Understanding the Components of a Commercial Espresso Machine

Exploring the intricate framework of a professional-grade beverage preparation setup reveals a world where precision and quality converge. Each element plays a crucial role in delivering the ultimate experience, ensuring that every cup produced meets the highest standards of taste and consistency.

Analyzing the structure of these systems allows enthusiasts and operators alike to grasp how various mechanisms interact. From the heating elements to the extraction components, each section contributes to the overall efficiency and flavor profile of the final product.

Delving into the specifics of these essential elements not only enhances understanding but also empowers users to maintain and optimize their equipment. Mastery of these components can lead to a more satisfying brewing process and superior results in every serving.

Understanding Espresso Machine Components

In the realm of brewing excellence, grasping the individual elements that contribute to the final cup is essential. Each component plays a vital role in creating the rich flavors and textures that enthusiasts appreciate.

Main Elements

- Boiler: Responsible for heating water to the perfect temperature.

- Group Head: The part where the brewing occurs, ensuring even extraction.

- Portafilter: Holds the coffee grounds in place during the brewing process.

Supporting Features

- Steam Wand: Creates milk froth for lattes and cappuccinos.

- Pressure Gauge: Monitors the force applied during extraction.

- Water Reservoir: Supplies the necessary liquid for brewing.

Each of these elements harmonizes to deliver the ultimate coffee experience, showcasing the importance of understanding their functions.

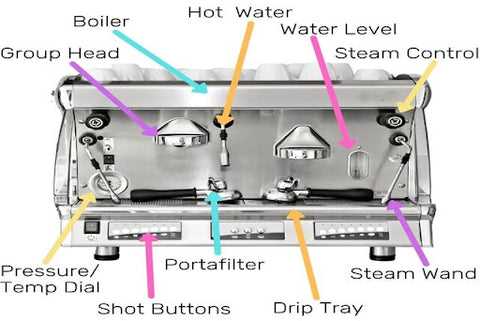

Key Parts of Commercial Machines

Understanding the essential components of brewing equipment is crucial for optimal performance and maintenance. Each element plays a significant role in delivering quality beverages, contributing to the overall efficiency and functionality.

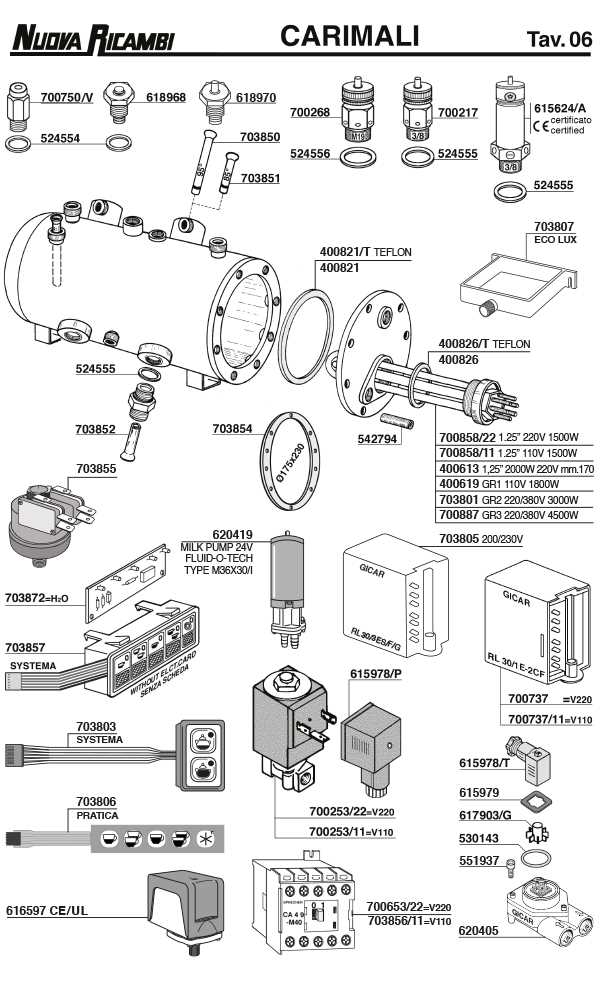

Boiler: This element generates steam and hot water, vital for brewing and milk frothing. Its capacity often determines the output and speed of service.

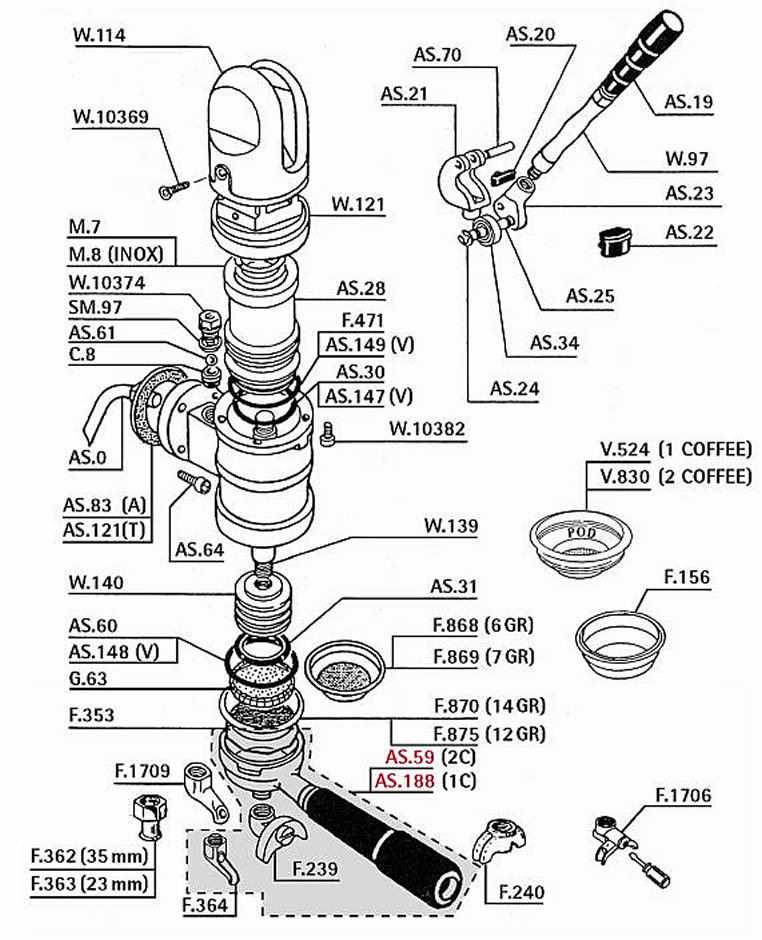

Group Head: This section is where the extraction occurs, ensuring that water interacts properly with the coffee grounds to achieve the desired flavor profile.

Portafilter: This detachable tool holds the coffee during extraction. Its design can influence the brewing process and the final taste.

Steam Wand: A crucial feature for frothing milk, it allows baristas to create creamy textures and intricate latte art.

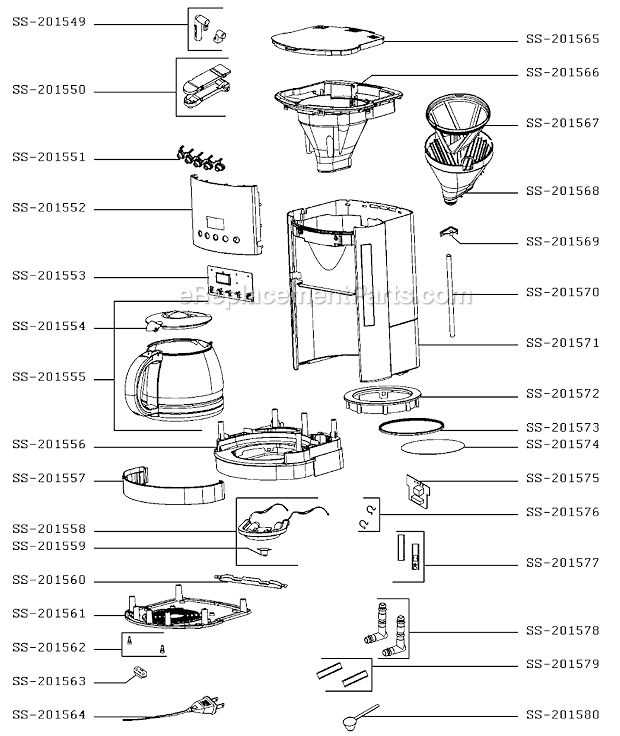

Control Panel: This interface provides the user with settings to adjust temperature, pressure, and brew time, making it essential for consistency in beverage preparation.

Drip Tray: Located below the brewing area, this component collects excess liquid, maintaining a clean workspace and preventing spills.

Delving into these elements reveals their interdependence, each contributing to the ultimate goal of crafting the perfect cup.

Function of Each Espresso Component

Understanding the role of each element within a brewing setup is crucial for achieving the perfect cup. Each component plays a significant role in the extraction process, influencing flavor, aroma, and overall quality. Let’s delve into the functions of these essential parts.

Boiler

The boiler serves as the heart of the setup, heating water to the precise temperature needed for optimal extraction. It maintains consistent heat, allowing for stable brewing conditions, which is vital for flavor development.

Group Head

The group head is where the brewing magic happens, delivering hot water to the coffee grounds. Its design ensures even distribution of water, which enhances extraction and results in a rich, balanced shot. Proper maintenance of this component is essential for quality brewing.

Common Issues with Machine Parts

When operating complex brewing devices, users often encounter various challenges that can hinder performance. Understanding these common pitfalls is essential for maintaining optimal functionality and ensuring a delightful experience. Identifying these frequent problems can help in taking proactive measures and avoiding significant downtime.

Malfunctioning Components

One of the most prevalent issues involves faulty components that may lead to inconsistent performance. Common culprits include malfunctioning valves, which can cause pressure fluctuations, and heating elements that may not reach the desired temperatures. Regular inspections can help detect these issues early, minimizing their impact on the brewing process.

Wear and Tear

Over time, normal usage can lead to wear and tear of various elements. Gaskets, seals, and other critical fittings may degrade, resulting in leaks or inefficient operation. Keeping a maintenance schedule and replacing worn components promptly can prevent larger complications and extend the lifespan of the equipment.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your brewing equipment requires regular attention and care. By following a systematic maintenance routine, you can significantly extend the lifespan of your setup and enhance its performance, ultimately leading to better beverage quality.

Regular Cleaning

One of the most crucial aspects of upkeep involves consistent cleaning. Neglecting this step can lead to residue buildup, affecting both functionality and flavor.

- Daily: Clean the brew group and portafilter after each use.

- Weekly: Run a cleaning solution through the system to remove oils and deposits.

- Monthly: Deep clean all components, including water tanks and filters.

Routine Checks

Performing periodic inspections can help identify potential issues before they escalate into major problems.

- Inspect seals and gaskets for wear and tear.

- Check water quality to prevent mineral buildup.

- Monitor temperature and pressure settings for optimal performance.

How to Identify Faulty Components

Recognizing malfunctioning elements within a brewing apparatus can significantly enhance its performance and longevity. By understanding common indicators of wear or damage, you can take proactive measures to ensure optimal functionality.

Visual Inspection: Begin with a thorough visual examination. Look for signs of leaks, corrosion, or physical damage. Components that appear burnt or discolored often indicate overheating or electrical issues.

Functional Testing: Conduct operational tests to assess performance. If certain functionalities, such as temperature control or pressure output, are inconsistent or absent, these discrepancies may point to underlying problems.

Listen for Unusual Sounds: Unusual noises can signal malfunctions. A grinding, hissing, or excessive clanking may suggest that moving parts are misaligned or worn out, necessitating further investigation.

Smell for Burnt Odors: Foul smells, particularly burnt odors, can be a clear indication of electrical failures or overheating. Immediate attention is required to prevent further damage.

Review Maintenance History: Assessing the maintenance log can provide insights into recurring issues. Frequent repairs on specific elements might signal the need for replacement or more in-depth examination.

By systematically evaluating these aspects, you can effectively identify faulty components and ensure a smoother operation of your brewing system.

Differences Between Machine Types

When exploring the world of coffee brewing devices, it’s essential to understand the various categories available. Each category is designed to cater to specific needs, preferences, and settings, influencing both the brewing process and the quality of the final product. This section will delve into the distinct characteristics that set these devices apart, highlighting their unique functionalities and applications.

Manual Devices require the user to exert control over the brewing process, allowing for a hands-on approach. These systems often appeal to enthusiasts who appreciate the artistry involved in crafting a perfect cup. The lack of automation means that every brew can be customized, but it also demands skill and practice to achieve consistent results.

Automatic Systems offer convenience by automating many aspects of the brewing process. These devices are ideal for high-traffic environments where speed and efficiency are crucial. They typically come equipped with programmable settings, ensuring that users can achieve a uniform taste with minimal effort.

Super-Automatic Models take convenience to the next level, combining grinding, brewing, and frothing into one streamlined process. These advanced units are perfect for those who desire quality without the intricacies of manual brewing. With just the push of a button, users can enjoy a wide variety of beverages with consistent results.

Specialty Machines focus on specific brewing techniques, such as pour-over or cold brew. These devices often attract aficionados who wish to explore diverse flavor profiles and extraction methods. While they may not be as versatile as other types, their dedicated designs allow for a deeper appreciation of coffee’s complexities.

Understanding these distinctions helps consumers make informed choices based on their brewing habits, preferences, and the environment in which they operate. Each type offers unique advantages, catering to different levels of expertise and desired outcomes in the coffee experience.

Choosing Quality Replacement Parts

When it comes to maintaining your equipment, selecting high-grade components is essential for ensuring optimal performance and longevity. Quality replacements not only enhance efficiency but also contribute to a seamless operation. Here are some factors to consider when making your choices:

- Material Quality: Look for components made from durable materials that can withstand frequent use and heat.

- Compatibility: Ensure that the replacements are designed to fit your specific model to avoid functionality issues.

- Brand Reputation: Opt for well-known brands that are recognized for their commitment to excellence and reliability.

- Warranty: Choose items that come with a warranty, which can provide peace of mind and protection against defects.

- Reviews and Ratings: Research user feedback to gauge the performance and satisfaction levels of other customers.

By prioritizing these elements, you can make informed decisions that enhance the overall reliability and efficiency of your setup.

Importance of Regular Cleaning

Maintaining the cleanliness of equipment is essential for ensuring optimal performance and longevity. Neglecting this crucial aspect can lead to a host of problems, including reduced efficiency and compromised quality of the final product. Regular upkeep not only enhances functionality but also promotes a safe environment for users.

Routine maintenance helps prevent the buildup of residues and contaminants that can affect taste and aroma. Over time, oils, minerals, and other substances can accumulate, leading to undesirable flavors and even operational issues. By implementing a consistent cleaning schedule, operators can ensure that every brew is as flavorful as intended.

Moreover, keeping equipment clean contributes to its durability. Components that are regularly cleaned are less prone to wear and tear, reducing the likelihood of costly repairs or replacements. This proactive approach not only saves money in the long run but also minimizes downtime, allowing for uninterrupted service.

In addition, a well-maintained setup fosters a positive perception among customers. Cleanliness reflects professionalism and attention to detail, enhancing the overall experience. This aspect is vital in a competitive environment where quality and presentation are key differentiators.

In summary, prioritizing cleanliness is fundamental for achieving excellence in operations. Regular maintenance not only ensures optimal performance and product quality but also supports the longevity of the equipment and enhances customer satisfaction.

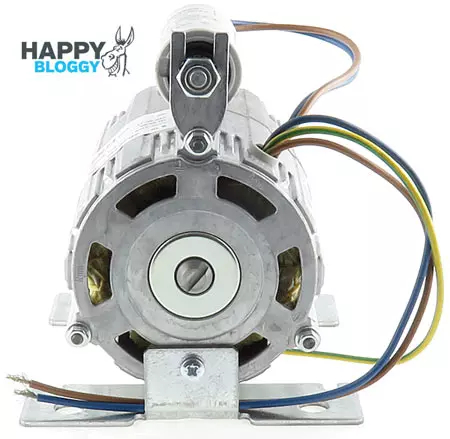

Upgrading Components for Better Performance

Enhancing specific elements of your brewing system can significantly elevate the overall quality of your beverages. By focusing on key upgrades, you can achieve more consistent extraction and improved flavor profiles, catering to the demands of discerning patrons.

Key Areas for Enhancement

- Heating Elements

- Group Heads

- Pumps

- Water Filtration Systems

Benefits of Upgrading

- Increased Temperature Stability

- Improved Pressure Control

- Enhanced Flavor Extraction

- Longer Lifespan of Equipment

Investing in these improvements not only boosts performance but also contributes to customer satisfaction, making every cup an ultimate experience.

Essential Tools for Espresso Repair

Maintaining and fixing specialized brewing devices requires a set of specific instruments that ensure efficient functionality. Having the right tools not only streamlines the repair process but also extends the lifespan of the equipment. Below are key tools that every technician should consider essential for effective repairs.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws on various components. |

| Wrench | For adjusting nuts and fittings that may require a firm grip. |

| Pliers | Used for gripping, twisting, and cutting wires or small parts. |

| Multimeter | For checking electrical connections and diagnosing issues. |

| Cleaning Brushes | Essential for maintaining cleanliness of internal components. |

| Replacement Parts | To swap out worn or damaged elements for optimal performance. |

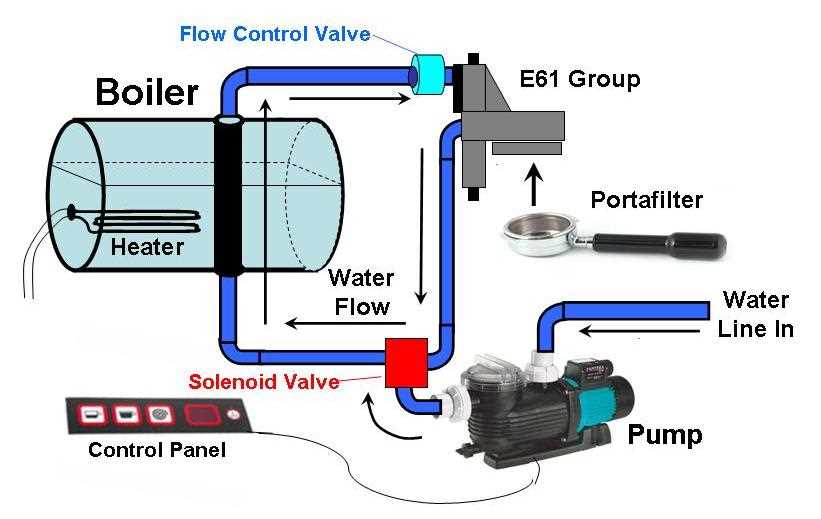

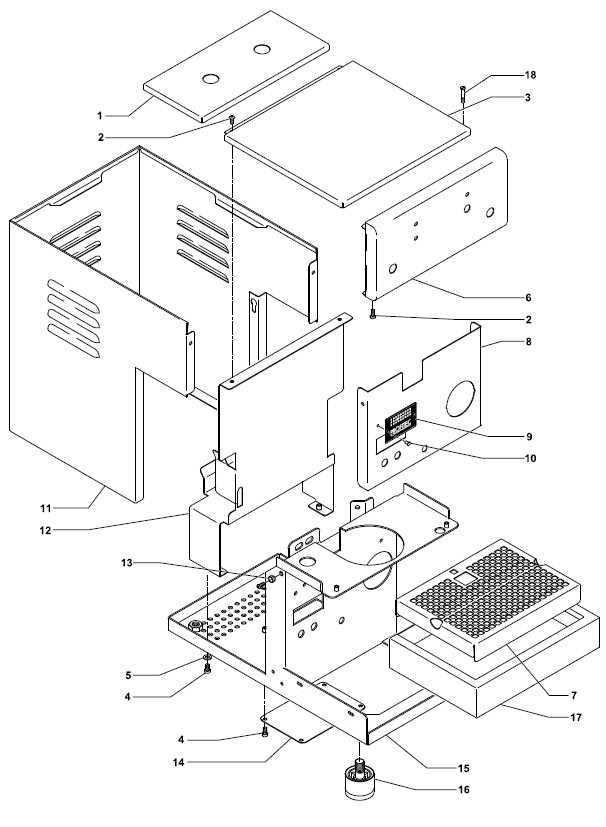

Understanding Machine Wiring and Plumbing

Grasping the intricacies of electrical connections and water systems is essential for the effective operation of brewing devices. Proper comprehension of these components ensures reliability, safety, and optimal performance.

Electrical wiring plays a crucial role in powering various functions, while plumbing systems deliver necessary fluids. Here are key aspects to consider:

- Electrical Schematics: Familiarize yourself with wiring diagrams that illustrate connections between components.

- Voltage and Amperage: Understand the required electrical specifications to prevent overloads and ensure safe operation.

- Safety Features: Identify fuses, circuit breakers, and emergency shut-off switches that protect the equipment and users.

On the plumbing side, knowledge of water flow and pressure is vital. Consider the following:

- Water Source: Ensure a reliable and clean supply of water to the device.

- Piping Configuration: Analyze the layout of pipes, including angles and connections that affect flow efficiency.

- Maintenance Needs: Regularly check for leaks, blockages, and mineral buildup to maintain optimal performance.

By mastering these essential elements, operators can enhance the functionality and longevity of their brewing systems.

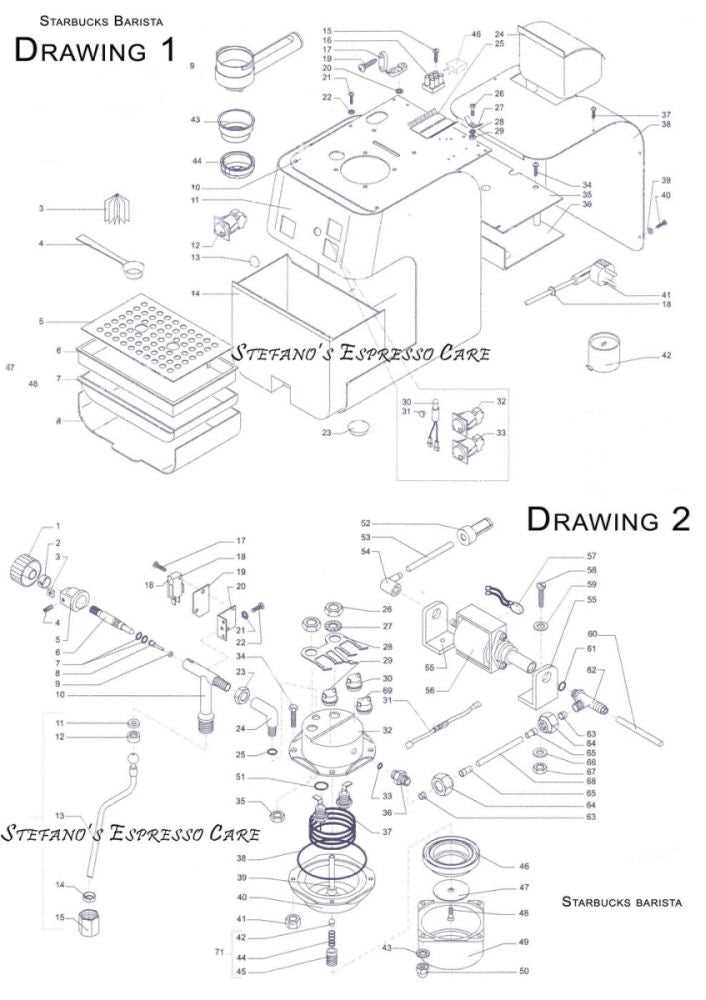

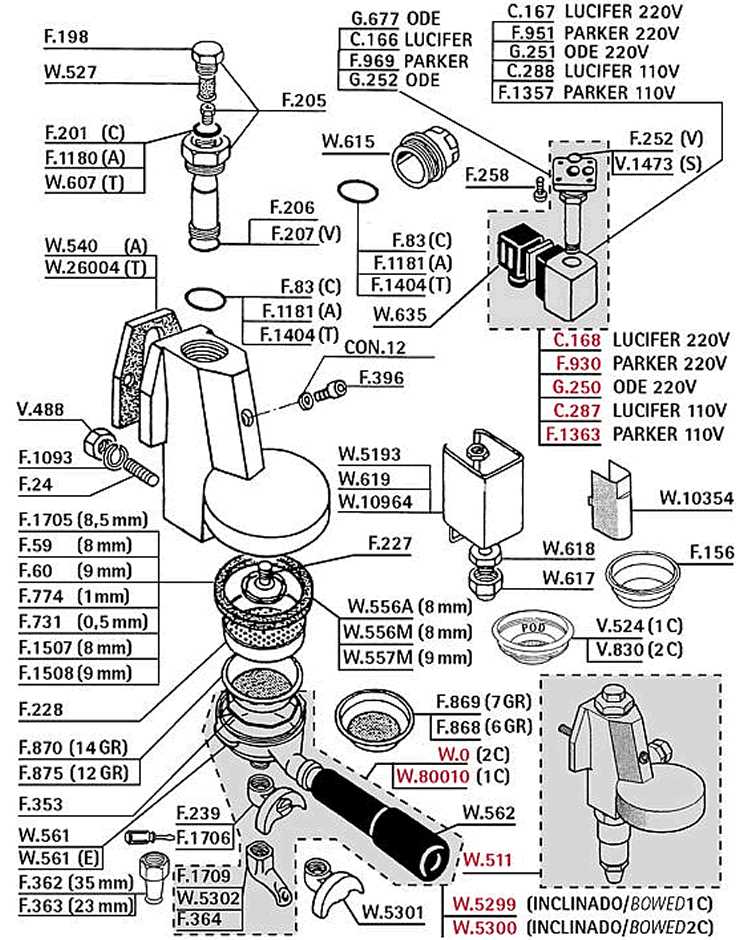

Resources for Espresso Machine Diagrams

Understanding the intricate workings of brewing equipment is essential for maintenance and repair. Various resources are available to aid enthusiasts and professionals alike in visualizing the components and their functions. These materials can enhance knowledge and facilitate troubleshooting, ultimately improving performance and longevity.

Online forums and communities often share detailed illustrations and schematics, allowing users to exchange insights and tips. Additionally, manufacturers frequently provide technical documentation that includes clear representations of the equipment, making it easier to identify specific elements. Video tutorials can also offer practical demonstrations that complement static visuals, ensuring a comprehensive understanding.

Books dedicated to brewing technology can serve as invaluable references, often featuring extensive illustrations that break down complex systems into digestible information. Furthermore, specialized retailers sometimes offer manuals that include in-depth breakdowns of their products, ensuring users have the necessary knowledge to operate and maintain their gear effectively.