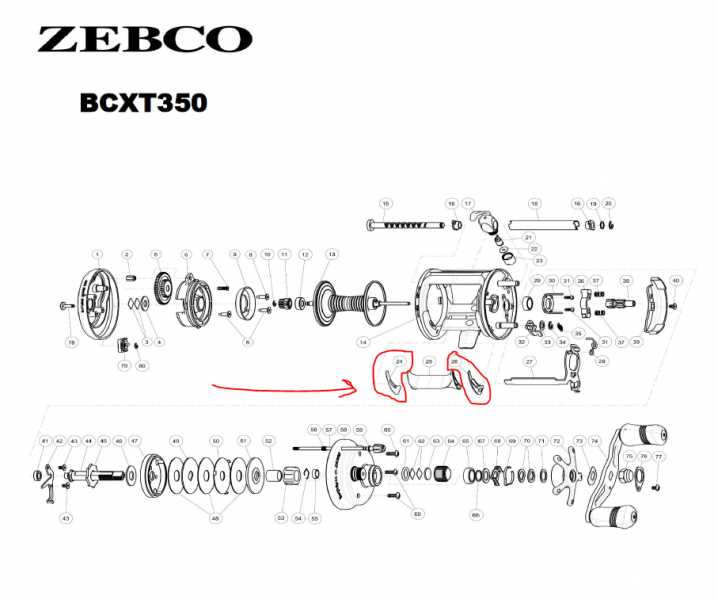

Zebco Reel Diagrams and Parts Lists

Exploring the internal workings of fishing equipment provides insight into how different elements interact to ensure smooth operation. By breaking down the structure into individual elements, one can grasp the design’s functionality and the role each element plays in enhancing performance.

When reviewing detailed layouts of various fishing mechanisms, identifying the core components becomes crucial. Understanding their placement and interrelation leads to better maintenance and improved efficiency in long-term use.

Having access to detailed breakdowns of the structural elements can assist enthusiasts and professionals alike in troubleshooting and upgrading their equipment for optimal results during fishing activities.

Understanding Zebco Reel Components

To effectively maintain and enhance the performance of your fishing tool, it is crucial to understand its inner workings. The device is made up of several intricate sections, each playing a specific role in ensuring smooth operation and reliability. Familiarizing yourself with these elements can help in identifying issues and performing necessary upkeep.

Core Functional Elements

- Handle: The part that allows for manual control, essential for retrieving your catch efficiently.

- Spool: Holds the fishing line and facilitates its smooth release and retraction.

- Drag System: Adjusts the resistance on the line to prevent it from snapping under pressure.

Supporting Mechanisms

- Bail: A mechanical arm that directs the line onto the spool when winding.

- Gearbox: Converts the handle’s rotation into the movement of other components for coordinated action.

- Anti-reverse: Prevents the handle from turning backward, ensuring secure retrieval.

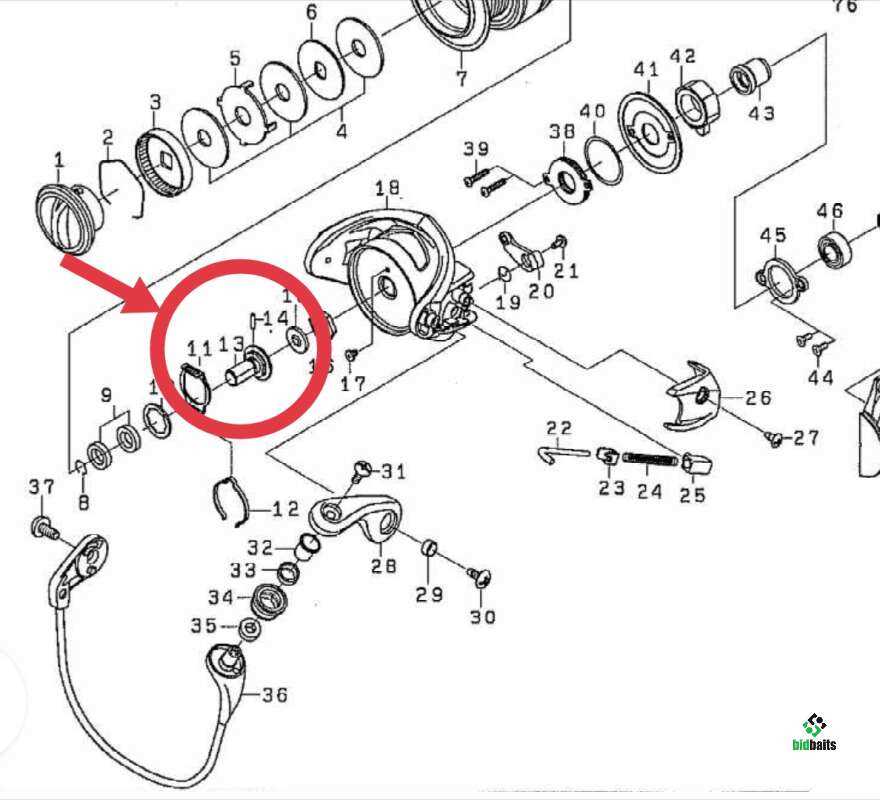

Detailed Breakdown of Gear Mechanism

The internal workings of the gear mechanism play a crucial role in the efficiency and smooth operation of the device. Understanding how each component interacts with the others provides valuable insight into maintaining and optimizing performance.

Main Gear and Pinion Interaction

The primary gear engages directly with the pinion, allowing for torque transfer that results in consistent motion. This engagement is designed to minimize friction, ensuring longevity and smooth operation under various conditions. Proper alignment is essential to avoid wear and tear.

Clutch and Drag System

The clutch and drag systems regulate tension and pressure, preventing overload on the gear assembly. The drag is adjustable, ensuring control over the force applied during high-resistance tasks. Both systems work together to distribute the load evenly across the gears.

| Component | Function | Material | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Gear | Transfers rotational force | Metal alloy | |||||||||||||||||||||||||||

| Pinion | Engages with main gear | Hardened steel | |||||||||||||||||||||||||||

| Clutch | Prevents reverse movement | Composite material | |||||||||||||||||||||||||||

| Drag System | Regulates tension | Ceram

How to Identify Spool PartsUnderstanding the different components of the spool mechanism is essential for effective maintenance and troubleshooting. By recognizing each element’s role, you can ensure smoother operation and quick repairs when needed.

By familiarizing yourself with these components, you’ll be better prepared to handle any issues that may arise during use. Common Materials Used in Fishing EquipmentIn high-quality fishing tools, manufacturers rely on a range of durable substances to ensure long-lasting performance and resistance to wear. The choice of materials directly impacts the device’s functionality and endurance, offering anglers a reliable experience in various conditions. Aluminum is a lightweight yet strong option often used for structural components. It resists corrosion, especially in saltwater environments, making it a favored material for outdoor applications. Its durability combined with minimal weight enhances comfort during extended use. Stainless steel is another popular choice, particularly for gears and other internal mechanisms. Known for its strength and resistance to rust, it ensures smooth operation even under harsh conditions. This alloy also offers longevity, reducing the need for frequent replacements. Graphite provides an excellent balance between strength and lightness. Its application in various parts of the device allows for reduced weight without compromising sturdiness, making it easier to handle. Additionally, it is less prone to corrosion, adding to its overall appeal for long-term use. High-grade carbon fiber is frequently selected for premium models due to its exceptional strength-to-weight ratio. This advanced material enhances precision and provides superior control, making it a valuable component in modern designs. Disassembling a Zebco Reel SafelyTaking apart your fishing equipment requires precision and attention to detail to avoid damaging any components. This process allows for thorough maintenance, cleaning, and replacing worn elements, ensuring your gear stays in optimal condition. Follow the steps below for a safe and efficient breakdown. Prepare the Necessary Tools

Step-by-Step Disassembly

Function of Bearings in the MechanismBearings play a crucial role in ensuring smooth operation and efficiency within mechanical systems. Their primary function is to reduce friction between moving parts, enabling smoother rotations and extending the lifespan of components. By allowing relative motion, they contribute to the overall effectiveness of various mechanisms. Types of BearingsDifferent types of bearings are utilized in mechanisms, each serving specific functions based on design and application. The choice of bearing affects performance, load capacity, and durability.

Importance of Proper MaintenanceRegular maintenance of bearings is essential for optimal performance. Insufficient lubrication or contamination can lead to increased wear and potential failure, impacting the efficiency of the entire mechanism. Ensuring cleanliness and appropriate lubrication extends the operational life of these critical components. Lubrication Points on a Zebco ReelProper maintenance is essential for ensuring the longevity and performance of fishing equipment. Regular lubrication is a key aspect of this upkeep, targeting specific areas that require attention to function smoothly. Understanding where to apply lubricants can greatly enhance the efficiency and durability of your gear. Key Areas for LubricationThe main focus should be on the bearings, gears, and any moving components that are subject to friction. Applying a suitable lubricant to these parts reduces wear and prevents corrosion. It is advisable to check these locations regularly, especially after extensive use. Recommended Lubricants

Using high-quality lubricants designed for fishing equipment will yield the best results. Options include grease for thicker applications and oil for lighter tasks. Always ensure that the lubricant is applied sparingly to avoid attracting dirt and debris. Regular Maintenance: Establish a routine to inspect and lubricate these areas to maintain optimal performance and extend the life of your fishing gear. Troubleshooting Reel Handle IssuesAddressing complications with the handle of your fishing device can enhance your overall experience. Common challenges often arise from wear and tear, misalignment, or inadequate lubrication. Identifying the specific issue is crucial for effective resolution and ensuring smooth operation. Common Problems and SolutionsHere are some typical problems you may encounter with the handle and their corresponding solutions:

Preventive MeasuresTo minimize future issues with the handle, regular maintenance is key. Ensure that the device is cleaned after each use, and lubricate moving parts periodically. Inspect for signs of wear and replace components as necessary to maintain optimal performance. Maintaining the Drag System EffectivelyProper upkeep of the drag mechanism is crucial for optimal performance in fishing equipment. This system plays a vital role in controlling line tension during a catch, ensuring that both the angler and the fish have a fair fight. Regular maintenance not only extends the lifespan of the system but also enhances the overall fishing experience. Here are some essential steps for effective maintenance:

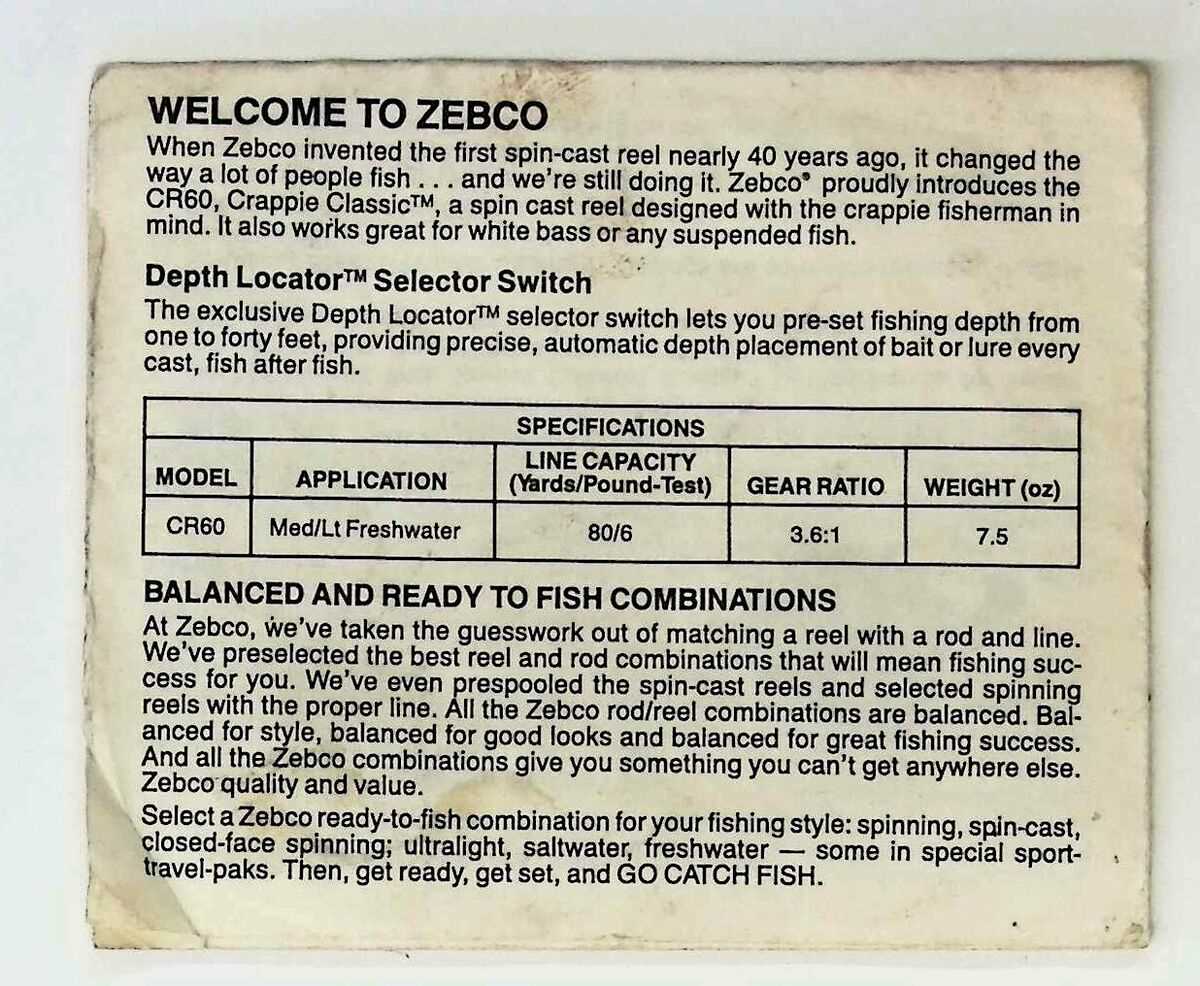

By following these guidelines, you can ensure that the drag system remains in excellent working condition, allowing for more successful fishing outings. Differences Between Spinning and Baitcasting ReelsUnderstanding the distinctions between two popular fishing mechanisms can significantly enhance the angling experience. Each type offers unique characteristics that cater to different fishing styles and preferences, making it essential for anglers to choose wisely based on their needs.

Choosing between these two types depends largely on individual skill levels and fishing objectives. Understanding their features helps in making an informed decision that enhances the overall fishing experience. Replacing Worn-Out Parts on Zebco ReelsMaintaining fishing gear in optimal condition is essential for achieving the best performance on the water. Over time, components may experience wear and tear, affecting functionality. Identifying and replacing these deteriorated elements is crucial for preserving the reliability and efficiency of your equipment. Begin by examining the various sections of your tackle for signs of damage or fatigue. Common indicators include unusual noises during operation or difficulty in handling. Once you’ve pinpointed the faulty parts, consult your manufacturer’s guide for suitable replacements. Ensure that you select high-quality alternatives to guarantee longevity and functionality. When ready to make the replacements, follow a systematic approach. Carefully disassemble the relevant sections, taking note of the arrangement of each component. This step helps avoid confusion during reassembly. After installing the new elements, conduct a thorough inspection to confirm proper alignment and functionality. Regular maintenance and timely replacements will enhance your overall fishing experience. Comparing Models Based on Part DesignWhen evaluating various fishing gear models, it is essential to examine their structural components and configurations. Different designs can significantly impact functionality, durability, and user experience. Structural Variations: Each model often features unique configurations that cater to specific fishing techniques. Some designs prioritize lightweight materials for ease of handling, while others may focus on robustness to withstand challenging conditions. User Preference: Personal choice plays a crucial role in selecting the right equipment. Anglers may favor particular designs based on comfort, efficiency, or aesthetic appeal. Understanding these preferences can help manufacturers tailor their offerings to better meet market demands. Performance Considerations: Analyzing the impact of different component designs on performance is vital. Features such as gear ratios, drag systems, and handle ergonomics can greatly influence the overall effectiveness of the equipment in various fishing scenarios. |