Mercury 9.9 Outboard Motor Parts Overview

Exploring the various elements of a marine propulsion system is essential for maintaining its performance and longevity. Knowing the different components involved can significantly enhance your understanding and ability to address any issues that may arise. This guide will provide insights into the intricate relationships between the various sections of your motor.

Identifying the key features within the assembly not only aids in troubleshooting but also empowers you to perform routine maintenance effectively. Each segment plays a vital role in the overall functionality, and comprehending their specific purposes will help you ensure optimal operation.

Whether you are an experienced technician or a recreational user, having access to detailed illustrations can simplify the repair process. Familiarizing yourself with the layout and configuration of each component will enable you to make informed decisions regarding upkeep and replacements.

Mercury 9.9 Outboard Overview

This section provides a comprehensive look at a specific type of marine propulsion system known for its reliability and efficiency. This motor is designed for small boats, offering a balance between power and fuel economy. Understanding its features and functionality can enhance the boating experience.

Key Features

- Compact design suitable for various watercraft

- Lightweight construction for easy handling

- Fuel-efficient engine for longer trips

- Simple maintenance requirements for longevity

- Quiet operation, enhancing the boating experience

Applications

This type of motor is ideal for several uses, including:

- Fishing boats for accessing remote locations

- Recreational vessels for family outings

- Small sailboats as auxiliary power sources

- Utility boats for various on-water tasks

Key Components of Mercury 9.9

The internal structure of marine engines includes several crucial elements that contribute to their performance and functionality. Understanding these essential components can greatly assist users in maintaining and troubleshooting their machinery effectively. Each section plays a significant role in the overall operation, ensuring reliability and efficiency during usage.

Essential Engine Parts

The following table summarizes the vital components found within the engine assembly, highlighting their primary functions:

| Component | Function |

|---|---|

| Powerhead | Generates thrust and houses critical engine parts. |

| Lower Unit | Transmits power to the propeller, enabling movement. |

| Fuel System | Delivers fuel to the engine for combustion. |

| Cooling System | Maintains optimal temperature to prevent overheating. |

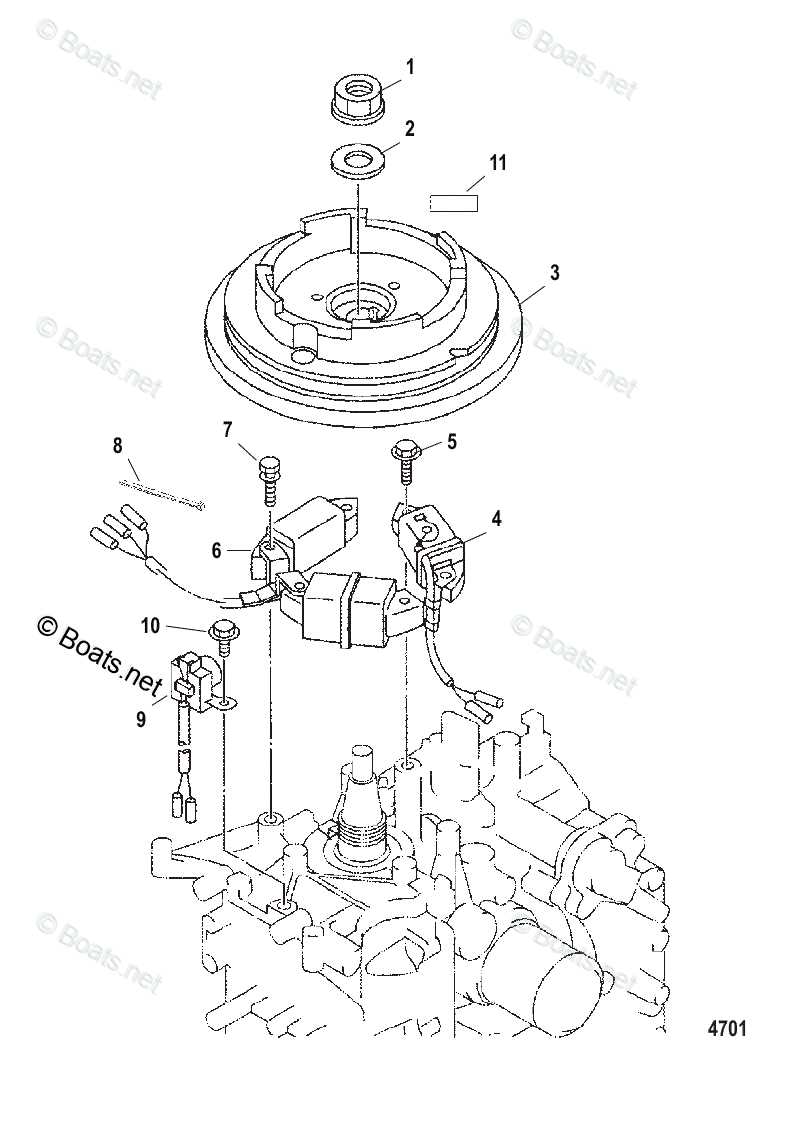

| Ignition System | Initiates the combustion process for power generation. |

Maintenance Considerations

Regular inspection and servicing of these components are vital for optimal performance. Users should familiarize themselves with the location and function of each part to address potential issues promptly. Proper care can extend the lifespan and reliability of the engine, ensuring enjoyable experiences on the water.

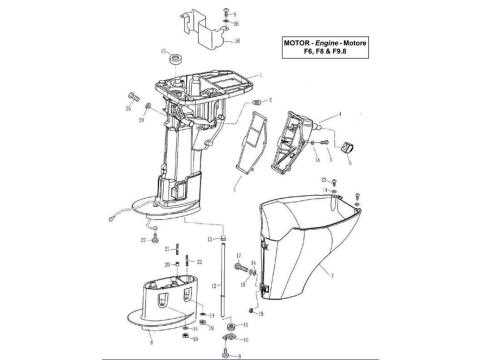

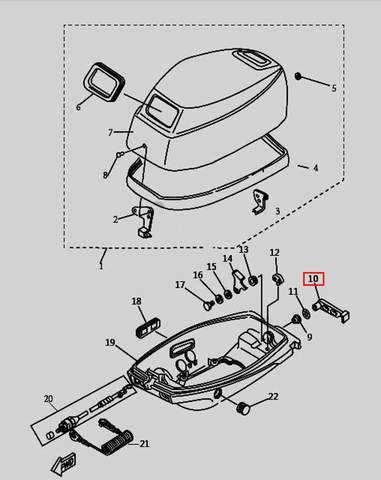

Understanding the Parts Diagram

Comprehending the layout of the components is crucial for effective maintenance and repair of any engine system. A well-illustrated representation can significantly aid users in identifying individual elements and their respective functions. This visual guide serves as an essential tool for both novice and experienced users, enhancing their ability to work efficiently.

Importance of Visual Guides

Visual aids play a vital role in understanding complex mechanical systems. They simplify the identification process, making it easier to locate specific pieces when troubleshooting or performing routine checks. By having a clear view of how components fit together, users can prevent errors and save time during repairs.

Navigating the Layout

To effectively navigate the visual layout, one should familiarize themselves with the common symbols and notations used. Recognizing the various representations will enhance one’s ability to interpret the information accurately. This understanding can empower users to undertake repairs with greater confidence, ensuring the longevity and performance of their equipment.

Common Issues with Outboard Engines

Marine propulsion systems are essential for smooth sailing, but they often encounter various problems that can hinder performance. Understanding these frequent challenges can help boaters troubleshoot and maintain their vessels effectively.

Frequent Problems

- Starting Difficulties: One of the most common issues is trouble starting the engine. This can be due to fuel delivery problems, battery issues, or faulty ignition components.

- Overheating: Engines may overheat if there is insufficient water flow or a blockage in the cooling system, leading to serious damage if not addressed.

- Fuel Issues: Contaminated or old fuel can cause poor engine performance and misfiring. Regular checks and fuel system maintenance are crucial.

- Electrical Failures: Problems with wiring or connections can lead to electrical malfunctions, impacting ignition and other critical functions.

Troubleshooting Tips

- Regular Maintenance: Conduct routine checks on fuel lines, filters, and spark plugs to ensure optimal performance.

- Monitor Temperature: Keep an eye on the engine temperature gauge to prevent overheating.

- Check Battery Health: Ensure the battery is charged and connections are clean to avoid starting issues.

- Inspect for Leaks: Regularly check for fuel and oil leaks to maintain safety and efficiency.

Maintenance Tips for Mercury 9.9

Proper upkeep of marine engines is essential for optimal performance and longevity. Regular maintenance ensures that your motor runs smoothly and efficiently, reducing the risk of breakdowns while out on the water.

Regular Inspections: Conduct routine checks on key components such as fuel lines, spark plugs, and the cooling system. This practice helps identify any potential issues before they escalate, allowing for timely repairs.

Fluid Changes: Change the oil and gear lube at regular intervals to maintain optimal lubrication. Clean fluids reduce wear and tear on engine parts, contributing to improved performance and durability.

Propeller Maintenance: Inspect the propeller for any signs of damage or wear. A well-maintained propeller enhances efficiency and performance, ensuring that the motor operates at its best.

Winterization: Properly prepare the engine for storage during colder months. This process may include draining fuel, adding anti-freeze, and ensuring that all moving parts are lubricated to prevent corrosion.

Follow Manufacturer Guidelines: Adhering to the recommended service schedule and guidelines provided by the manufacturer is crucial. These instructions are designed to help you maintain your engine effectively and ensure its reliability.

Replacing Worn Parts Effectively

Maintaining optimal performance of your watercraft requires timely replacement of degraded components. Identifying these elements and addressing their wear is essential to ensure smooth operation and longevity. By understanding the process and the necessary tools, you can carry out replacements efficiently, enhancing your vessel’s functionality.

Steps for Identifying Worn Components

Begin by conducting a thorough inspection of the engine and its accessories. Look for signs of wear, such as cracks, fraying, or discoloration. Regularly checking the condition of seals, gaskets, and other critical elements will help you catch potential issues early. Keeping a log of observations can assist in tracking wear patterns over time.

Choosing Quality Replacements

Select high-quality substitutes when it’s time for replacements. Using premium materials ensures durability and reliability, which can lead to improved performance. Research various suppliers and read reviews to find reputable sources that offer parts compatible with your engine. Proper installation of these components will help avoid future complications.

Identifying Each Component’s Function

Understanding the roles of various elements in a marine propulsion system is essential for effective maintenance and troubleshooting. Each part serves a specific purpose, contributing to the overall functionality and efficiency of the unit. By recognizing these functions, users can better diagnose issues and perform repairs as needed.

Key Components and Their Roles

- Engine Block: The core structure housing the internal components and providing stability.

- Propeller: Translates engine power into thrust, propelling the vessel forward.

- Fuel System: Delivers the necessary fuel mixture to the engine for combustion.

- Cooling System: Regulates the temperature of the engine to prevent overheating.

- Ignition System: Initiates combustion by generating a spark at the correct moment.

Additional Critical Parts

- Steering Mechanism: Allows for maneuverability and control of the vessel’s direction.

- Electrical System: Powers various components and ensures proper functionality.

- Exhaust System: Removes gases produced during combustion, reducing emissions.

- Transmission: Transfers power from the engine to the propeller, optimizing performance.

Best Practices for Engine Repairs

Effective maintenance of a marine engine requires careful attention to detail and a systematic approach. Adhering to established guidelines ensures that repairs are conducted safely and efficiently, extending the lifespan of the engine while optimizing performance.

1. Understand the Manual

Familiarize yourself with the manufacturer’s manual. This document contains essential specifications, diagrams, and troubleshooting steps that are crucial for understanding the engine’s design and function.

2. Use Quality Tools

Invest in reliable tools tailored for engine repairs. Quality equipment minimizes the risk of damage during maintenance and ensures precision in every task.

3. Maintain a Clean Workspace

Always work in a clean environment. A tidy workspace reduces the chance of contamination and makes it easier to locate tools and parts when needed.

4. Follow Safety Protocols

Prioritize safety by wearing protective gear such as gloves and goggles. Ensure that the engine is turned off and cool before starting any repair work.

5. Document the Process

Keep detailed records of any repairs or replacements performed. This documentation can be invaluable for future maintenance and troubleshooting.

6. Seek Professional Help When Necessary

If you encounter complex issues, don’t hesitate to consult a professional mechanic. Their expertise can provide insights that enhance the repair process.

How to Use the Parts Diagram

Understanding a visual reference for components is essential for effective maintenance and repair. This guide provides insight into navigating the reference image, enabling you to identify various elements with ease.

Identifying Components

Begin by familiarizing yourself with the layout. Each segment corresponds to a specific area of the device. Take your time to match the labeled parts to their physical locations. This practice ensures accurate replacements and adjustments.

Utilizing the Reference for Repairs

When conducting repairs, refer back to the illustration for guidance. Cross-reference the damaged elements with the image to confirm you have the correct replacements. This method streamlines the repair process and minimizes errors.

Where to Buy Replacement Parts

Finding the right components for your marine engine can significantly enhance its performance and longevity. There are various sources available to acquire these essential elements, ensuring your vessel remains in top condition. This section will guide you through the best options for obtaining the necessary items to keep your engine running smoothly.

Authorized Dealers and Retailers

One of the most reliable methods to purchase components is through authorized dealers. These retailers often stock original items and can provide expert advice on what is needed for your specific model. Additionally, visiting local shops may allow you to examine the products firsthand, ensuring compatibility and quality.

Online Marketplaces

Another convenient option is to explore various online marketplaces. Websites specializing in marine supplies often offer a vast selection of components, sometimes at competitive prices. When purchasing online, it is crucial to check customer reviews and return policies to ensure you are making a safe and informed decision.

Enhancing Performance of Your Outboard

Improving the functionality of your marine engine can significantly enhance your overall boating experience. By focusing on various aspects, you can optimize efficiency, speed, and reliability. Here are some essential tips for maximizing the performance of your motor.

Regular Maintenance Practices

Consistent upkeep is crucial for maintaining optimal performance. Consider the following tasks:

- Check Fuel Quality: Use clean, fresh fuel to avoid engine issues.

- Inspect Propeller: Ensure it is free from damage and debris for smooth operation.

- Change Oil Regularly: Use high-quality oil to ensure proper lubrication.

- Clean Filters: Replace fuel and air filters to improve airflow and efficiency.

Upgrading Components

Investing in high-performance components can greatly impact your engine’s capabilities. Explore these upgrades:

- High-Performance Propellers: Choose propellers designed for better speed and fuel efficiency.

- Power-Boosting Kits: Consider kits that enhance power output without compromising reliability.

- Advanced Ignition Systems: Upgrade to systems that improve spark efficiency and fuel combustion.