Comprehensive Parts Diagram for Lincoln Idealarc 250

The intricacies of welding machinery often require a detailed examination of their internal structures. By exploring the various elements that contribute to the functionality of these devices, one can gain valuable insights into their operation and maintenance.

Visual representation of these components plays a crucial role in understanding how each part interacts within the system. Having a clear layout enables technicians and enthusiasts alike to troubleshoot and optimize performance effectively.

Additionally, familiarity with the essential elements enhances the overall knowledge base, making it easier to identify potential issues or areas for improvement. This exploration ultimately leads to more efficient welding processes and increased reliability of the equipment.

Understanding Lincoln Idealarc 250

This section aims to explore a renowned welding machine that has garnered respect in the industry for its reliability and efficiency. It serves as a vital tool for professionals seeking precision in their welding tasks. Understanding the components and functionality of this equipment is essential for optimizing performance and achieving high-quality results.

At its core, this welding apparatus is designed to deliver consistent power output, allowing users to work with various materials effectively. The robust construction ensures durability, making it suitable for both industrial and field applications. Familiarity with its internal mechanisms can significantly enhance the user experience, promoting better maintenance practices and prolonging the lifespan of the device.

By examining the intricate layout of the system, operators can identify key elements that contribute to its operational efficiency. Each component plays a pivotal role in the overall functionality, and comprehending their interactions can lead to improved performance. This understanding not only aids in troubleshooting but also empowers users to execute welding tasks with greater confidence and skill.

Ultimately, gaining insights into this welding machine fosters a deeper appreciation for its capabilities and the technology that underpins it. Whether one is a seasoned professional or a newcomer to the field, this knowledge is invaluable for mastering the art of welding.

Key Features of the Welder

This welding machine stands out due to its robust design and versatility, making it an essential tool for both professional welders and hobbyists. Its innovative technology enhances performance, ensuring high-quality results across various applications.

Durability and Reliability

Engineered for tough environments, this equipment offers exceptional durability. Key attributes include:

- Heavy-duty construction for long-lasting use

- Resistance to wear and tear under challenging conditions

- Consistent performance over extended periods

Versatile Welding Capabilities

Designed to accommodate a range of welding techniques, the machine is suitable for various materials and thicknesses. Notable features include:

- Adjustable settings for different welding processes

- Compatibility with various electrode types

- Ability to work on both thin and thick materials

With its combination of reliability and versatility, this welder is a valuable asset in any workshop.

Common Applications of Lincoln Idealarc 250

The versatility of this welding equipment makes it suitable for a wide range of tasks across various industries. Its robust design and reliable performance allow for effective joining of metals in diverse applications.

Construction is one of the primary fields where this machine excels. It is frequently utilized for structural steel fabrication, allowing workers to create strong and durable frameworks for buildings and bridges.

In manufacturing, this tool is indispensable for fabricating components and parts. Its ability to handle different materials and thicknesses ensures high-quality welds, which are crucial for the production of reliable machinery.

Another significant application is in automotive repair. Mechanics often rely on this equipment to repair or fabricate parts for vehicles, ensuring safety and functionality on the road.

Moreover, in the realm of shipbuilding, it is employed to weld large sections of metal together, contributing to the construction of robust and seaworthy vessels.

Lastly, this equipment is also used in artistic projects, where artists and sculptors create intricate metal sculptures, showcasing creativity and craftsmanship. The adaptability of this welding machine facilitates innovation in both practical and artistic applications.

Parts Overview and Functionality

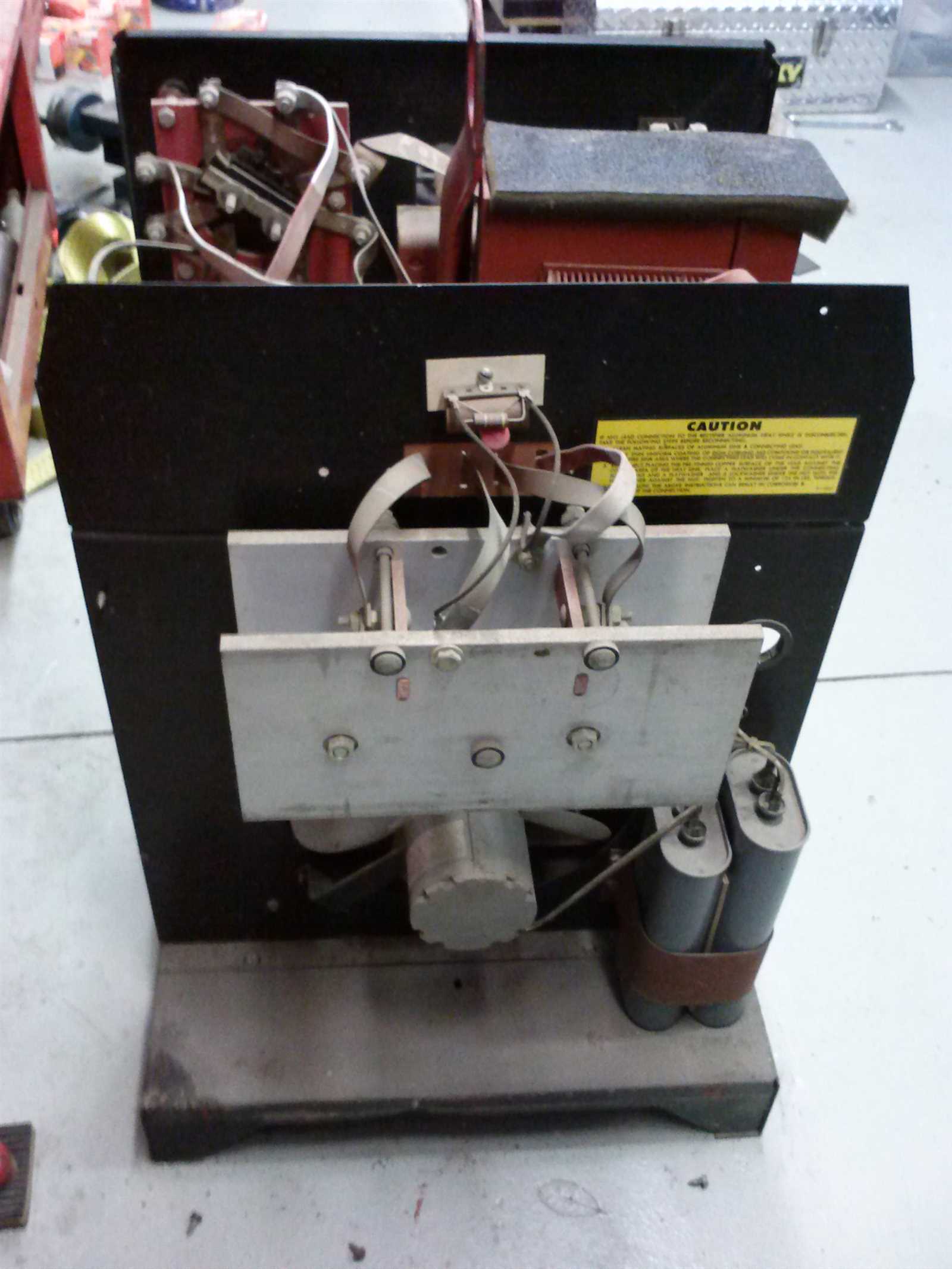

This section provides a comprehensive look at the various components that make up the welding machine, highlighting their essential roles in the overall operation. Understanding these elements is crucial for effective use and maintenance.

| Component | Description | Function |

|---|---|---|

| Power Supply | Delivers electrical energy to the system. | Transforms input voltage into usable output for welding. |

| Control Panel | User interface for settings and adjustments. | Enables operator to modify parameters for optimal performance. |

| Cooling System | Regulates temperature of the machine. | Prevents overheating during prolonged use. |

| Electrode Holder | Secures the electrode in place. | Facilitates stable arc formation during welding. |

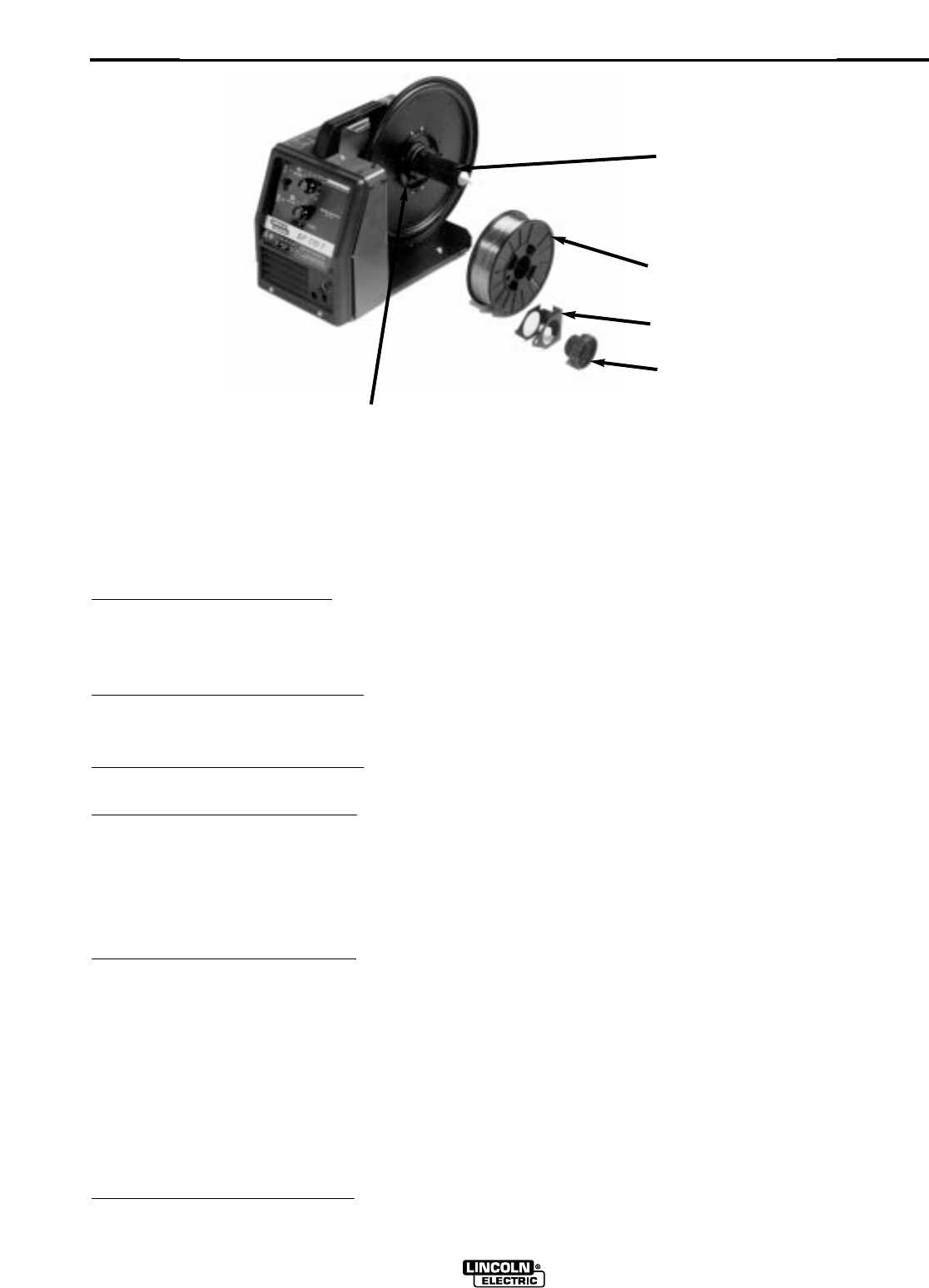

| Wire Feed Mechanism | Feeds welding wire to the torch. | Ensures a consistent supply of material for the welding process. |

Safety Precautions When Operating

Ensuring safety during operation is paramount for effective and secure performance. Adhering to established guidelines helps prevent accidents and promotes a safe working environment. Awareness of potential hazards and proper handling techniques are essential for all users.

Below are key safety measures to consider:

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment, including goggles, gloves, and protective clothing. |

| Check Equipment | Regularly inspect the machine for any signs of wear or damage before use. |

| Maintain Workspace | Keep the area clean and free of clutter to minimize tripping hazards. |

| Follow Instructions | Always adhere to the manufacturer’s operating guidelines and safety protocols. |

| Stay Alert | Maintain focus during operation and avoid distractions to ensure proper handling. |

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires consistent attention and care. By implementing a few essential practices, you can significantly enhance performance and minimize the risk of breakdowns.

Regular Cleaning: Keep the machinery free from dust and debris. Regular cleaning prevents buildup that can lead to overheating and malfunctions.

Routine Inspections: Conduct periodic checks to identify wear and tear early. This proactive approach allows for timely replacements, avoiding more significant issues down the line.

Lubrication: Proper lubrication of moving parts reduces friction and prevents unnecessary wear. Follow the manufacturer’s guidelines for the best results.

Electrical Connections: Ensure that all electrical connections are secure and free from corrosion. Regularly checking these can prevent operational failures.

Follow Operating Guidelines: Always adhere to the recommended operating procedures. This ensures that the equipment functions efficiently and reduces the risk of damage.

How to Troubleshoot Issues

Tackling challenges in equipment operation requires a systematic approach. Identifying symptoms accurately can lead to effective solutions, minimizing downtime and enhancing performance.

Begin by observing any unusual behaviors or indicators. Document these findings to facilitate analysis and ensure a thorough examination. Below is a useful checklist for troubleshooting common problems:

| Symptom | Possible Cause | Recommended Action |

|---|---|---|

| No power | Faulty connection or blown fuse | Check connections and replace fuse if necessary |

| Overheating | Insufficient ventilation | Ensure vents are clear and clean |

| Inconsistent performance | Worn components | Inspect and replace worn parts |

| Unusual noises | Lack of lubrication | Lubricate moving parts |

By following this structured method, you can effectively resolve issues and maintain optimal functionality.

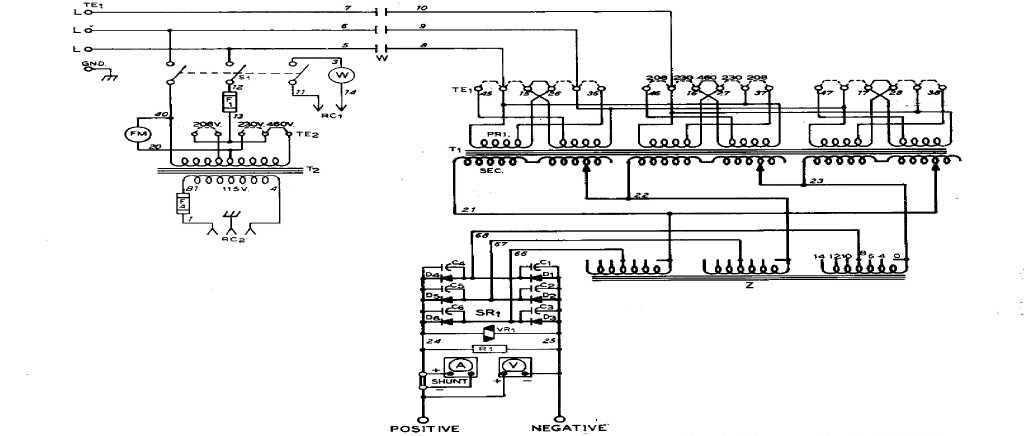

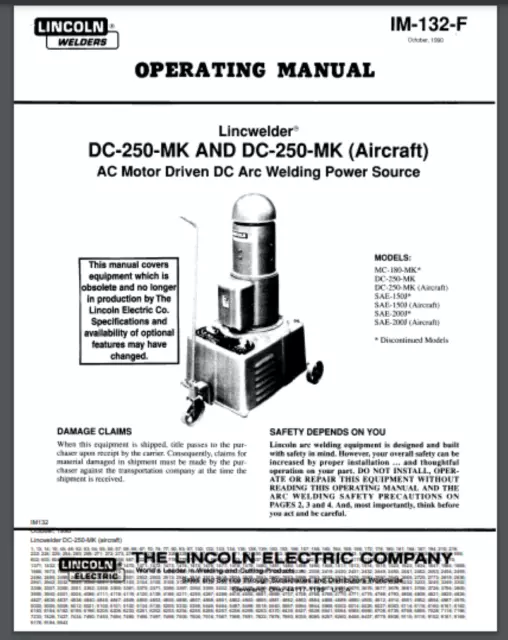

Detailed Parts Diagram Explanation

This section provides a comprehensive overview of the intricate assembly of components within a specific welding machine. Understanding the layout and function of each element is crucial for effective operation and maintenance. Each section of the visual representation plays a vital role in the overall functionality, offering insights into how the machine performs its tasks.

The illustration breaks down the key elements, detailing their respective positions and interconnections. It highlights the significance of individual parts, such as the power supply, control panel, and cooling system. Each component is meticulously labeled to facilitate easy identification, ensuring that users can quickly locate and assess any area of interest.

Furthermore, the visual guide serves as an invaluable tool for troubleshooting and repairs. By recognizing the specific locations of various elements, operators can more efficiently address issues that may arise during use. This not only enhances the longevity of the equipment but also promotes safety and reliability in its operation.

In conclusion, a thorough understanding of the schematic representation empowers users to optimize their experience, ensuring that they can navigate the complexities of the machine with confidence and ease. Such knowledge is essential for both novice and experienced operators alike, fostering a deeper connection with the equipment they utilize.

Where to Find Replacement Parts

Locating suitable components for your welding machine can significantly enhance its performance and longevity. Several avenues exist for sourcing these essential items, ensuring your equipment remains in top condition.

- Authorized Dealers: Visit local or online retailers who specialize in equipment and accessories. They often carry a wide range of components.

- Manufacturer Websites: Explore the official site of the manufacturer for specific items, manuals, and contact information for inquiries.

- Online Marketplaces: Platforms like eBay or Amazon can offer various components, often at competitive prices.

- Specialty Shops: Check with stores focused on welding and industrial supplies for expert advice and availability.

- Forums and Community Groups: Engage with online communities where members share insights on sourcing parts and their experiences.

Utilizing these resources will help you find the right components to keep your equipment functioning optimally.

Upgrades for Enhanced Performance

Improving the efficiency and functionality of your welding machine can significantly impact the quality of your work. By incorporating advanced components and modifications, users can achieve better results, extend equipment life, and enhance overall productivity. Here, we will explore several options that can elevate your welding experience.

Essential Modifications

To maximize the potential of your equipment, consider implementing the following enhancements:

| Upgrade | Description | Benefits |

|---|---|---|

| Cooling System | Upgrading to a more efficient cooling mechanism helps prevent overheating during extended use. | Increases durability and maintains optimal operating temperatures. |

| Wire Feed Unit | Installing a high-performance wire feed unit ensures consistent feeding and reduces jams. | Improves weld quality and reduces downtime. |

| Power Supply | Replacing the standard power supply with a higher capacity model can enhance performance. | Provides greater power for heavier welding tasks. |

Additional Accessories

In addition to core upgrades, consider integrating various accessories that can further improve your setup:

| Accessory | Description | Benefits |

|---|---|---|

| TIG Torch | A versatile torch that allows for precise welding on thin materials. | Enhances control and quality of welds. |

| Welding Helmet | Investing in an auto-darkening helmet provides better visibility and safety. | Increases comfort and protects eyes from UV radiation. |

| Work Table | A sturdy work table with adjustable height can enhance workspace organization. | Improves efficiency and comfort during long projects. |

Comparing to Other Welding Machines

When evaluating various welding systems, it’s essential to consider their performance, features, and suitability for different applications. This comparison can help users make informed decisions based on their specific needs and preferences.

Key Features Comparison

| Feature | Machine A | Machine B | Machine C |

|---|---|---|---|

| Power Output | 250A | 200A | 300A |

| Weight | 150 lbs | 120 lbs | 180 lbs |

| Type of Welding | MIG/TIG | Stick | MIG |

Performance and Efficiency

Each system offers distinct advantages in terms of efficiency and ease of use. Analyzing these aspects can reveal which machine best meets the ultimate demands of both professionals and hobbyists alike.

User Reviews and Experiences

This section highlights the insights and feedback from users who have interacted with the equipment. Personal experiences can provide valuable information regarding performance, reliability, and overall satisfaction, helping prospective buyers make informed decisions.

Positive Feedback

- Many users praise the machine for its durability and robust construction, emphasizing its ability to withstand rigorous use.

- Reviewers often mention the ease of operation, particularly for beginners who appreciate intuitive controls and clear instructions.

- Customers frequently note the quality of the welds produced, stating that the results consistently meet or exceed their expectations.

Areas for Improvement

- Some users express concerns regarding the weight of the unit, suggesting that portability could be an issue for certain applications.

- A few reviews point out that while the setup is generally straightforward, detailed assembly instructions could enhance the experience for first-time users.

- While most users are satisfied with performance, a handful have reported occasional maintenance challenges, indicating that access to replacement components might be a consideration.

FAQs About Lincoln Idealarc 250

This section addresses common inquiries related to a specific welding machine model, providing clarity and assistance to users seeking information on its functionality, maintenance, and operational features.

Common Questions

- What is the recommended voltage for optimal performance?

- How often should I perform maintenance checks?

- What accessories are essential for effective use?

Operational Tips

- Always ensure proper grounding before starting.

- Regularly inspect cables and connectors for wear.

- Adjust settings based on material thickness for better results.