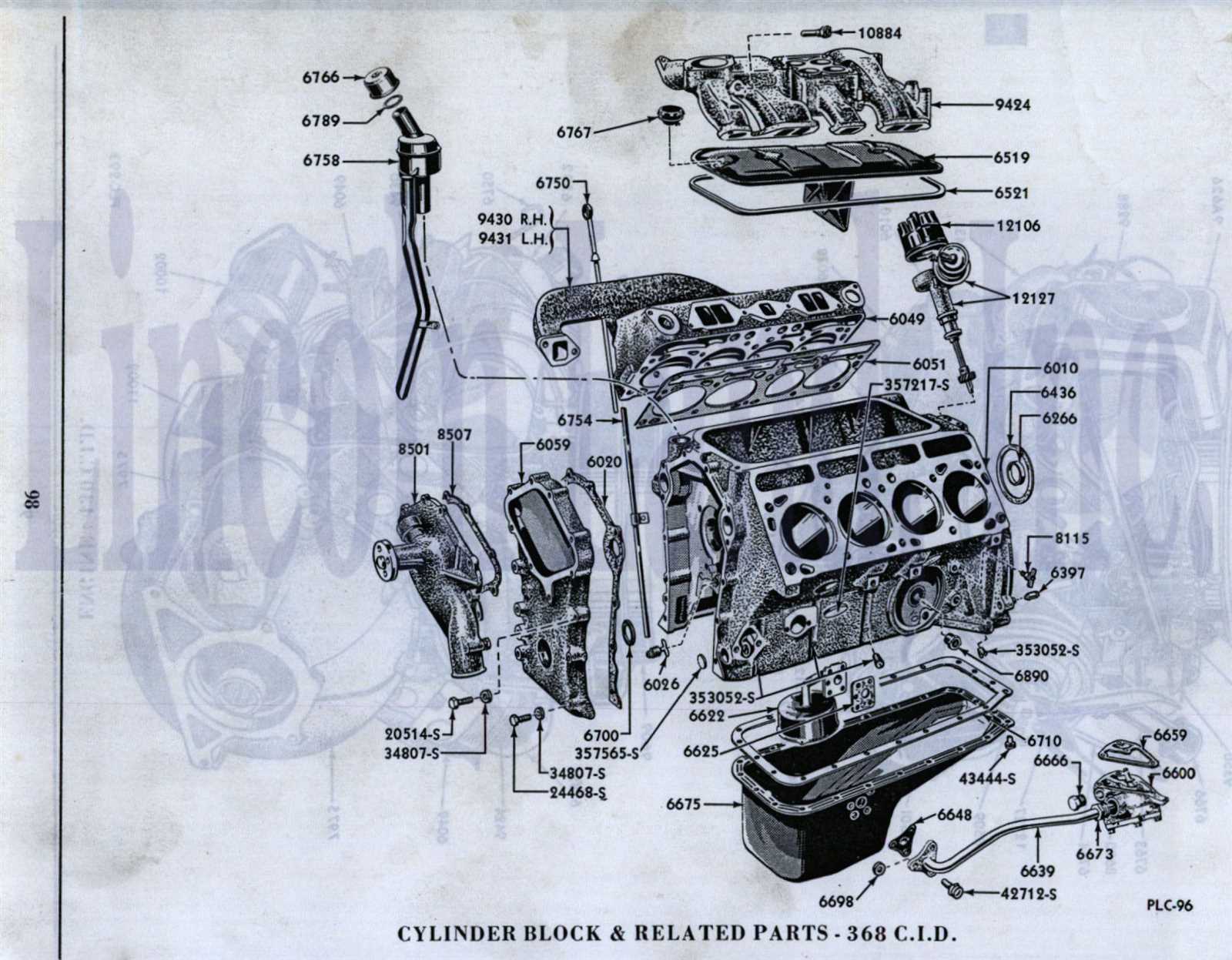

Overview of Lincoln 180 Components

This section provides an in-depth look at the essential elements that make up a popular welding machine. Understanding these components is crucial for users aiming to enhance their skills and ensure optimal performance. Each part plays a significant role in the functionality and efficiency of the device.

Power Supply: The source of energy, typically converting electrical input into usable output for welding processes.

Welding Gun: A crucial tool that directs the filler material and shielding gas, essential for achieving strong welds.

Control Panel: The interface for operators, allowing adjustments to settings like voltage and wire feed speed for precise control during operation.

Cooling System: Maintains optimal operating temperatures, preventing overheating and ensuring longevity of the equipment.

Chassis: The frame that supports and houses all components, providing stability and protection during use.

Feed Mechanism: Responsible for transporting the filler material to the welding area, influencing the quality and speed of the welding process.

By delving into these components, users can appreciate how each contributes to the ultimate functionality and reliability of the machine.

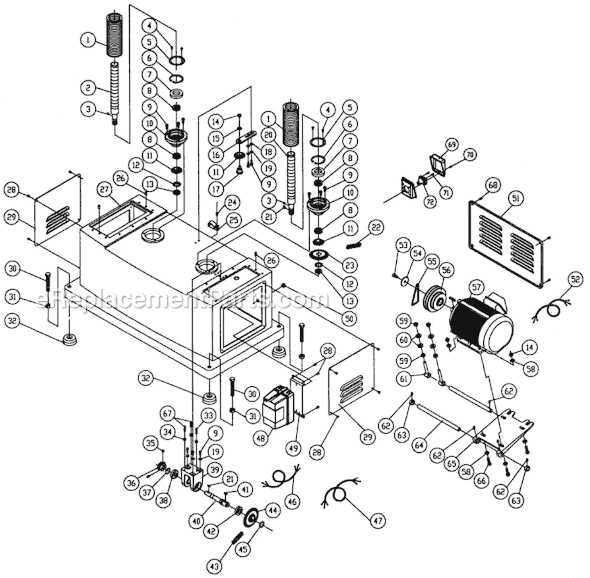

Importance of Accurate Diagrams

Precise visual representations are essential for effective communication in technical fields. They serve as crucial references for understanding complex systems and ensure that all components are correctly identified and assembled. Without clarity in these illustrations, the risk of errors increases significantly, potentially leading to inefficiencies and costly mistakes.

Enhanced Understanding

Well-crafted visuals facilitate a deeper comprehension of intricate structures. They break down complicated information into manageable segments, allowing users to grasp how each element fits into the overall mechanism. This clarity is vital for both novices and experienced professionals, ensuring everyone is on the same page when discussing or working with the system.

Streamlined Processes

Accurate visuals also contribute to more efficient workflows. By providing clear guidance, they minimize confusion and reduce the time spent troubleshooting issues. Teams can quickly locate and rectify problems, which ultimately leads to smoother operations and improved productivity.

| Benefit | Description |

|---|---|

| Clarity | Eliminates ambiguity in understanding complex systems. |

| Efficiency | Reduces time spent on repairs and troubleshooting. |

| Collaboration | Ensures all team members are aligned in their understanding. |

| Training | Acts as a valuable resource for onboarding new personnel. |

Common Parts in Lincoln 180

This section explores essential components commonly found in a specific welding machine model. Understanding these elements is crucial for maintenance and repair, ensuring optimal performance and longevity.

Key Components

Among the various elements, several play a vital role in the functionality and efficiency of the device. Familiarity with these components aids users in troubleshooting and enhancing their welding experience.

| Component Name | Function |

|---|---|

| Electrode Holder | Holds the welding rod securely during operation. |

| Ground Clamp | Establishes a connection to the workpiece to complete the circuit. |

| Power Supply | Provides the necessary energy for the welding process. |

| Cooling Fan | Prevents overheating by circulating air around critical parts. |

| Welding Torch | Delivers heat and electrode to the joint being welded. |

Conclusion

Recognizing these fundamental elements enhances one’s ability to operate and maintain the welding equipment effectively, ultimately leading to improved results and efficiency.

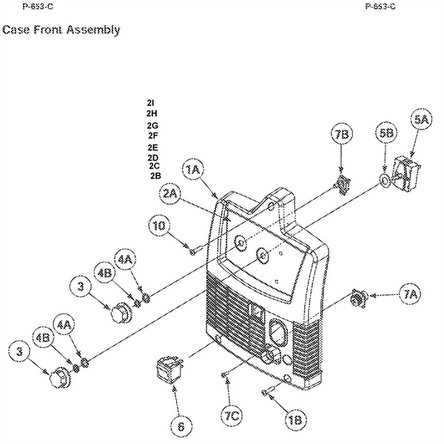

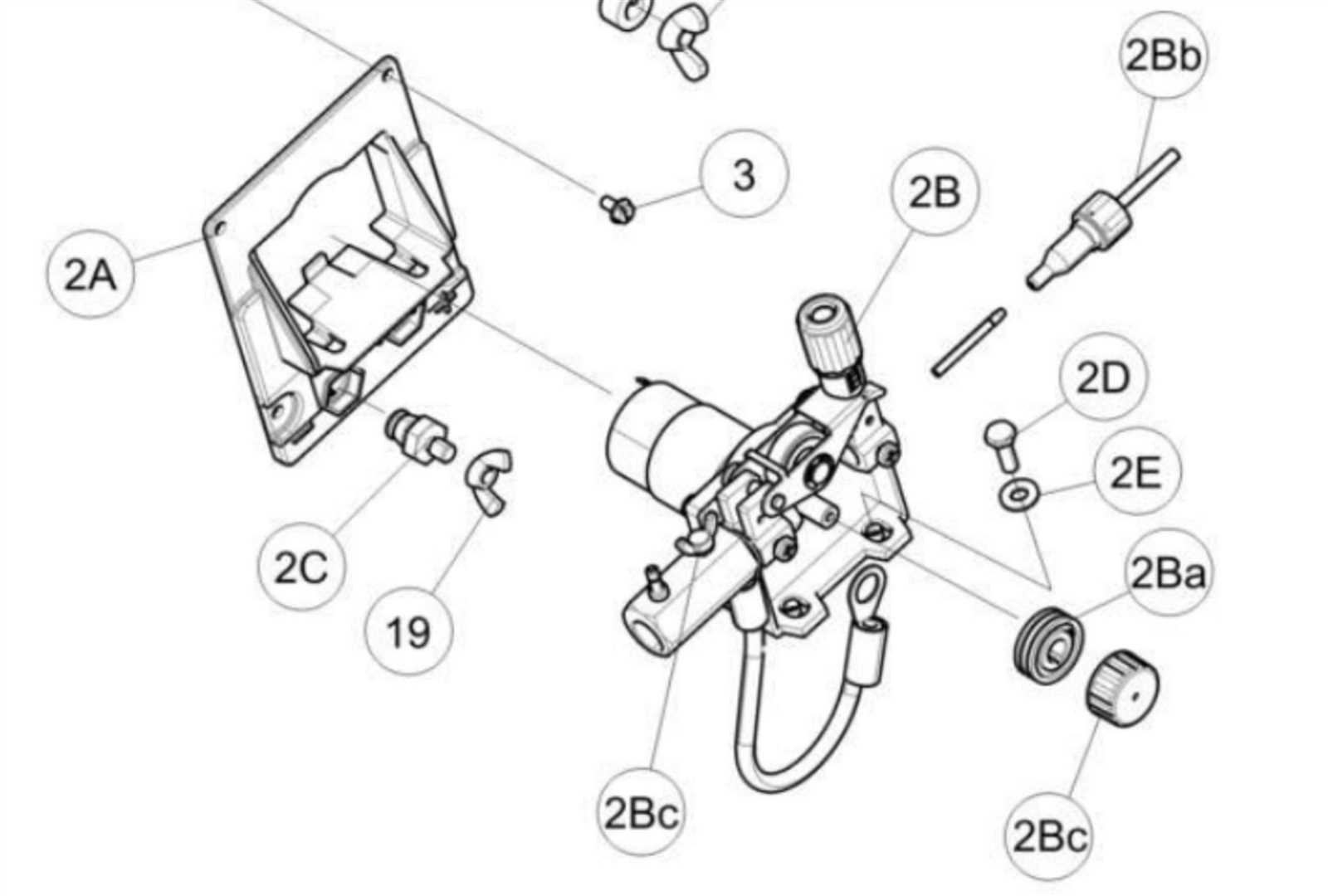

How to Read Parts Diagrams

Understanding visual representations of components is crucial for effective maintenance and repair. These illustrations provide essential insights into the organization and relationships between various elements, enabling users to identify and locate specific items efficiently.

Key Elements to Observe

Begin by familiarizing yourself with the symbols and labels used in these visuals. Pay attention to the numbering or lettering that indicates specific components, as well as any legends that explain the meaning of various icons. This foundational knowledge will streamline the identification process.

Cross-Referencing with Manuals

To enhance comprehension, cross-reference the visual with any accompanying literature. This can provide context and additional details, ensuring you grasp the ultimate function and placement of each item within the system. Combining visual and textual information fosters a deeper understanding of the assembly.

Maintenance Tips for Lincoln 180

Proper upkeep is essential for ensuring longevity and optimal performance of your equipment. Regular attention to specific components can prevent issues and enhance overall efficiency.

- Check and replace consumables frequently to maintain consistent output.

- Clean the exterior and interior to avoid dust accumulation, which can impact functionality.

- Inspect electrical connections and wiring for any signs of wear or damage.

- Ensure all moving parts are adequately lubricated to prevent friction and overheating.

- Monitor cooling systems to avoid overheating during extended use.

By following these guidelines, you can delve deeper into the maintenance routine and achieve the ultimate performance from your equipment.

Identifying Key Replacement Parts

Understanding essential components is crucial for effective maintenance and repair. Knowing how to pinpoint these items ensures longevity and optimal functionality of your equipment.

Common Components to Consider

- Engines

- Transmissions

- Suspension systems

- Braking mechanisms

- Electrical units

Steps for Identification

- Refer to the owner’s manual for specifications.

- Inspect the equipment for visible wear or damage.

- Consult with experts or authorized dealers for guidance.

- Utilize online resources for visual references.

Common Issues and Solutions

When dealing with complex machinery, it is common to encounter various challenges that can affect performance and reliability. Understanding these issues and their solutions can help in maintaining optimal functionality and prolonging the lifespan of the equipment. Below, we explore frequent problems and effective remedies that can be implemented.

Frequent Malfunctions

One of the most prevalent issues involves mechanical failures due to wear and tear. Components may become misaligned or degraded over time, leading to decreased efficiency. Regular inspections and timely replacements of worn parts are essential to avoid more severe breakdowns. Additionally, ensure that all moving parts are adequately lubricated to minimize friction-related problems.

Electrical Concerns

Another common difficulty arises from electrical components malfunctioning. This can manifest as erratic behavior or complete failure to operate. It is vital to check wiring connections and circuit integrity regularly. In case of persistent issues, consulting a qualified technician may be necessary to diagnose and rectify the underlying causes effectively.

Finding Original Parts Suppliers

Locating authentic sources for vehicle components is crucial for maintaining performance and reliability. With the right suppliers, enthusiasts can ensure their machines operate optimally, preserving both value and functionality.

Researching Reputable Vendors

Begin by exploring specialized retailers known for quality offerings. Online forums and communities can provide valuable recommendations, helping you identify trusted vendors with a history of excellence.

Checking Certifications and Reviews

Always verify the credentials of potential suppliers. Customer feedback and industry certifications are vital indicators of a supplier’s reliability and commitment to quality, guiding you toward the best choices for your needs.

Upgrading Lincoln 180 Components

Enhancing the functionality of your welder can significantly improve its performance and longevity. By focusing on key elements that can be upgraded, you can achieve better results in your projects while ensuring that your equipment remains reliable. This section explores various components that can be modified to elevate your welding experience.

Essential Enhancements

Consider upgrading the power source for increased efficiency and output. Additionally, replacing the welding gun with a higher-grade option can lead to improved precision and ease of use. These upgrades not only contribute to better weld quality but also enhance the overall workflow.

Accessories for Improved Performance

Incorporating superior accessories, such as advanced wire feed systems and better shielding gas options, can make a noticeable difference. These enhancements help achieve cleaner welds and reduce spatter, making your projects more efficient and effective.

Tools Required for Maintenance

Proper upkeep of machinery necessitates a selection of essential instruments that facilitate effective servicing. These implements not only enhance performance but also prolong the lifespan of equipment, ensuring optimal functionality.

Wrenches are vital for loosening and tightening bolts, while screwdrivers are essential for securing screws in place. Additionally, pliers can be utilized for gripping and bending tasks.

For more intricate procedures, torque wrenches help achieve precise tension levels, and socket sets provide versatility for various fasteners. To delve deeper into the maintenance process, diagnostic tools can be employed to identify potential issues before they escalate.

Ultimately, having the right array of tools ensures that all maintenance tasks are performed efficiently and effectively, contributing to the overall reliability of the equipment.

Comparing Diagrams with Other Models

Analyzing various schematics allows for a deeper understanding of design differences and similarities across multiple frameworks. By juxtaposing different visual representations, one can uncover unique features and functionalities inherent to each model, leading to enhanced knowledge and informed decisions.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Dimension | 120×80 | 125×85 | 115×75 |

| Weight | 150 kg | 160 kg | 140 kg |

| Power Output | 200 HP | 210 HP | 190 HP |

| Fuel Type | Diesel | Petrol | Electric |

Resources for Further Learning

Exploring in-depth materials can enhance your understanding and expertise in mechanical systems. Whether you’re a novice or seasoned professional, various resources can provide valuable insights and knowledge.

- Online Courses: Platforms like Coursera and Udemy offer specialized courses in mechanics and engineering.

- Technical Manuals: Manufacturer manuals provide essential specifications and maintenance tips.

- Forums and Communities: Engage with online communities such as Reddit or specialized forums for discussions and advice.

- Books: Consider classic texts and contemporary publications on engineering principles.

Utilizing these resources will help you delve deeper into the subject and achieve your ultimate learning goals.