Singer Quantum Stylist 9960 Parts Overview

Understanding the various elements that make up a modern sewing device is crucial for both beginners and experienced users. Each part works in harmony to ensure precision, efficiency, and smooth operation during sewing projects. This guide will provide an in-depth look at the essential elements of the machine and their individual functions.

Whether you’re familiar with mechanical systems or just starting to explore the world of sewing, recognizing the main components is key to ensuring proper maintenance and troubleshooting. Knowing how these elements interact allows for more efficient use and longer-lasting performance of your equipment.

From the needle mechanism to the complex tension systems, every detail plays an important role. We’ll explore these mechanisms step by step, giving you a clearer understanding of how everything fits together. With this knowledge, you’ll be able to make informed decisions about repairs, replacements, and overall care

Detailed Overview of Key Components

The structure and functionality of this sewing machine revolve around various essential mechanisms that work together seamlessly. Understanding these components can significantly enhance your usage and maintenance experience, allowing for smoother operation and better results in sewing projects.

Main Operational Mechanisms

At the core of the device are the elements responsible for stitching, fabric movement, and needle adjustments. These parts collaborate to ensure precision and durability, allowing users to create various stitch patterns with ease. Proper knowledge of these mechanisms will help in troubleshooting and maintaining peak performance.

Supporting Features

Beyond the fundamental mechanisms, the machine includes additional features that enhance usability. These may include automatic systems for thread handling, speed adjustments, and various customization options. These extra functionalities contribute to a more streamlined sewing experience, making the device versatile for both beginners and professionals.

Main Features and Their Functions

This versatile sewing machine offers a range of capabilities designed to make both simple and complex projects more manageable. Equipped with advanced settings, it allows users to customize their work with precision and ease. Whether you’re adjusting stitch length or selecting from various automated options, the device adapts to suit individual preferences.

The machine includes a variety of automatic features such as needle threading and buttonhole creation, which streamline the sewing process. With multiple stitch patterns available, users can experiment with different techniques, ensuring that every project meets high-quality standards. The adjustable speed control and backlit display enhance the overall experience, providing both convenience and accuracy.

Commonly Used Attachments and Tools

When working with a versatile sewing machine, there are several attachments and tools that are essential for handling a wide range of sewing projects. These accessories enhance functionality, allowing users to achieve professional results with different fabrics and techniques.

Presser Feet

A variety of presser feet can be utilized to simplify tasks such as sewing zippers, creating buttonholes, or applying decorative stitches. Each type of foot is designed for a specific purpose, providing accuracy and ease during the sewing process.

Needle Types and Sizes

Different needle types and sizes are available to accommodate various fabrics and sewing techniques. From heavier needles for thick materials to finer ones for delicate fabrics, the right choice ensures smooth operation and precise stitching.

Understanding the Machine’s Internal Mechanism

The internal workings of this advanced sewing tool are designed to provide seamless functionality and precision. The mechanism, composed of various interconnected components, ensures that every stitch is accurately placed, offering reliability for both simple and complex projects.

Key internal elements include a series of mechanical and electronic systems that work together to control movement, speed, and tension. By understanding how these elements interact, users can better appreciate the machine’s efficiency and make more informed decisions when troubleshooting or maintaining it.

Additionally, familiarity with the internal setup can help in identifying potential issues, whether they relate to thread tension or motor performance. With careful observation and regular maintenance, the machine can continue to perform at an optimal level for years.

Exploring the Needle and Threading System

The needle and threading mechanism plays a crucial role in ensuring smooth and efficient operation, allowing for precise stitching and reliable fabric handling. Understanding how this system works can help in maintaining accuracy during the sewing process and prevent common issues such as thread breakage or misalignment. The design of the needle and threading path is crafted to support a wide range of fabrics and techniques, offering versatility for various projects.

Proper use of the needle and threading process involves not only correctly positioning the needle but also ensuring the thread is passed through all necessary guides and tension systems. This ensures consistent stitch formation and prevents jams or interruptions. By regularly checking and maintaining these

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the long-lasting performance of your sewing machine. By following a few straightforward guidelines, you can enhance its durability and maintain optimal functionality over time.

Regular Cleaning

Keeping the machine clean is crucial to prevent dust and lint buildup. After each use, remove any debris from the machine and its components.

Proper Storage

When not in use, store the machine in a dry and dust-free environment. Utilize a protective cover to shield it from external elements and ensure its longevity.

| Maintenance Task | Frequency |

|---|---|

| Clean the exterior and interior | After every use |

| Oil moving parts | Every month |

| Check for loose screws | Every three months |

| Inspect electrical components | Every six months |

How to Troubleshoot Basic Issues

Troubleshooting common problems can significantly enhance your sewing experience and ensure the machine operates smoothly. By identifying and resolving these basic challenges, you can maintain the efficiency and longevity of your sewing device.

Identifying Common Problems

When issues arise, start by observing the symptoms carefully. Unusual noises, thread jams, or inconsistent stitching are all signs that something may be amiss. Documenting these occurrences can help in diagnosing the problem effectively.

Steps to Resolve Issues

Begin troubleshooting by checking the following:

- Thread Tension: Ensure that the tension settings are appropriate for the type of fabric being used.

- Needle Condition: Inspect the needle for any damage or bending, which could lead to sewing complications.

- Feed Dogs: Make sure the feed dogs are engaged and functioning properly to prevent fabric from sticking.

If these basic steps do not resolve the issue, consult the user manual for further guidance or consider seeking professional assistance.

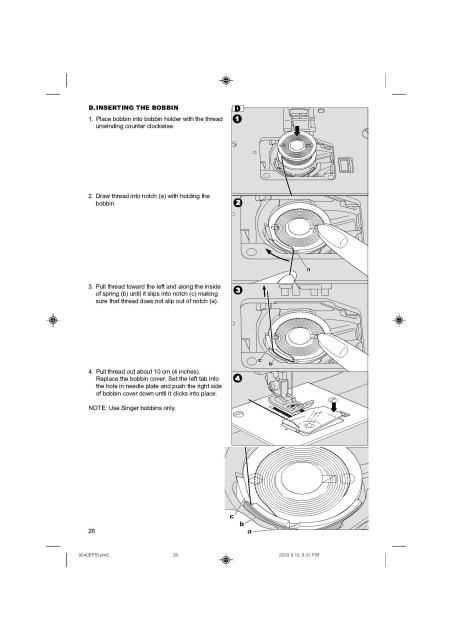

Important Parts of the Bobbin System

The bobbin mechanism plays a crucial role in the functionality of sewing machines, ensuring smooth operation and precise stitching. Understanding the essential components of this system helps users maintain their devices effectively and troubleshoot any issues that may arise.

Key Components

- Bobbin Case: This component securely holds the bobbin in place and guides the thread during sewing.

- Bobbin Winder: This part is responsible for winding the thread onto the bobbin, allowing for efficient preparation before sewing.

- Thread Tension Disc: It regulates the tension of the thread, ensuring even stitches and preventing snags or breaks.

- Bobbin Holder: This element keeps the bobbin firmly in position, allowing for smooth thread flow during operation.

Maintenance Tips

- Regularly clean the bobbin area to prevent dust accumulation.

- Check the thread tension to ensure it is set correctly for optimal performance.

- Replace worn or damaged components to maintain sewing efficiency.

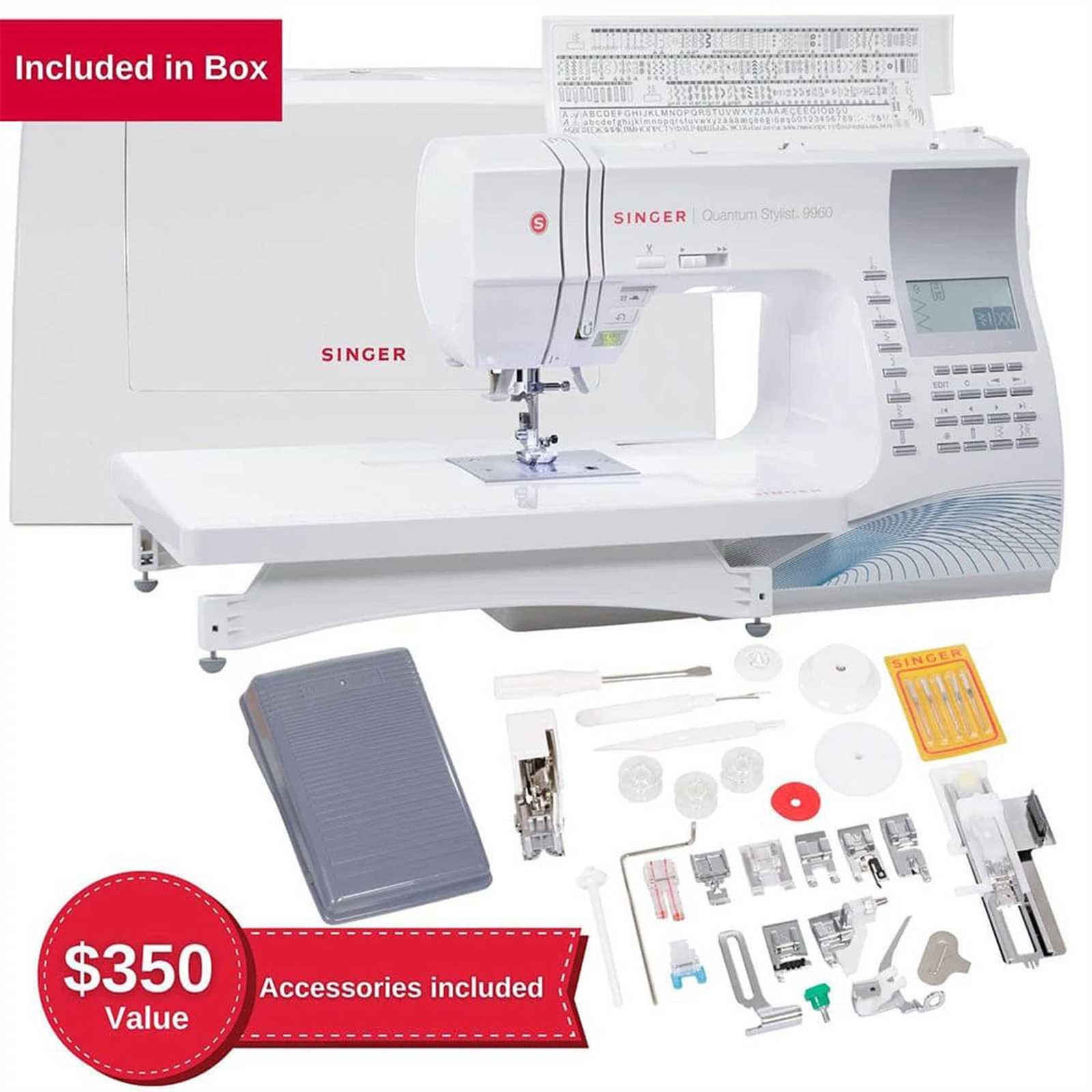

Accessories Included with the Machine

This section provides an overview of the various tools and attachments that accompany the sewing device. These components are designed to enhance functionality and improve the overall sewing experience, ensuring users can tackle a wide range of projects with ease.

Among the included accessories, you will typically find a standard presser foot, which is essential for most sewing tasks, along with a zigzag foot that allows for more intricate stitching patterns. Additionally, a buttonhole foot is often provided, making it simple to create professional-looking buttonholes with precision.

Other common attachments may include a zipper foot for installing zippers seamlessly, a walking foot for managing multiple layers of fabric, and various stitch feet tailored for specialty sewing techniques. Furthermore, the package usually contains a set of needles, bobbins, and a seam ripper, which are indispensable for any sewing enthusiast.

Each accessory plays a vital role in expanding the machine’s capabilities, allowing for creative exploration and efficient sewing processes. Familiarity with these tools can greatly enhance your sewing projects, making them more enjoyable and successful.

Control Panel Layout and Usage

The control interface of a sewing machine is designed to provide users with easy access to various functions and settings, enhancing the overall sewing experience. Understanding the arrangement of buttons and displays is essential for efficient operation.

Key Components

The main features typically found on the control panel include selection buttons, adjustment dials, and display screens. Each component serves a specific purpose, allowing users to navigate through different sewing options with ease.

Functionality Overview

The functionality of the control panel can vary, but generally includes options for stitch selection, tension adjustments, and speed control. Familiarity with these functions will enable users to tailor their sewing projects more effectively.

| Component | Description |

|---|---|

| Selection Buttons | Used to choose different stitch types and patterns. |

| Adjustment Dial | Allows for fine-tuning of stitch length and width. |

| Display Screen | Shows selected settings and provides helpful prompts. |

Foot Pedal Mechanism and Its Role

The foot control system is a crucial component in modern sewing machines, allowing users to operate the device efficiently and intuitively. This mechanism enables seamless speed adjustments, providing the flexibility needed for various sewing tasks. By utilizing the foot pedal, users can maintain hands-free operation, enhancing productivity and precision during the stitching process.

One of the primary functions of the foot pedal is to regulate the sewing speed. By pressing down with varying pressure, users can accelerate or decelerate the machine’s operation. This dynamic control helps in achieving delicate tasks such as intricate patterns or heavy fabric work, where consistent speed is vital.

Additionally, the foot control system often incorporates a safety feature that prevents accidental starts. This ensures that the machine remains inactive when not in use, thereby enhancing user safety. Understanding the operation and maintenance of the foot pedal mechanism is essential for any sewing enthusiast, as it significantly impacts the overall sewing experience.

Key Features of the Foot Pedal Mechanism:

- Speed Control: Allows precise adjustments based on the user’s comfort.

- Hands-Free Operation: Facilitates multitasking while sewing.

- Safety Features: Prevents unintended activation of the machine.

Upgrading and Replacing Machine Parts

Maintaining and enhancing your sewing device can significantly improve its performance and longevity. This section focuses on the essential aspects of upgrading and replacing components, ensuring optimal functionality and efficiency. Regularly evaluating the machine’s condition and making necessary adjustments can lead to a more enjoyable sewing experience.

When considering replacements, it is crucial to understand the specific functions of various components. Upgrading parts can not only enhance performance but also introduce new features, making sewing tasks easier and more efficient. Here are some common components that may require attention:

| Component | Description | Benefits of Upgrading |

|---|---|---|

| Needles | Essential for fabric piercing and stitching. | Improved stitch quality and precision. |

| Presser Foot | Holds the fabric in place during sewing. | Enhanced fabric handling and versatility. |

| Bobbin | Holds the lower thread, crucial for stitching. | Consistent thread tension and fewer jams. |

| Motor | Powers the sewing machine’s operation. | Increased speed and efficiency. |

By staying proactive with maintenance and upgrades, users can ensure their sewing device operates at its best, allowing for creative freedom and productivity

Care Instructions for the Sewing Machine

To ensure the longevity and optimal performance of your sewing device, regular maintenance is essential. Proper care not only enhances functionality but also prevents potential issues that may arise from neglect. Following a few straightforward guidelines will help keep your machine in excellent working condition.

First, it is important to regularly clean the exterior and interior of the device. Dust and fabric lint can accumulate, affecting performance. Use a soft cloth to wipe down the outside and a small brush to remove debris from the bobbin area and feed dogs.

Next, oiling the machine is crucial. Refer to the user manual for specific instructions on lubrication points and the type of oil to use. Proper lubrication minimizes friction and ensures smooth operation.

Additionally, changing the needle frequently can prevent skipped stitches and other sewing complications. Always use the correct needle type for the fabric being worked on to achieve the best results.

Lastly, storing the machine in a dust-free environment when not in use will protect it from environmental factors. Covering the machine with a protective cloth can further safeguard against dust and moisture.