Understanding the Lincoln Floor Jack Parts Diagram

In the realm of mechanical assistance, various devices play a crucial role in elevating and supporting heavy loads. These tools are essential for both professional and personal use, providing the necessary strength and stability to perform numerous tasks safely and effectively. A comprehensive understanding of their individual elements enhances not only the efficiency of the equipment but also ensures longevity and reliability in operations.

Identifying the various components of hydraulic lifting mechanisms allows users to troubleshoot issues, perform maintenance, and ultimately optimize performance. Each element serves a specific function, contributing to the overall operation and safety of the apparatus. By exploring the structure and roles of these components, operators can gain insights into effective usage and care practices.

Furthermore, a detailed visual representation of these mechanisms can serve as a valuable reference. It aids in familiarizing oneself with the intricate design and functionality of each section. Whether for repairs, upgrades, or general knowledge, having access to such illustrations empowers users to manage their equipment more proficiently.

Understanding Lincoln Floor Jacks

This section explores the fundamental aspects of hydraulic lifting devices commonly used in automotive maintenance and repair. These tools are essential for elevating vehicles safely, enabling easy access to undercarriages for inspection or repair work. Knowing the components and their functions can significantly enhance the effectiveness and longevity of these lifting mechanisms.

Key Components and Their Functions

Hydraulic lifting systems consist of several crucial elements, each playing a vital role in the overall operation. The cylinder is responsible for converting fluid pressure into mechanical force, allowing the lift to rise. The pump facilitates this process by generating pressure through the manipulation of hydraulic fluid. Additionally, the handle serves as the user interface, enabling operators to control the lift’s movement efficiently.

Maintenance and Care

Regular maintenance is imperative to ensure optimal performance and safety. Checking hydraulic fluid levels and inspecting seals for leaks can prevent malfunctions. Moreover, keeping the lifting surface clean and free of debris enhances stability during use. Adopting these practices not only extends the tool’s lifespan but also ensures safe operation during every lifting task.

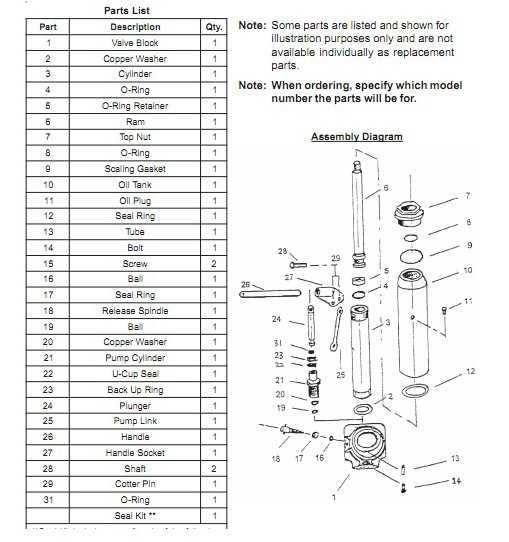

Key Components of Lincoln Jacks

Understanding the essential elements of a hydraulic lifting device is crucial for effective operation and maintenance. Each component plays a vital role in ensuring the tool functions smoothly and safely.

- Frame: The robust structure that supports the entire mechanism and provides stability during use.

- Hydraulic Cylinder: This component is responsible for lifting the load through the application of hydraulic pressure.

- Pump: The mechanism that generates the hydraulic pressure required to elevate the device.

- Handle: The lever used to operate the pump, allowing the user to lift and lower the equipment with ease.

- Wheels: Mobile features that enhance maneuverability, allowing for easy positioning of the apparatus.

- Release Valve: A critical feature that allows for controlled lowering of the lifted load.

Each of these elements is designed to work in harmony, providing efficiency and safety during operation. Regular maintenance of these components is essential for optimal performance.

Common Issues with Floor Jacks

Various challenges can arise with hydraulic lifting devices, impacting their performance and reliability. Understanding these issues is crucial for ensuring safe and effective use.

Frequent Problems

- Leaking Fluid: Often caused by damaged seals or worn-out components.

- Inability to Lift: May result from a lack of hydraulic fluid or internal damage.

- Slow Descent: Usually indicates a malfunctioning release valve.

Preventative Measures

- Regular Maintenance: Routine checks can identify wear and tear early.

- Proper Storage: Keeping the device in a dry, temperature-controlled environment can prevent damage.

- Fluid Replacement: Regularly changing the hydraulic fluid can enhance performance.

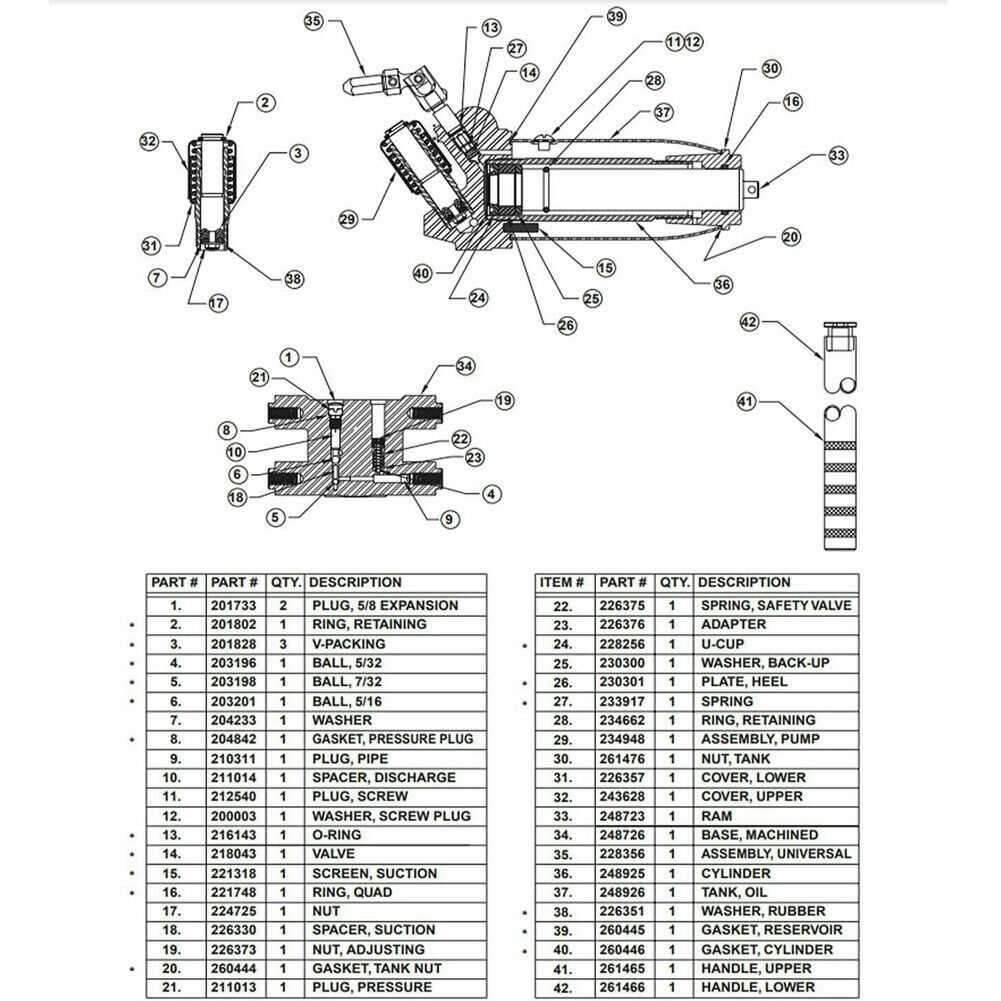

How to Identify Part Numbers

Recognizing component identifiers is crucial for effective maintenance and replacement. Understanding these numbers can streamline repairs and ensure compatibility with your equipment.

Steps to Identify Part Numbers

- Check the Owner’s Manual: Most manuals contain a section listing part numbers.

- Inspect the Equipment: Look for labels or engravings on the device that may indicate specific numbers.

- Visit Manufacturer’s Website: Many manufacturers provide online resources for identifying components.

Resources for Assistance

- Online Forums: Engaging with community forums can provide insights and experiences from other users.

- Customer Support: Reaching out to customer service can clarify any uncertainties regarding identification.

- Local Retailers: Visiting a parts dealer can offer hands-on assistance with finding the right identifiers.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your lifting equipment requires regular attention and care. By following a few essential maintenance practices, you can significantly extend the lifespan of your device and maintain its efficiency over time.

Regular Inspections

Conduct frequent evaluations to identify any wear and tear. Look for signs of damage, corrosion, or leaks. Addressing minor issues early can prevent more significant problems in the future.

Proper Storage

Store your equipment in a clean, dry place to protect it from environmental factors. Keeping it covered when not in use helps minimize dust accumulation and potential rust formation.

Safety Features to Consider

When working with lifting equipment, ensuring user safety should be a top priority. Various mechanisms and features can greatly reduce the risk of accidents and enhance overall operational security. Understanding these attributes is essential for both novice and experienced users alike.

Essential Safety Mechanisms

- Overload Protection: This feature prevents the equipment from lifting beyond its maximum weight capacity, reducing the risk of failure.

- Stability Enhancements: Features such as wide bases and non-slip surfaces improve stability and prevent tipping.

- Automatic Safety Lock: This mechanism locks the equipment in place when elevated, ensuring that it remains securely positioned during use.

- Pressure Relief Valves: These valves help manage pressure levels, preventing sudden release that could lead to accidents.

Operational Precautions

- Always inspect the equipment for any signs of wear or damage before use.

- Ensure the area is clear of obstacles to avoid potential hazards.

- Follow the manufacturer’s guidelines for safe operation and maintenance.

- Utilize appropriate personal protective equipment (PPE) during operation.

By prioritizing these safety features and operational practices, users can significantly mitigate risks and ensure a secure working environment.

Where to Buy Replacement Parts

Finding the right components for your lifting equipment can be crucial for maintaining its functionality and safety. Fortunately, there are several reliable sources where you can acquire these necessary items, ensuring your machinery remains in top condition.

Online Retailers: The internet offers a plethora of platforms specializing in hardware and accessories for various machinery. Websites like Amazon and eBay often feature a wide selection, complete with customer reviews and ratings to help you make informed choices.

Manufacturer Websites: Visiting the official site of the equipment’s manufacturer can yield authentic components specifically designed for your model. This ensures compatibility and often comes with the benefit of warranty coverage.

Local Auto Parts Stores: Many brick-and-mortar shops carry a variety of essential components and can be a convenient option if you prefer to see items in person before purchasing. Additionally, staff can offer expert advice on what you might need.

Specialized Supply Stores: Consider seeking out retailers that focus specifically on lifting and hydraulic equipment. These establishments often have knowledgeable staff and a more extensive inventory tailored to your specific requirements.

Second-Hand Options: For those on a budget, exploring thrift shops, classified ads, or online marketplaces can lead to finding quality used components at a fraction of the price. Just ensure you assess the condition and compatibility before purchasing.

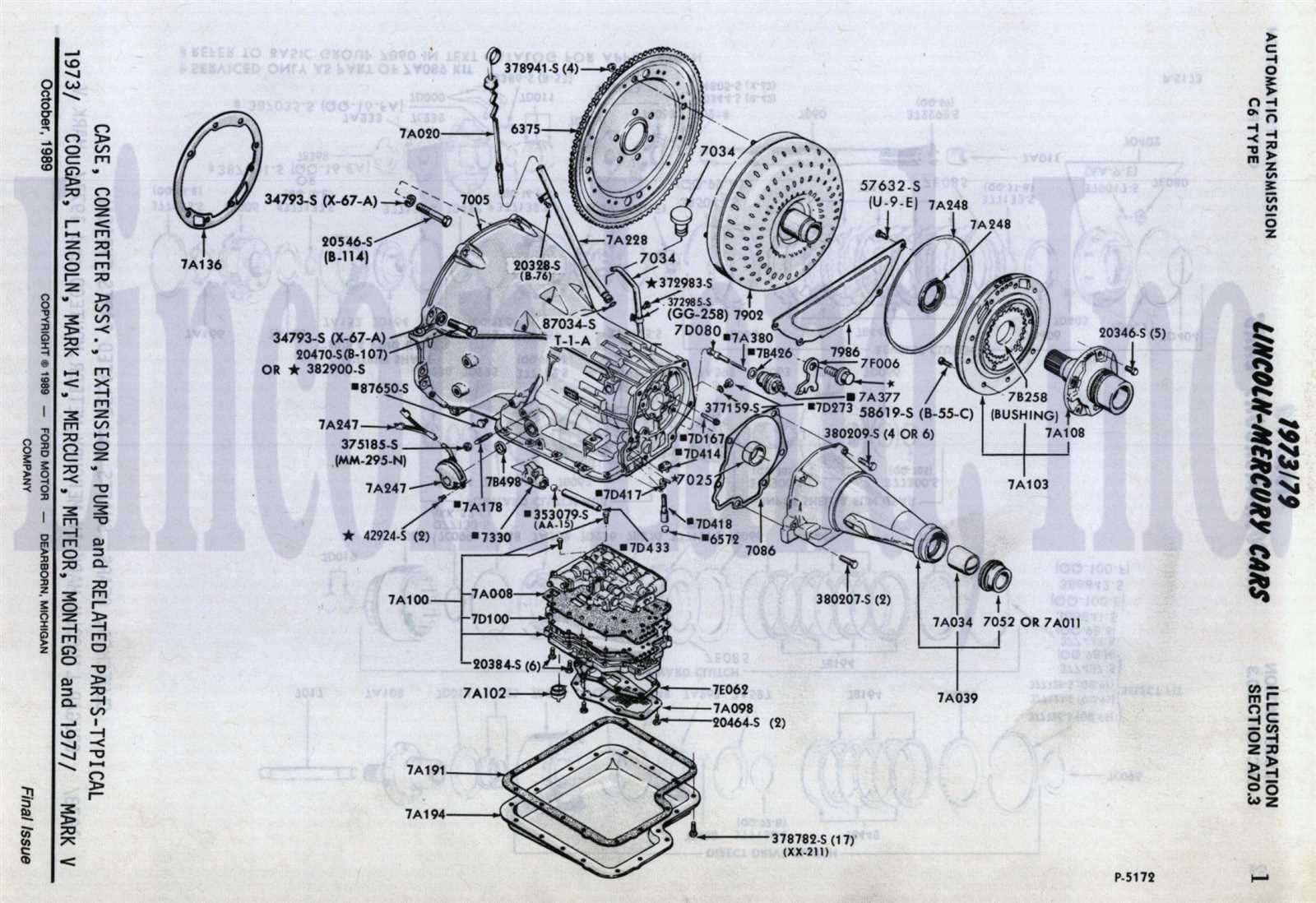

Comparing Models of Lincoln Jacks

When exploring different variants of lifting equipment, it’s essential to evaluate their unique features and functionalities. Each model is designed to cater to specific needs, making it vital to understand the distinctions to select the most suitable option.

Key Features to Consider

- Load Capacity

- Height Range

- Construction Material

- Wheel Design

- Weight

Popular Models Overview

- Model A: Known for its high load capacity and durability, ideal for heavy-duty tasks.

- Model B: Offers a compact design, perfect for limited spaces while maintaining excellent performance.

- Model C: Features advanced wheel technology, enhancing maneuverability and ease of use.

DIY Repairs: A Step-by-Step Guide

Embarking on do-it-yourself repairs can be a rewarding experience, allowing you to enhance your skills while saving time and money. This guide will provide you with a structured approach to tackle common issues effectively, ensuring a smooth and efficient process.

Understanding the Basics

Before diving into any repair, familiarize yourself with the essential components involved. Knowing the structure and function of each element will enable you to diagnose problems more accurately and identify the necessary tools and materials.

Step-by-Step Process

Start by gathering all required tools and components. Next, follow a systematic approach: disassemble carefully, inspect for wear and tear, and replace any damaged elements. Once repairs are complete, reassemble everything with precision, ensuring that each piece fits perfectly before testing the functionality.

Upgrading Your Floor Jack System

Enhancing your lifting equipment can significantly improve efficiency and safety in your workspace. Upgrading components not only boosts performance but also extends the lifespan of your gear. Consider the following aspects when looking to enhance your system.

Key Components to Consider

- Hydraulic Fluid Quality

- Seal and Gasket Upgrades

- Wheel Replacement for Better Mobility

- Lift Arm Modifications for Increased Reach

Benefits of Upgrading

- Improved Load Handling

- Enhanced Safety Features

- Increased Stability and Control

- Reduced Maintenance Costs Over Time

FAQs About Lincoln Jack Parts

This section addresses common inquiries regarding components and their functionalities, providing clarity for users seeking assistance with their equipment. Understanding these elements can enhance the maintenance and operation experience.

What are the most common issues encountered with these components?

The typical problems often involve wear and tear, leakage, or difficulty in raising or lowering loads. Regular checks and timely replacements can mitigate these issues significantly.

How can I identify the right component for my equipment?

To ensure compatibility, consult the manufacturer’s guide or specifications. Cross-referencing part numbers and descriptions is essential to find the ultimate fit for your needs.

Resources for Technical Support

When dealing with mechanical equipment, having access to reliable support resources is essential for ensuring optimal performance and longevity. Whether you encounter issues or require guidance for maintenance, numerous avenues are available to assist you. Utilizing these resources can help you troubleshoot problems effectively and enhance your understanding of the machinery.

Online Resources

The internet offers a wealth of information through forums, instructional videos, and manufacturer websites. Many dedicated communities discuss common issues and solutions, allowing users to share their experiences and expertise. Additionally, official sites often provide downloadable manuals and FAQs that can be invaluable in resolving queries.

Customer Support and Service Centers

For more specialized assistance, reaching out to customer support representatives or visiting authorized service centers can be beneficial. These professionals possess in-depth knowledge of the equipment and can provide tailored advice. They can also assist with repairs and ensure that all components are functioning as intended.