Comprehensive Guide to 90 HP Mercury Outboard Parts Diagram

When it comes to maximizing the performance of your aquatic propulsion system, a comprehensive understanding of its components is essential. Whether you are an enthusiast or a casual user, familiarity with each element will ensure that you can maintain and troubleshoot effectively.

Visual representation of these components can significantly enhance your grasp of how everything works together. This guide aims to illuminate the intricacies of a 90 HP engine, allowing you to delve deeper into the various sections that make up this powerful machinery.

By exploring the layout and functionality of the individual elements, you will gain the ultimate insight necessary for optimal performance and longevity. Prepare to uncover the essential features and how they contribute to your overall experience on the water.

Understanding 90 HP Mercury Outboard Parts

When it comes to high-performance marine engines, grasping the components that contribute to their functionality is essential for optimal operation and maintenance. A thorough comprehension of these elements ensures that users can identify issues, perform repairs, and enhance the overall longevity of their equipment.

Key Components include the powerhead, which houses the engine’s core mechanisms, and the lower unit, responsible for propulsion and steering. Each element works in harmony to deliver reliable performance on the water. Understanding how these components interact helps boaters troubleshoot potential problems more efficiently.

Regular maintenance is crucial. Familiarity with components such as the fuel system, ignition system, and cooling system can prevent minor issues from escalating into major malfunctions. By staying informed about the specific roles of each section, operators can ensure their marine engine remains in peak condition.

Moreover, knowing where to locate replacement items and enhancements can significantly improve the performance and reliability of the vessel. Access to a detailed reference allows users to pinpoint parts quickly, making repairs and upgrades simpler and more efficient.

Common Components of Mercury Outboards

When exploring the intricacies of marine engines, one encounters a variety of essential elements that work in unison to ensure optimal performance. These integral pieces not only contribute to the functionality but also influence the overall efficiency and durability of the machinery.

Powerhead is the heart of the system, housing the engine and key components that generate propulsion. Its design is crucial for delivering power effectively.

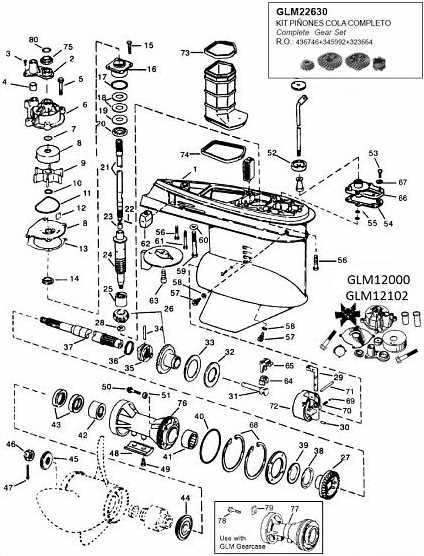

Gearcase plays a vital role in transferring the engine’s power to the propeller, allowing for smooth movement through the water. This assembly also includes the lower unit, which protects the internal workings from the harsh marine environment.

Propeller is the primary interface with the water, converting rotational motion into thrust. The design and pitch of the propeller can greatly affect speed and handling.

Fuel System is essential for delivering the right mixture of fuel and air to the engine, impacting performance and efficiency. Key components include the fuel pump, filters, and injectors.

Cooling System prevents overheating by circulating water through the engine. Maintaining this system is critical for longevity and reliable operation.

Electrical System powers various functions, including ignition and navigation lights. A well-functioning electrical network is vital for ensuring safety and operational efficiency.

Understanding these components allows users to delve deeper into maintenance and troubleshooting, ultimately enhancing the experience on the water.

Importance of Regular Maintenance

Consistent upkeep is crucial for the longevity and efficiency of any mechanical system. By prioritizing routine inspections and care, one can prevent minor issues from escalating into major problems, ensuring smooth operation and optimal performance. This proactive approach not only enhances reliability but also safeguards against unexpected failures.

Regular maintenance allows for the identification of wear and tear, enabling timely replacements of components before they compromise functionality. Additionally, it fosters an understanding of the system, helping users recognize when something is amiss. This vigilance contributes to a safer environment and reduces the risk of costly repairs.

Furthermore, well-maintained machinery tends to retain its value over time. Owners can enjoy improved fuel efficiency and overall performance, leading to a more enjoyable experience. Investing time in routine care ultimately pays off, enhancing both reliability and satisfaction.

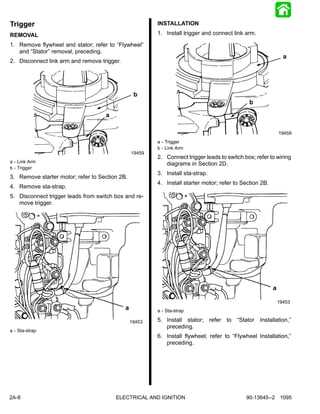

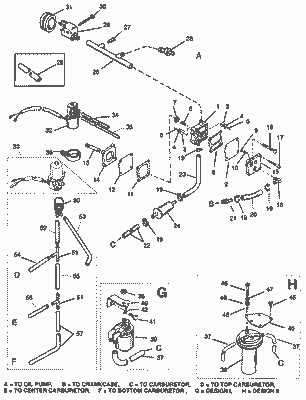

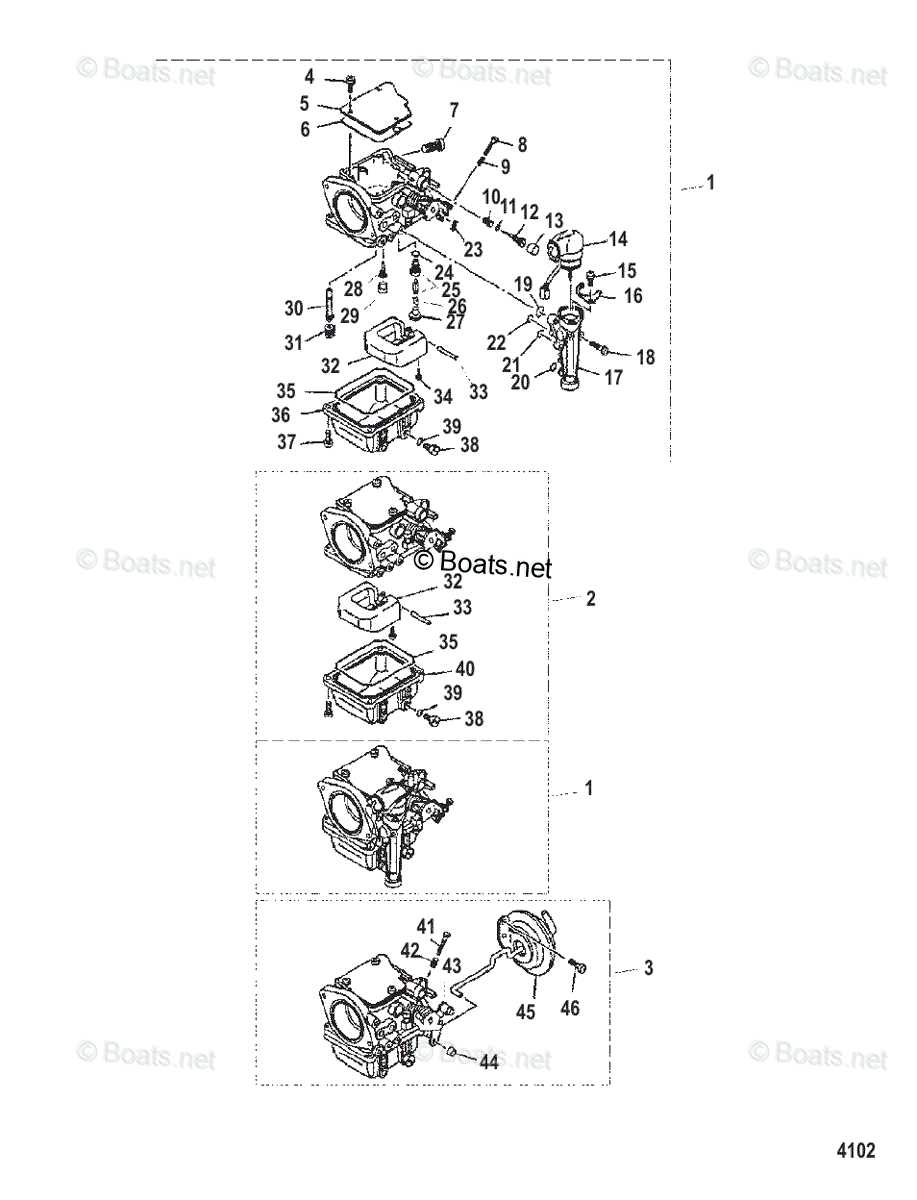

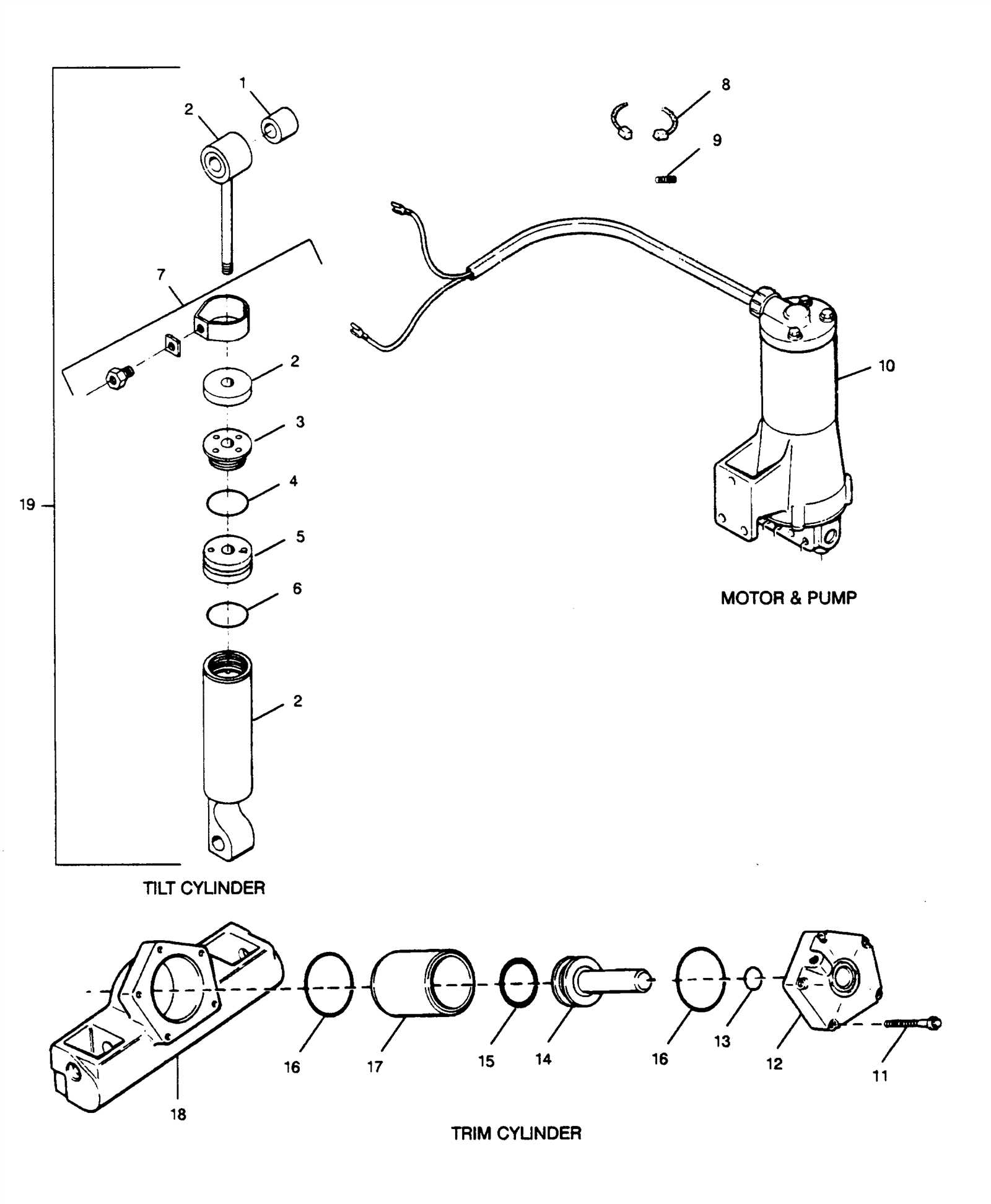

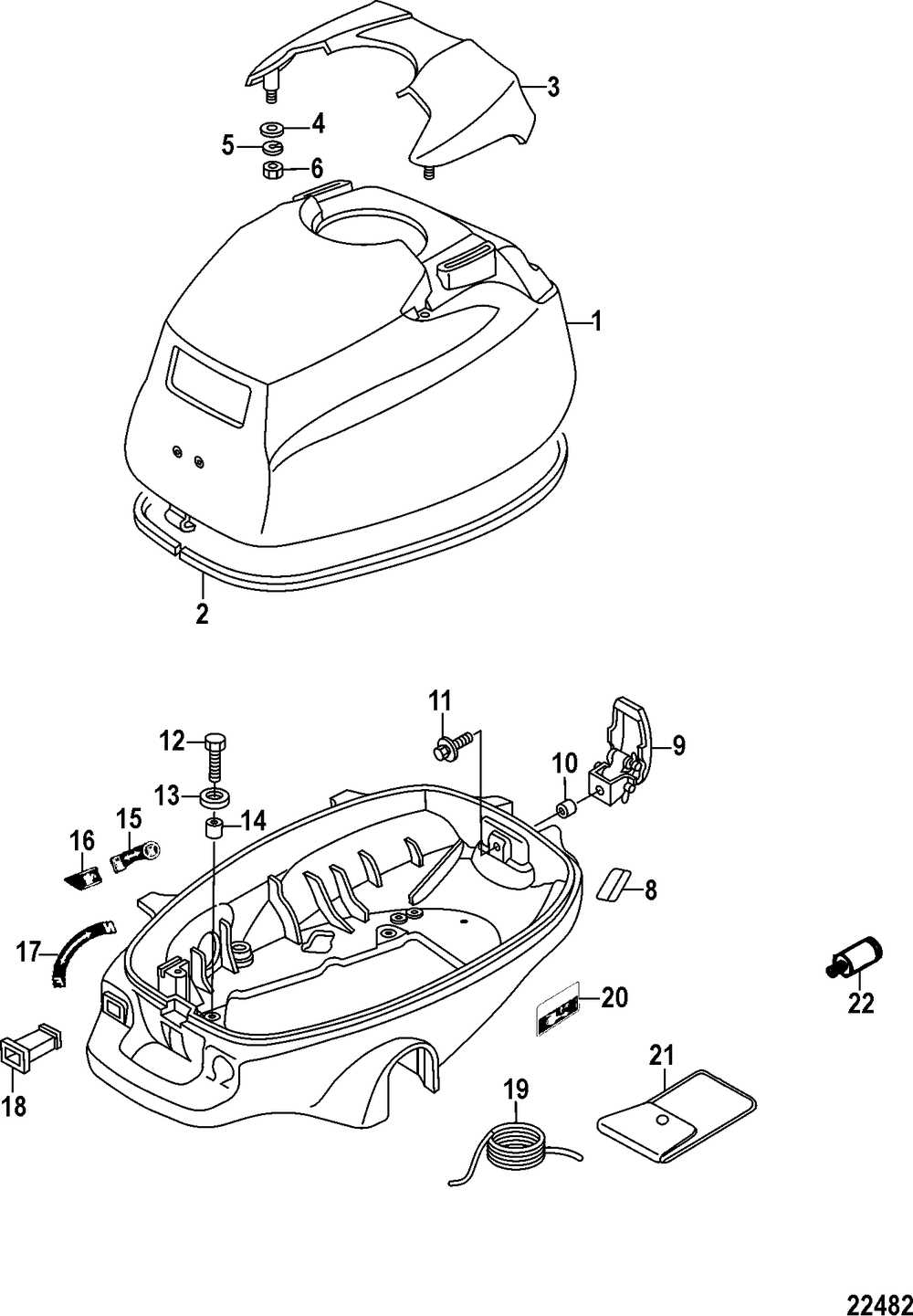

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair tasks. These visual representations provide a detailed view of components and their arrangement, allowing users to identify specific elements easily.

1. Familiarize Yourself with the Legend: Most visuals include a legend that explains symbols and numbering. This is your key to interpreting the image accurately.

2. Identify Sections: Look for divisions within the illustration. Each segment often corresponds to a specific assembly or function, making it easier to navigate.

3. Pay Attention to Annotations: Written notes or arrows can indicate important information about placement or assembly order, guiding you through the process.

4. Cross-Reference with Manuals: Always consult accompanying documentation for additional context. This can clarify any ambiguities found within the visual.

5. Practice: The more you engage with these illustrations, the more adept you will become at interpreting them, ultimately enhancing your repair skills.

Identifying Key Engine Features

Understanding the essential characteristics of a marine engine is crucial for effective maintenance and performance optimization. Each component plays a vital role in ensuring the overall functionality and efficiency of the unit. By familiarizing oneself with these features, operators can troubleshoot issues more effectively and enhance the longevity of their equipment.

Key engine features typically include:

- Fuel System: This encompasses the fuel tank, lines, and delivery mechanisms, all of which are integral to the engine’s operation.

- Ignition System: Essential for starting the engine, this system includes spark plugs and ignition coils, which generate the necessary spark for combustion.

- Cooling System: Vital for preventing overheating, it includes water pumps and thermostats that regulate the engine temperature.

- Exhaust System: Responsible for directing exhaust gases away from the engine, ensuring optimal performance and safety.

- Electrical Components: This includes the battery, wiring, and other elements that provide power to various systems within the engine.

Familiarity with these elements allows operators to monitor performance, recognize signs of wear, and make informed decisions regarding repairs or upgrades. Understanding the relationship between these components can lead to improved efficiency and reliability.

Ordering Replacement Parts Effectively

Ensuring optimal performance of your marine engine often requires sourcing specific components. To facilitate this process, it’s essential to follow a systematic approach that enhances efficiency and accuracy. This guide will provide insights into how to effectively procure the necessary items to keep your watercraft in peak condition.

Research and Preparation

Before making a purchase, thorough research is crucial. Consider the following steps:

- Identify the exact components needed by referring to your service manual.

- Gather the serial number and model information for precise matching.

- Check for compatibility with your existing setup.

Choosing the Right Supplier

Selecting a reliable source can greatly impact your experience. Keep these points in mind:

- Look for authorized dealers or reputable retailers.

- Read customer reviews to gauge reliability and service quality.

- Compare prices and warranties to ensure you get the best deal.

By following these guidelines, you can streamline the procurement process and ensure that your vessel remains in excellent operational condition.

Tips for DIY Repairs

Taking on repair tasks by yourself can be a rewarding experience, enabling you to save money and gain valuable skills. With the right knowledge and tools, you can address various issues effectively. Here are some essential tips to help you navigate your next project with confidence.

Gather Essential Tools

Before starting any repair, ensure you have the necessary tools at hand. Here’s a basic list:

- Wrenches

- Screwdrivers

- Pliers

- Socket set

- Safety gear (gloves, goggles)

Research and Plan

Understanding the problem is crucial. Take the time to research and create a plan:

- Identify the issue through troubleshooting.

- Consult manuals or online resources for guidance.

- Outline the steps needed for the repair.

With preparation and attention to detail, you’ll enhance your chances of achieving successful results in your repair endeavors.

Safety Precautions When Working

Engaging in maintenance or repair tasks requires careful attention to safety to prevent accidents and injuries. Ensuring a secure work environment and using appropriate protective equipment are essential steps in safeguarding yourself and others during any mechanical undertaking.

Personal Protective Equipment

Wearing the right gear is crucial when handling tools and machinery. This includes items that protect against physical hazards, chemicals, and noise. Here are some recommended types of personal protective equipment:

| Type of Equipment | Purpose |

|---|---|

| Safety Goggles | Protect eyes from debris and chemical splashes. |

| Gloves | Shield hands from cuts, abrasions, and chemicals. |

| Ear Protection | Reduce exposure to loud noises that can cause hearing damage. |

| Steel-Toed Boots | Protect feet from heavy objects and provide slip resistance. |

Work Area Safety

Maintaining a clean and organized workspace is vital for safety. Ensure that all tools are in good condition and stored properly. Remove any unnecessary items that could cause tripping hazards, and always have a fire extinguisher accessible. Regularly check for any signs of wear or damage in equipment to avoid malfunctions during operation.

Recommended Tools for Repairs

When undertaking maintenance or restoration tasks on your watercraft, having the right instruments can significantly enhance the efficiency and quality of your work. A well-equipped toolkit not only simplifies the repair process but also ensures that each component is handled correctly, leading to a safer and more reliable operation.

Essential Hand Tools

Start with a set of high-quality hand tools. Wrenches, screwdrivers, and pliers are fundamental for loosening and tightening various fittings. Consider investing in a torque wrench to ensure you apply the correct force, preventing damage to the components. A socket set is also invaluable, providing the versatility needed for different bolt sizes.

Specialized Equipment

In addition to basic hand tools, specialized equipment can greatly aid in specific repair tasks. A multimeter is crucial for electrical diagnostics, allowing you to troubleshoot wiring issues effectively. For tasks involving fluids, a pump and funnel can help with oil changes and fuel transfers, ensuring a clean and efficient process. Lastly, a work light is essential for illuminating dark spaces, making your repairs safer and more manageable.

Where to Find Parts Online

Finding components for your engine can be a straightforward task if you know where to look. The internet offers a vast array of resources that can assist you in locating what you need quickly and efficiently.

Online Retailers

- Amazon – A reliable marketplace with various options.

- eBay – Great for both new and used items.

- Specialized websites – Focused platforms dedicated to marine equipment.

Forums and Community Groups

- Online forums – Discussions often lead to great recommendations.

- Social media groups – Engage with enthusiasts for tips on sourcing.

- Local classifieds – Check community boards for nearby sellers.

Upgrading Your Outboard Engine

Enhancing the performance of your marine propulsion system can significantly improve your overall boating experience. By focusing on key components, you can achieve greater efficiency, speed, and reliability on the water.

Key Considerations for Upgrades

- Assess your current setup and identify areas for improvement.

- Consider performance upgrades, such as propeller changes or tuning options.

- Evaluate the benefits of lightweight materials to enhance speed.

Benefits of Upgrading

- Improved fuel efficiency leading to cost savings.

- Enhanced speed and maneuverability for a better experience.

- Increased longevity of your propulsion system with modern components.