Comprehensive Guide to Mercury 115 Outboard Parts Diagram

Exploring the intricate world of marine propulsion systems reveals a vast array of crucial elements that work in harmony to ensure optimal performance on the water. A comprehensive understanding of these components is essential for both enthusiasts and professionals alike.

In this section, we will delve into the specific features and configurations that make up a particular model of an outboard motor. By analyzing these components, one can appreciate their roles and how they contribute to the overall efficiency and reliability of the engine.

Whether you are performing maintenance, troubleshooting issues, or simply seeking to enhance your knowledge, familiarizing yourself with the various segments of a marine engine will prove invaluable. With this ultimate guide, you’ll gain insights that can elevate your experience on the water.

Understanding Mercury 115 Outboard Motor

This section explores the fundamental components and operational principles of a popular marine propulsion system. By examining its structure and functionality, enthusiasts can gain insight into how these mechanisms contribute to efficient navigation on water.

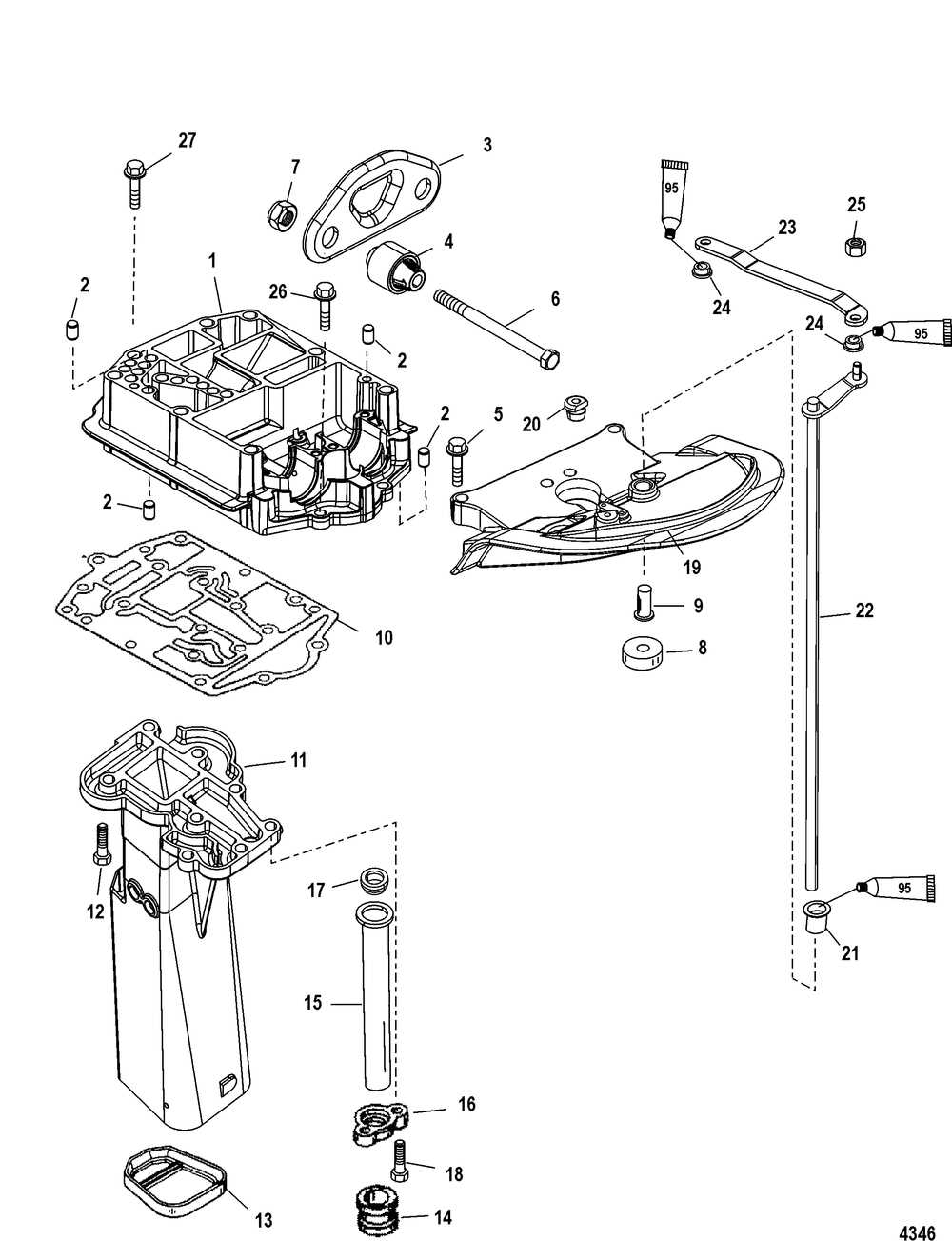

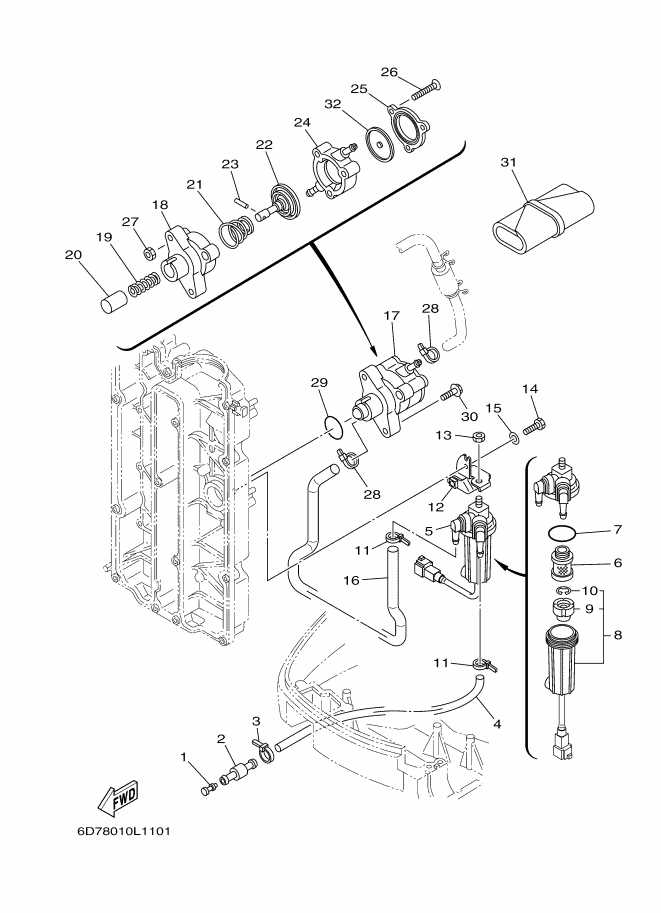

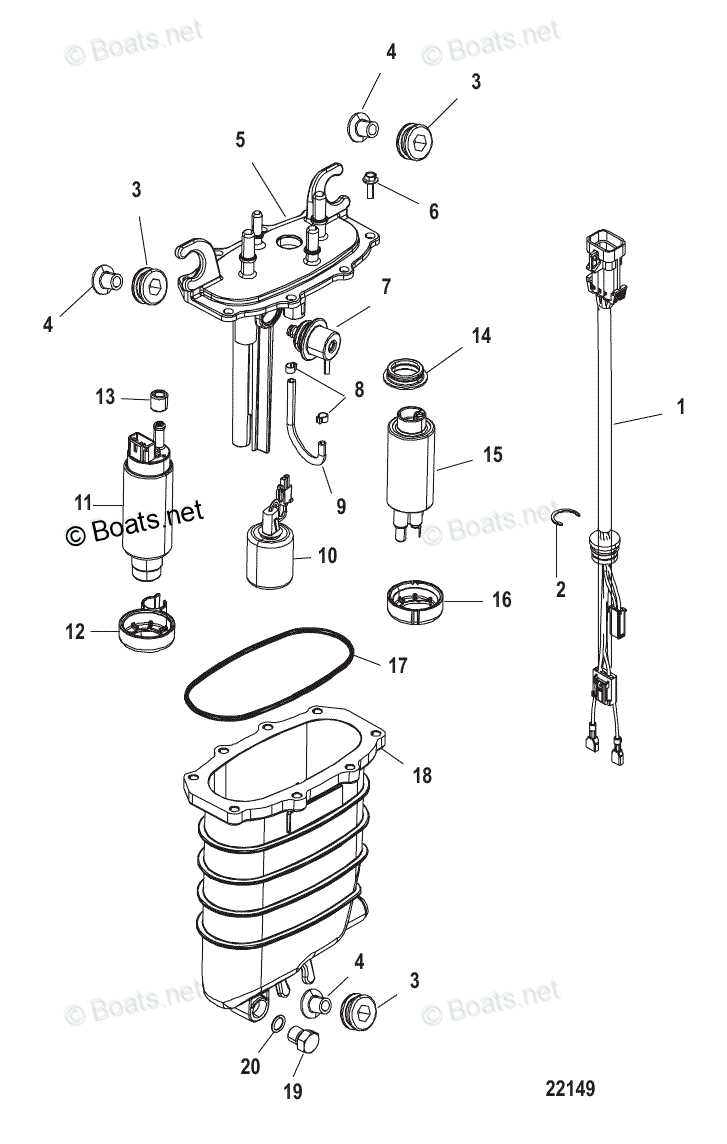

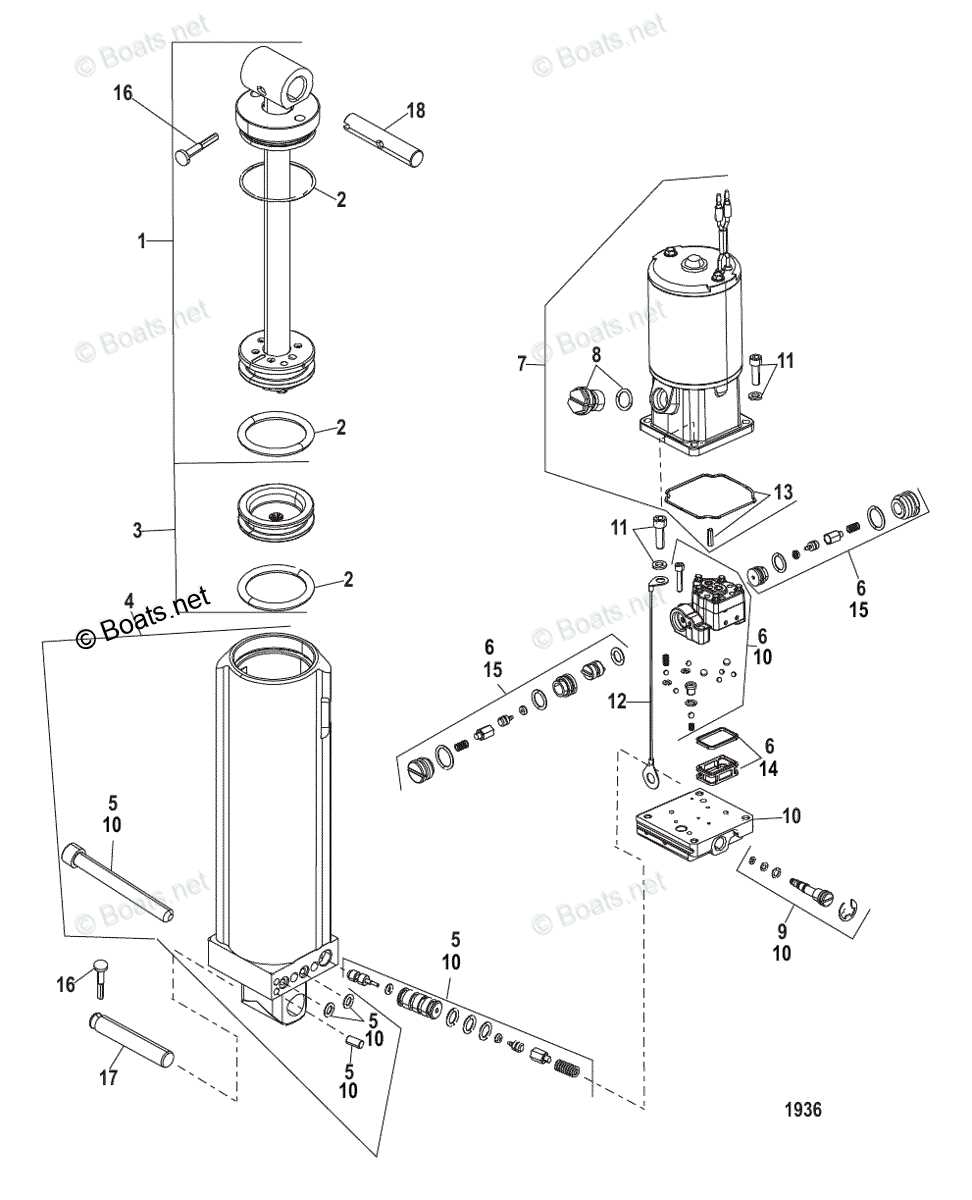

Key elements of this engine include the powerhead, lower unit, and fuel system, each playing a crucial role in performance and reliability. Understanding how these components interact enhances the overall boating experience.

Maintenance is vital for longevity and efficiency. Regular checks and servicing can prevent common issues, ensuring optimal operation and safety while on the water. Familiarity with these systems allows users to troubleshoot effectively and enjoy smoother outings.

Key Components of the Outboard Engine

Understanding the essential elements of a marine propulsion system is crucial for efficient operation and maintenance. Each part plays a vital role in ensuring optimal performance and reliability on the water.

- Powerhead: The core of the engine that houses the combustion chamber and crankshaft.

- Lower Unit: Contains the gearbox and propeller, transferring power to the water.

- Fuel System: Responsible for delivering the right mixture of fuel and air for combustion.

- Cooling System: Ensures the engine remains at the correct operating temperature.

- Electrical System: Provides ignition and powers various components, including lights and sensors.

Each of these elements is interconnected, contributing to the ultimate functionality and performance of the entire marine unit.

Importance of Proper Maintenance Practices

Regular upkeep is essential for ensuring the longevity and reliability of marine engines. Adopting a routine maintenance schedule not only enhances performance but also prevents unexpected breakdowns and costly repairs. Proper care ultimately contributes to a safer and more enjoyable experience on the water.

Benefits of Consistent Maintenance

Engaging in systematic care can lead to improved efficiency, reduced fuel consumption, and extended equipment life. It also fosters a greater understanding of the machinery, allowing for early detection of potential issues.

Common Maintenance Practices

| Practice | Description |

|---|---|

| Oil Changes | Regularly replacing oil ensures smooth engine operation and prevents damage. |

| Fuel System Inspection | Checking fuel lines and filters helps avoid clogs and maintains optimal performance. |

| Cooling System Maintenance | Cleaning and checking the cooling system prevents overheating and prolongs engine life. |

Common Issues and Troubleshooting Tips

When operating a marine propulsion unit, users may encounter several frequent problems that can affect performance and reliability. Understanding these common issues and knowing how to address them can enhance the overall experience on the water. Below are some typical challenges along with practical solutions to help troubleshoot effectively.

Frequent Problems

Some of the most prevalent issues include starting difficulties, overheating, and irregular idling. Each of these problems can stem from various underlying causes, and recognizing these can assist in prompt resolution.

| Issue | Possible Cause | Troubleshooting Steps |

|---|---|---|

| Starting Issues | Battery failure or fuel blockage | Check battery connections and charge; inspect fuel lines for obstructions. |

| Overheating | Clogged cooling system | Examine the water intake and flush the system if necessary. |

| Irregular Idling | Fuel quality or air leaks | Replace old fuel and inspect gaskets for wear or damage. |

Preventive Measures

To minimize the occurrence of these issues, regular maintenance is essential. Routine checks on fuel quality, battery health, and cooling systems can prevent many common malfunctions. Adhering to a scheduled maintenance plan will ensure smoother operation and extend the lifespan of your equipment.

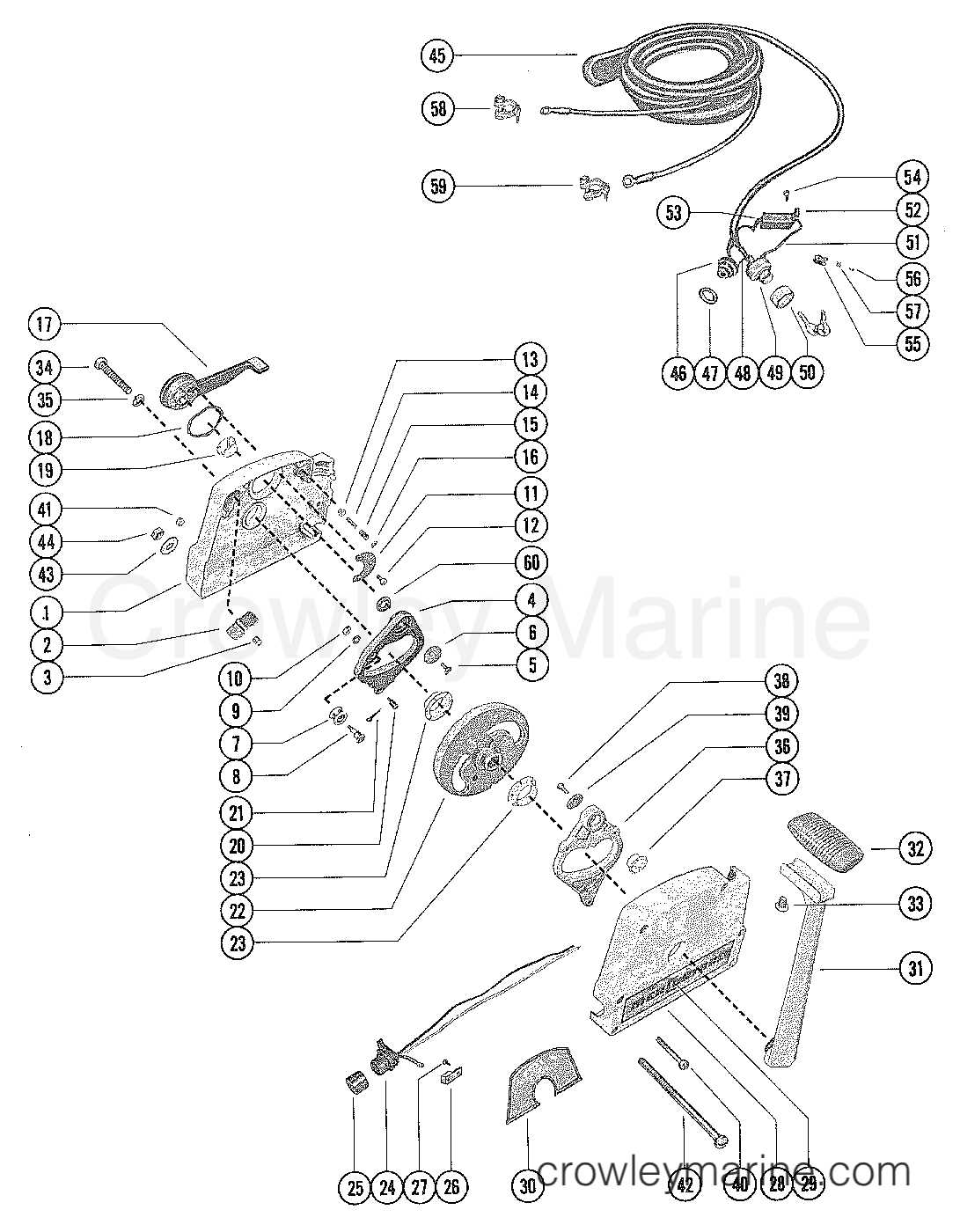

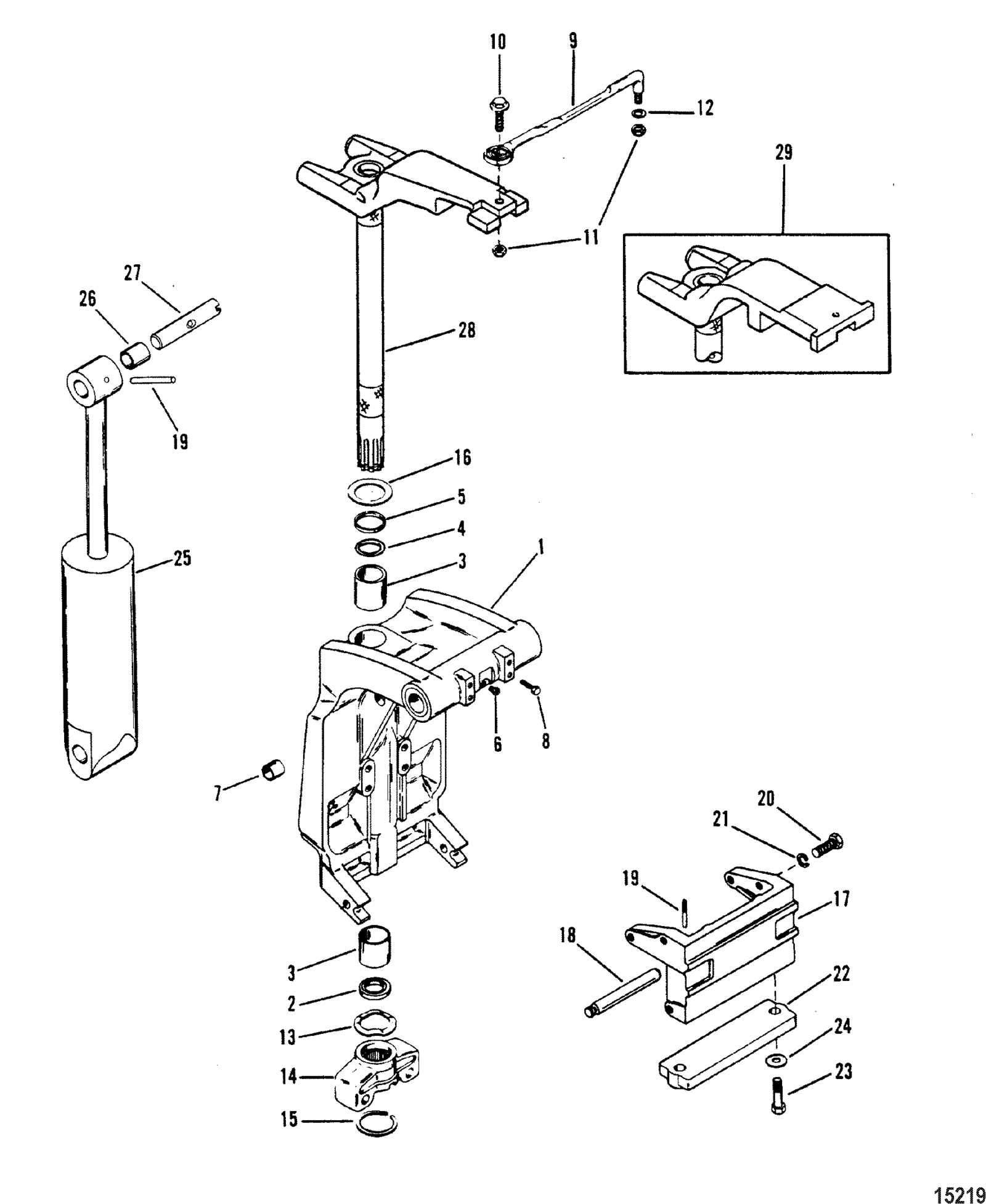

How to Read Parts Diagrams Effectively

Understanding visual representations of components is essential for successful maintenance and repair tasks. These illustrations serve as guides, helping users identify and locate specific elements within a mechanical assembly. Mastering the interpretation of these visuals can streamline your workflow and enhance your overall efficiency.

Key Elements to Focus On

- Labels: Look for annotations that specify each component’s name or number, providing clarity on what each part is.

- Sections: Diagrams are often divided into segments, making it easier to focus on specific areas without feeling overwhelmed.

- Connections: Pay attention to how different pieces connect to one another, as this will aid in reassembly and troubleshooting.

Tips for Effective Interpretation

- Familiarize Yourself: Spend time learning common symbols and notations used in illustrations.

- Cross-Reference: Use the visual alongside manuals or online resources to verify information and gain deeper insights.

- Take Notes: Jot down key observations or questions as you study the visual, facilitating a more thorough understanding.

Essential Tools for Repairing Outboards

Maintaining and fixing marine propulsion systems requires a specific set of instruments that ensure efficiency and accuracy. Having the right tools not only simplifies the repair process but also enhances safety and performance. This section outlines the fundamental instruments that every technician should consider having on hand for effective maintenance and troubleshooting.

| Tool | Description |

|---|---|

| Socket Set | Essential for loosening and tightening bolts in various engine components. |

| Wrench Set | Varied sizes are necessary for adjusting and securing parts that require torque. |

| Screwdriver Set | Includes both flathead and Phillips for working with screws in different assemblies. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage. |

| Multimeter | Vital for diagnosing electrical issues and ensuring proper voltage levels. |

| Fuel Line Wrench | Specifically designed for easy access to fuel system components without damage. |

| Pliers | Useful for gripping, twisting, and cutting various materials in tight spaces. |

| Cleaning Supplies | Including brushes and solvents for maintaining cleanliness and preventing corrosion. |

Equipping yourself with these essential tools will not only facilitate smoother repairs but also promote longevity in the systems you work on. Regular maintenance becomes much more manageable when you have the right instruments at your disposal.

Where to Buy Replacement Parts

Finding reliable sources for acquiring components is essential for maintaining the performance and longevity of your marine engine. Whether you are looking for original equipment or high-quality aftermarket alternatives, knowing where to search can make all the difference.

One of the best options is to visit authorized dealerships, which often carry genuine components and can provide expert advice tailored to your needs. Additionally, reputable online retailers specialize in marine equipment, offering a vast selection at competitive prices. Always check customer reviews and ratings to ensure you are purchasing from a trustworthy source.

Another avenue is local marine supply shops, where you can often find knowledgeable staff who can help identify the right items for your engine. For those comfortable with DIY repairs, salvage yards or online marketplaces can also be valuable for finding used components at a lower cost.

Lastly, engaging with online forums and communities can provide recommendations and insights from fellow enthusiasts, making it easier to track down hard-to-find pieces. Be sure to compare prices and return policies to make informed decisions.

Comparing Mercury 115 with Other Models

When examining various models within the marine engine market, it’s essential to understand the distinctions in performance, efficiency, and design features. Each engine has its unique strengths and weaknesses that cater to different boating needs and preferences. This analysis provides insights into how one particular model stands out against its competitors.

Performance Metrics

Performance is a critical factor for any marine engine. Here are some key aspects to consider:

- Power Output: Different models offer varying horsepower, influencing acceleration and speed.

- Fuel Efficiency: Comparison of fuel consumption rates can highlight cost-effectiveness over time.

- Torque: This affects the engine’s ability to perform under load, crucial for towing and carrying heavy gear.

Design Features

Engine design significantly impacts user experience. Consider the following:

- Weight: Lighter models can improve overall vessel performance and handling.

- Noise Levels: Quieter engines enhance the enjoyment of time on the water.

- Maintenance Requirements: Simplicity in maintenance can lead to longer operational life and reduced downtime.

Understanding these differences aids in making informed choices when selecting the right engine for specific boating activities.

Expert Recommendations for Performance Upgrades

Enhancing the efficiency and speed of your marine engine requires a strategic approach. By focusing on key components and modifications, you can significantly boost performance while ensuring reliability.

1. Upgrade the Propeller: Selecting a high-performance propeller tailored to your vessel can improve acceleration and top speed. Consider materials that reduce weight and increase durability.

2. Fuel System Optimization: Enhancing the fuel delivery system with high-flow injectors and performance pumps can ensure that your engine receives the right amount of fuel for optimal combustion.

3. Exhaust Modifications: Upgrading to a performance exhaust system can reduce back pressure, improving engine efficiency and producing a more aggressive sound.

4. Tuning the ECU: Reprogramming the engine control unit can unlock additional horsepower and torque, optimizing fuel maps for better performance.

5. Weight Reduction: Removing unnecessary weight from your vessel can dramatically enhance speed and maneuverability. Consider using lighter materials for components.

Implementing these recommendations will not only elevate your engine’s capabilities but also provide a more thrilling experience on the water.

Safety Measures When Working on Engines

When engaging in engine maintenance or repair, prioritizing safety is essential to prevent accidents and injuries. Proper precautions not only protect the individual but also ensure that the equipment functions efficiently. Understanding and implementing safety protocols can significantly reduce the risks associated with engine work.

Here are some crucial safety guidelines to follow:

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear, such as gloves, goggles, and ear protection, to shield yourself from potential hazards. |

| Ventilation | Ensure the workspace is well-ventilated to avoid inhaling harmful fumes or gases released during engine operation. |

| Disconnect Power Sources | Before performing any work, disconnect batteries and power sources to prevent accidental starts. |

| Use Tools Correctly | Employ the right tools for the job and maintain them in good condition to avoid injuries caused by faulty equipment. |

| Stay Organized | Keep your workspace tidy to minimize risks of tripping or misplacing tools, which can lead to accidents. |

| Follow Manufacturer Guidelines | Refer to the specific guidelines provided by the manufacturer for safe handling and servicing practices. |

By adhering to these measures, individuals can create a safer environment while working on engines, reducing the likelihood of mishaps and promoting efficient maintenance practices.

FAQs About Mercury Outboard Parts

This section aims to address common inquiries related to components used in marine propulsion systems, ensuring that users have the necessary information to make informed decisions and facilitate maintenance.

Common Questions

| Question | Answer |

|---|---|

| What should I consider when purchasing components? | Evaluate compatibility, quality, and manufacturer reputation. |

| How can I identify the right component for my engine? | Refer to the model number and consult the owner’s manual or a professional. |

| Are aftermarket components reliable? | Many are dependable, but research and reviews are essential for quality assurance. |

Maintenance Tips

Regular checks and prompt replacements of worn components enhance performance and longevity, ensuring a smooth experience on the water.