Comprehensive Guide to Mercury 150 Outboard Parts Diagram

In the world of boating, having a clear grasp of engine components is essential for maintenance and troubleshooting. A comprehensive exploration of these mechanisms can significantly enhance performance and longevity, ensuring a smooth experience on the water.

Every engine consists of numerous elements that work in harmony. Recognizing the layout and function of each component is crucial for any enthusiast or professional seeking to optimize their vessel’s operation.

Through careful examination, one can delve into the intricate relationships between these parts. This knowledge not only empowers boaters to make informed decisions but also serves as the ultimate guide for effective repairs and upgrades.

Understanding Mercury 150 Outboard Engine

This section aims to provide a comprehensive overview of a popular marine propulsion system, highlighting its key components and functionality. With a focus on performance and reliability, this engine is designed to meet the demands of both recreational and professional users. Understanding its structure and operation can enhance maintenance practices and improve overall user experience.

Key Features

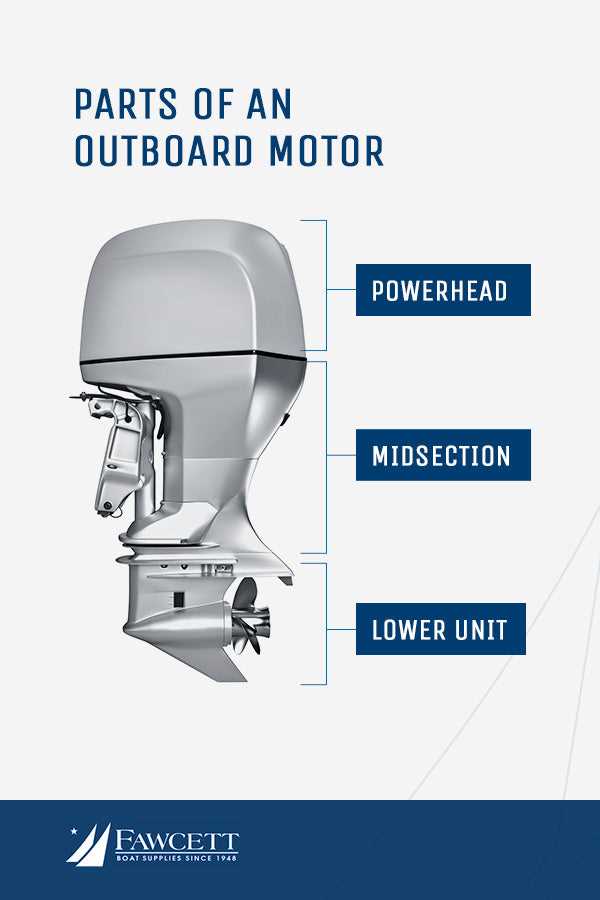

At the heart of this engine lies a powerful and efficient powerhead, which plays a crucial role in delivering optimal performance. Fuel efficiency is a standout characteristic, allowing for longer trips without frequent refueling. Additionally, the lightweight design contributes to better handling and maneuverability on the water, making it suitable for various applications.

Maintenance Insights

Regular upkeep is essential to ensure longevity and reliability. Familiarity with the engine’s internal and external components is vital for identifying potential issues early on. Routine checks of the cooling system, electrical components, and fuel lines can prevent costly repairs and enhance safety. Investing time in understanding these elements can significantly impact performance and reliability.

Key Components of the Outboard Motor

Understanding the essential elements of a marine propulsion system is crucial for both maintenance and performance. Each component plays a vital role in ensuring the engine operates smoothly and efficiently, contributing to overall functionality and reliability on the water.

Core Elements

The primary constituents of a marine engine include various mechanical and electrical systems that work together. From fuel delivery to cooling mechanisms, each part has specific functions that impact the motor’s efficiency and longevity.

Component Overview

| Component | Function |

|---|---|

| Powerhead | Houses the engine and is responsible for generating power. |

| Lower Unit | Contains the gearbox and propeller, translating power into movement. |

| Fuel System | Delivers fuel to the engine for combustion. |

| Cooling System | Regulates temperature to prevent overheating. |

| Electrical System | Powers ignition and other electronic components. |

Each of these elements is crucial for optimal operation, and regular checks can prevent issues that may arise during use. Understanding their roles helps in making informed decisions about repairs and upgrades.

Importance of Proper Maintenance

Regular upkeep of marine engines is crucial for ensuring optimal performance and longevity. Neglecting maintenance can lead to a range of issues, from decreased efficiency to complete breakdowns. A proactive approach not only enhances reliability but also minimizes repair costs over time.

Enhancing Performance

Consistent care and servicing help maintain peak functionality. When all components are in top shape, the engine operates smoothly, providing better fuel efficiency and improved speed. This directly translates to a more enjoyable experience on the water.

Preventing Costly Repairs

Addressing minor issues before they escalate is essential. Regular checks and timely replacements can prevent significant damage, saving both time and money. By investing in routine maintenance, owners can avoid unexpected failures and ensure a safer journey.

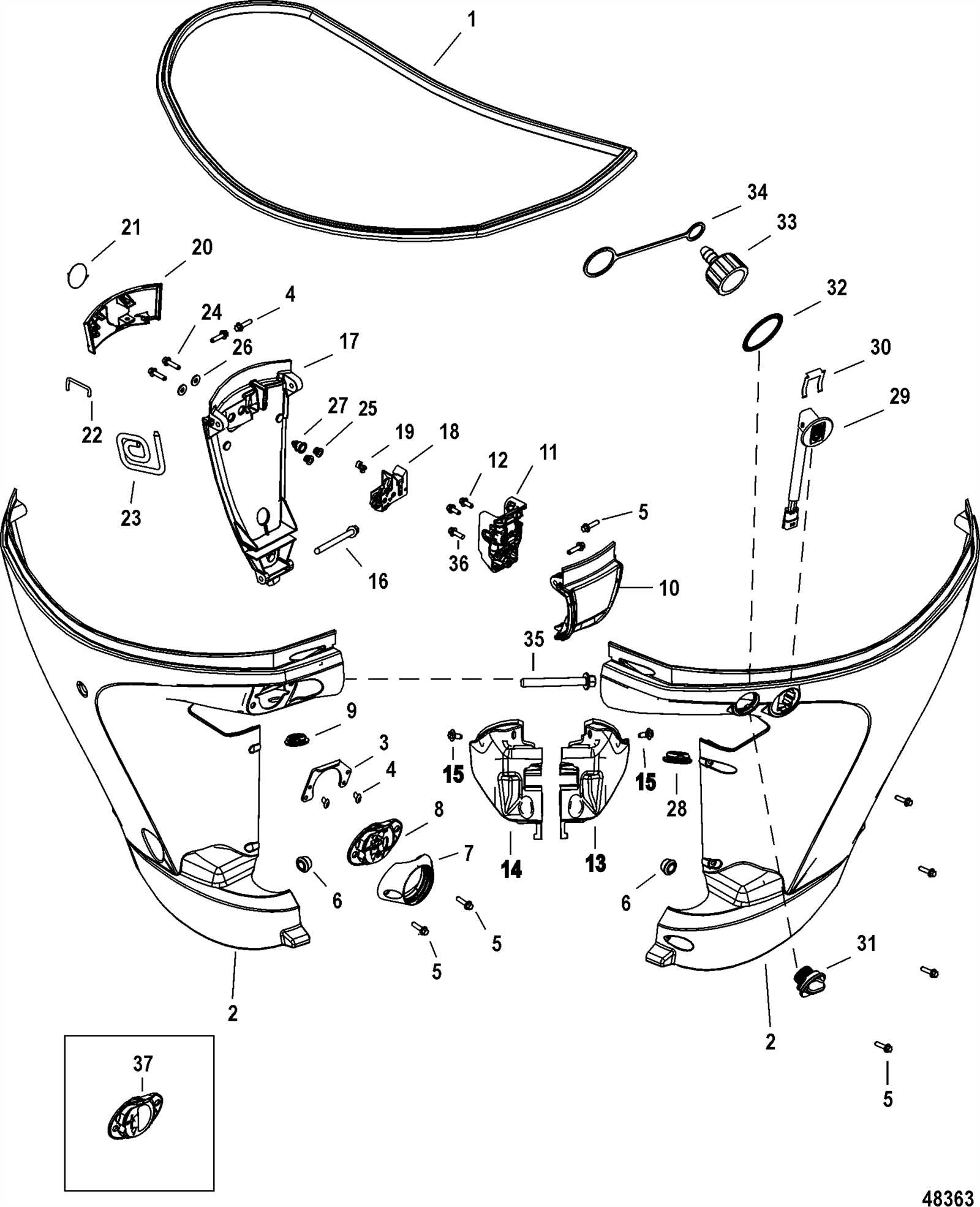

How to Read Parts Diagrams

Understanding technical illustrations can be crucial for effective maintenance and repair. These visual representations provide valuable insights into the components of a machine, helping users identify parts and their relationships. Mastering the art of interpreting these visuals can simplify the troubleshooting process and enhance the overall efficiency of your work.

Key Elements to Observe

Begin by familiarizing yourself with the overall layout. Typically, you will find a numbered key or legend that correlates with specific components. Pay attention to the symbols and lines, as they indicate connections and functions. It’s important to grasp how the elements interact with each other, providing context to their arrangement.

Common Terminology

Knowing the language used in these illustrations can greatly aid comprehension. Terms like assembly, component, and accessory frequently appear and have specific meanings. Understanding these definitions helps in accurately identifying what each part does and where it fits within the larger system.

Common Parts and Their Functions

Understanding the various components of a marine engine is essential for maintaining optimal performance and longevity. Each element plays a vital role, contributing to the overall functionality and efficiency of the system. Below is a breakdown of key components and their respective roles.

- Propeller: Converts engine power into thrust, propelling the vessel forward.

- Fuel System: Delivers the necessary fuel mixture to the combustion chamber, ensuring proper engine operation.

- Ignition System: Initiates the combustion process by generating a spark at the right moment.

- Cooling System: Regulates engine temperature by circulating water, preventing overheating.

- Gearbox: Transmits power from the engine to the propeller, allowing for speed adjustments and directional control.

- Exhaust System: Channels exhaust gases away from the engine, enhancing performance and reducing emissions.

- Steering Mechanism: Enables the operator to control the direction of the vessel smoothly.

- Electrical System: Powers various components, including the starter, lights, and navigation equipment.

Familiarity with these essential elements can aid in troubleshooting and maintenance, ensuring a reliable and efficient operation on the water.

Identifying Replacement Parts Easily

Finding the right components for your marine engine can be a straightforward process when you know what to look for. Understanding the layout and function of various elements is crucial for ensuring compatibility and performance. By utilizing reliable resources and visual aids, you can streamline the search for the necessary items without unnecessary complications.

Utilizing Resources: Start by consulting official manuals or reputable online platforms that offer detailed schematics. These documents provide clear illustrations that make it easier to identify each element based on its appearance and placement within the system.

Cross-Referencing: Always check part numbers and specifications. Many components are shared across different models, so cross-referencing can lead to more options and potentially lower costs. This approach ensures that you are not limited to a single source for procurement.

Community Engagement: Engaging with fellow enthusiasts through forums or social media can also be beneficial. Others may have faced similar challenges and can offer valuable insights on sourcing specific items or alternatives that work just as well.

By following these guidelines, you can enhance your ability to identify and acquire the necessary components efficiently, keeping your marine vessel in optimal condition.

Benefits of Using Original Parts

Utilizing authentic components in marine engines ensures superior performance and longevity. These specially designed elements provide a perfect fit and enhance the overall functionality of the machinery. By opting for genuine items, boat owners can avoid potential issues that may arise from inferior alternatives.

Quality Assurance

One of the primary advantages of selecting original components is the assurance of quality. These items are:

- Manufactured to meet specific industry standards.

- Tested rigorously for reliability and performance.

- Crafted from durable materials that withstand harsh marine environments.

Enhanced Performance

Genuine components are engineered to work seamlessly with existing systems. This compatibility results in:

- Smoother operation and improved efficiency.

- Reduced risk of mechanical failure.

- Better fuel economy, leading to cost savings over time.

In conclusion, investing in original items not only safeguards your vessel but also enhances its overall performance and longevity.

Tools Required for Repairs

When undertaking maintenance or repair tasks on marine engines, having the right tools at your disposal is essential for ensuring efficiency and safety. A well-equipped toolbox can make the difference between a successful project and unnecessary frustration. Understanding the necessary instruments will help streamline your workflow and achieve optimal results.

Basic Hand Tools

Every technician should possess a variety of hand tools, including wrenches, screwdrivers, and pliers. These are fundamental for loosening and tightening components, as well as for performing general adjustments. A good quality socket set is also crucial for accessing hard-to-reach areas and ensuring a secure fit.

Specialized Equipment

In addition to standard hand tools, specialized equipment may be required for more complex repairs. This can include torque wrenches for precise fastening, multimeters for electrical diagnostics, and compression testers for engine performance evaluation. Investing in quality tools not only enhances the repair process but also prolongs the lifespan of the equipment being serviced.

Finding a Reliable Parts Supplier

When seeking components for marine engines, identifying a trustworthy source is crucial. Quality and reliability can significantly impact performance and longevity.

Here are some key considerations when selecting a supplier:

- Reputation: Look for reviews and testimonials from other customers.

- Quality Assurance: Ensure the provider offers genuine or high-quality alternatives.

- Range of Inventory: A comprehensive selection indicates expertise in the field.

- Customer Support: Responsive and knowledgeable staff can assist with inquiries.

- Return Policy: A flexible policy shows confidence in their products.

By evaluating these factors, you can delve deeper into your search for the ultimate supplier, ensuring your marine vessel remains in top condition.

Installation Tips for Outboard Components

Proper assembly of marine machinery components is essential for optimal performance and longevity. Following a few key guidelines can help ensure that each part is securely and accurately installed, reducing the risk of malfunctions during use.

Start by carefully reviewing the manufacturer’s guidelines and specifications. Familiarize yourself with each component’s requirements and compatibility with other elements in the system. Preparation is crucial, so gather all necessary tools and materials before beginning the process.

Here are some helpful tips to consider during installation:

| Tip | Description |

|---|---|

| Clean Surfaces | Ensure that all surfaces are free of dirt and debris to promote a secure fit. |

| Use Proper Torque | Follow the recommended torque specifications to avoid over-tightening or under-tightening. |

| Double-Check Alignments | Verify that all parts are aligned correctly before securing them in place. |

| Seal Connections | Apply appropriate sealants or gaskets to prevent leaks and ensure a tight seal. |

| Test Components | After installation, conduct a thorough testing to ensure everything is functioning as intended. |

By following these installation tips, you can help ensure that your marine machinery operates smoothly and efficiently, ultimately enhancing your boating experience.

Signs of Wear and Tear

Understanding the indicators of degradation is crucial for maintaining the longevity of marine engines. Regularly monitoring for these signs can prevent major malfunctions and enhance overall performance.

Common Indicators

Look for discoloration or fraying on components, as these often signal the onset of deterioration. Additionally, unusual noises during operation may hint at internal issues.

Impact of Neglect

Ignoring these symptoms can lead to severe damage and costly repairs. Timely attention to wear not only safeguards the engine but also ensures optimal functioning over time.

Understanding Warranty and Support Options

When investing in marine equipment, it’s essential to comprehend the warranty and support services available for your purchase. These aspects not only ensure peace of mind but also safeguard your investment against unforeseen issues. A well-defined warranty can cover repairs, replacements, and maintenance, while robust support options can assist you in troubleshooting and resolving problems efficiently.

Typically, warranties vary in length and scope, offering different levels of coverage based on the type of product and manufacturer. It’s advisable to thoroughly review the warranty documentation to understand what is included and any potential limitations. This knowledge can help you make informed decisions and avoid unexpected costs.

In addition to warranty provisions, manufacturers often provide a range of support services. These may include customer service hotlines, online resources, and access to certified technicians. Utilizing these services can enhance your experience and ensure that you receive prompt assistance when needed.

Ultimately, being aware of your warranty and support options is crucial for maintaining the longevity and performance of your marine equipment. Always keep documentation handy and don’t hesitate to reach out for help if any issues arise.