Comprehensive Guide to Lincoln AC-225 Parts Diagram

In the realm of welding technology, comprehending the intricate elements that comprise various machines is crucial for optimal performance and maintenance. Knowledge of these individual components enhances a user’s ability to troubleshoot and repair, ensuring longevity and efficiency.

Examining the structure of welding apparatuses reveals a complex interplay of parts, each serving a unique purpose. Whether it’s the power supply, control mechanisms, or cooling systems, a clear understanding of how these components interact is essential for any welder.

Furthermore, detailed visual aids can significantly enhance one’s grasp of these systems. By delving into the specifics, operators can identify potential issues before they escalate, ultimately leading to more effective repairs and upgrades.

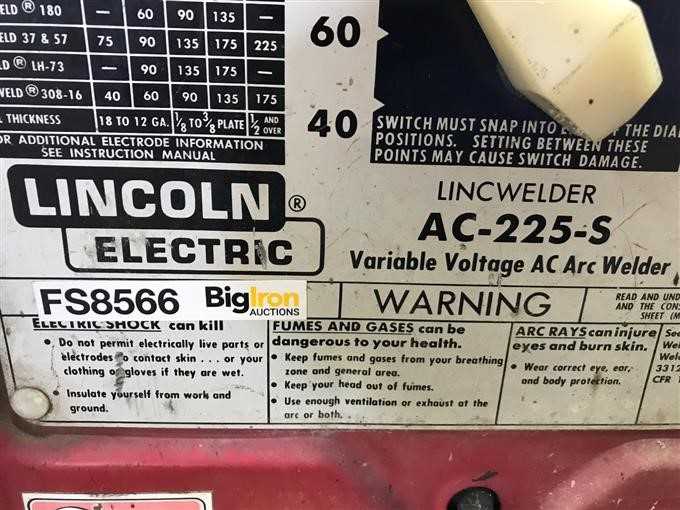

Understanding the Lincoln AC-225

This section explores a popular welding device known for its versatility and reliability in various metal fabrication tasks. Whether you are a professional or a hobbyist, comprehending its components and functionality is essential for achieving optimal results in your welding projects.

Key Features

This machine is equipped with several important features that enhance its performance. The robust design allows for stable operation, making it suitable for a range of applications. Additionally, its user-friendly interface ensures that even beginners can navigate its settings effectively. Understanding these characteristics can significantly improve your welding experience.

Maintenance and Care

Proper upkeep is crucial for maintaining efficiency and longevity. Regular inspections of the internal elements, along with routine cleaning, can prevent potential issues. Familiarizing yourself with the main components will allow you to troubleshoot common problems, ensuring your equipment remains in top condition.

Essential Components of the Welder

Understanding the crucial elements of a welding machine is vital for effective operation and maintenance. Each part plays a significant role in ensuring optimal performance and durability. Familiarity with these components can enhance both the user’s skills and the longevity of the equipment.

Power Source: The core of any welding unit, this component converts electrical energy into usable power for the welding process. It determines the machine’s output and efficiency.

Electrode Holder: This part securely grips the electrode, allowing for controlled welding. It must be durable to withstand high temperatures during operation.

Ground Clamp: Essential for safety and performance, this device connects the welding machine to the workpiece, ensuring a proper electrical circuit.

Cooling System: Maintaining optimal operating temperatures is critical. Effective cooling prevents overheating, prolonging the life of the welder.

Control Panel: The interface for the user, it includes settings for voltage and amperage, allowing precise adjustments for various welding tasks.

Welding Cables: These flexible conduits carry electricity from the power source to the electrode and ground clamp, playing a key role in overall conductivity.

By delving into these essential components, users can enhance their understanding of welding technology and improve their overall results.

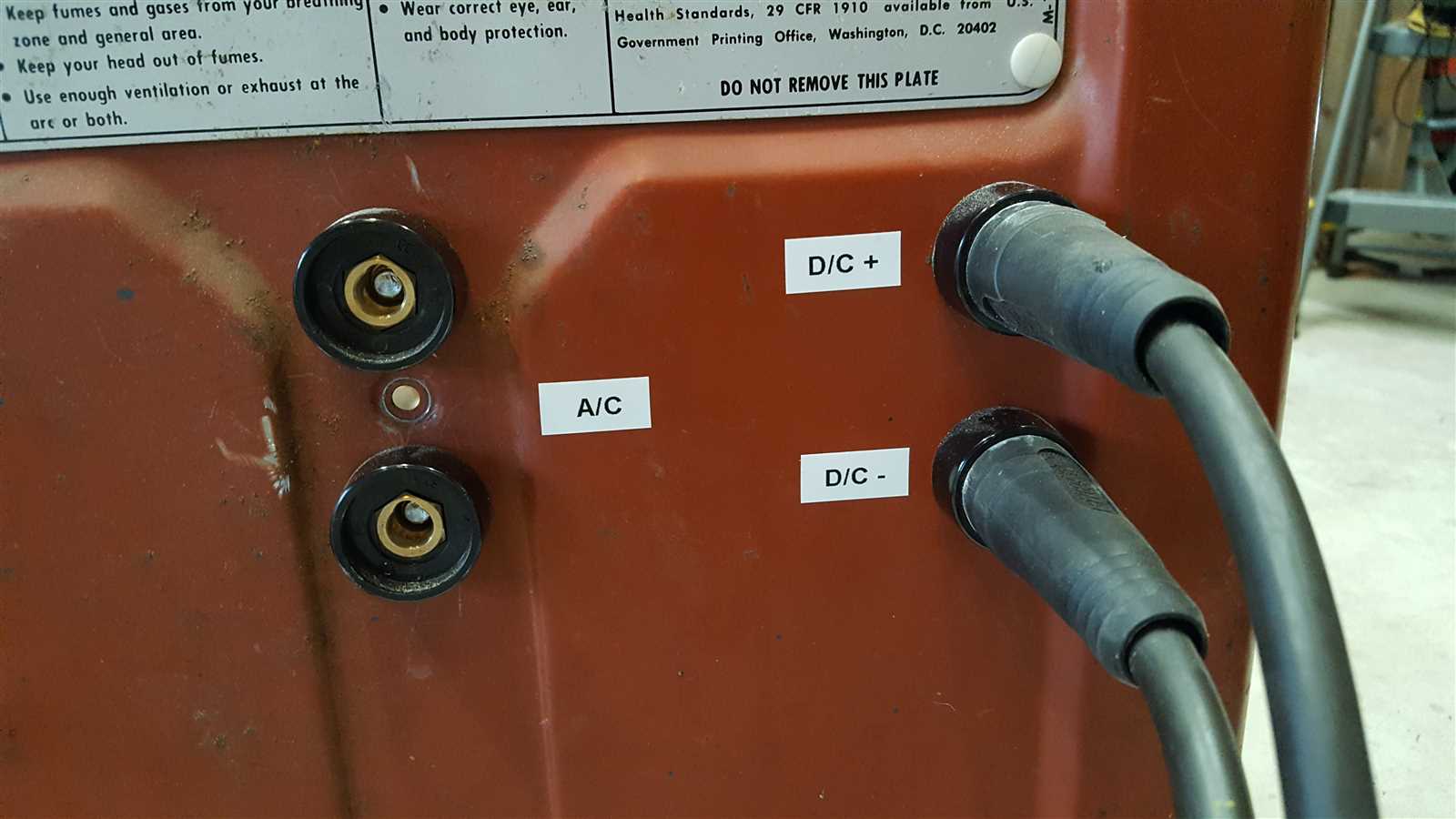

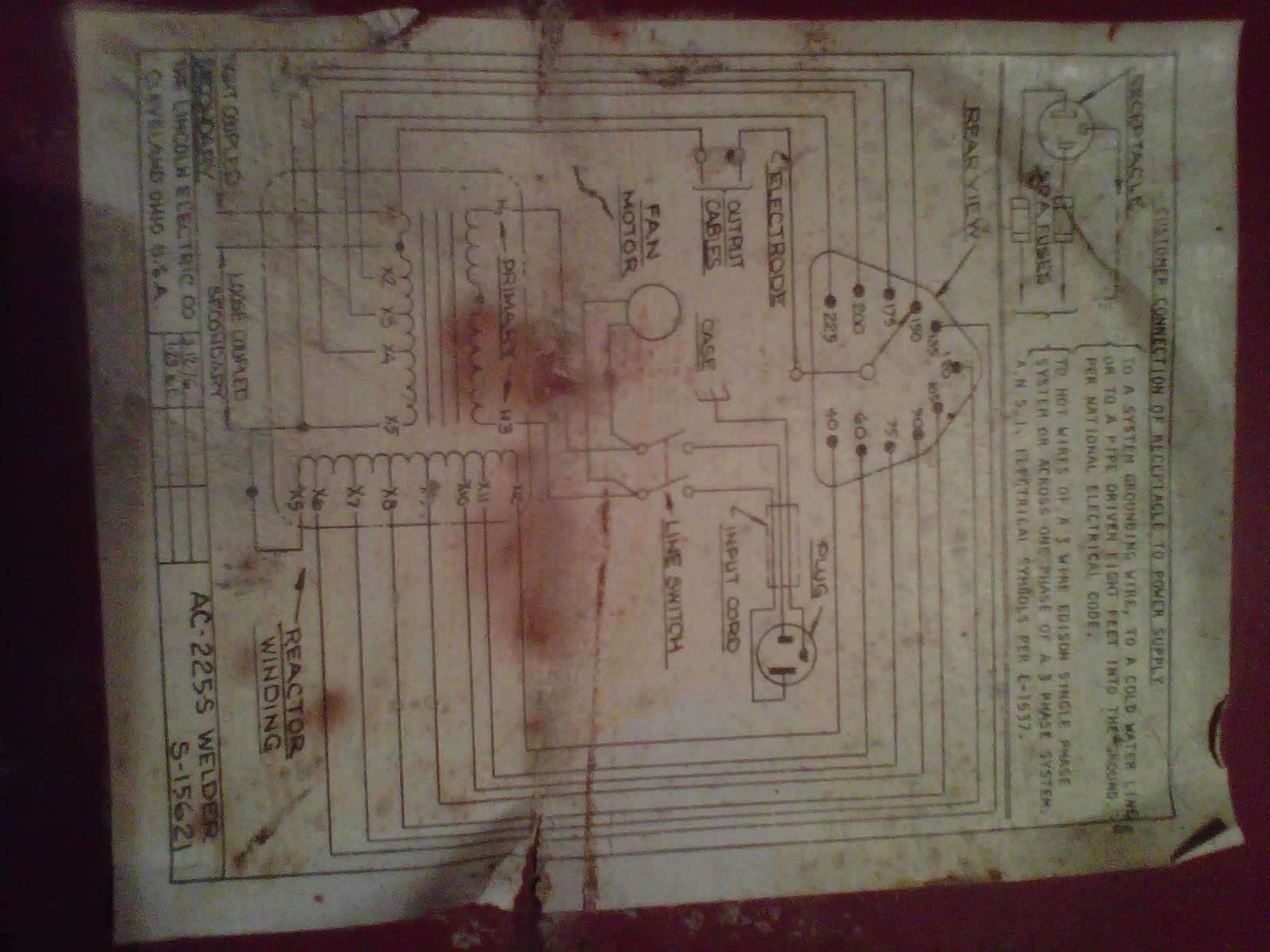

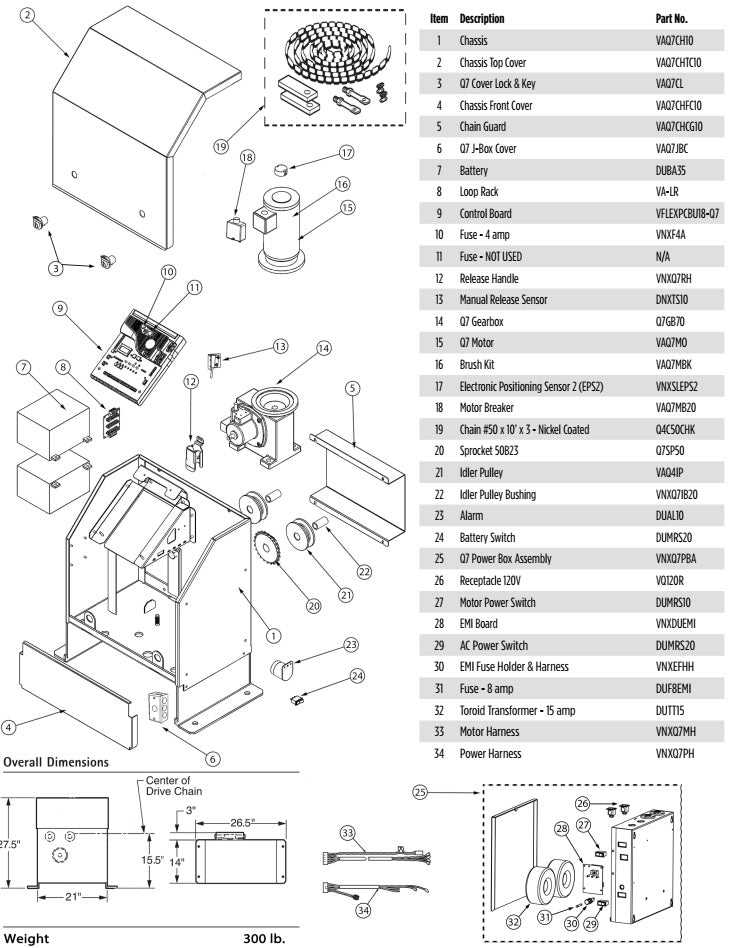

Interpreting the Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. This visual guide allows users to quickly identify and locate individual elements, facilitating a smoother workflow and minimizing potential errors.

Key aspects to consider when analyzing the schematic include:

- Identification: Familiarize yourself with the symbols and labels used to represent different elements.

- Organization: Note how components are grouped, which can indicate their function and relationship.

- Connections: Pay attention to lines and arrows that denote how various parts interact with each other.

By focusing on these elements, you can delve deeper into understanding how each section contributes to the overall functionality.

Common Replacement Parts Explained

When it comes to maintaining welding equipment, understanding the essential components that may require replacement is crucial for ensuring optimal performance. This section delves into the frequently needed items that contribute to the functionality and longevity of your machine.

One vital element is the electrode holder, which plays a significant role in securely gripping the welding rod. Over time, wear and tear can compromise its effectiveness, leading to inconsistent welding results. Regular inspection and timely replacement can help maintain a stable arc and improve overall efficiency.

Another important component is the ground clamp. Its primary function is to establish a solid electrical connection between the workpiece and the machine. If this part becomes damaged or corroded, it can result in poor conductivity, causing issues such as erratic welding arcs and inadequate penetration. Ensuring that the ground clamp is in good condition is essential for reliable operation.

The cooling system, including fans and vents, is also critical for preventing overheating during extended use. Accumulated debris or malfunctioning fans can hinder airflow, leading to potential damage. Regular maintenance and replacement of these cooling components can help prolong the lifespan of the equipment.

Lastly, consider the hoses and cables that facilitate the flow of gas and electricity. These components are subject to wear from frequent movement and exposure to heat. Inspecting for cracks or frays and replacing them as needed can prevent leaks and ensure safe operation.

By understanding these commonly needed components, users can better maintain their equipment, enhancing both performance and safety during welding tasks.

How to Identify Each Part

Understanding the components of your equipment is essential for effective maintenance and operation. Each element plays a critical role in the overall functionality, and recognizing them can greatly enhance your ability to troubleshoot issues and perform repairs. This guide will help you familiarize yourself with the various elements, making it easier to work with your machinery.

Visual Inspection

Start by conducting a thorough visual examination. Look for labels, numbers, or unique shapes that can help differentiate one component from another. Familiarize yourself with the layout and common characteristics of the elements to streamline the identification process.

Reference Materials

Utilizing reference materials, such as manuals or online resources, can provide valuable insights into the specifications and roles of each component. Diagrams and photographs in these resources often highlight specific features, aiding in accurate identification. Pay attention to any notes regarding compatibility and functionality to ensure correct usage.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires regular attention and proactive measures. Consistent upkeep not only enhances performance but also prevents potential issues from escalating into costly repairs. By integrating a few essential practices into your routine, you can significantly improve durability and reliability.

Start with routine inspections to identify wear and tear before it becomes problematic. Clean components regularly to remove debris and contaminants that can lead to malfunctions. Additionally, always follow manufacturer guidelines regarding lubrication and servicing intervals to maintain optimal functionality.

Utilize quality materials and tools during any repair or replacement processes. Keeping a clean and organized workspace reduces the risk of accidents and enhances efficiency. Lastly, maintain a detailed maintenance log to track service history, which can be invaluable for troubleshooting and planning future upkeep.

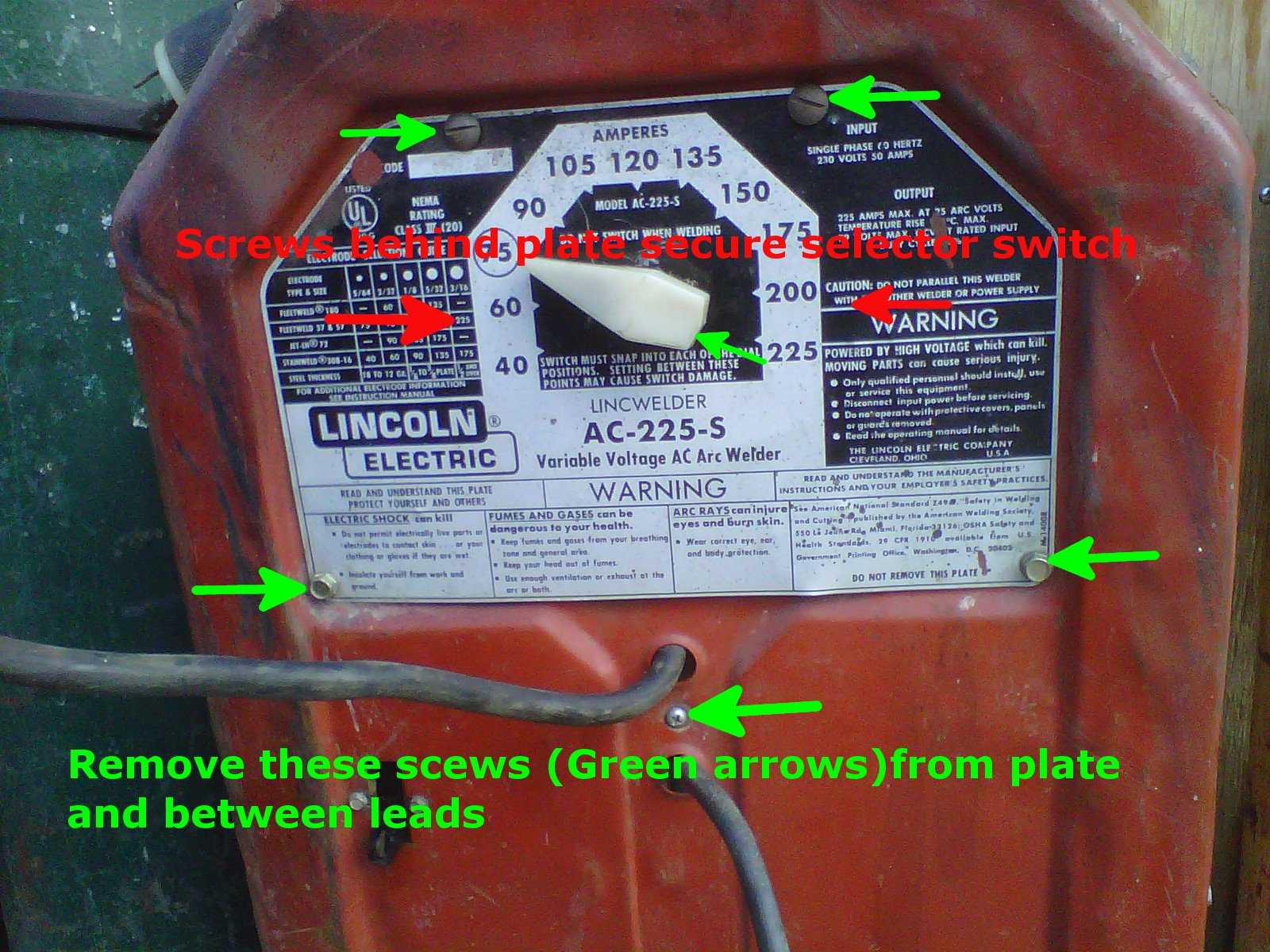

Assembly and Disassembly Guidelines

Proper assembly and disassembly are crucial for ensuring optimal performance and longevity of the equipment. Following specific steps can simplify the process, enhance safety, and reduce the risk of damage.

Before starting, gather all necessary tools and safety gear. Adhering to the following steps will facilitate a smooth operation:

- Review the user manual for specific instructions.

- Ensure the workspace is clean and well-lit.

- Disconnect all power sources to prevent accidents.

For assembly:

- Organize all components in a logical order.

- Follow the sequence outlined in the manual.

- Use appropriate fasteners and tools to secure parts.

For disassembly:

- Work methodically, keeping track of each part removed.

- Label components if necessary for easier reassembly.

- Handle delicate parts with care to avoid damage.

By adhering to these guidelines, the process will be more efficient and effective, ultimately leading to better results.

Troubleshooting Common Issues

When working with welding equipment, various challenges may arise that can affect performance and efficiency. Understanding how to identify and resolve these common problems is essential for maintaining optimal functionality. Below are some frequently encountered issues along with their potential causes and solutions.

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| No Power | Disconnected power source, blown fuse | Check connections, replace fuse if necessary |

| Inconsistent Arc | Worn electrode, incorrect settings | Replace electrode, adjust settings |

| Overheating | Insufficient ventilation, prolonged use | Ensure proper airflow, take breaks during operation |

| Excessive Spatter | Improper technique, incorrect filler material | Refine technique, verify filler compatibility |

| Poor Weld Quality | Dirty surface, wrong travel speed | Clean workpiece thoroughly, adjust travel speed |

Upgrading Parts for Performance

Enhancing the components of your equipment can significantly boost its overall efficiency and functionality. By selecting superior materials and modern designs, users can experience improvements in power output, reliability, and operational ease. These upgrades not only extend the lifespan of the machinery but also optimize performance in various applications.

When considering enhancements, it’s crucial to evaluate compatibility with existing systems. Researching available options and their benefits allows for informed decisions that align with specific performance goals. Implementing state-of-the-art upgrades ensures that your equipment meets contemporary demands, providing a competitive edge.

Ultimately, a strategic approach to component enhancement can lead to remarkable gains in productivity. Prioritizing quality and innovation paves the way for a more efficient and effective operation, reflecting the user’s commitment to excellence in performance.

Safety Precautions When Repairing

Ensuring safety during the maintenance and repair of equipment is crucial to prevent accidents and injuries. Adhering to specific guidelines and practices can significantly reduce risks associated with electrical and mechanical work. This section outlines essential precautions that should be taken before and during the repair process.

Personal Protective Equipment

Wearing the appropriate personal protective gear is essential. Safety glasses protect your eyes from debris and sparks, while gloves shield your hands from sharp edges and electrical hazards. Additionally, steel-toed boots help safeguard your feet from heavy equipment. Ensure that your attire is free from loose clothing that could get caught in moving parts.

Work Area Safety

Maintaining a clean and organized workspace is vital. Remove any clutter that could pose a tripping hazard, and ensure that tools and materials are stored properly. Good lighting is necessary for visibility, allowing you to work safely. Always disconnect power sources before starting repairs to prevent electrical shock, and use tools that are in good condition to minimize the risk of malfunctions.

Finding Quality Replacement Parts

When it comes to maintaining equipment, sourcing high-grade components is crucial for ensuring optimal performance and longevity. Identifying reliable alternatives can make a significant difference in both functionality and safety. This section will explore effective strategies for locating top-notch substitutes.

Research and Reviews

Before making a purchase, conducting thorough research is essential. Consider the following steps:

- Check online marketplaces for user ratings and feedback.

- Consult forums and communities dedicated to the specific machinery or equipment.

- Look for reviews on independent sites to gauge the reputation of manufacturers.

Evaluating Suppliers

Once you’ve gathered information, the next step involves assessing potential vendors. Keep these factors in mind:

- Verify the supplier’s credibility through certifications and warranties.

- Compare prices, but avoid sacrificing quality for a lower cost.

- Inquire about return policies and customer support services.

By following these guidelines, you can enhance the likelihood of acquiring reliable replacements that meet your operational needs.

Resources for Further Learning

This section aims to provide valuable materials and tools for those interested in enhancing their understanding of welding equipment and its components. Whether you’re a novice or an experienced user, expanding your knowledge can significantly improve your skills and expertise.

Books and Manuals

- Welding Essentials: Techniques and Applications

- The Complete Guide to Welding: A Comprehensive Manual

- Fabrication and Welding Engineering

Online Courses and Tutorials

- Welding Basics: An Introduction

- Advanced Welding Techniques

- Safety Practices in Welding

Utilizing these resources can help you delve deeper into the intricacies of welding machinery and achieve the ultimate proficiency in your craft.