Comprehensive Guide to 90 HP Mercury Outboard Motor Parts Diagram

The performance of any marine vessel heavily relies on the intricate assembly of its key components. A thorough understanding of these elements is crucial for maintaining efficiency and ensuring longevity. In this section, we will explore the essential features of a specific 90 horsepower engine, providing clarity on its various components and their functions.

Whether you are a seasoned enthusiast or a newcomer to the world of watercraft, grasping the layout and interaction of these elements can greatly enhance your experience. From the power delivery systems to the control mechanisms, each part plays a pivotal role in the overall operation. Recognizing these parts can help in troubleshooting and optimizing performance.

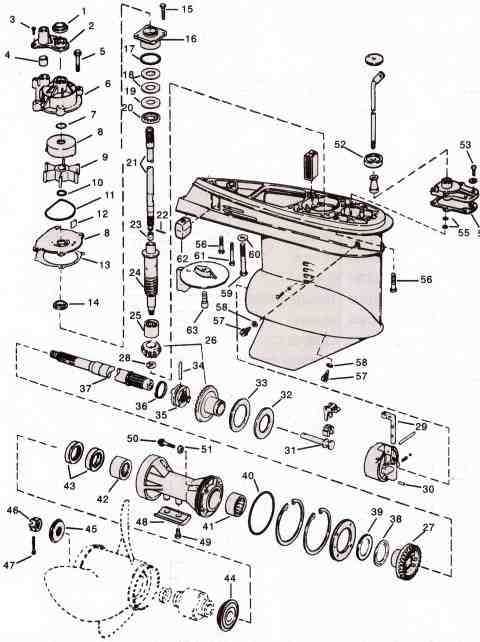

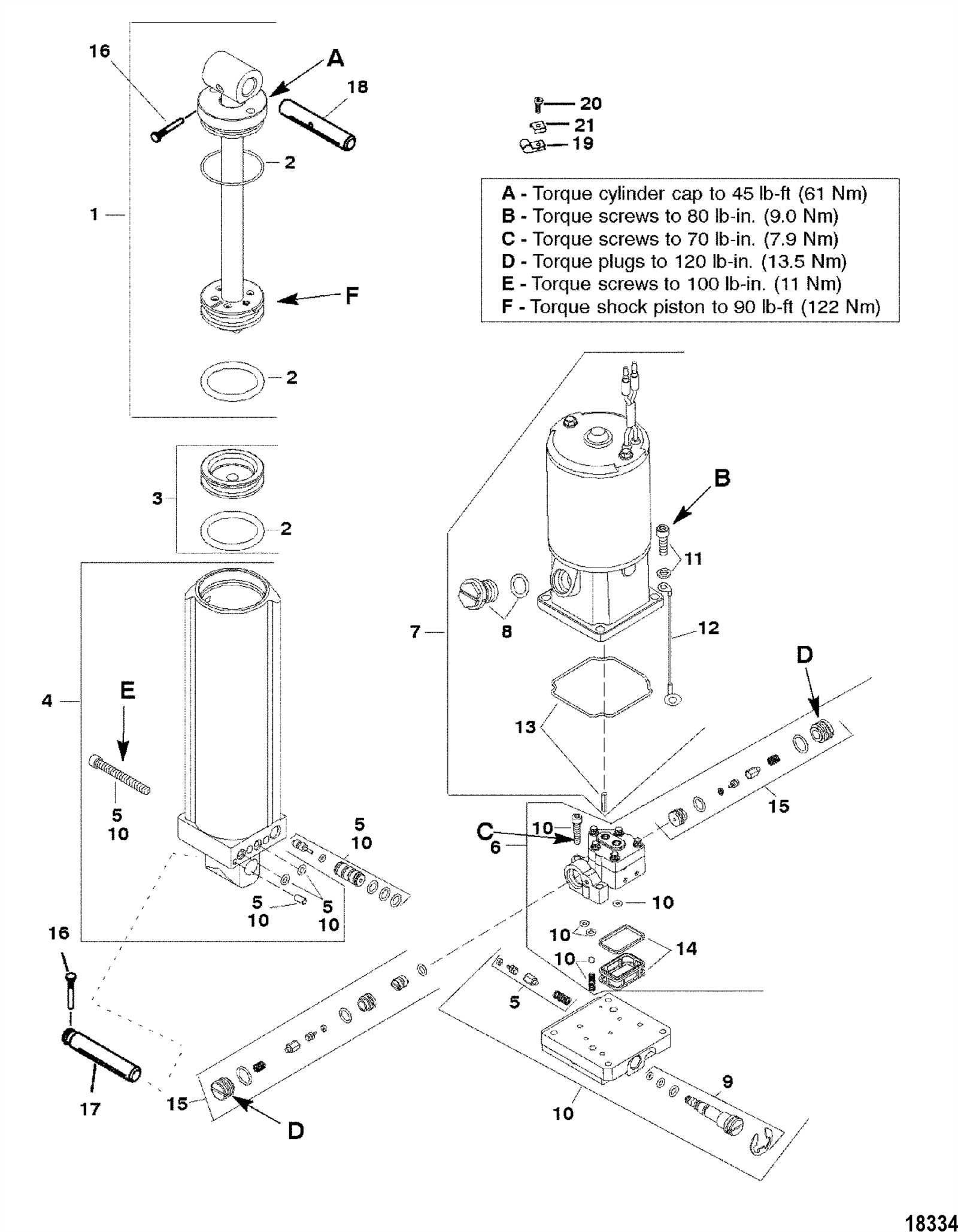

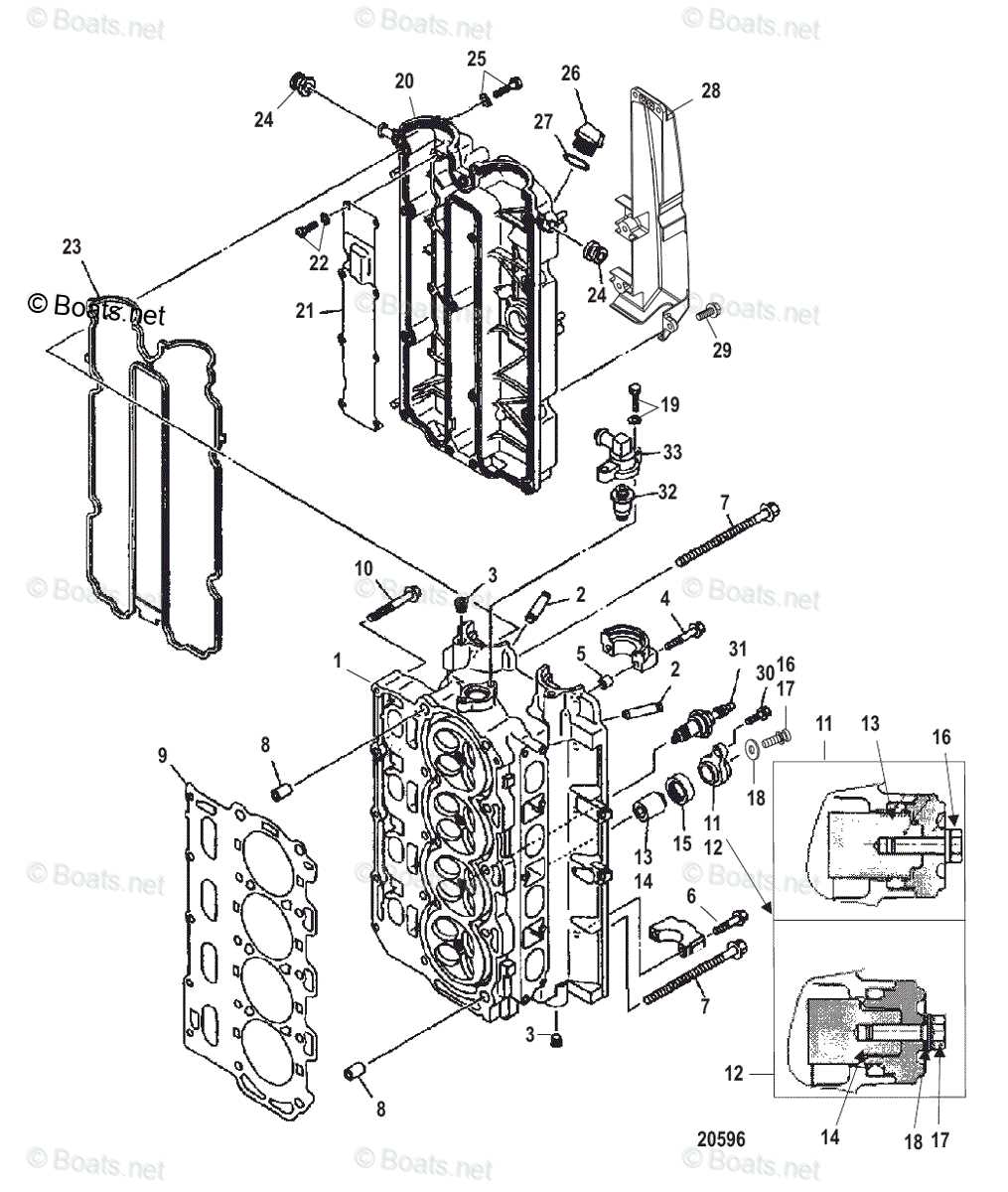

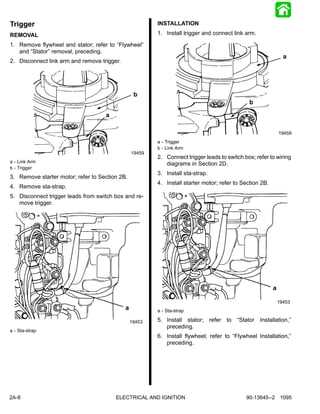

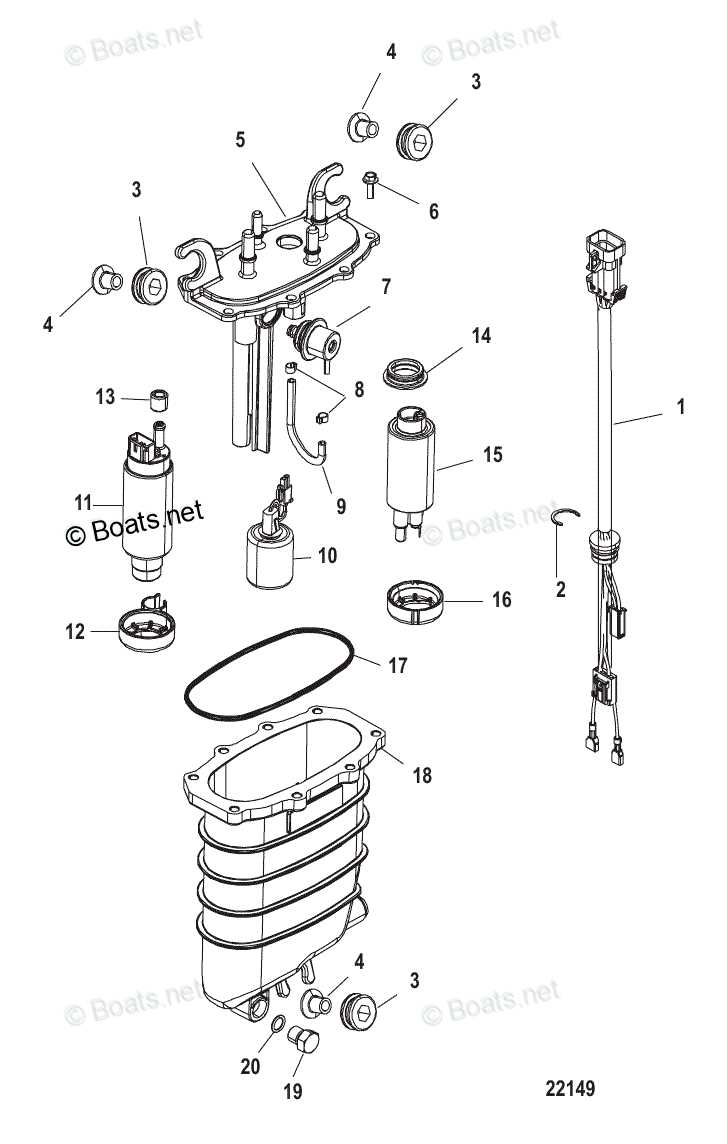

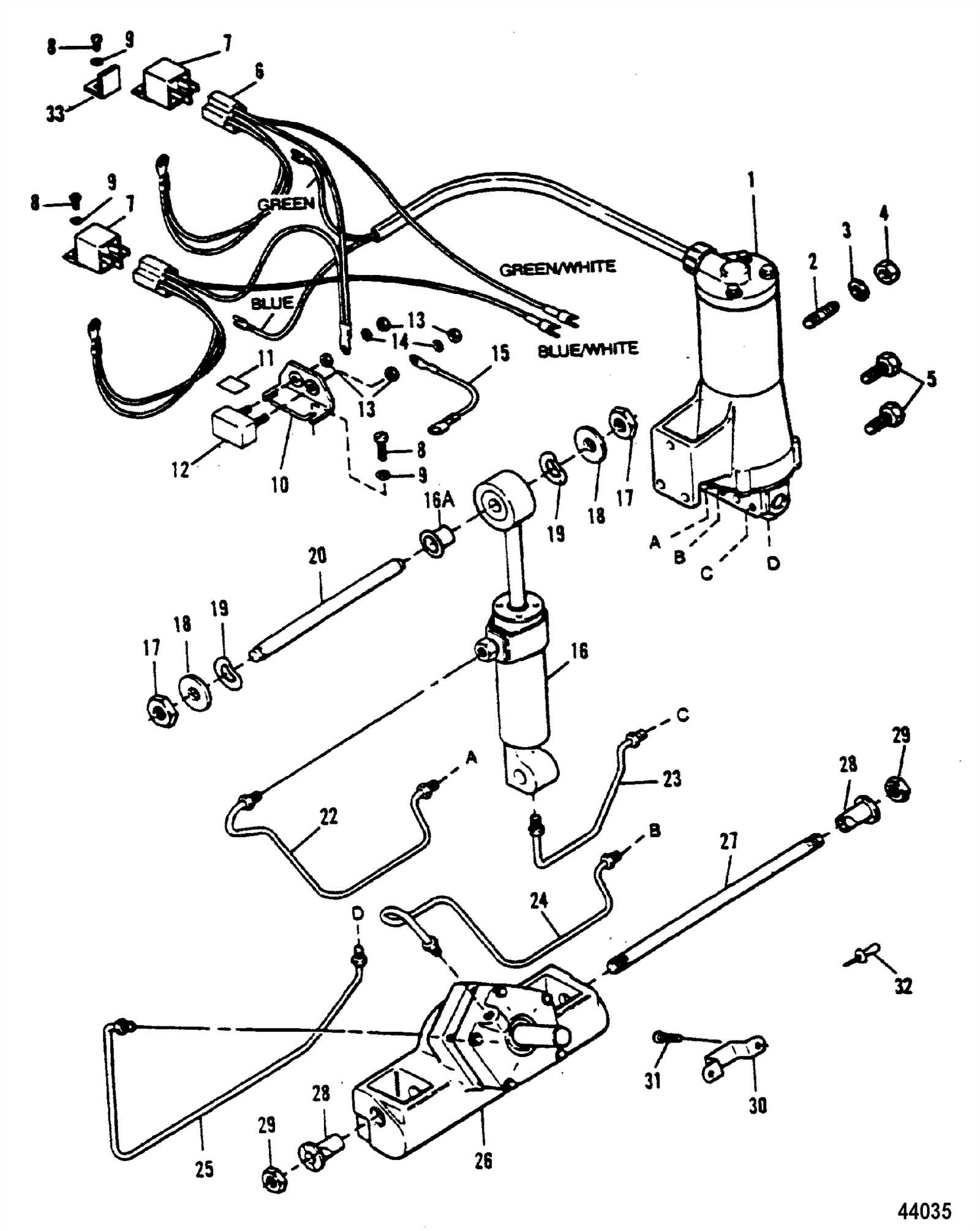

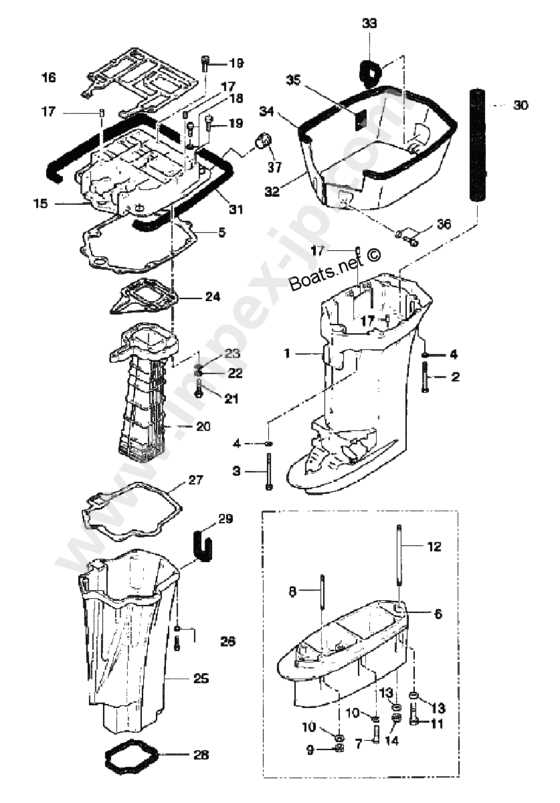

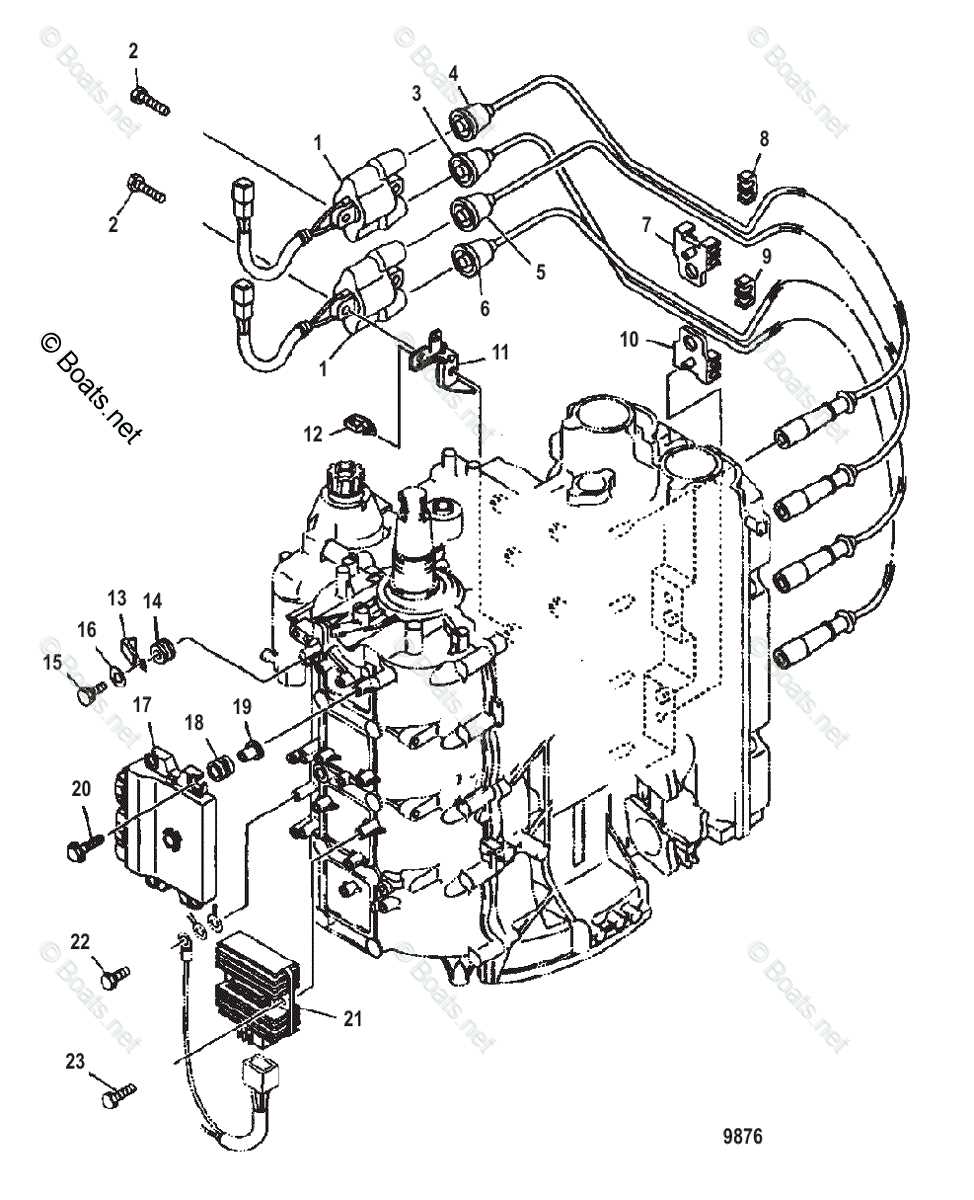

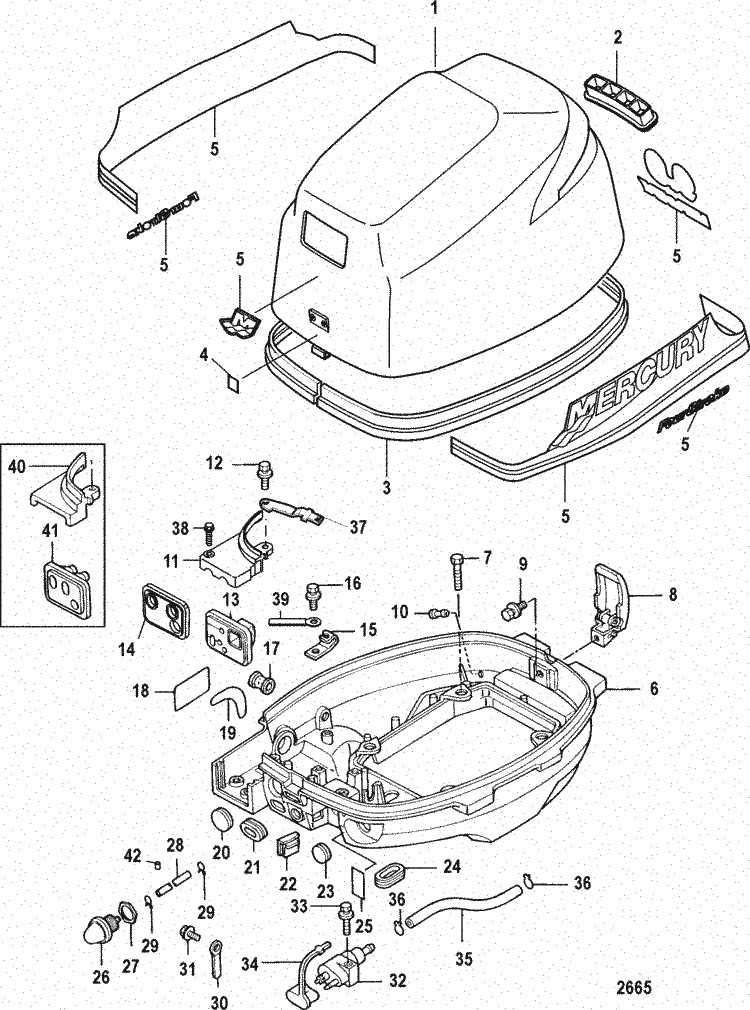

In addition, visual aids can serve as invaluable resources for understanding the configuration of these components. By examining a detailed representation, one can easily identify each segment and comprehend how they contribute to the engine’s functionality. This knowledge empowers users to make informed decisions regarding maintenance and upgrades.

Understanding Mercury Outboard Motor Basics

This section delves into the fundamental concepts behind marine propulsion systems, focusing on their construction, operation, and maintenance. Knowing the essential components and their functions can enhance performance and longevity, ensuring an optimal experience on the water.

Key Components

Several critical elements contribute to the functionality of these propulsion systems:

- Powerhead: The engine assembly that generates thrust.

- Lower Unit: Houses the gearbox and propeller, converting engine power into movement.

- Cooling System: Maintains optimal temperatures, preventing overheating.

- Fuel System: Delivers the necessary fuel for combustion.

- Electrical System: Powers ignition, lighting, and other electronic components.

Maintenance Tips

Regular upkeep is vital for efficient operation:

- Check and replace the oil regularly.

- Inspect the fuel filter for clogs.

- Clean the cooling passages to prevent blockages.

- Examine the propeller for damage.

- Ensure electrical connections are secure and corrosion-free.

Understanding these basics can significantly improve reliability and performance on the water, making for a more enjoyable boating experience.

Key Components of 90 HP Motors

Understanding the essential elements of 90 HP engines is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring the efficiency and reliability of the unit, contributing to its overall functionality.

| Component | Description |

|---|---|

| Powerhead | The main section that houses the engine’s combustion process, critical for generating power. |

| Gearcase | Encases the gear system, enabling the transfer of power to the propeller for propulsion. |

| Fuel System | Includes the fuel tank and lines, delivering fuel to the engine for combustion. |

| Ignition System | Responsible for igniting the fuel-air mixture, vital for engine start-up and operation. |

| Cooling System | Ensures the engine remains within optimal temperature ranges, preventing overheating. |

| Exhaust System | Channels exhaust gases away from the engine, essential for maintaining performance. |

Importance of Maintenance and Repair

Regular upkeep and timely fixes are essential for ensuring the longevity and efficiency of any aquatic propulsion system. Neglecting these aspects can lead to diminished performance, increased fuel consumption, and even catastrophic failures.

- Enhances operational reliability

- Reduces long-term costs

- Improves fuel efficiency

- Increases safety on the water

Consistent inspections can help identify potential issues early, allowing for proactive solutions that ultimately save time and resources. Additionally, a well-maintained system contributes to a smoother and more enjoyable experience for users.

- Check fluid levels regularly

- Inspect components for wear and tear

- Follow manufacturer recommendations for servicing

- Replace worn parts promptly

By prioritizing maintenance and repairs, enthusiasts can ensure optimal performance and safety, making every outing enjoyable and worry-free.

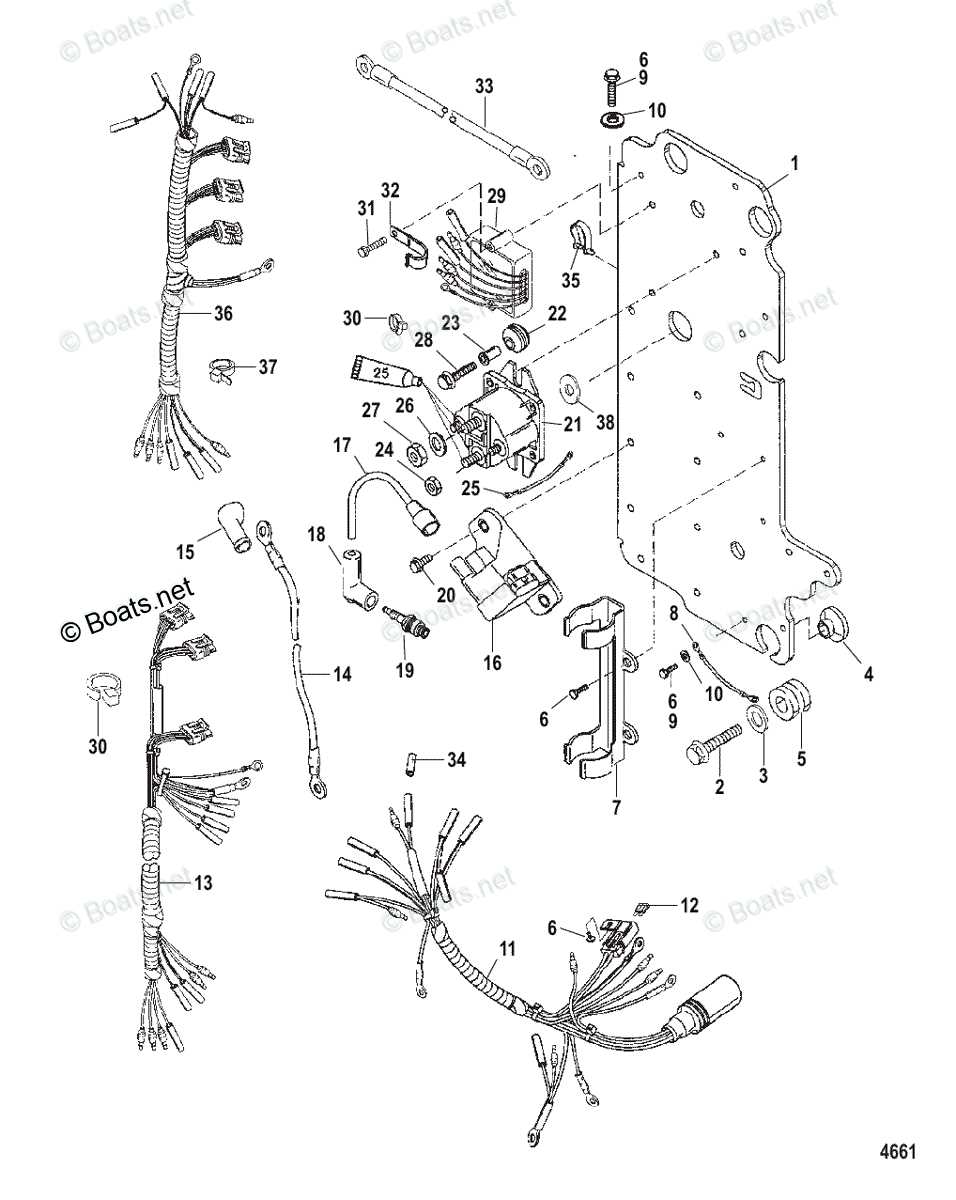

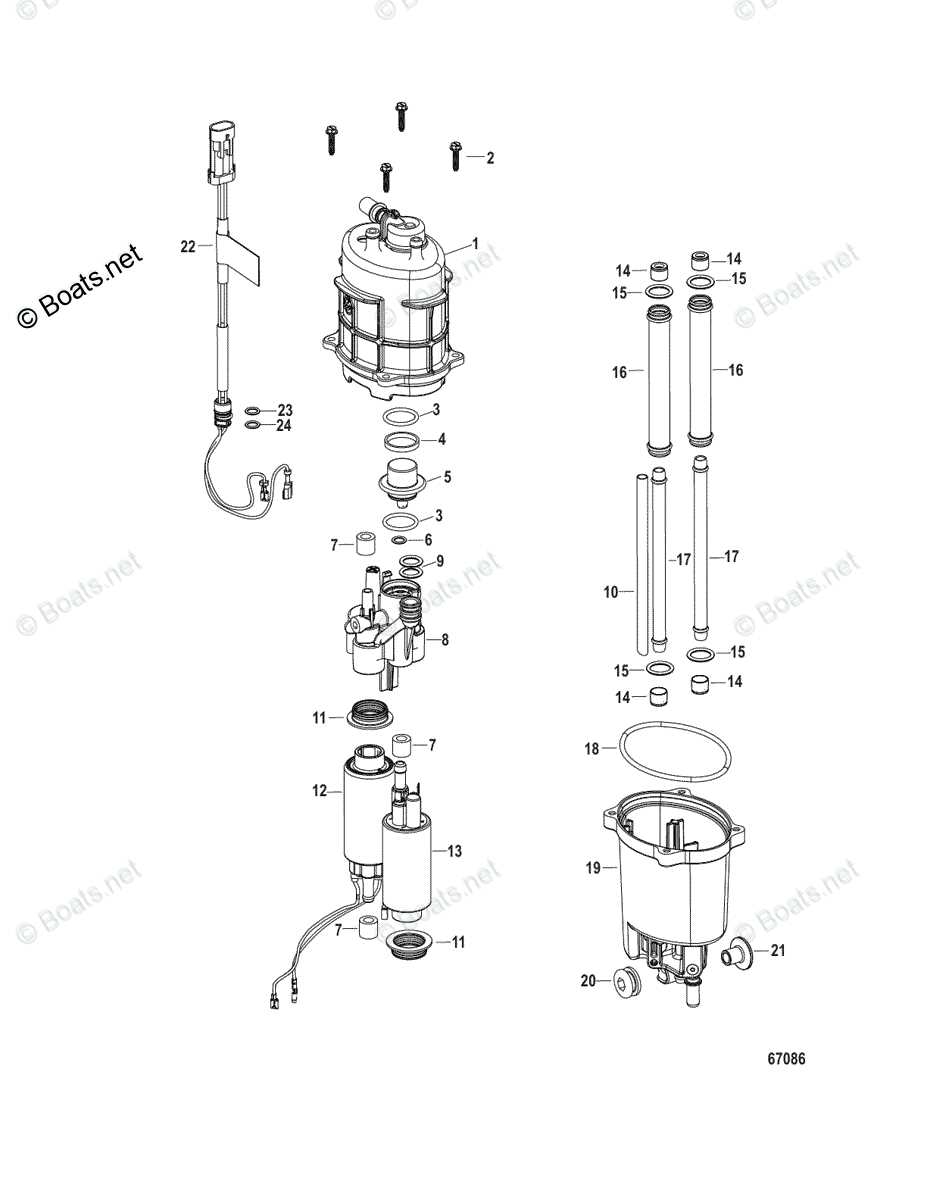

How to Read a Parts Diagram

Understanding a schematic representation is essential for effective maintenance and repair of any mechanical device. These visual guides provide a detailed overview of components, helping you identify and locate each element within the assembly. By mastering how to interpret these illustrations, you can streamline the repair process and ensure that you have all necessary components at hand.

1. Familiarize Yourself with the Symbols

Each illustration uses specific symbols to represent different components. Spend some time reviewing these icons to grasp what each one signifies. Commonly, parts are represented by simple shapes, and their orientation can indicate their placement within the overall structure.

2. Pay Attention to Numbering

Most visual representations include a numbering system that corresponds to a list of components. This allows you to easily identify what each item is and find additional information or specifications. Take note of these numbers as they guide you through the identification process.

3. Follow the Flow

Understanding the order in which components connect is crucial. Many schematics will depict the relationship between parts, often showing how they fit together or interact. This flow can help you troubleshoot issues more effectively by highlighting potential areas of concern.

4. Refer to the Key

A key or legend is often provided alongside the illustration, explaining any color coding or additional notations. Refer to this section frequently, as it offers valuable insights into the specific functions and characteristics of each component.

5. Cross-Reference with Documentation

Having the right manuals or service guides on hand can enhance your understanding. These documents often provide context and additional details that complement the schematic representation, making it easier to comprehend the overall assembly.

By applying these strategies, you will be better equipped to navigate through any schematic representation effectively, facilitating a more efficient repair or maintenance process.

Common Issues with Mercury Outboards

Like any mechanical device, marine engines often encounter a range of challenges that can affect their performance and reliability. Understanding these common difficulties can help owners identify symptoms early and take appropriate action to maintain their equipment.

One frequent concern is fuel-related problems, which may arise from contaminated fuel or clogged filters. These issues can lead to starting difficulties or irregular operation. Additionally, overheating is a serious threat, often caused by insufficient cooling water flow or a malfunctioning thermostat, which can result in engine damage if not addressed promptly.

Electrical failures also present significant challenges. Issues such as faulty wiring or a weak battery can lead to starting problems or erratic performance. Furthermore, wear and tear on components like seals and gaskets can result in leaks, affecting overall efficiency and safety.

Regular maintenance and thorough inspections are essential to mitigate these issues. By staying vigilant and addressing potential problems early, users can ensure a longer lifespan and optimal performance for their marine engines.

Tools Required for Motor Repairs

Proper maintenance and repair of aquatic engines require a selection of essential instruments. Having the right tools not only simplifies the process but also ensures safety and efficiency. From basic hand tools to specialized equipment, each item plays a vital role in diagnosing issues and performing repairs effectively.

Start with the fundamentals, such as wrenches, screwdrivers, and pliers. These are indispensable for tightening, loosening, and securing various components. Additionally, a torque wrench is crucial for ensuring that fasteners are tightened to manufacturer specifications, preventing potential damage.

Next, consider diagnostic tools like multimeters and compression testers. These devices help assess electrical systems and engine performance, allowing for accurate troubleshooting. A reliable set of sockets can also enhance your ability to work with different sizes and types of fasteners.

For more extensive repairs, equipment like a workbench and engine hoist can provide the necessary support and stability. Safety gear, including gloves and goggles, is equally important to protect against potential hazards during repairs.

In conclusion, equipping yourself with the right assortment of tools is crucial for effective engine maintenance. This not only improves the quality of your work but also extends the lifespan of the equipment.

Where to Find Replacement Parts

Locating components for your watercraft can be essential for maintaining performance and ensuring longevity. Various sources provide a range of options, from local suppliers to online marketplaces, catering to different needs and budgets.

Local Suppliers

Visiting nearby shops can yield immediate results. Many specialized retailers offer a selection of essential items and knowledgeable staff to assist you.

Online Resources

The internet presents a vast array of choices. Numerous websites focus on selling components, often featuring user reviews to help you make informed decisions.

| Source Type | Advantages |

|---|---|

| Local Retailers | Immediate availability, expert advice |

| Online Marketplaces | Wider selection, competitive prices |

Tips for Troubleshooting Motor Problems

When faced with issues in your engine, a systematic approach can help identify and resolve the underlying causes. Understanding the common symptoms and applying logical steps will enhance your troubleshooting efficiency.

1. Check Fuel Quality: Ensure that the fuel is fresh and free from contaminants. Old or dirty fuel can lead to performance issues.

2. Inspect Electrical Connections: Examine wires and connectors for corrosion or damage. Poor connections can disrupt power delivery and cause erratic behavior.

3. Evaluate Cooling System: Verify that the cooling system is functioning properly. Overheating can result in severe damage, so ensure water intake is unobstructed.

4. Listen for Unusual Noises: Pay attention to any strange sounds while operating. They can indicate mechanical issues that require immediate attention.

5. Conduct Regular Maintenance: Regular inspections and maintenance can prevent many common issues. Follow the manufacturer’s guidelines for servicing.

By methodically addressing these areas, you can delve deeper into the health of your engine and find the ultimate solutions to its problems.

Upgrading Your Outboard Motor

Enhancing the performance and efficiency of your aquatic engine can significantly elevate your overall experience on the water. Whether you’re aiming for greater speed, improved fuel economy, or increased reliability, there are numerous strategies to explore that can bring your engine to its full potential.

Identifying Key Areas for Improvement

Start by assessing the current capabilities of your engine. Focus on components that influence speed and efficiency, such as the fuel system, ignition, and propeller. Each of these elements plays a critical role in how well your vessel performs and can be optimized for superior output.

Choosing Quality Upgrades

When selecting enhancements, prioritize durability and compatibility with your existing setup. Quality aftermarket components can offer significant benefits, but ensure they align with the specifications of your current engine. Investing in reputable brands will ultimately yield the best results and longevity.

Environmental Impact of Outboard Motors

The use of aquatic propulsion devices has raised concerns regarding their influence on ecosystems. These engines can contribute to pollution, both through emissions and fuel spillage, impacting water quality and marine life. The ultimate effect on biodiversity and habitats is significant, necessitating a closer examination of their operational practices.

Pollutants released into the atmosphere and waterways can lead to harmful consequences for aquatic organisms. Exhaust emissions, including hydrocarbons and nitrogen oxides, degrade air quality and can cause acidification in nearby environments. This pollution not only affects local fauna but also disrupts the food chain.

Furthermore, oil leaks from these devices can contaminate water bodies, creating toxic conditions for fish and other wildlife. The accumulation of these substances in the ecosystem poses risks to both aquatic health and human activities such as fishing and recreational boating.

To mitigate these effects, advancements in technology are being pursued. Innovations aim to enhance fuel efficiency and reduce harmful emissions, promoting a more sustainable approach to aquatic transport. By prioritizing eco-friendly alternatives, we can minimize our ecological footprint while enjoying the benefits of these devices.

Customer Reviews of Mercury Parts

This section explores feedback from users regarding their experiences with components for marine engines. Understanding customer opinions can provide valuable insights into quality, performance, and reliability.

Many users highlight the following aspects:

- Durability: Components are often praised for their longevity and resilience.

- Performance: Many reviews note improvements in engine efficiency after installation.

- Ease of Installation: Users appreciate clear instructions and compatibility with various models.

Overall, these testimonials help prospective buyers make informed decisions:

- Research user experiences before purchasing.

- Consider compatibility with your specific engine model.

- Check for warranties or guarantees offered by suppliers.