Understanding the Mercury 6hp Parts Diagram for Efficient Maintenance

When delving into the intricacies of small motor systems, a comprehensive understanding of their structure is essential. Each element plays a crucial role in the overall performance and efficiency of the engine. Gaining insight into how these components interconnect can greatly enhance both maintenance practices and operational knowledge.

In this section, we will explore the intricate arrangements and relationships between various elements of a specific engine type. By examining the configuration, enthusiasts and technicians alike can better appreciate the mechanics at play. This knowledge is invaluable for troubleshooting, repairs, and upgrades, ensuring that the system runs smoothly and effectively.

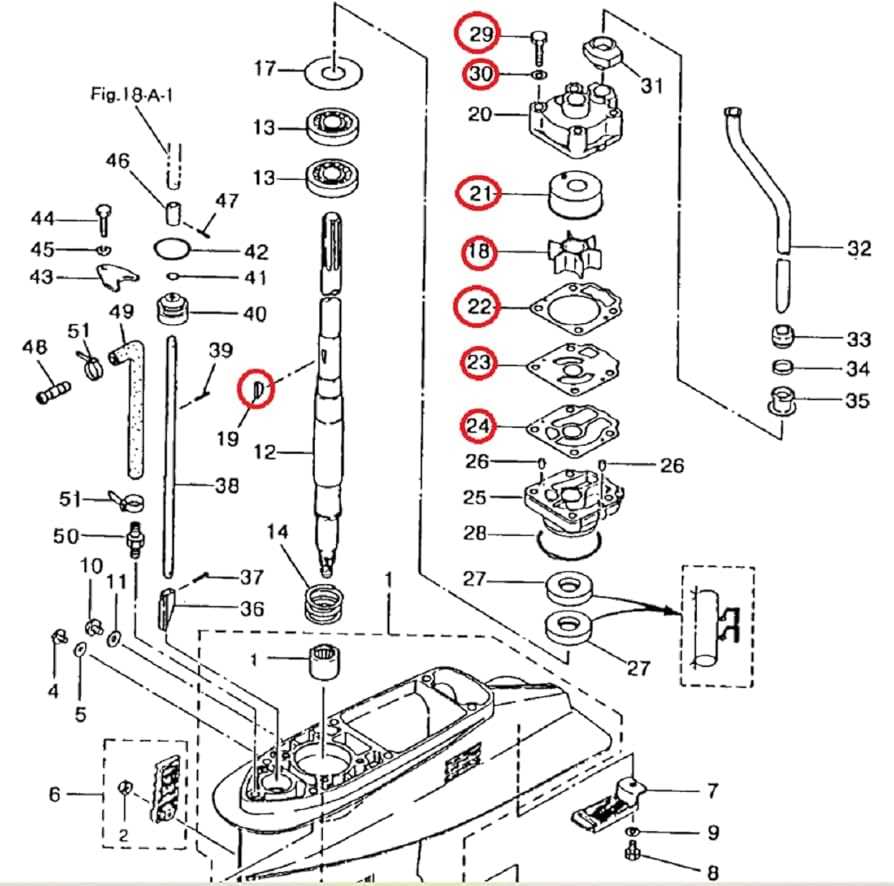

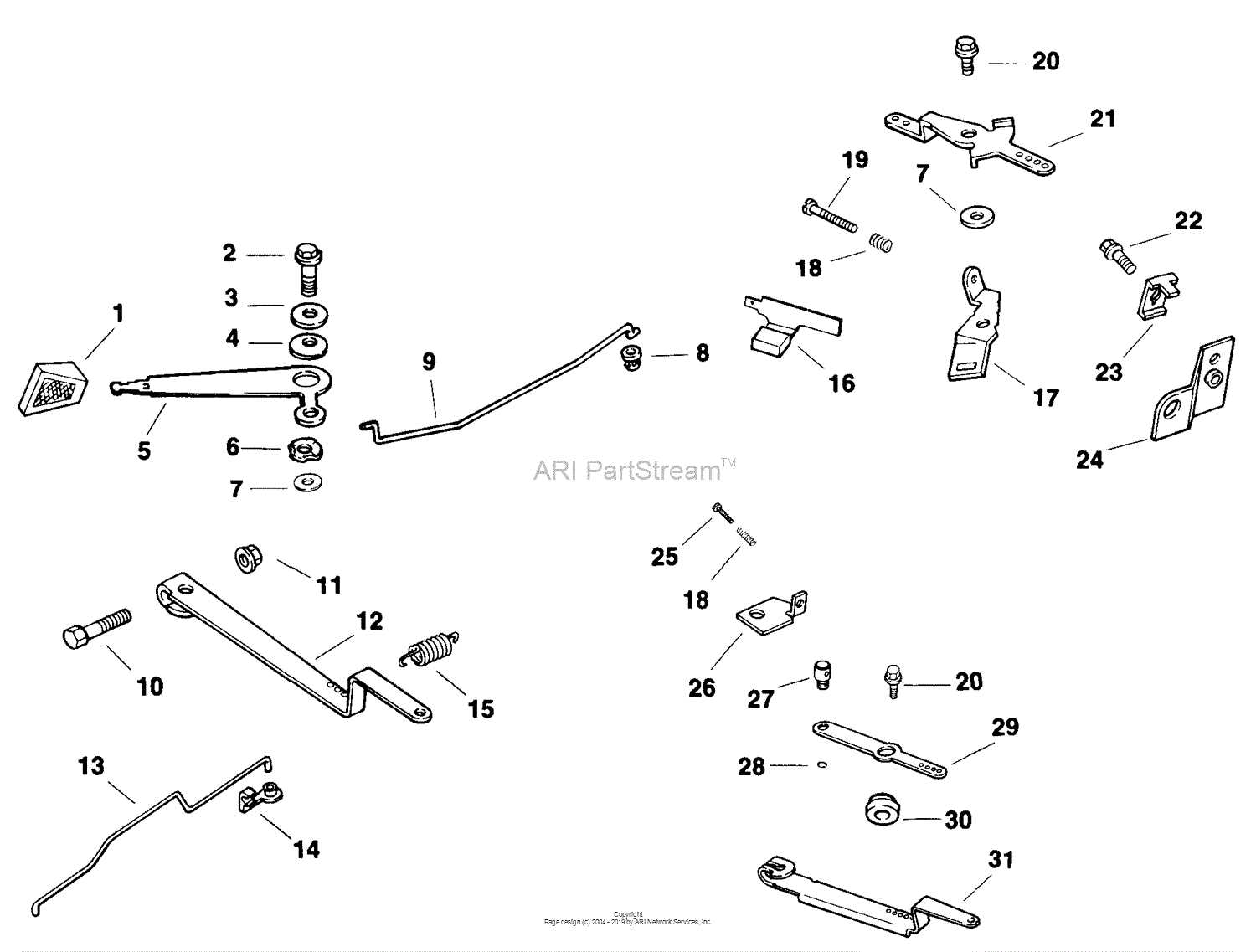

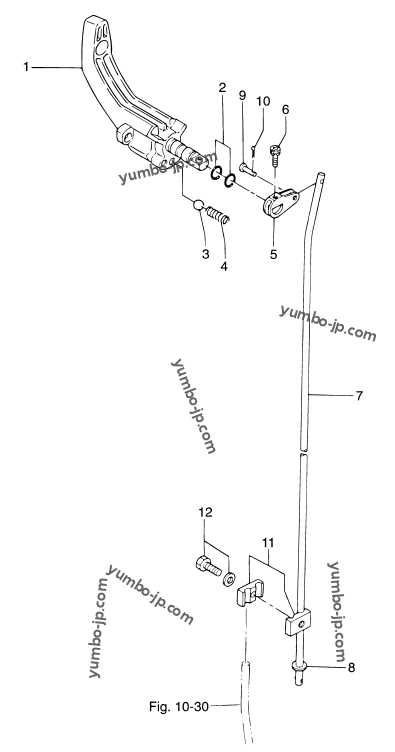

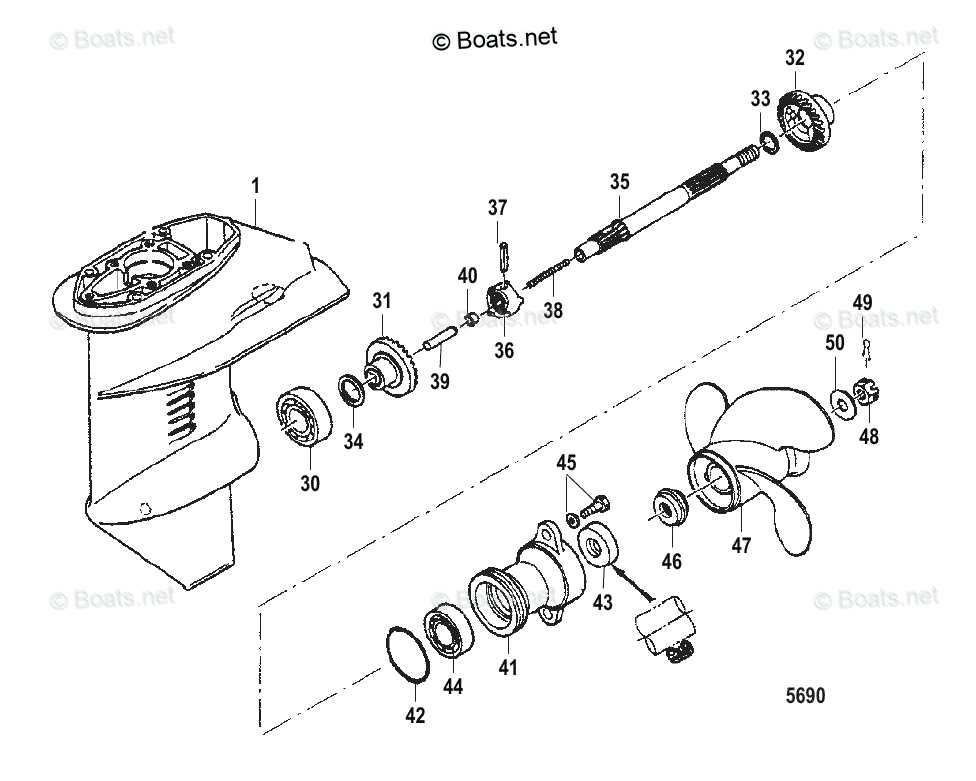

Utilizing a visual representation of the engine’s composition can significantly aid in grasping its functionality. Such illustrations serve as a reference point, allowing for clearer identification of parts and their respective roles. This not only facilitates a deeper understanding but also empowers individuals to undertake their own maintenance and repairs with confidence.

Understanding Mercury 6hp Engine Components

This section explores the essential elements that make up a compact marine propulsion system. Each component plays a crucial role in ensuring optimal performance and reliability on the water. By grasping the functionality of these parts, users can better appreciate their importance and maintain their equipment effectively.

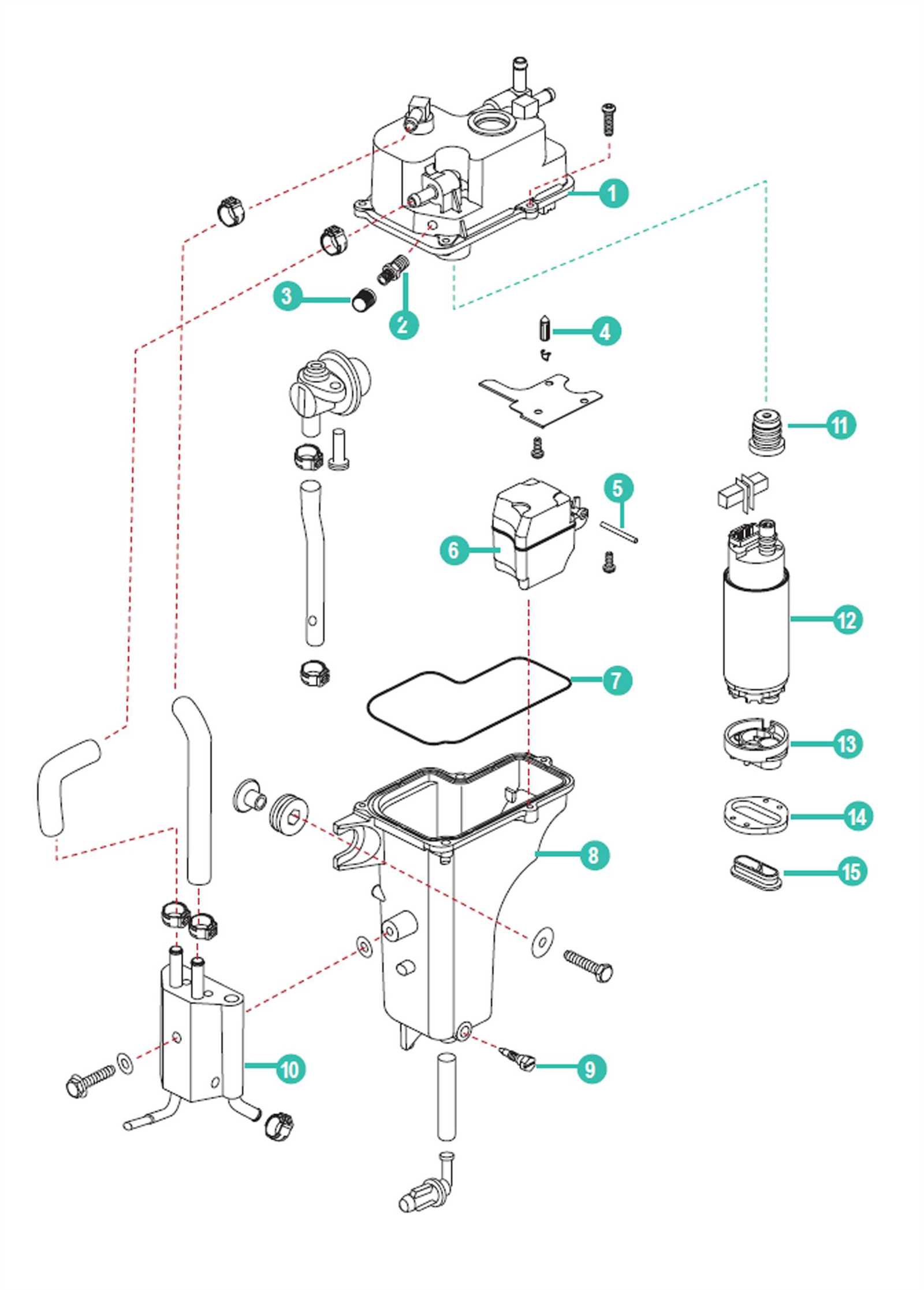

At the heart of the mechanism is the combustion chamber, where fuel and air mix to create the power needed for propulsion. Surrounding it are the cooling system and exhaust components, designed to manage heat and byproducts efficiently. Additionally, the fuel delivery system ensures that the engine receives the right mixture for optimal operation.

Understanding the assembly also involves recognizing how each element interacts with the others. The ignition system ignites the fuel-air mixture, while the transmission transmits the power to the propeller, completing the cycle of energy transformation.

By delving into the intricacies of these components, users can achieve the ultimate efficiency and longevity of their marine engine. Knowledge of these systems is invaluable for troubleshooting and performing maintenance, ensuring that every outing on the water is smooth and enjoyable.

Key Parts of the Mercury 6hp

Understanding the essential components of this outboard motor is crucial for optimal performance and maintenance. Each element plays a significant role in the overall functionality, ensuring reliability on the water.

Powerhead serves as the heart of the engine, where combustion occurs to generate propulsion. This assembly is vital for efficiency and speed.

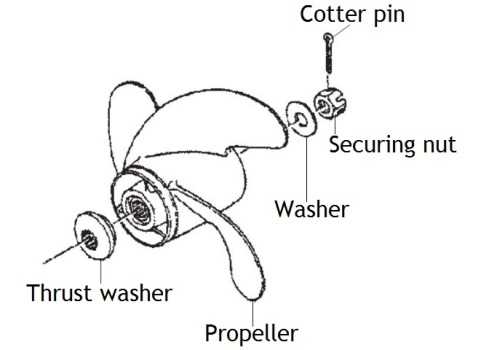

Lower Unit houses the gears and driveshaft, facilitating movement and allowing the vessel to navigate smoothly. Its integrity is critical for handling and maneuverability.

Fuel System includes the tank and carburetor, responsible for delivering the right mixture of air and fuel to the engine. Proper maintenance of this system is essential for preventing issues like clogging and poor performance.

Cooling System ensures that the engine operates within safe temperature limits, using water to prevent overheating. This part is key to prolonging the life of the motor.

Ignition System ignites the fuel-air mixture, initiating the power cycle. A well-functioning ignition is crucial for reliable starting and consistent performance.

How to Read the Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repair. Familiarity with symbols, labels, and organization within the illustration allows for easier identification of necessary items and their functions.

Key Elements to Recognize

- Labels: Each element is typically marked with a number or letter for quick reference.

- Sections: Components are grouped logically, often by function or location.

- Legend: A key usually accompanies the illustration, explaining the symbols and terminology used.

Steps to Follow

- Begin by locating the legend to familiarize yourself with the symbols.

- Identify the section relevant to your task.

- Cross-reference labeled items with the legend for accurate identification.

- Make notes of any specific parts needed for replacement or repair.

Importance of Accurate Diagrams

Having precise illustrations is crucial in any technical field, as they serve as essential tools for understanding complex systems. Clear representations help users identify components and their relationships, facilitating smoother assembly, maintenance, and repair processes.

First and foremost, accurate visuals reduce the likelihood of errors during installation or troubleshooting. When users can easily interpret the layout and positioning of elements, they are less prone to making mistakes that could lead to costly damage or malfunction.

Moreover, detailed illustrations enhance communication among team members. Whether in a workshop or an educational setting, everyone can reference the same materials, ensuring that everyone is on the same page and understands the tasks at hand.

In addition, clear and precise illustrations save time. When users can quickly find the information they need, they can complete their tasks more efficiently. This efficiency not only streamlines workflows but also increases productivity.

Lastly, having well-crafted visuals contributes to overall safety. Accurate representations can highlight potential hazards or critical steps in a process, helping to prevent accidents and ensuring that all operations are conducted smoothly.

Common Issues with Mercury 6hp Parts

When dealing with small outboard engines, enthusiasts often encounter a variety of frequent challenges that can affect performance and reliability. Understanding these common problems can aid in maintenance and enhance the longevity of the equipment.

Overheating and Cooling System Failures

One prevalent issue involves overheating, which can stem from blockages in the cooling system or faulty impellers. Regular inspections and cleanings are essential to ensure proper water flow and prevent severe damage.

Fuel System Complications

Another concern relates to fuel delivery, where clogged lines or dirty filters can hinder engine efficiency. Ensuring that fuel components are clean and functioning can help maintain optimal performance and reduce the risk of breakdowns.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires diligent care and regular upkeep. By following a few essential practices, you can enhance performance and minimize the risk of costly repairs.

- Regular Cleaning: Keep the exterior and interior components clean to prevent buildup of dirt and debris. This practice helps avoid corrosion and maintains optimal functionality.

- Routine Inspections: Periodically check for wear and tear. Inspect seals, gaskets, and connections for any signs of deterioration or leakage.

- Proper Lubrication: Apply appropriate lubricants to moving parts as per manufacturer recommendations. This reduces friction and prolongs the life of mechanical components.

Additionally, maintaining a consistent schedule for service checks can help identify potential issues before they escalate. Keeping an organized log of maintenance activities can also assist in tracking the health of your machinery.

- Use Quality Fuels: Always use high-quality fuels and lubricants to avoid engine knock and ensure smooth operation.

- Store Properly: When not in use, store equipment in a dry, sheltered location to protect it from environmental damage.

- Follow Manufacturer Guidelines: Adhere to specific maintenance recommendations provided in the user manual to ensure compliance with warranty conditions.

By integrating these practices into your routine, you can significantly enhance the durability and efficiency of your equipment, ensuring it serves you well for years to come.

Where to Find Replacement Parts

Finding the right components for your outboard engine can be a straightforward process if you know where to look. There are several avenues to explore, each offering a variety of options that can meet your needs. Whether you are looking for original equipment or aftermarket alternatives, the right resources can save you time and ensure you get quality replacements.

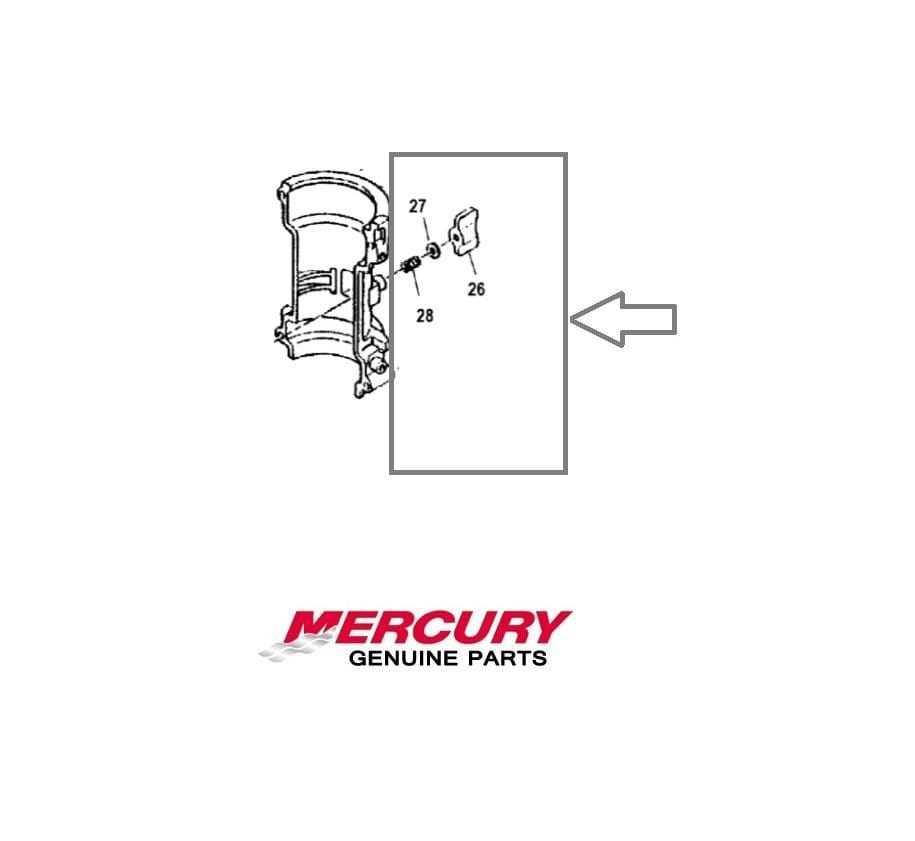

One of the most reliable sources is authorized dealers or service centers, which often stock genuine items that guarantee compatibility and performance. Additionally, online retailers provide a vast selection, often at competitive prices, making it easy to compare different options. Specialized forums and community groups can also be valuable, as fellow enthusiasts often share insights and recommend trusted suppliers.

Furthermore, local marine supply shops may carry essential items or be able to order them for you, offering the advantage of immediate assistance. Don’t overlook the possibility of exploring auction sites or classified ads, where you might find unused or gently used components at reduced prices. By leveraging these resources, you can ensure that your engine remains in optimal condition for years to come.

Tools Needed for Repairs

When undertaking maintenance tasks, having the right equipment is essential for achieving optimal results. The correct tools not only streamline the repair process but also enhance safety and efficiency.

Essential Tools

- Wrenches: Various sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips for different screw types.

- Pliers: For gripping and bending materials securely.

- Socket Set: Provides versatility in working with different fasteners.

Additional Equipment

- Torque Wrench: Ensures proper tightness according to specifications.

- Multimeter: Useful for electrical diagnostics and troubleshooting.

- Cleaners and Lubricants: Essential for maintaining moving parts.

- Safety Gear: Goggles and gloves to protect against potential hazards.

Upgrading Your Mercury 6hp Engine

Enhancing the performance of your small marine engine can significantly improve its efficiency and longevity. By focusing on key components, you can boost power output and overall functionality. This section explores various upgrades that can transform your engine into a more reliable and powerful machine for your watercraft adventures.

Key Performance Enhancements

One of the most effective ways to elevate your engine’s capabilities is by upgrading the fuel system. Consider installing a high-performance carburetor that allows for better air-fuel mixing, resulting in improved acceleration and throttle response. Additionally, replacing the standard ignition system with a more advanced one can enhance spark quality, leading to smoother operation and reduced fuel consumption.

Maintenance and Reliability Improvements

Regular maintenance is crucial for any engine, but incorporating quality components can further enhance reliability. Upgrading to heavy-duty gaskets and seals helps prevent leaks, while a more robust cooling system ensures optimal operating temperatures. Moreover, using premium lubricants and filters can contribute to a longer lifespan, ensuring your engine performs well under various conditions.

Safety Precautions During Repairs

When undertaking maintenance tasks, ensuring personal safety and equipment integrity is paramount. Proper precautions can prevent accidents and damage, allowing for a smoother repair process. Adhering to guidelines and using appropriate tools will contribute to a safer working environment.

| Precaution | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and masks to protect against debris and chemicals. |

| Work in a Ventilated Area | Ensure good airflow to avoid inhaling harmful fumes or dust. |

| Disconnect Power Sources | Unplug or disconnect any electrical sources before beginning work to prevent shocks. |

| Organize Tools | Keep tools organized to avoid accidents and ensure easy access during repairs. |

| Follow Manufacturer Instructions | Always refer to official guidelines for proper handling and assembly. |

Customer Reviews of Mercury Parts

This section highlights feedback from users who have purchased components for their outboard motors. Insights from actual customers can guide potential buyers in making informed decisions regarding the quality and performance of these essential items.

Positive Experiences

Many users express satisfaction with the reliability and durability of the components. Customers often note that their engines run smoother and more efficiently after installing these high-quality items. Additionally, ease of installation is frequently praised, making the process hassle-free for those who prefer DIY repairs.

Areas for Improvement

While numerous reviews are positive, some users mention challenges related to compatibility and pricing. A few have encountered issues with certain items not fitting as expected, leading to frustration. Furthermore, a segment of customers believes that while the quality is high, the cost could be more competitive.

| Rating | Comment |

|---|---|

| 5/5 | Excellent quality! My motor runs like new. |

| 4/5 | Good parts, but a bit pricey. |

| 3/5 | Installation was tricky, had to modify a bit. |

Comparison with Other Outboard Engines

When evaluating different models of marine propulsion systems, it’s essential to consider various factors that contribute to their performance, efficiency, and usability. By examining the characteristics and capabilities of various engines, one can make an informed choice based on individual needs and preferences.

Performance and Efficiency

- Power Output: Different brands offer varying horsepower, affecting speed and load capacity.

- Fuel Consumption: Some engines are designed for optimal fuel efficiency, reducing operating costs over time.

- Torque: The ability to deliver torque at lower RPMs can enhance acceleration and maneuverability.

Weight and Size

- Portability: Lightweight models are easier to transport and handle.

- Footprint: Compact designs may fit better on smaller vessels, maximizing available space.

- Mounting Options: Compatibility with different transom heights and configurations can influence choice.

By assessing these factors alongside specific engine features, users can determine the best fit for their boating activities, ensuring a smooth and enjoyable experience on the water.

DIY Repair vs. Professional Service

When it comes to fixing mechanical equipment, enthusiasts often face the choice between tackling repairs themselves or seeking expert assistance. Both approaches have their merits and drawbacks, influencing not only the quality of the work but also the cost and time involved.

Choosing to repair on your own can be rewarding. Here are some advantages:

- Cost savings by avoiding labor fees.

- Flexibility in scheduling repairs at your convenience.

- Opportunity to learn and gain hands-on experience.

However, there are also significant challenges:

- Potential for errors leading to further damage.

- Lack of access to specialized tools and parts.

- Time-consuming research and troubleshooting.

On the other hand, opting for professional service offers distinct benefits:

- Expertise from trained technicians ensures high-quality repairs.

- Access to specialized equipment and resources.

- Peace of mind with warranties on services provided.

Yet, this route comes with considerations:

- Higher costs compared to DIY methods.

- Scheduling delays based on the service provider’s availability.

- Less control over the repair process and outcomes.

Ultimately, the decision hinges on individual circumstances, expertise, and the specific issues at hand. Weighing the pros and cons can guide enthusiasts in choosing the best path for their repair needs.