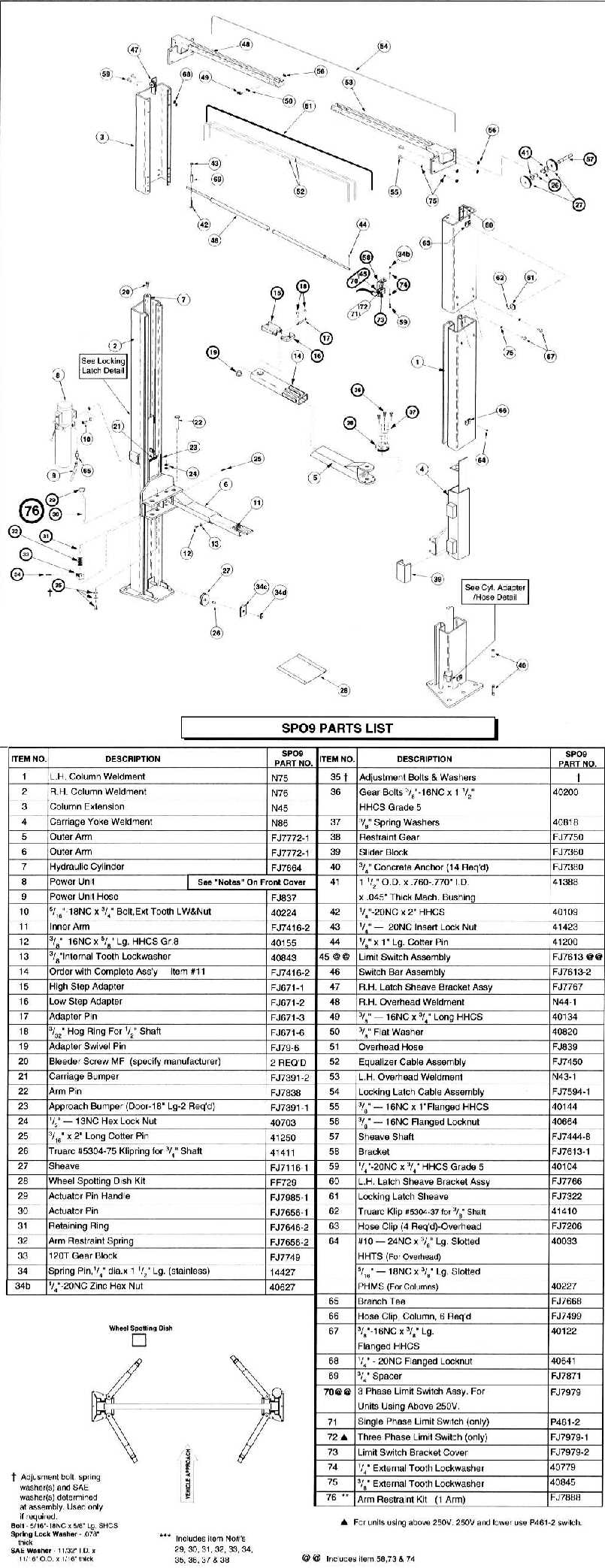

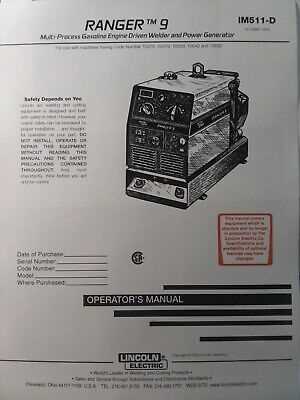

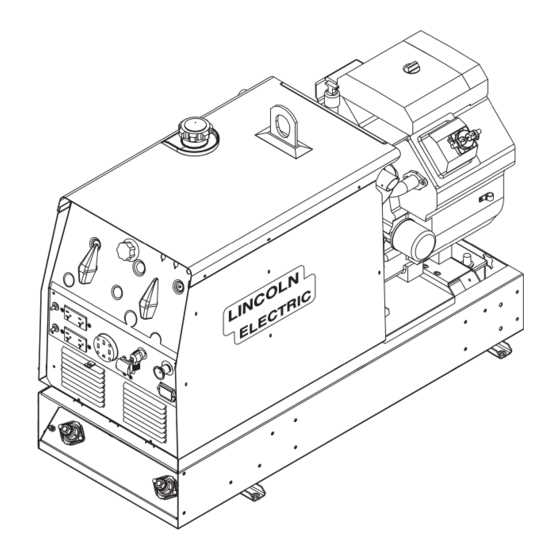

Understanding the Lincoln Ranger 9 Parts Diagram

Understanding the intricate design of a particular vehicle model can significantly enhance maintenance and repair efforts. Analyzing the components and their configurations allows enthusiasts and professionals alike to ensure optimal performance and longevity. A comprehensive overview of these elements is essential for anyone looking to delve deeper into the mechanics of their automobile.

In this section, we will break down the essential elements that contribute to the functionality of the machine. Each piece plays a vital role in the overall system, and familiarity with their arrangement and interconnections can simplify troubleshooting and restoration processes. This knowledge empowers users to approach repairs with confidence and precision.

By utilizing a structured visual representation, one can easily navigate through the various sections of the mechanism. Such a guide serves not only as a reference but also as a tool for enhancing one’s understanding of the vehicle’s anatomy. Whether you are a seasoned mechanic or a curious owner, grasping the layout and relationship of each component can lead to more informed decisions and effective maintenance practices.

Understanding Lincoln Ranger 9 Parts

Exploring the components of a specific welding machine is essential for anyone seeking to enhance their skills and maintain their equipment effectively. Familiarity with the various elements not only aids in troubleshooting but also improves overall performance and longevity of the apparatus. Recognizing the functionality and arrangement of these crucial elements can lead to more efficient operation.

Core Elements: At the heart of the system lies the power source, which provides the necessary energy for the welding process. This unit is complemented by a control panel that allows the operator to adjust settings for optimal results. The interaction between these main components is vital for achieving desired outcomes in welding tasks.

Supportive Mechanisms: Additional features, such as cooling systems and safety devices, play significant roles in ensuring the machine operates smoothly and securely. These systems prevent overheating and protect the user, highlighting the importance of safety in welding operations.

Maintenance Considerations: Regular inspection and maintenance of these individual components are crucial for preventing breakdowns and extending the lifespan of the equipment. Understanding how each part contributes to the overall functionality will empower users to perform better care and identify issues early.

Overview of Lincoln Ranger 9 Components

This section delves into the essential elements that contribute to the functionality and efficiency of a portable welding machine. Understanding these components is crucial for both maintenance and performance enhancement. Each part plays a specific role, ensuring that the device operates smoothly and meets the demands of various welding applications.

Key Functional Elements

The primary components of this welding equipment include the power supply unit, which converts electricity into usable energy for welding processes. Additionally, the control panel allows the user to adjust settings for different tasks, providing flexibility and precision. Cooling systems are also vital, preventing overheating during extended use and ensuring the longevity of the equipment.

Safety and Performance Features

Integral to the design are safety mechanisms that protect both the user and the device. Overload protection features help prevent damage from excessive current, while insulation materials ensure safe operation in various environments. Regular inspection of these critical components is essential to maintain optimal performance and user safety.

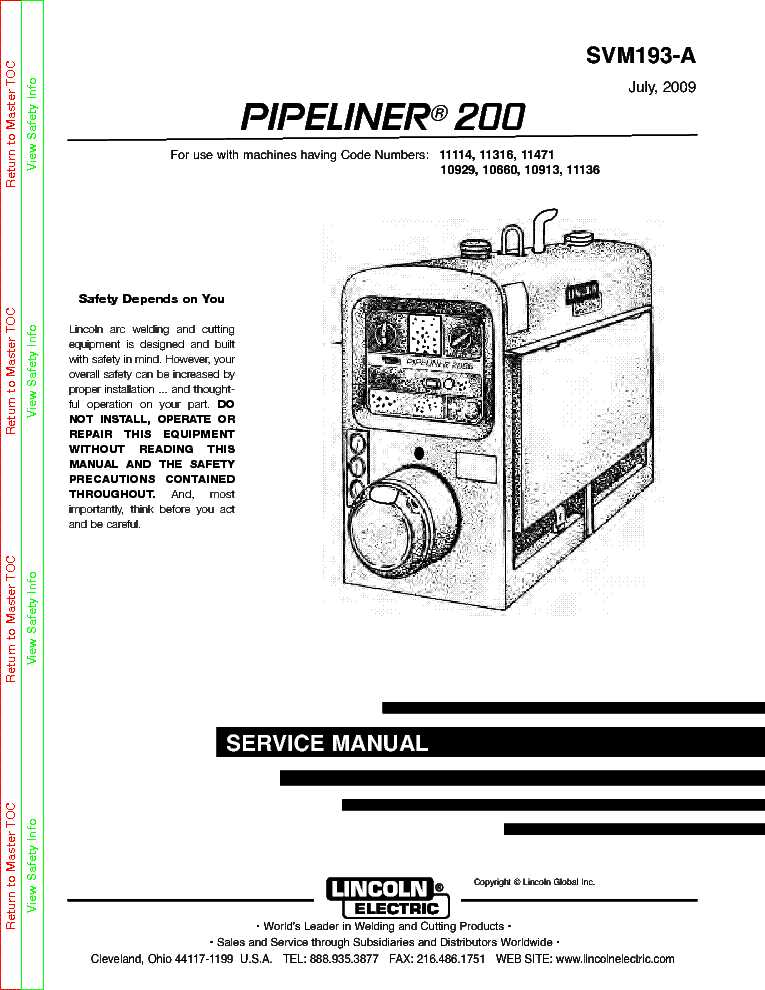

Importance of Accurate Parts Diagram

Having a precise visual representation of components is crucial in any mechanical context. Such illustrations not only facilitate understanding of the structure but also streamline the assembly and maintenance processes. Clarity in these representations minimizes confusion, ensuring that individuals can identify each element swiftly and accurately.

When components are clearly outlined, the likelihood of errors during repairs or replacements decreases significantly. Users can follow the provided guides effectively, which leads to enhanced efficiency and reduced downtime. Moreover, accurate illustrations serve as a vital reference for training new personnel, enabling them to become proficient in handling various tasks more rapidly.

| Benefits | Explanation |

|---|---|

| Improved Efficiency | Clear visuals help in quick identification of components, speeding up repairs. |

| Reduced Errors | Accurate depictions minimize mistakes during assembly or maintenance. |

| Enhanced Training | New employees can learn processes faster with reliable references. |

| Cost Savings | Efficiency and accuracy lead to lower operational costs over time. |

Common Issues with Ranger 9 Parts

In any machinery, certain components are prone to wear and tear, leading to a variety of complications that can hinder performance. Understanding these common challenges can help users maintain functionality and extend the life of their equipment. Below are some frequent concerns that may arise with these particular elements.

Wear and Tear

Over time, certain elements may degrade due to prolonged usage. This deterioration can manifest as reduced efficiency or complete failure, often necessitating replacement. Regular inspections are crucial to identify these issues early on, thereby preventing more significant damage.

Compatibility Issues

Another prevalent problem is the compatibility of various components. Mismatched elements can lead to operational inefficiencies or even cause malfunction. It’s essential to ensure that any replacements or upgrades are specifically designed to work seamlessly with existing systems.

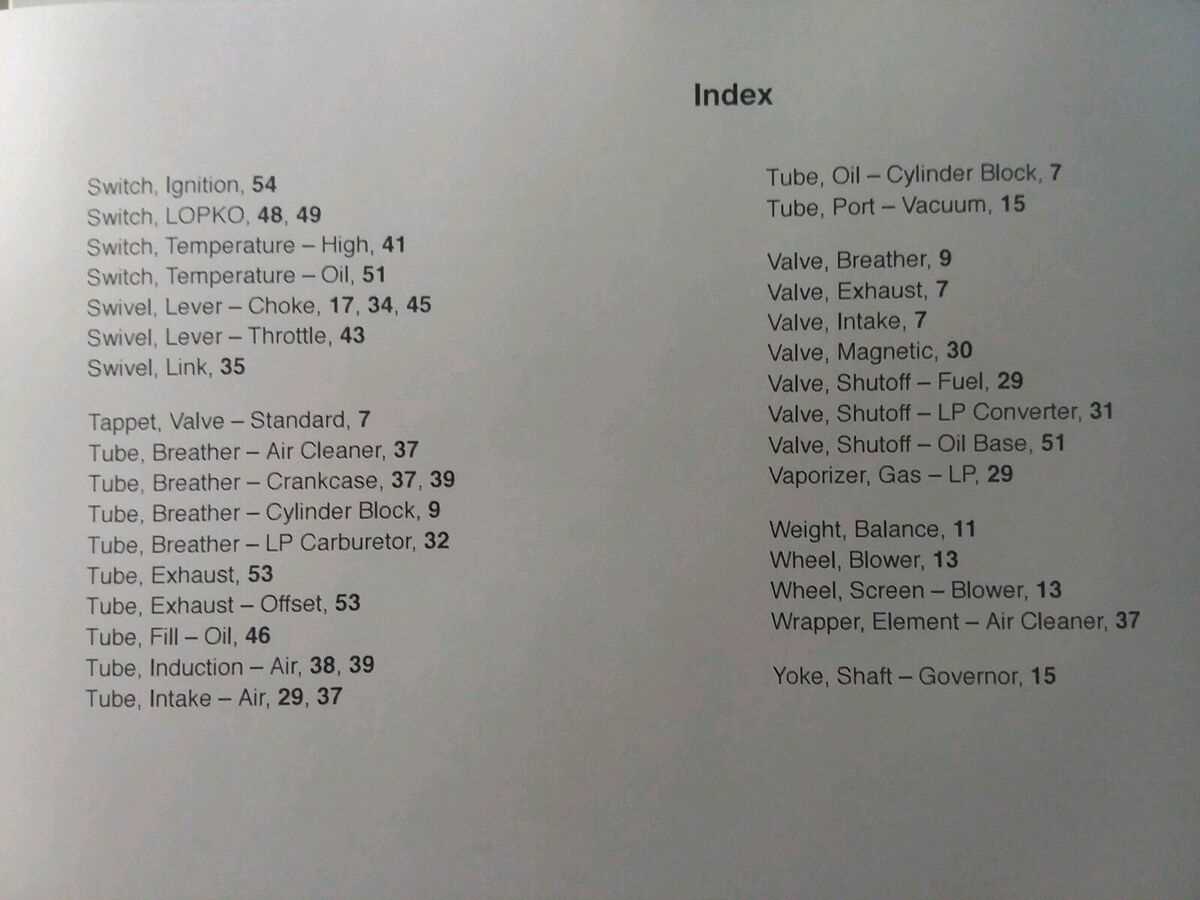

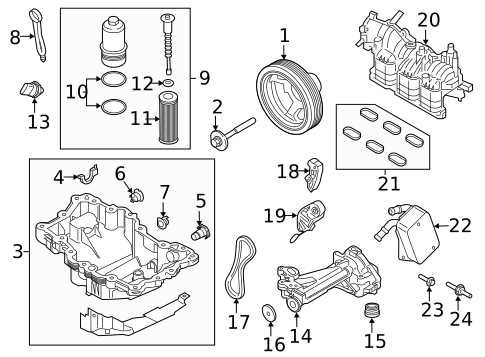

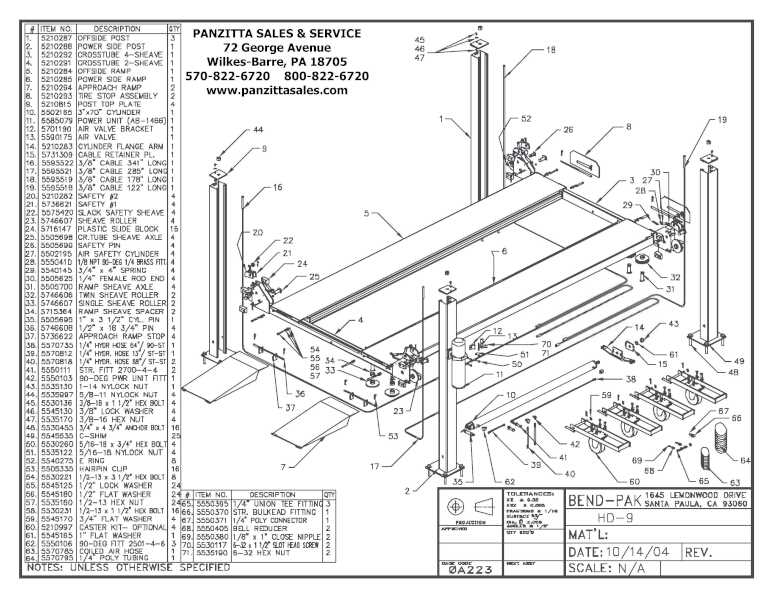

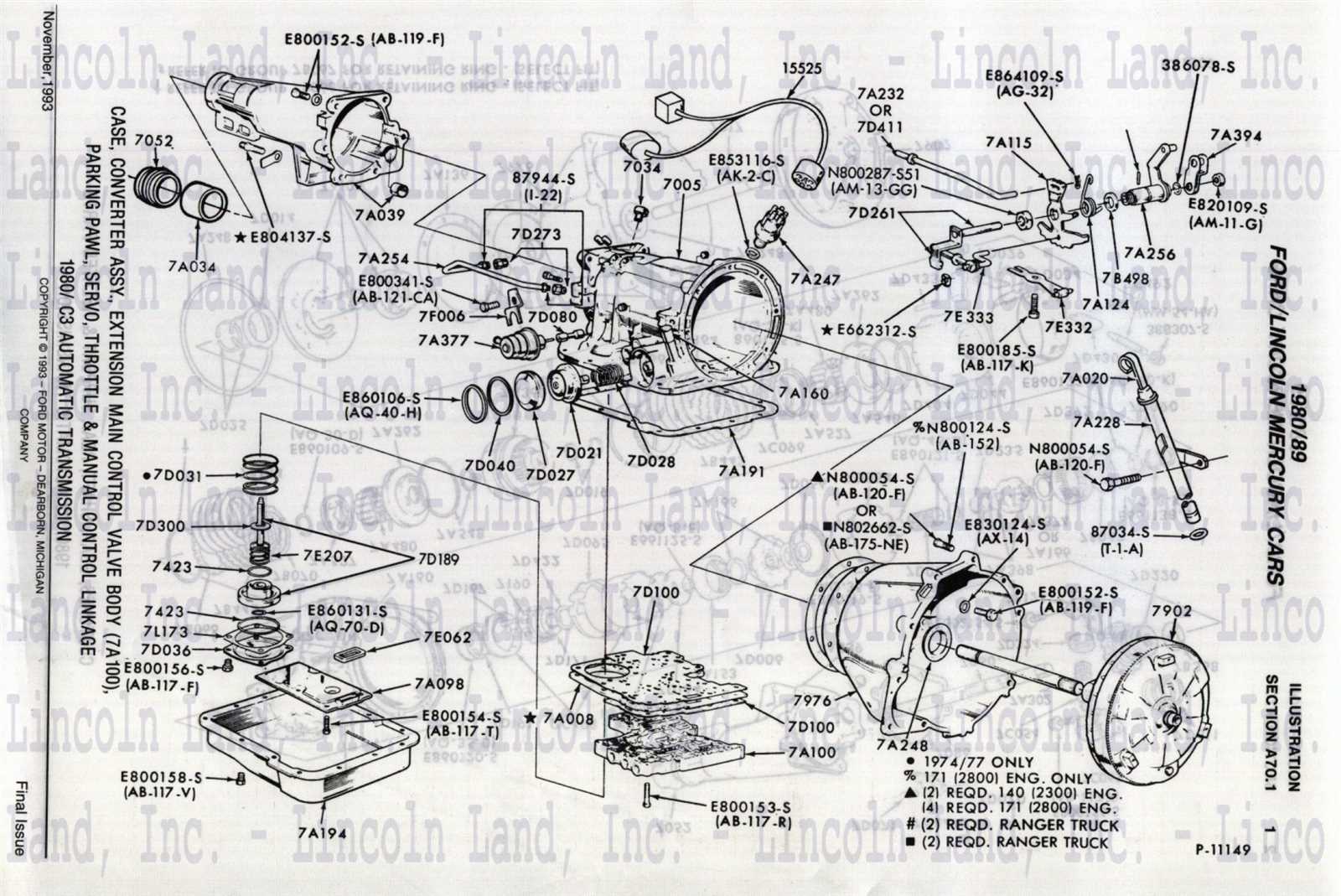

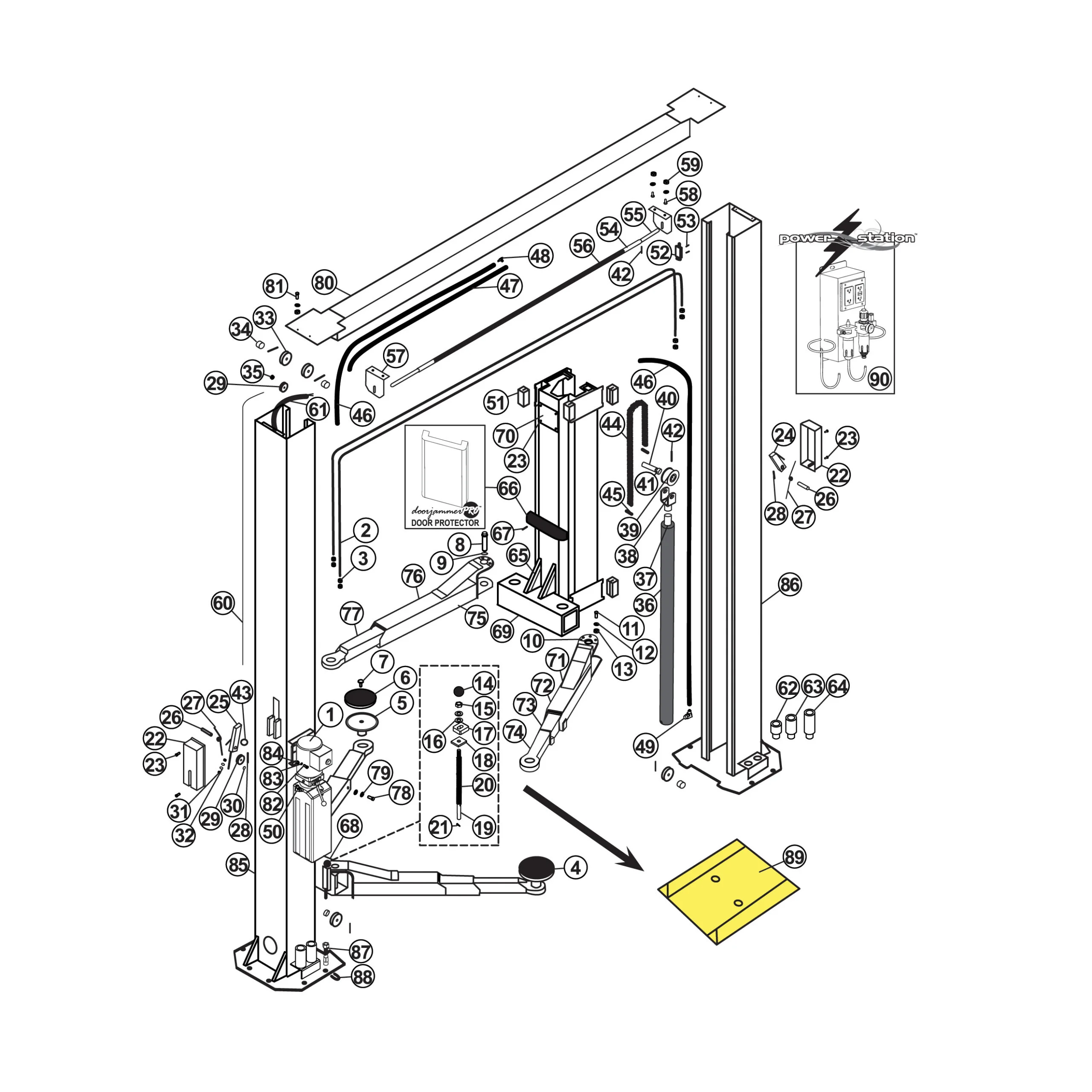

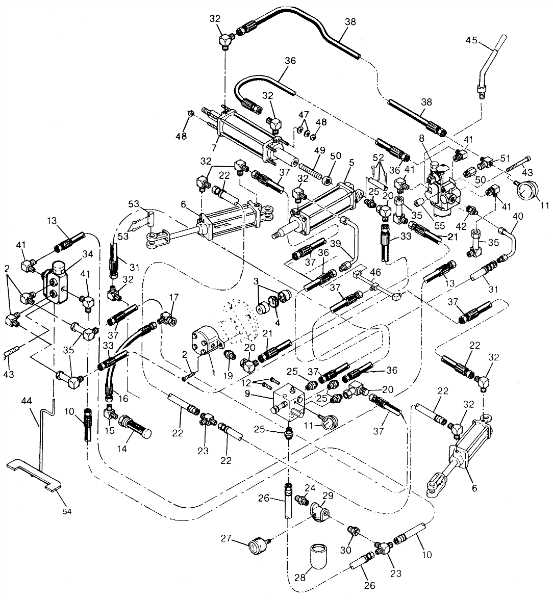

How to Read the Parts Diagram

Understanding a schematic representation of components is crucial for effective maintenance and repairs. This guide will help you interpret these visuals, ensuring you can identify and locate each element accurately.

First, familiarize yourself with the overall layout. Typically, these visuals are organized in a way that shows how various components interact with each other. Pay attention to the arrangement, as it often reflects the assembly order or functional relationships.

Next, look for a legend or key that explains the symbols used. Different shapes and lines represent various types of items, such as electrical elements or mechanical parts. Knowing these symbols will enhance your comprehension.

| Symbol | Description |

|---|---|

| Circle | Electrical component |

| Square | Mechanical part |

| Arrow | Connection or flow direction |

Finally, take your time to trace each element and its connections. This careful examination will not only help you understand the structure but also aid in diagnosing issues when they arise. A clear grasp of these visuals will empower you to perform repairs and maintenance with confidence.

Essential Tools for Maintenance

Proper upkeep of machinery requires a set of fundamental instruments that ensure efficiency and longevity. These tools not only facilitate routine inspections but also assist in repairs, ultimately saving time and resources. Understanding which implements are vital can help maintain optimal performance and prevent unexpected breakdowns.

Basic Hand Tools

Every maintenance toolkit should include essential hand tools. Items such as wrenches, screwdrivers, and pliers are crucial for adjusting and tightening components. Wrenches are particularly important for loosening or securing bolts, while screwdrivers come in various sizes and types to accommodate different fasteners. Additionally, pliers are invaluable for gripping, twisting, and cutting tasks.

Specialized Equipment

In addition to basic tools, having specialized equipment can greatly enhance maintenance efforts. Torque wrenches ensure that bolts are tightened to the correct specifications, preventing damage. Multimeters are essential for diagnosing electrical issues, allowing for effective troubleshooting. Furthermore, lubrication systems help maintain smooth operation, reducing wear and tear on moving parts.

Where to Find Replacement Parts

Locating the necessary components for your vehicle can often feel daunting, but with the right approach, it becomes a manageable task. Whether you’re performing routine maintenance or addressing specific issues, understanding where to source high-quality substitutes is essential for keeping your machine running smoothly.

Online Retailers: Numerous e-commerce platforms specialize in automotive components. These sites provide extensive catalogs, allowing you to search by make and model, ensuring you find what you need without hassle. Look for reputable vendors with customer reviews and clear return policies.

Local Auto Shops: Don’t overlook the value of visiting nearby stores that focus on automotive supplies. Many local establishments offer knowledgeable staff who can assist in identifying the right items for your needs. Additionally, they may have options for same-day pickup.

Salvage Yards: For those seeking budget-friendly alternatives, salvage yards can be a treasure trove. Here, you may find gently used components at a fraction of the retail price. Just be sure to inspect the items carefully for quality and compatibility.

Manufacturer Websites: Many manufacturers provide a comprehensive list of authorized dealers and distributors. Visiting the official site can direct you to verified sources for genuine components, ensuring you maintain the integrity and performance of your vehicle.

Forums and Community Groups: Online communities and forums dedicated to automotive enthusiasts can be invaluable resources. Members often share their experiences and recommend trustworthy vendors, helping you connect with sources that may not be widely advertised.

Step-by-Step Repair Process

This section outlines a comprehensive guide to effectively restore equipment functionality. By following a systematic approach, you can identify issues and apply necessary fixes, ensuring optimal performance and longevity of the machinery.

Preparation Phase

- Gather essential tools: screwdriver set, pliers, wrenches, and any specialized instruments required for specific tasks.

- Obtain a detailed reference guide or manual to familiarize yourself with the equipment layout.

- Ensure a clean, well-lit workspace to facilitate efficient repairs.

- Wear appropriate safety gear, including gloves and goggles, to protect yourself during the process.

Repair Steps

- Begin by disconnecting power sources to prevent any accidents.

- Carefully disassemble the components, taking notes or photographs for easier reassembly.

- Inspect each part for wear or damage, noting any areas that require replacement or adjustment.

- Clean all surfaces and components to remove dirt and debris that could hinder performance.

- Replace any faulty parts, ensuring they are compatible with your equipment.

- Reassemble the machinery in the reverse order of disassembly, double-checking connections and fittings.

- Reconnect power sources and conduct a thorough test to confirm that the repairs were successful.

By adhering to these steps, you can ensure a methodical approach to repairs, minimizing the risk of further complications and enhancing the overall efficiency of your equipment.

Tips for Proper Maintenance

Ensuring the longevity and efficiency of your machinery requires consistent upkeep and attention to detail. Proper care not only enhances performance but also prevents costly repairs and extends the lifespan of the equipment. Adopting a systematic approach to maintenance can yield significant benefits.

Regular Inspections

Conducting frequent assessments is essential for identifying potential issues before they escalate. A routine check-up should include examining critical components for wear and tear, ensuring that everything operates smoothly. Keeping an eye on performance metrics can also provide early warnings of any irregularities.

Lubrication and Cleaning

Maintaining cleanliness and ensuring proper lubrication are key aspects of effective maintenance. Regularly removing debris and dirt helps to prevent overheating and mechanical failure. Additionally, applying the correct lubricants to moving parts minimizes friction and prolongs their functionality.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Weekly | Check for visible signs of wear |

| Lubrication | Monthly | Use recommended lubricants |

| Cleaning | Bi-weekly | Remove dirt and debris |

| Performance Check | Quarterly | Monitor for irregularities |

Frequently Asked Questions About Parts

This section addresses common inquiries related to components and their maintenance. Understanding these elements can enhance your experience and ensure optimal performance.

What should I consider when selecting components?

When choosing components, focus on quality and compatibility with your system. Research the specifications and ensure they align with your requirements. Consulting manuals or expert reviews can provide valuable insights.

How can I maintain the longevity of my components?

Regular upkeep is crucial for extending the lifespan of your components. Routine inspections and cleaning can prevent wear and tear. Additionally, using the right tools during installation and replacement can avoid unnecessary damage.

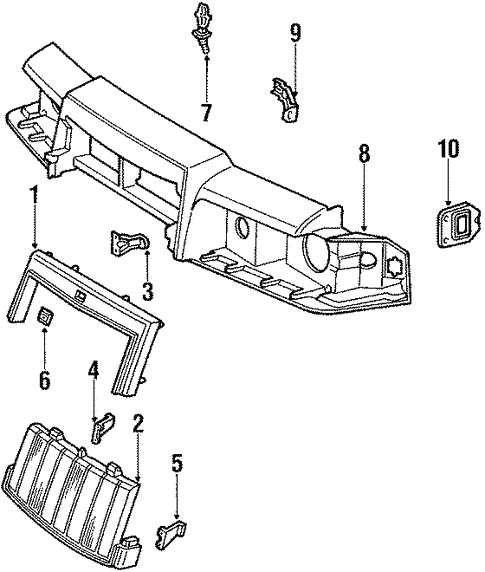

Upgrades and Modifications for Performance

Enhancing vehicle efficiency and power often involves a combination of upgrades and modifications. These improvements can lead to better acceleration, increased torque, and overall enhanced driving experience. By focusing on key components and making strategic changes, enthusiasts can significantly elevate the capabilities of their vehicles.

Engine Enhancements

One of the most impactful areas for improvement is the engine. Upgrading components such as the intake system, exhaust headers, and fuel injectors can lead to substantial gains in horsepower. Additionally, tuning the engine control unit (ECU) allows for optimized fuel-air mixtures and ignition timing, further enhancing performance. Using high-performance spark plugs and ignition coils can also contribute to more efficient combustion.

Suspension and Handling

To complement engine upgrades, improving suspension systems is crucial for better handling and stability. Installing performance shocks, struts, and sway bars can dramatically enhance cornering capabilities and ride comfort. Upgrading to larger wheels and tires with better grip also plays a vital role in achieving a balanced and responsive driving experience, especially during high-speed maneuvers.