Comprehensive Guide to Mercury 60 HP Outboard Parts Diagram

For those navigating the waters with a 60 horsepower marine engine, having a clear understanding of its various components is essential. Proper knowledge not only enhances maintenance but also ensures optimal performance during your excursions. Whether you’re an avid fisherman or a weekend sailor, recognizing how each part functions can significantly impact your experience on the water.

Every engine comprises numerous elements, each playing a crucial role in its overall operation. Familiarity with these components enables you to identify issues early on, allowing for timely repairs and replacements. This proactive approach can save both time and money, preventing minor problems from escalating into major malfunctions.

In this section, we will explore the intricate layout of the engine’s components, providing insights into their specific functions and relationships. By delving into the structure, you’ll gain valuable information that will aid in both troubleshooting and maintenance, ultimately enhancing your boating adventures. Understanding the makeup of your marine engine is the first step towards ensuring a reliable and enjoyable time on the water.

Understanding Mercury 60 HP Outboards

The 60-horsepower engine designed for marine use is an essential piece of equipment for boating enthusiasts. Its efficient performance and reliability make it a popular choice for various watercraft. This section explores key components and operational principles that define this engine’s effectiveness in delivering power and maneuverability on the water.

At its core, this engine is engineered for optimal fuel efficiency and torque, allowing vessels to achieve impressive speeds while maintaining a steady flow of power. Key elements include the fuel system, which ensures proper combustion, and the cooling mechanism, vital for preventing overheating during prolonged use.

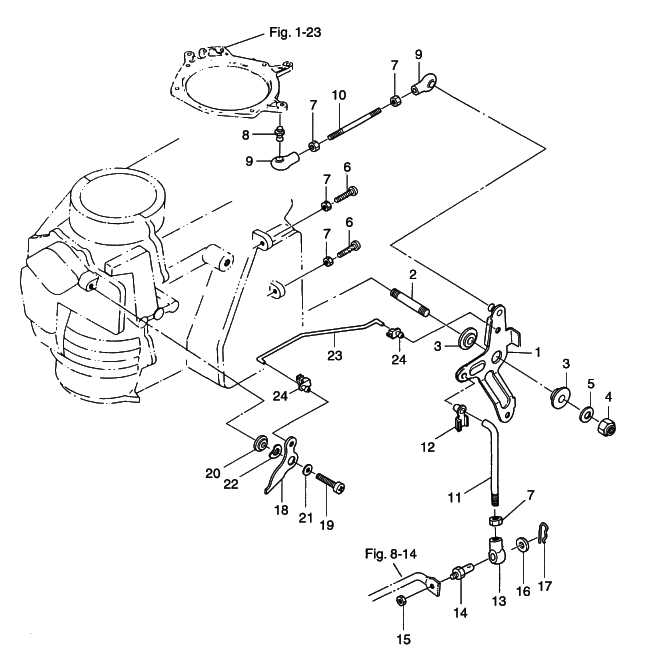

Understanding the internal mechanics is crucial for effective maintenance and troubleshooting. Knowledge of the ignition system, the role of the propeller, and the importance of regular oil changes can significantly enhance performance and longevity. Moreover, familiarizing oneself with the structure of the lower unit and its interaction with the hull contributes to a smoother boating experience.

By grasping these fundamental concepts, boaters can better appreciate the technology behind their marine engines, leading to more informed decisions regarding upgrades and repairs. Whether navigating serene lakes or tackling coastal waters, this engine remains a steadfast companion for adventure on the open sea.

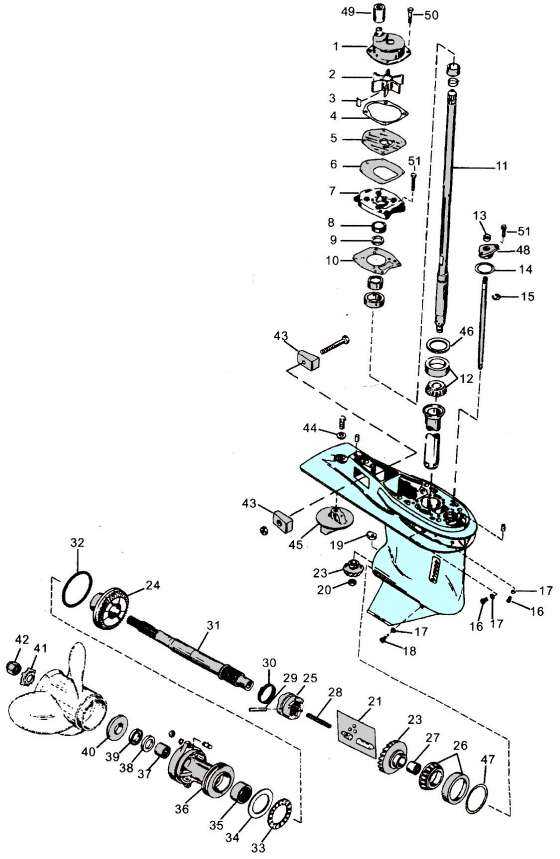

Key Components of the Outboard Engine

Understanding the essential elements of a marine propulsion system is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring efficiency and reliability, making knowledge of these parts beneficial for any boat enthusiast.

| Component | Description |

|---|---|

| Powerhead | The engine’s core, housing the cylinders and ignition system, responsible for generating thrust. |

| Lower Unit | Contains the gears and drive mechanism, transferring power from the engine to the propeller. |

| Propeller | The rotating blade system that propels the vessel forward or backward in the water. |

| Cooling System | Regulates engine temperature, using water to prevent overheating during operation. |

| Fuel System | Manages the delivery of fuel to the engine, ensuring efficient combustion and performance. |

Importance of Regular Maintenance

Routine upkeep is crucial for ensuring longevity and optimal performance of any mechanical device. Neglecting this aspect can lead to a range of issues that ultimately affect functionality and safety. By adhering to a consistent maintenance schedule, owners can prevent minor problems from escalating into major repairs.

Benefits of Consistent Care

- Enhances overall efficiency

- Extends lifespan of the equipment

- Reduces the risk of unexpected breakdowns

- Improves safety for users

Key Maintenance Practices

- Regular fluid checks and changes

- Inspection of electrical systems

- Cleaning and replacing filters

- Monitoring wear and tear on components

By committing to these practices, users can significantly improve the reliability and effectiveness of their machinery.

Common Issues and Troubleshooting Tips

When operating marine engines, users may encounter various challenges that can affect performance. Understanding these common problems and their solutions can enhance the overall experience and ensure smooth functioning.

- Starting Difficulties:

- Check the fuel supply and connections.

- Inspect the battery condition and connections.

- Examine the ignition system for any faults.

- Overheating:

- Ensure the cooling system is not clogged.

- Verify the water intake is unobstructed.

- Monitor the thermostat for proper operation.

- Unusual Noises:

- Identify any loose components or fasteners.

- Check the propeller for damage or debris.

- Inspect the gear system for signs of wear.

- Fuel Leaks:

- Examine fuel lines and fittings for integrity.

- Inspect the fuel tank for any cracks or damage.

- Replace any worn or damaged seals.

Addressing these issues promptly can prevent further complications and enhance the longevity of your engine.

Parts Availability and Sources

Access to components is essential for maintaining and repairing marine engines. Knowing where to find high-quality replacements can save time and ensure the longevity of your equipment. Various options exist for sourcing these essential elements, each with its advantages and considerations.

Authorized Dealers

Official distributors provide a reliable source for genuine components, ensuring compatibility and quality. They often have access to the latest inventory and can offer expert advice for specific models.

Aftermarket Suppliers

Alternative vendors offer a range of options, often at competitive prices. While some aftermarket products may not meet the original manufacturer’s specifications, many reputable suppliers provide reliable alternatives.

| Source Type | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine components, expert support | Higher prices, limited availability |

| Aftermarket Suppliers | Cost-effective options, wide selection | Variable quality, may not fit perfectly |

| Online Marketplaces | Convenient, often competitive prices | Quality varies, check seller ratings |

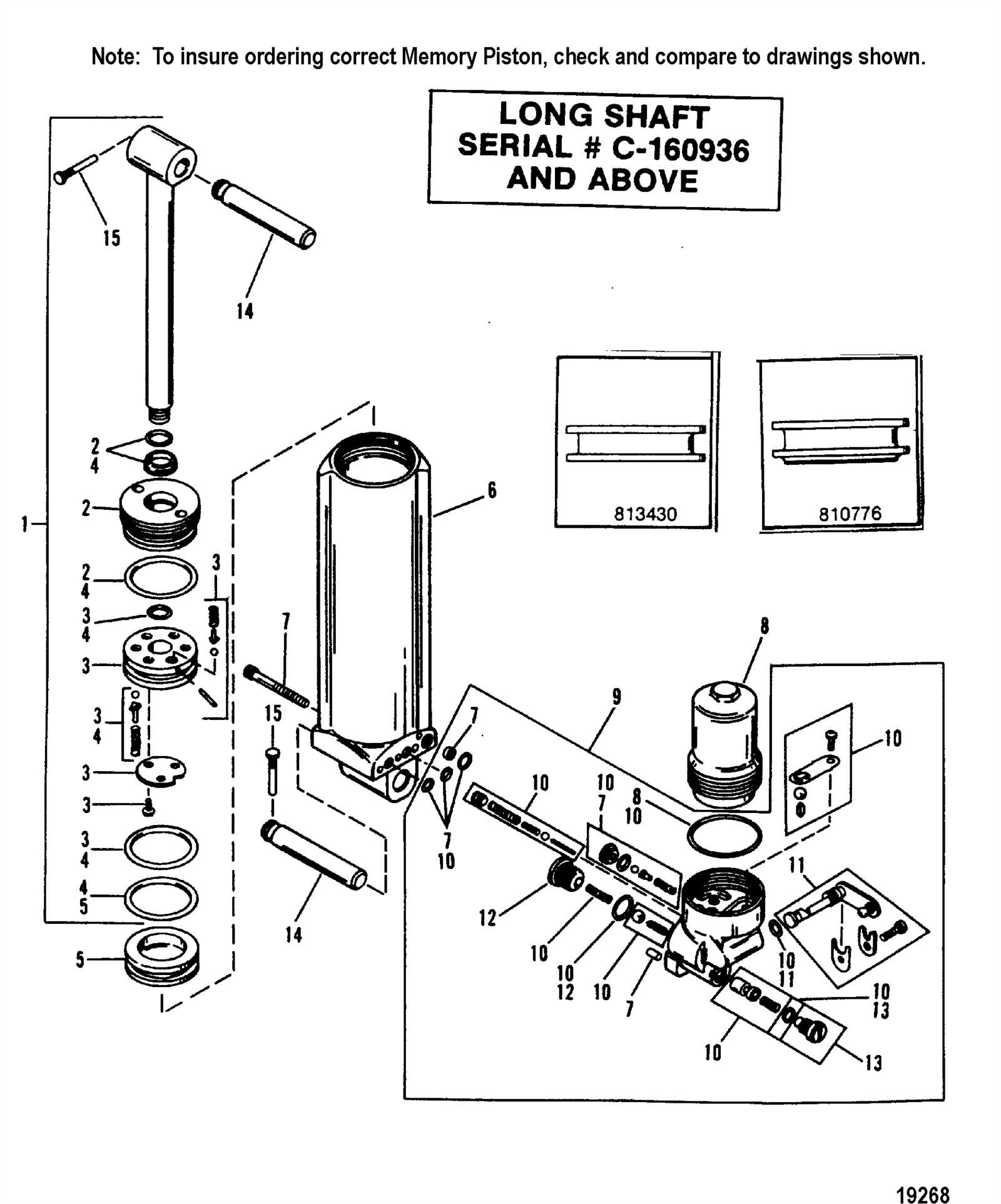

Step-by-Step Repair Guide

This guide offers a comprehensive approach to addressing common issues with marine engines. By following these steps, you can effectively troubleshoot and resolve problems, ensuring optimal performance and longevity of your equipment.

Step 1: Begin by gathering all necessary tools and safety equipment. Ensure you have a clean workspace to facilitate the repair process.

Step 2: Identify the symptoms your engine is exhibiting. This may include unusual noises, poor performance, or starting difficulties. Take notes to help in diagnosing the issue.

Step 3: Refer to the relevant service manual to understand the layout and components of your engine. Familiarize yourself with the key parts to efficiently address the problem.

Step 4: Carefully disassemble the necessary components, keeping track of screws and parts for easy reassembly. Use labeled containers to organize everything.

Step 5: Inspect each component for wear and damage. Replace any faulty parts with high-quality replacements to maintain reliability.

Step 6: Reassemble the engine, ensuring all connections are secure. Follow the manual’s specifications for torque settings and alignment.

Step 7: Conduct a thorough test of the engine after repairs. Monitor its performance and listen for any irregularities during operation.

Step 8: Finally, perform regular maintenance checks to prevent future issues and enhance the durability of your marine engine.

Safety Precautions When Working

Ensuring safety during maintenance and repairs is crucial for both personal well-being and effective outcomes. Proper precautions can significantly reduce risks and enhance the working environment.

First and foremost, always wear appropriate protective gear, such as gloves, goggles, and sturdy footwear, to shield against potential hazards. Proper attire can prevent injuries from sharp objects or chemicals.

Additionally, ensure your workspace is organized and free of clutter. Clear areas allow for safer movement and reduce the chances of accidents. Maintain good lighting to enhance visibility and minimize risks.

Lastly, familiarize yourself with all tools and equipment before use. Understanding their functions and safety features can prevent mishaps and enhance efficiency during tasks.

Tools Needed for Repairs

When it comes to performing maintenance or fixing equipment, having the right instruments is crucial. The appropriate tools not only ensure efficiency but also contribute to the quality of the work done. Understanding which tools are essential can help streamline the repair process and prevent potential issues.

Essential Instruments

Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for any repair task. Additionally, specialized tools like torque wrenches and diagnostic devices may be necessary to tackle more complex problems effectively. Investing in high-quality instruments can lead to better results and prolonged equipment lifespan.

Safety Gear

Equally important is the use of safety equipment to protect oneself during repairs. Items such as gloves, goggles, and ear protection should be included in any toolkit. Prioritizing safety not only enhances the repair experience but also safeguards against potential injuries.

Exploring Performance Enhancements

Maximizing efficiency and speed is a common goal among enthusiasts. By understanding various modifications and upgrades, users can achieve improved capabilities and a more thrilling experience on the water.

- Engine Tuning: Adjusting fuel mixtures and ignition timing can lead to significant gains in power output.

- Propeller Selection: Choosing the right propeller type and size enhances thrust and improves handling.

- Weight Reduction: Removing unnecessary components or opting for lightweight materials can boost performance.

- Regular Maintenance: Ensuring all systems are in optimal condition prevents performance loss over time.

Delving into these enhancements provides a pathway to achieving the ultimate performance for aquatic adventures.

Understanding Fuel Systems in Outboards

The fuel systems in marine engines play a crucial role in ensuring optimal performance and efficiency. These systems are designed to deliver the necessary fuel to the engine, where it is mixed with air to facilitate combustion. A thorough comprehension of how these mechanisms operate is essential for both maintenance and troubleshooting.

At the heart of any marine engine’s fuel system is the fuel tank, which stores the fuel until it is needed. From there, the fuel is transported through a series of lines and filters that ensure cleanliness and proper flow. Any contaminants can lead to decreased performance or even engine failure, highlighting the importance of regular checks and maintenance.

Another vital component is the fuel pump, responsible for moving the fuel from the tank to the engine. This pump can be either mechanical or electric, and its efficiency directly impacts the engine’s ability to perform. Additionally, the carburetor or fuel injection system plays a significant role in the mixing of fuel and air, determining the optimal ratio for combustion.

Understanding the intricacies of these systems not only aids in effective maintenance but also enhances the overall reliability and longevity of the engine. Regular inspections and timely replacements of worn components are essential practices for any marine enthusiast.

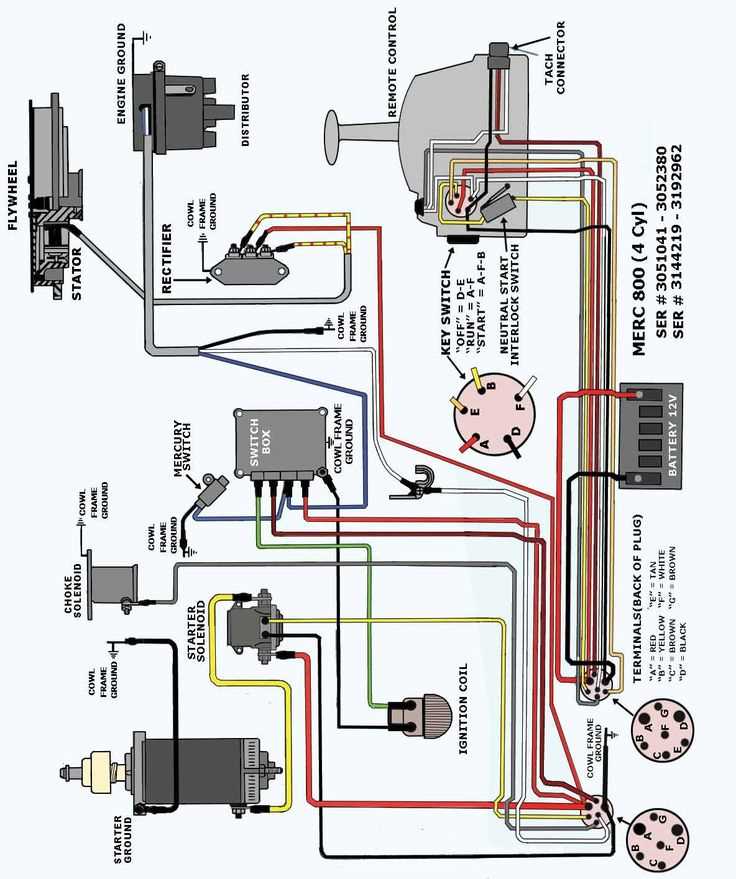

Wiring Diagrams and Electrical Systems

Understanding the intricacies of electrical configurations is essential for effective maintenance and troubleshooting. Proper schematics illustrate how components interact within a system, ensuring seamless operation and enhancing reliability.

Electrical systems play a crucial role in the functionality of marine engines, involving various elements such as batteries, switches, and wiring. A comprehensive grasp of these connections allows for more efficient diagnostics and repairs, ultimately prolonging the lifespan of the equipment.

For those seeking to delve deeper into their systems, referring to accurate electrical layouts is invaluable. These visual aids provide insights into the arrangement and interdependencies of components, guiding users through the repair process.

Best Practices for Winterizing

Preparing your watercraft for the colder months is essential to ensure its longevity and optimal performance. Proper winterization protects critical components from damage due to freezing temperatures and moisture buildup.

- Flush the System: Thoroughly flush the cooling system with fresh water to remove any salt, debris, or contaminants.

- Change the Oil: Replace the engine oil and filter to eliminate impurities and prevent corrosion.

- Fuel Stabilization: Add a fuel stabilizer to the gas tank to prevent oxidation and gumming.

- Battery Care: Disconnect and store the battery in a cool, dry place, ensuring it’s fully charged.

- Check for Damage: Inspect all components for wear and tear, replacing any worn parts as necessary.

By following these practices, you can ensure your vessel is ready to hit the water when the season returns.

Benefits of OEM vs. Aftermarket Parts

Choosing between original components and alternative offerings can significantly impact performance and longevity. Understanding the advantages of each option helps users make informed decisions tailored to their specific needs.

Quality Assurance

Original equipment manufacturers typically provide components that meet rigorous standards, ensuring compatibility and reliability. In contrast, aftermarket options may vary in quality, with some exceeding originals while others fall short.

Cost Considerations

While aftermarket components often come at a lower price, the potential for higher long-term costs due to premature failure or increased maintenance must be considered. Investing in original components can ultimately yield better value over time.