Mercury 200 EFI Parts Overview

When dealing with intricate machinery, understanding how various elements work together is crucial. Each piece has its role in ensuring the system functions smoothly, and having a clear visual reference for these components can greatly aid in maintenance and repairs.

Identifying individual elements within a system can sometimes be challenging without proper guidance. A well-organized schematic offers insight into the assembly process, helping technicians and enthusiasts alike ensure that each element is placed correctly.

Visual breakdowns of mechanical structures are invaluable tools. They help in troubleshooting by providing a clear picture of how each section fits into the overall system. Such references are indispensable for anyone working on complex engines or mechanical units.

Engine Overview

The high-performance motor is designed for reliability and efficiency on the water. Known for smooth operation and advanced technology, this engine offers power while maintaining fuel efficiency. Its compact design allows for easy integration with a variety of boat models, providing both performance and durability in demanding marine environments.

Key Features

One of the standout features of this engine is its seamless electronic control system. It adjusts fuel delivery and ignition timing automatically to optimize performance. Additionally, the cooling system is designed to withstand high temperatures, ensuring that the motor runs smoothly under pressure.

Performance Benefits

With its innovative design, this motor delivers impressive acceleration and top speed. It balances power output with efficient fuel consumption, making it an ideal choice for those seeking both performance and economy on long boating trips.

Main Components of the Mercury 200 EFI

The essential elements of this outboard motor play a crucial role in ensuring its reliable operation and performance. Each component is designed to work together seamlessly, offering efficient fuel delivery and power output for smooth functionality on the water.

| Component | Description |

|---|---|

| Fuel Injector | Responsible for delivering fuel directly into the engine’s combustion chamber, ensuring precise fuel-to-air mixture. |

| Ignition System | This system initiates combustion by providing the necessary spark at the right time. |

| Cooling Mechanism | Keeps the engine temperature regulated to prevent overheating during prolonged operation. |

| Throttle Body | Controls the amount of air entering the engine, directly influencing power and performance. |

| Exhaust System | Channels exhaust gases away from the engine, reducing back pressure and improving efficiency. |

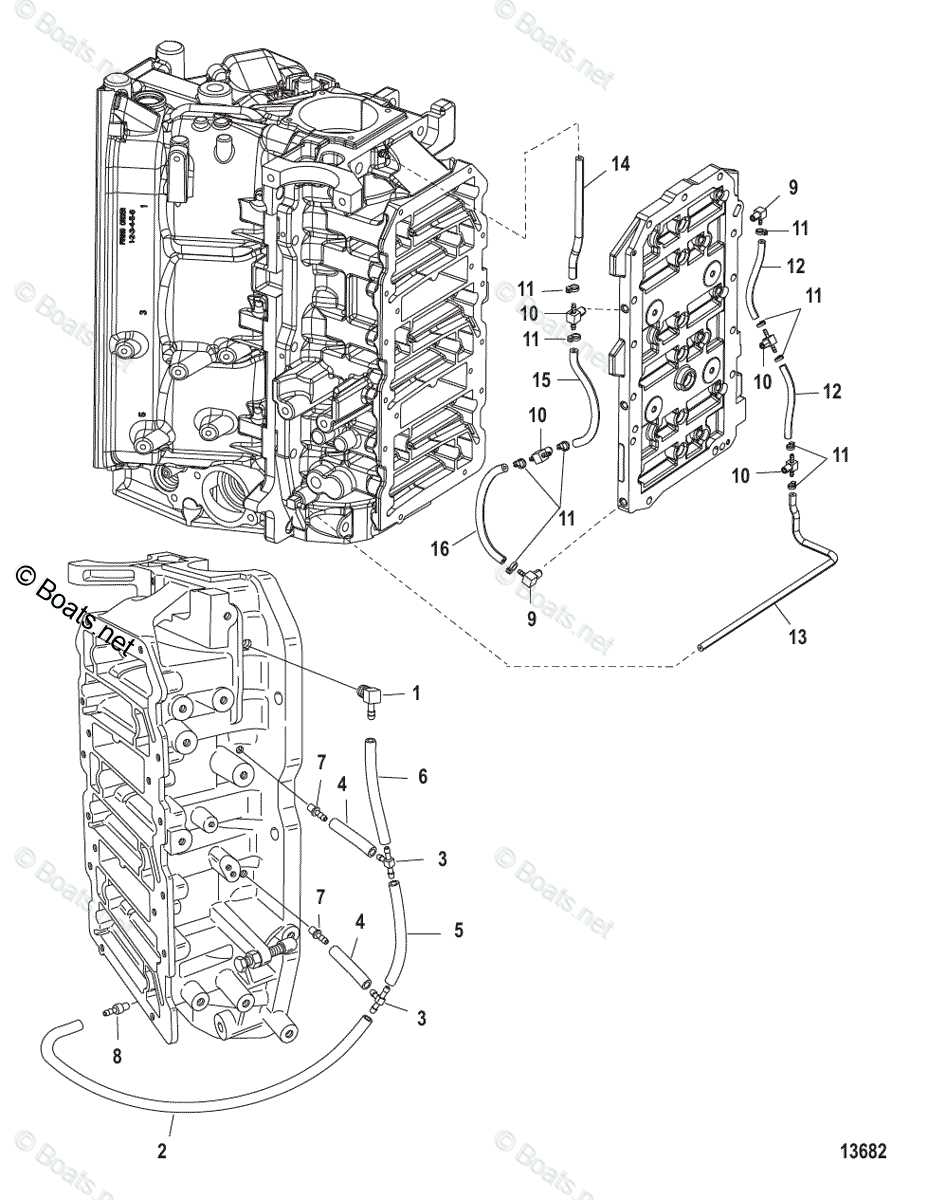

Understanding the Fuel System Structure

The fuel system is a critical component in ensuring the smooth and efficient operation of an engine. It manages the flow of fuel from the tank to the combustion chambers, providing the engine with the necessary power to function. A well-organized fuel system ensures optimal performance and fuel efficiency, while preventing potential issues caused by irregular fuel supply.

Main Components of the Fuel System

- Fuel Pump: Responsible for delivering fuel from the tank to the engine under pressure, ensuring the right amount of fuel reaches the combustion chamber.

- Fuel Filter: Cleans the fuel by removing debris and impurities, protecting the engine from damage and maintaining a smooth flow of fuel.

- Fuel Injectors: Precisely spray the fuel into the engine’s intake system, ensuring the fuel mixes with air for efficient combustion.

How the Fuel System Works

- Fuel is drawn from the tank by the pump and pushed through the filter.

- Cleaned fuel reaches the injectors, where it is sprayed in a controlled manner into the intake system.

- Combustion occurs when the fuel mixes with air and ignites, powering the engine.

By understanding the basic structure of the fuel system, users can better maintain their engines, ensuring optimal performance and preventing costly repairs.

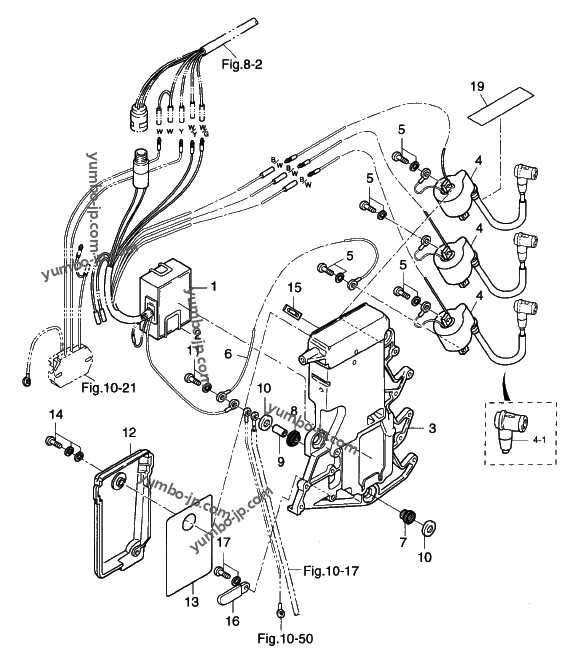

Detailed View of the Ignition System

The ignition system plays a crucial role in ensuring the efficient functioning of the engine. It is responsible for initiating the combustion process, which powers the motor. A well-designed ignition setup ensures that the engine runs smoothly and efficiently, minimizing fuel consumption and maximizing performance.

Key components of the system include spark distributors, wires, and electrical connections, which work together to generate and deliver the necessary spark. These elements must be in proper alignment to guarantee that the system performs reliably and consistently.

Regular maintenance of the ignition components is essential to avoid issues such as misfires or performance drops. Replacing worn-out parts and checking electrical connections will help keep the engine operating at its peak performance.

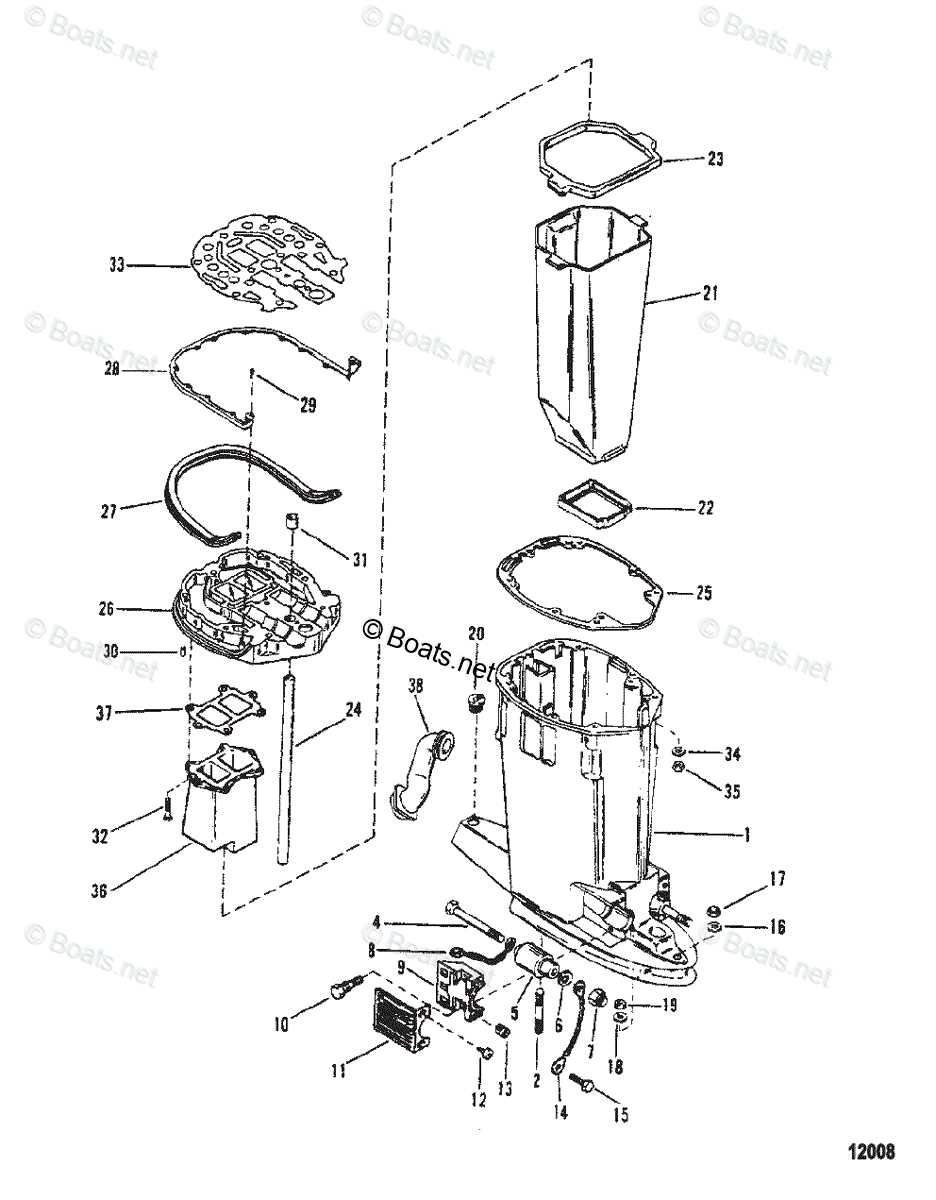

Cooling System Parts and Functionality

The cooling system is essential for maintaining optimal engine temperature during operation. Its purpose is to prevent overheating, which could lead to significant damage. By efficiently regulating the temperature, the system ensures the engine runs smoothly and extends its lifespan.

Key components of the system include the pump, which circulates fluid throughout the engine, and the radiator, where excess heat is dissipated. The fluid flows through various passages, cooling down hot areas and carrying heat away. Additionally, the thermostat helps to manage temperature levels by controlling the flow of coolant when needed.

Each element plays a crucial role in ensuring that the system works as intended, promoting efficient heat exchange and maintaining stable engine performance. Understanding how these components interact can aid in troubleshooting issues and ensuring smooth operation under various conditions.

Electrical System Breakdown

The electrical system in high-performance marine engines plays a crucial role in ensuring optimal functionality and efficiency. Understanding its components and their interactions is essential for troubleshooting and maintenance. This section delves into the various elements of the electrical setup, highlighting their purposes and connections within the overall structure.

Key Components

At the heart of the electrical network are essential elements such as the battery, ignition system, and various sensors. The battery serves as the primary power source, providing the necessary voltage for starting the engine and powering accessories. Meanwhile, the ignition system is responsible for initiating combustion, utilizing signals from sensors to ensure precise timing.

Wiring and Connectivity

The integrity of wiring is vital for reliable operation. High-quality connections and properly insulated wires help prevent short circuits and ensure efficient power distribution. Regular inspections of these components can significantly enhance performance and longevity, making it imperative for boat owners to prioritize electrical maintenance.

Throttle and Control Mechanism Explanation

The throttle and control system plays a crucial role in the functionality of marine engines. This mechanism is responsible for regulating the flow of air and fuel, thereby influencing the engine’s performance and responsiveness. Understanding its components and operation is essential for effective maintenance and troubleshooting.

At its core, the control mechanism comprises several key elements:

- Throttle Valve: This component regulates the amount of air entering the engine, affecting acceleration and speed.

- Control Cables: These cables connect the throttle lever to the throttle valve, enabling the operator to adjust the engine’s power output.

- Linkage System: This system translates the movement of the throttle lever into the opening and closing of the throttle valve.

- Position Sensors: These devices monitor the position of the throttle valve, providing feedback to the engine control unit for optimal performance.

Each part plays a specific role in ensuring the engine operates smoothly. Proper calibration and adjustment of these components are vital for achieving the desired performance and efficiency.

Regular inspections and maintenance of the throttle and control system can help prevent issues, ensuring reliable operation during various marine activities.

Exhaust System Configuration and Design

The exhaust system plays a crucial role in optimizing engine performance and ensuring effective emission control. This section explores the fundamental aspects of exhaust system configuration, highlighting key design elements that influence functionality and efficiency.

Key Components of Exhaust Systems

- Exhaust Manifold: Directs exhaust gases from the engine cylinders to the exhaust pipe.

- Catalytic Converter: Reduces harmful emissions by converting exhaust gases into less harmful substances.

- Muffler: Minimizes noise generated by the engine’s exhaust process.

- Exhaust Pipe: Channels exhaust gases from the engine to the outside atmosphere.

Design Considerations

- Material Selection: Choosing durable materials that can withstand high temperatures and corrosion is essential.

- Pipe Diameter: Optimizing the diameter ensures adequate gas flow, enhancing performance and efficiency.

- Layout: A well-planned layout minimizes bends and obstructions, improving exhaust flow and reducing backpressure.

- Noise Control: Implementing effective noise-dampening solutions to meet regulatory standards while maintaining performance.

Steering and Linkage System Layout

The steering and linkage system is a crucial component in ensuring effective maneuverability and control in various marine vessels. This assembly comprises several elements that work in concert to translate the operator’s inputs into directional changes, enhancing navigation and overall performance.

In this layout, key components include the steering wheel, cable system, and associated linkages. Each part plays a significant role in maintaining responsiveness and precision while steering, contributing to a seamless boating experience.

| Component | Description |

|---|---|

| Steering Wheel | The primary interface for the operator, allowing for directional control. |

| Cable Assembly | Transmits the motion from the steering wheel to the linkage system. |

| Linkage Arms | Connects the cable assembly to the steering mechanism, facilitating movement. |

| Pulleys | Guides the cable and reduces friction during operation. |

| Mounting Brackets | Secures various components in place, ensuring stability and alignment. |

Lubrication System Components and Purpose

The lubrication system is essential for maintaining optimal performance in any engine, ensuring that various components operate smoothly and efficiently. This system minimizes friction, reduces wear, and helps to dissipate heat, thereby extending the life of the engine and improving overall functionality.

Key Components of the Lubrication System

The lubrication system consists of several critical elements that work together to deliver oil to engine parts. These components include:

| Component | Function |

|---|---|

| Oil Pump | Pumps lubricant throughout the engine to ensure all moving parts are adequately supplied. |

| Oil Filter | Removes contaminants from the lubricant, preventing them from causing damage to engine components. |

| Oil Pan | Stores excess lubricant and allows for easy retrieval for circulation within the system. |

| Oil Galleries | Passages through which the lubricant flows, directing it to various engine parts that require lubrication. |

Purpose of the Lubrication System

The primary goal of the lubrication system is to protect and enhance the performance of the engine by ensuring that all moving parts remain lubricated. This prevents overheating, reduces friction, and ultimately contributes to the engine’s longevity and reliability. By facilitating efficient operation, the lubrication system plays a vital role in the overall functioning of the engine.

Key Sensors and Their Locations

The effective operation of an outboard engine relies significantly on various sensors that monitor essential parameters. These sensors play a crucial role in providing real-time data, which aids in optimizing performance and ensuring safety during operation. Understanding their locations and functions can help users maintain their equipment more efficiently.

Among the vital sensors are the throttle position sensor, which is typically mounted near the throttle body, and the temperature sensor, often located in the engine block. Additionally, the fuel pressure sensor can be found along the fuel rail, while the oxygen sensor is usually situated in the exhaust system. Recognizing the exact placement of these components is essential for troubleshooting and routine maintenance.