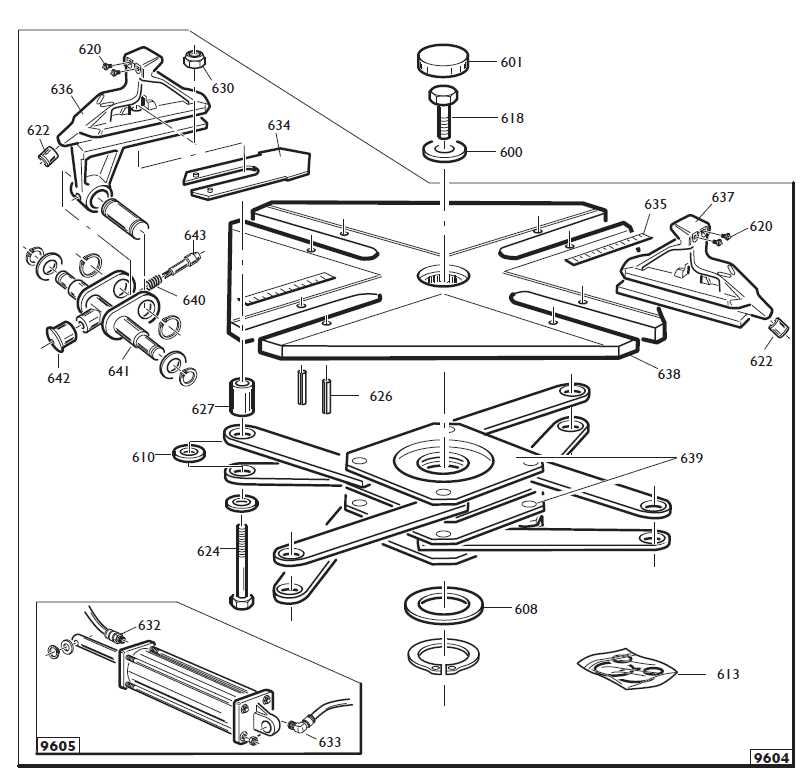

Understanding the Diagram of Hunter Tire Machine Parts

In the realm of automotive services, the efficiency of tools plays a crucial role in achieving optimal performance. A thorough comprehension of how various elements work together can significantly enhance productivity and precision. This section aims to illuminate the intricate relationships among these components, providing insights into their functionalities and interactions.

By exploring the essential building blocks of this specialized equipment, one can gain a deeper appreciation for its engineering. A visual representation serves as an invaluable resource, offering clarity on the arrangement and operation of each individual unit. This knowledge empowers technicians to troubleshoot effectively and maintain equipment in peak condition.

Moreover, understanding these intricate details is vital for those who aspire to excel in the field. With the right information, professionals can ensure that their tools not only perform optimally but also stand the test of time. This journey into the core of mechanical design will ultimately equip readers with the skills necessary for success.

Understanding Hunter Tire Machines

This section delves into the intricacies of specialized equipment designed for the handling of wheels and their components. These advanced tools streamline various processes, enhancing efficiency and precision in workshops. With a focus on functionality, they play a crucial role in automotive maintenance and service tasks.

Key Features of the Equipment

The sophisticated design of these devices includes several notable features. From automatic adjustments to user-friendly interfaces, they cater to the needs of professionals. Durability is another hallmark, ensuring that these systems withstand the rigors of daily use while maintaining optimal performance.

Benefits of Utilizing Advanced Tools

Employing such specialized tools not only improves workflow but also enhances the accuracy of the work performed. Reducing manual effort minimizes the risk of errors, leading to higher customer satisfaction. Furthermore, the integration of innovative technology ensures that these devices remain relevant in a rapidly evolving automotive landscape.

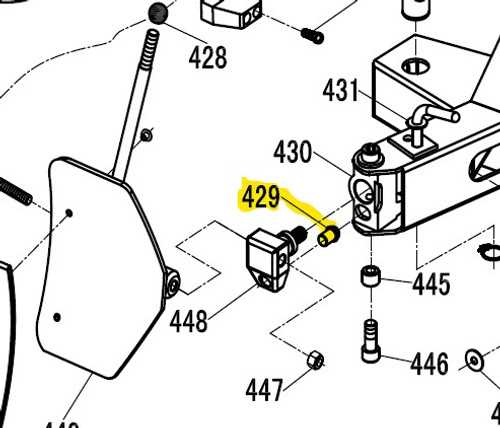

Key Components of Tire Machines

Understanding the essential elements of equipment used for wheel maintenance is crucial for efficient operation. Each component plays a vital role in ensuring functionality and performance, contributing to the overall effectiveness of the apparatus.

Primary Elements

The core elements involved in this type of equipment include mechanisms for handling, lifting, and adjusting wheels. Each part must work in harmony to facilitate smooth operation and achieve the desired outcomes.

Functionality Overview

Key functions are often performed by several interconnected units. Below is a table summarizing these vital components and their respective roles:

| Component | Function |

|---|---|

| Clamp | Secures the wheel in place during the process. |

| Lifter | Raises and lowers the wheel for accessibility. |

| Bead Breaker | Separates the tire from the rim. |

| Rotating Arm | Facilitates the fitting and removal of the wheel. |

Importance of Accurate Diagrams

Clear representations are essential for the effective operation and maintenance of any complex equipment. They provide crucial information that aids technicians in understanding the intricate relationships and functions within the system. The precision of these visual aids directly influences efficiency and reduces the likelihood of errors during repairs and adjustments.

Enhancing Understanding

Visual clarity helps users grasp complex concepts more easily. By illustrating components and their interactions, these representations facilitate quicker comprehension, leading to improved performance and reduced downtime.

Reducing Errors

Accuracy in visuals minimizes the risk of mistakes during service tasks. When technicians rely on precise guides, the chance of misalignment or incorrect assembly decreases significantly, ensuring that operations run smoothly and safely.

Types of Hunter Tire Machines

This section explores various models designed for wheel maintenance, highlighting their unique features and capabilities. Understanding the different options available can aid in selecting the right equipment for specific needs.

-

Automatic Models:

These systems streamline the process, minimizing manual intervention and enhancing efficiency. They are ideal for high-volume settings.

-

Manual Variants:

These units require operator input for adjustments, offering a hands-on experience for precise control. They are often preferred in smaller workshops.

-

Heavy-Duty Equipment:

Designed for larger vehicles, these robust units can handle increased weight and size, ensuring durability and reliability.

-

Portable Solutions:

Compact and easy to transport, these options are suitable for mobile service providers, allowing for flexibility and convenience.

Each type serves distinct purposes, catering to various operational demands and customer needs.

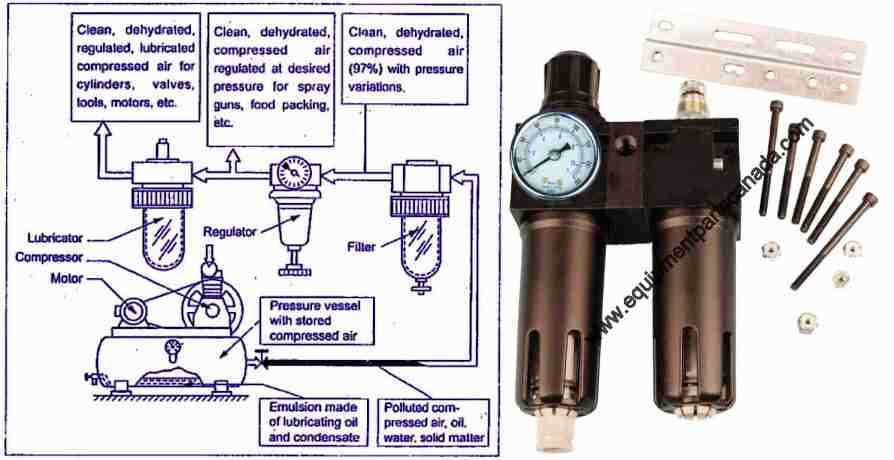

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By implementing effective maintenance strategies, you can significantly extend the lifespan of your apparatus and enhance its performance.

- Regularly inspect components for wear and tear.

- Clean surfaces to prevent dust accumulation.

- Lubricate moving parts as recommended.

- Monitor and replace consumables promptly.

- Keep the surrounding area organized and free of obstacles.

Incorporating these practices into your routine will yield the ultimate benefits for your investment.

Common Issues and Solutions

This section explores frequent challenges encountered in equipment operation and their effective remedies. Understanding these issues can enhance performance and extend the lifespan of the apparatus.

-

Inconsistent Performance:

This can stem from various factors such as misalignment or wear. Regular calibration and maintenance checks can mitigate this issue.

-

Unusual Noises:

Strange sounds may indicate mechanical problems. Inspecting components for damage and lubrication can often resolve these concerns.

-

Power Failures:

Intermittent power issues can arise from faulty wiring or electrical connections. Ensuring all connections are secure and replacing damaged wires is advisable.

-

Fluid Leaks:

Leaks can lead to operational inefficiencies. Regularly checking seals and hoses for wear and replacing them as necessary will help maintain functionality.

By addressing these common challenges, users can significantly improve the reliability and efficiency of their equipment.

Replacement Parts Availability

Ensuring the longevity and optimal performance of equipment relies heavily on the accessibility of components that can be substituted when needed. The ease of sourcing these essential items plays a crucial role in maintaining operational efficiency and minimizing downtime. A well-stocked supply of alternative elements is vital for technicians and business owners alike.

Finding Quality Components

When seeking out replacements, it’s important to prioritize quality over price. Reliable sources provide components that meet rigorous standards, ensuring compatibility and performance. Look for suppliers that offer warranties and support, which can enhance confidence in the products being acquired.

Online Resources and Support

The internet has transformed the way individuals locate necessary items. Numerous platforms facilitate the search for suitable alternatives, complete with detailed specifications and customer reviews. Additionally, many manufacturers provide direct support or recommendations, making it easier to find what you need without hassle.

Assembly Process Explained

The assembly procedure is a crucial phase in the manufacturing workflow, ensuring that every component fits together seamlessly to create a functional unit. This section will outline the essential steps and considerations involved in this intricate process.

Key Stages of Assembly

- Preparation of Components

- Inspection for Quality Assurance

- Sequential Assembly Steps

- Final Testing

Considerations for Efficient Assembly

- Understanding Component Compatibility

- Utilizing Proper Tools and Equipment

- Training Personnel for Precision

- Implementing Safety Protocols

Identifying Faulty Components

Recognizing malfunctioning elements within any apparatus is crucial for maintaining optimal performance. A thorough understanding of the various components involved and their interrelations can significantly aid in diagnosing issues effectively. Regular inspections and a keen eye for detail are essential in pinpointing the sources of problems that may arise during operation.

Common Signs of Malfunction

Several indicators can suggest that a particular element is not functioning as intended. Unusual noises, inconsistent performance, and visible wear or damage are among the most common symptoms. Observing these signs early can prevent further complications and reduce downtime.

Testing and Verification Methods

To accurately assess the condition of components, implementing systematic testing procedures is essential. Utilizing diagnostic tools, performing visual inspections, and conducting functional tests can provide valuable insights into the integrity of the system. These methods not only help confirm the presence of faults but also guide decisions regarding repairs or replacements.

Benefits of Using Diagrams

Visual representations serve as powerful tools that enhance understanding and communication. They simplify complex information, making it accessible and easier to digest.

Clarity and Comprehension

- Facilitates quick understanding of intricate concepts.

- Highlights relationships between various components.

- Reduces cognitive load by presenting information visually.

Enhanced Communication

- Promotes effective collaboration among team members.

- Acts as a universal language, transcending barriers.

- Improves retention of information through visual engagement.

How to Read a Diagram

Understanding visual representations is essential for effectively interpreting mechanical layouts. These illustrations often convey complex information through symbols and lines, allowing users to grasp the relationships and functions within a system. Familiarity with these conventions enhances problem-solving and maintenance capabilities.

To decode such visuals, start by examining the legend or key, which explains the symbols used. Each symbol typically represents a specific component or function. Pay attention to the connections indicated by lines, as they reveal how elements interact.

| Symbol | Description |

|---|---|

| Circle | Represents a component or junction point. |

| Line | Indicates connections or pathways. |

| Arrow | Shows direction of flow or movement. |

Practice by analyzing different representations to develop your skills in interpreting these useful tools. This proficiency will ultimately empower you to troubleshoot and optimize systems effectively.

Safety Practices for Operators

Ensuring a secure working environment is paramount for individuals handling specialized equipment. Adhering to best practices not only minimizes the risk of accidents but also promotes efficiency and confidence among operators. A proactive approach to safety fosters a culture of responsibility, where every individual is aware of their role in maintaining a hazard-free zone.

Personal Protective Equipment

Utilizing appropriate personal protective gear is essential for safeguarding against potential injuries. Operators should always wear safety glasses, gloves, and steel-toed boots. This equipment acts as a first line of defense against various risks, from flying debris to heavy objects. Regular inspection and maintenance of this gear ensure that it remains effective and reliable.

Proper Training and Protocols

Comprehensive training programs are crucial in equipping operators with the necessary skills to handle equipment safely. Familiarity with operating procedures and emergency protocols enhances awareness of potential hazards. Regular refresher courses can keep safety at the forefront, ensuring that all team members are updated on the latest safety standards and practices.

Upgrading Your Tire Machine

Enhancing the efficiency and performance of your equipment can significantly improve overall productivity. Investing in modern technology and quality components not only streamlines operations but also prolongs the lifespan of your setup. This section explores essential upgrades that can elevate your setup to its ultimate potential.

Key Components to Consider

When considering enhancements, focus on critical elements such as automation systems, user interfaces, and specialized tools. Upgrading these aspects can provide greater precision and ease of use, which ultimately results in higher quality service.

Benefits of Modernization

Upgrading brings several advantages, including increased speed, reduced downtime, and improved safety features. These improvements not only enhance user experience but also foster a more reliable and effective workspace, ensuring your operations remain competitive.