Understanding the Parts Diagram of Manual Ingersoll Rand Air Compressors

The intricate machinery that powers various industrial applications relies on a well-designed assembly of elements. Each component plays a vital role in ensuring optimal functionality and efficiency. Recognizing the layout and relationship between these elements is essential for effective maintenance and troubleshooting.

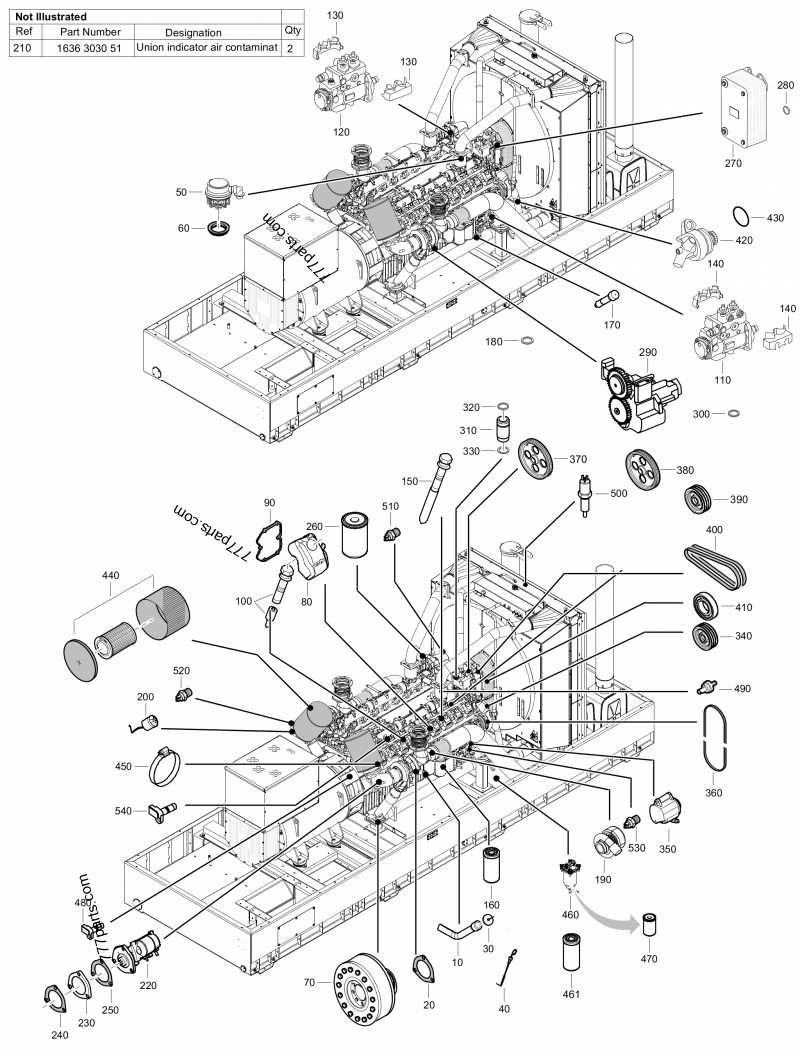

Having a clear visual representation of these components not only aids in understanding their functions but also enhances the ability to diagnose issues swiftly. This insight empowers users to make informed decisions when it comes to repairs and replacements, ultimately prolonging the lifespan of the machinery.

In this section, we will explore a detailed representation of the essential elements that make up this equipment. By familiarizing yourself with each part’s role and interconnections, you will be better equipped to maintain peak performance and avoid unnecessary downtime.

Understanding Ingersoll Rand Air Compressors

The essence of efficient machinery lies in its ability to convert energy into usable power seamlessly. This transformation is crucial in various industries, enabling a plethora of applications that range from simple tasks to complex processes. Grasping how these machines operate can significantly enhance their effectiveness and longevity.

When examining the inner workings, it is essential to recognize the primary components that facilitate the operation. Each element plays a vital role in ensuring smooth functionality and optimal performance. By familiarizing oneself with these components, operators can better maintain and troubleshoot their equipment, thereby minimizing downtime.

Moreover, understanding the principles behind the system allows for informed decisions regarding upgrades and modifications. Knowledge of the structure not only aids in routine checks but also empowers users to enhance efficiency through strategic improvements. In the long run, this understanding fosters a deeper appreciation for the technology, ultimately leading to superior results in various applications.

In summary, a comprehensive grasp of these machines contributes to more effective usage and maintenance practices. Embracing this knowledge can pave the way for enhanced operational capabilities and sustained performance over time.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex machinery. They provide clarity and enhance comprehension, enabling users to identify each element effectively. Such illustrations facilitate maintenance, repair, and assembly, ensuring that tasks are performed accurately and efficiently.

Enhancing Understanding

By offering a detailed view of individual elements, these illustrations help technicians and operators grasp the relationships between various components. This understanding is essential for diagnosing issues and implementing effective solutions, ultimately leading to improved performance and longevity of the equipment.

Streamlining Maintenance and Repairs

Access to clear representations significantly reduces the likelihood of errors during maintenance tasks. When users can easily locate and recognize each part, the process becomes more efficient. This not only saves time but also minimizes the risk of damage, ensuring that machinery operates smoothly for extended periods.

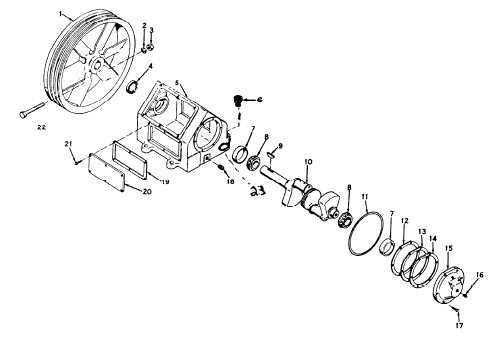

Common Components of Air Compressors

Understanding the essential elements of pressure-generation systems is crucial for both maintenance and efficiency. These systems consist of various interconnected components that work together to convert power into stored energy. Each part plays a significant role in ensuring optimal functionality and performance.

Key Elements

- Motor: The power source that drives the entire mechanism, converting electrical energy into mechanical motion.

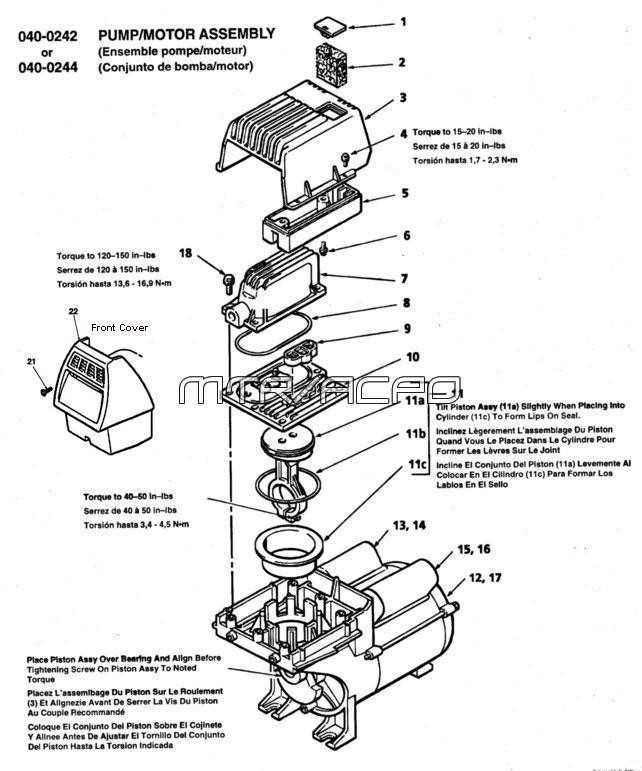

- Pump: Responsible for compressing the gas, this element increases the pressure of the air for storage and use.

- Tank: A storage vessel that holds the compressed gas until it is needed, ensuring a steady supply for various applications.

- Regulator: Maintains and controls the pressure levels within the system, ensuring safe and efficient operation.

- Valves: Control the flow of gas and allow for safe release or redirection of pressure as needed.

Additional Components

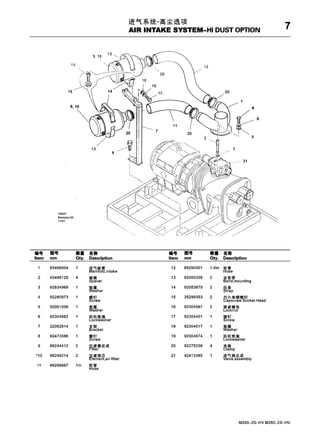

- Filters: Remove contaminants from the air, protecting the internal components and ensuring clean output.

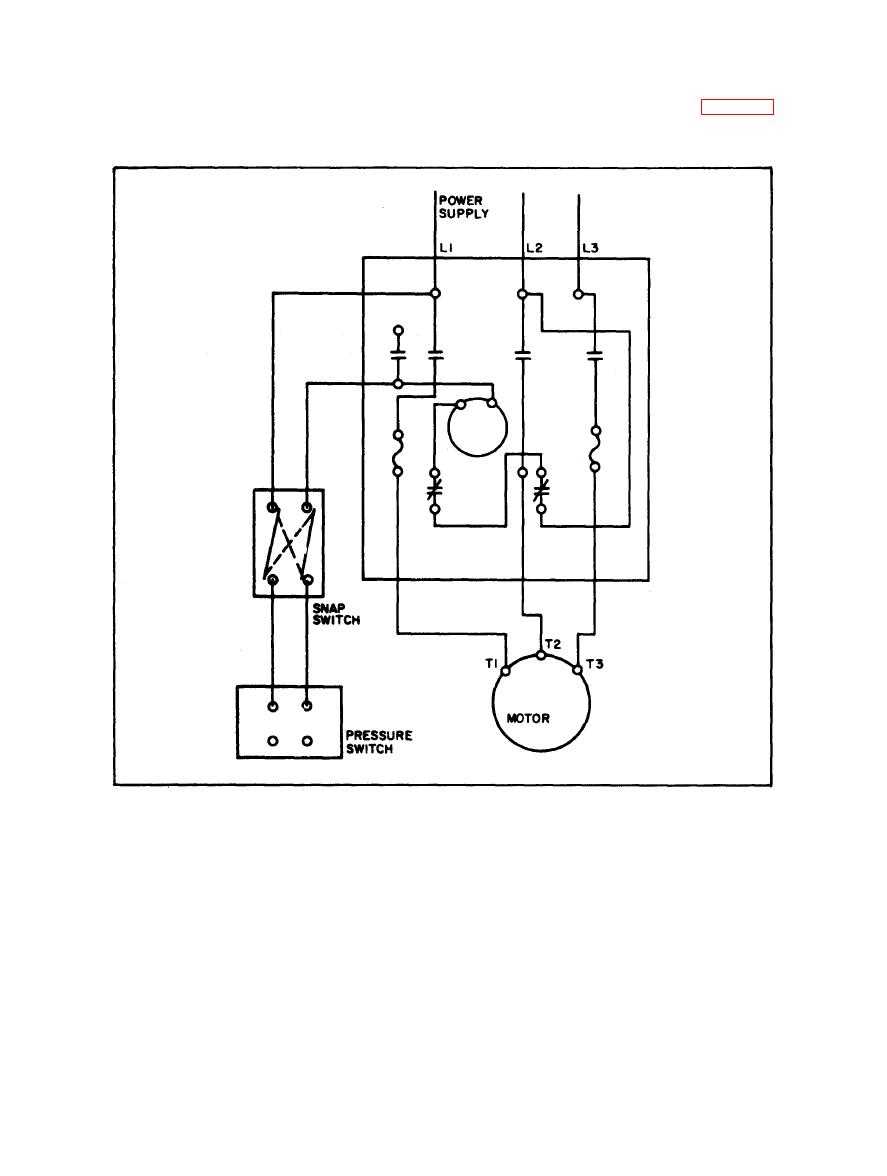

- Pressure Switch: Automatically turns the motor on and off to maintain desired pressure levels in the storage tank.

- Cooling System: Prevents overheating by dissipating heat generated during the compression process.

- Hoses: Facilitate the transport of compressed gas to tools and equipment, providing flexibility in usage.

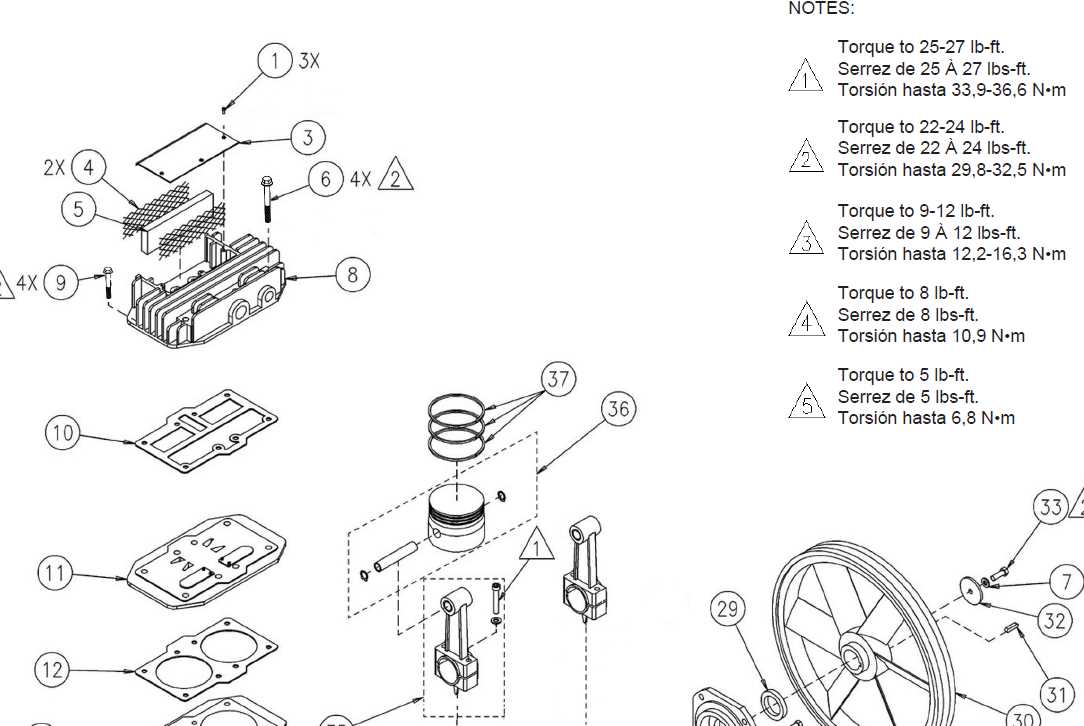

How to Read a Parts Diagram

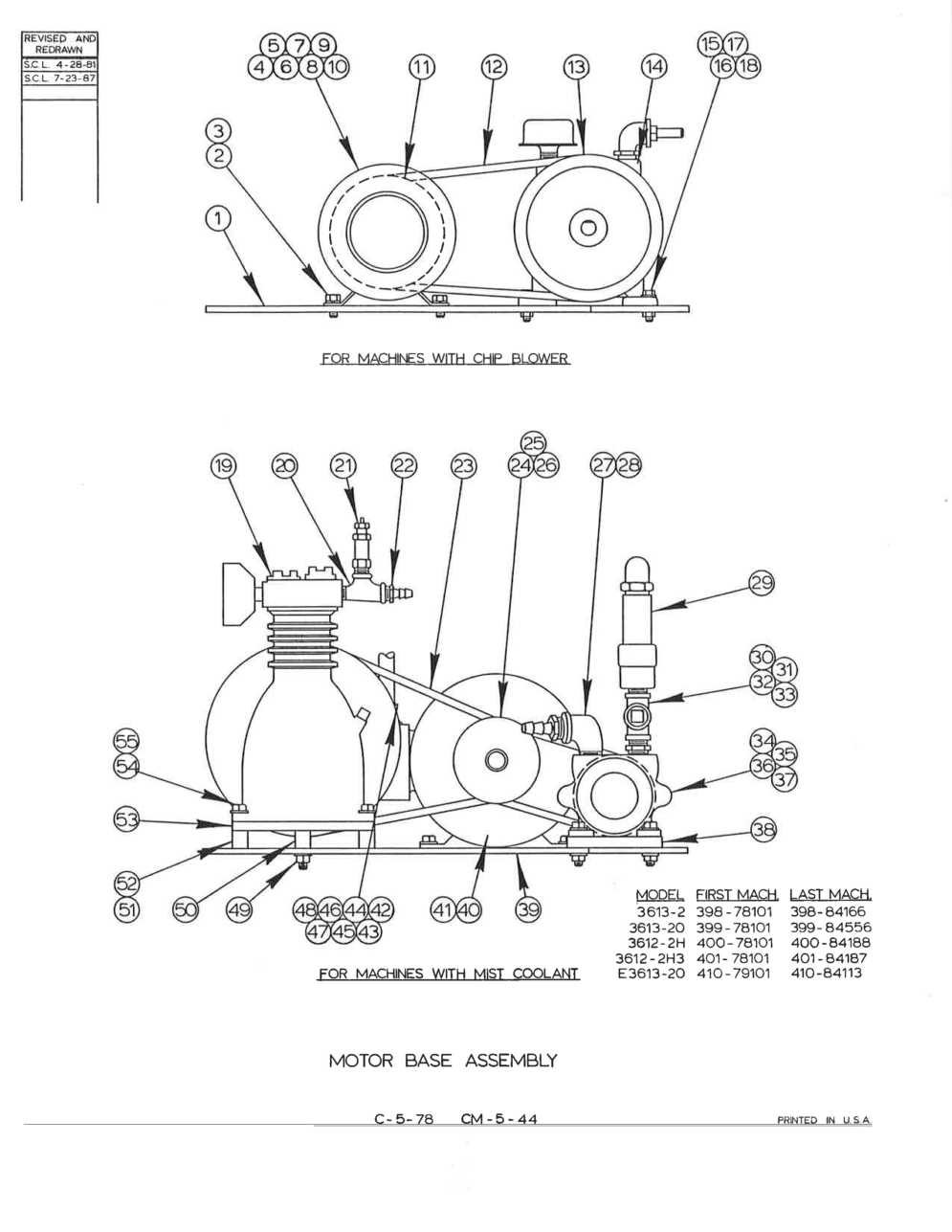

Understanding an illustration that displays components of a machine can greatly enhance your ability to maintain and repair it. These visuals serve as a roadmap, guiding you through the various elements and their relationships, enabling more efficient troubleshooting and assembly.

To effectively interpret such an illustration, consider the following steps:

- Familiarize Yourself with Symbols: Each element typically has a specific symbol or number. Refer to the legend or key provided.

- Identify Sections: Components are often grouped by functionality. Take note of how parts are organized, which can aid in understanding their roles.

- Follow the Flow: Look for arrows or lines indicating connections or sequences. This will help you comprehend how components interact.

- Check Annotations: Many illustrations include notes or comments that provide additional context. Read these carefully for insights.

By following these guidelines, you can enhance your comprehension of the illustration, making it easier to address issues and perform maintenance tasks effectively.

Identifying Key Components in Diagrams

Understanding the essential elements represented in schematic illustrations is crucial for effective maintenance and troubleshooting. These visuals serve as guides, providing insight into the relationships and functions of various components within a system. By familiarizing oneself with these representations, users can enhance their comprehension and operational skills.

Common Elements to Recognize

- Connectors: Often depicted as lines or arrows, these indicate how components interact and communicate.

- Valves: Typically shown as symbols, they control the flow within the system and are vital for functionality.

- Compressors: Represented in specific shapes, these are the heart of the system, managing pressure and airflow.

- Filters: Indicated by unique icons, they ensure that the medium remains clean and efficient.

Interpreting the Legend

Many illustrations come with a legend or key, detailing the symbols used throughout the diagram. This reference is essential for accurate interpretation, allowing users to quickly identify each component’s role and importance. Familiarizing oneself with this key can streamline the understanding process and reduce confusion.

- Consult the legend first for a comprehensive overview of symbols.

- Identify each component within the context of the whole system.

- Pay attention to any notes or annotations that provide additional context.

Maintenance Tips for Air Compressors

Proper upkeep of your equipment is essential to ensure longevity and optimal performance. Regular attention not only enhances efficiency but also helps to prevent unexpected breakdowns. Here are key strategies to maintain your machinery effectively.

Regular Inspections

Routine check-ups are vital for identifying wear and tear early. Focus on the following components during inspections:

| Component | What to Check |

|---|---|

| Filters | Clean or replace as necessary to maintain airflow. |

| Hoses | Look for cracks or leaks; replace if damaged. |

| Oil Levels | Ensure proper lubrication for smooth operation. |

Keep it Clean

Maintaining a clean environment around your machinery can prevent dirt and debris from affecting performance. Regularly clean external surfaces and ensure proper ventilation to prevent overheating.

Replacing Worn Out Parts Effectively

Maintaining optimal performance in mechanical systems requires timely replacement of deteriorated components. Identifying when these elements have reached the end of their useful life is crucial to ensure efficiency and prevent further damage. Proper replacement techniques not only enhance functionality but also prolong the overall lifespan of the machinery.

Identifying Signs of Wear

To effectively replace components, one must first recognize the indicators of wear. Common signs include unusual noises, decreased efficiency, and visible deterioration. Regular inspections can help detect these issues early, allowing for proactive measures. Additionally, consulting with technical resources can provide guidance on the expected lifespan of specific components.

Choosing Quality Replacements

When it comes to replacements, quality is paramount. Opting for high-grade materials ensures reliability and compatibility with existing systems. Researching reputable suppliers and understanding the specifications needed for replacements can significantly impact performance. Always prioritize components that meet or exceed original equipment standards to achieve the best results.

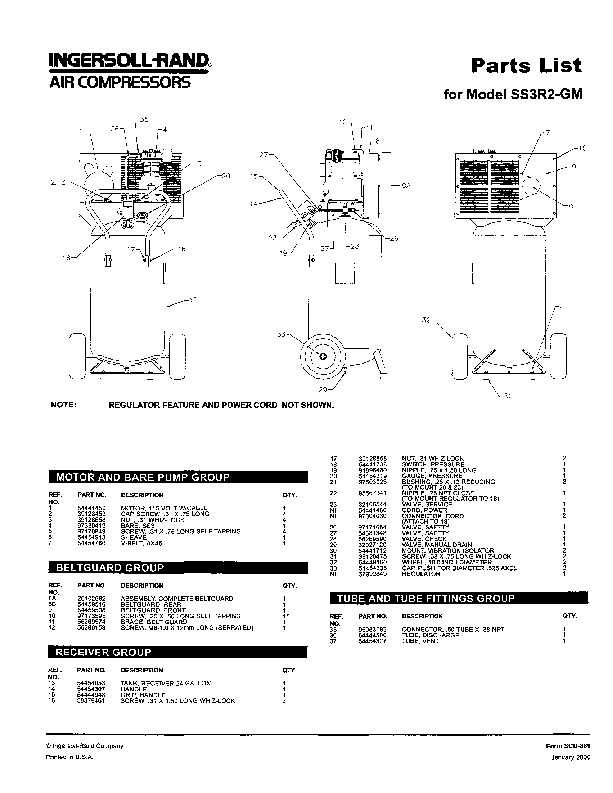

Where to Find Parts Diagrams Online

Locating detailed schematics for machinery can significantly streamline maintenance and repair tasks. These visual resources are essential for understanding the components and their configurations. Below are several reliable avenues to explore for obtaining these invaluable references online.

Official Manufacturer Websites

- Many manufacturers host online libraries where users can access technical documents, including schematics.

- Look for sections labeled “Resources,” “Support,” or “Documentation” on these sites.

- Some platforms may require registration to access specific materials, so be prepared to create an account.

Online Parts Retailers

- Numerous online retailers specializing in machinery components often provide diagrams as part of their product listings.

- Check the product detail pages for downloadable PDFs or interactive schematics.

- Retailers might also have forums or customer support where additional assistance is available regarding specific models.

By utilizing these resources, users can gain the necessary insights to effectively troubleshoot and maintain their equipment.

Understanding Compressor Functionality

Grasping the principles behind the operation of pressure-generating machinery is essential for both efficiency and maintenance. These devices convert mechanical energy into stored pressure, enabling a variety of applications across numerous industries. By comprehending their inner workings, one can enhance performance and troubleshoot issues effectively.

Basic Components

The primary elements of such machinery play crucial roles in the overall functionality. Each part contributes to the effective compression of gases, facilitating the transition from ambient conditions to high-pressure environments.

| Component | Function |

|---|---|

| Motor | Drives the unit, providing the necessary energy for operation. |

| Piston | Compresses the gas, creating the required pressure level. |

| Valves | Regulate the flow of gas in and out of the chamber. |

| Tank | Stores the compressed gas for later use. |

Operational Cycle

The cycle of operation consists of several stages that ensure efficient gas compression. Understanding this sequence allows users to optimize usage and minimize wear and tear on the equipment.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is essential to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also safeguard equipment and the surrounding environment. Here are key measures to follow during repairs.

- Wear appropriate personal protective equipment (PPE), such as gloves, goggles, and ear protection.

- Disconnect power sources before starting any repair to avoid electrical hazards.

- Ensure the work area is well-ventilated to prevent the accumulation of harmful fumes.

Before initiating repairs, it’s crucial to familiarize yourself with the equipment and any associated risks.

- Read the safety guidelines specific to the equipment.

- Inspect tools and materials for any signs of damage before use.

- Keep the workspace clean and organized to reduce the risk of accidents.

Additionally, having a first aid kit readily available can be invaluable in case of minor injuries. Always work with a partner when handling large or heavy components to ensure safe lifting techniques are employed.

By adhering to these safety measures, you can create a secure environment that minimizes risks and promotes efficient repairs.

Upgrading Your Air Compressor System

Enhancing your pneumatic system can significantly improve performance and efficiency. By focusing on key components and technologies, you can create a more reliable and powerful setup that meets your operational demands. This section explores various strategies for upgrading your equipment and optimizing functionality.

Key Components to Consider

When planning an upgrade, it’s essential to evaluate the critical elements that contribute to overall performance. Here are some components worth considering:

| Component | Description | Benefits |

|---|---|---|

| Motor | High-efficiency motors reduce energy consumption. | Lower operating costs and improved reliability. |

| Storage Tank | Larger tanks provide more reserve capacity. | Consistent pressure and reduced cycling. |

| Filters | Advanced filtration systems eliminate contaminants. | Enhanced quality and longevity of tools. |

| Regulator | Precision regulators maintain stable output. | Improved performance and control over pressure. |

Installation and Maintenance Tips

Proper installation and ongoing maintenance are crucial for maximizing the benefits of your upgrades. Ensure all components are compatible and follow the manufacturer’s recommendations for installation. Regular inspections and maintenance schedules will help you identify potential issues before they escalate, keeping your system running smoothly and efficiently.