Comprehensive Parts Diagram for Mercury 90 Elpto

The intricate world of marine propulsion systems reveals a wealth of components that work harmoniously to ensure optimal performance on the water. Navigating through this complex structure allows enthusiasts and technicians alike to appreciate the engineering behind reliable power and efficiency.

When examining the configuration of a specific engine, grasping the arrangement of its various elements becomes crucial. Each section plays a vital role in the overall functionality, contributing to everything from power delivery to maintenance considerations.

By exploring the detailed layout of these essential elements, one can ultimately enhance their understanding of how to maintain and optimize their marine engine. Whether for troubleshooting or upgrades, a thorough knowledge of these components ensures a smoother and more enjoyable boating experience.

Understanding Mercury 90 Elpto Components

When it comes to marine engines, grasping the intricacies of their individual elements is essential for optimal performance. Each component plays a crucial role, contributing to the overall functionality and efficiency of the machinery. By exploring these parts, one can gain insights into maintenance, repairs, and enhancements that can be made for better operation.

| Component | Function |

|---|---|

| Powerhead | Houses the engine’s core mechanisms and facilitates combustion. |

| Lower Unit | Transmits power from the engine to the propeller. |

| Fuel System | Delivers the necessary fuel for combustion. |

| Cooling System | Regulates engine temperature to prevent overheating. |

| Ignition System | Initiates the combustion process for engine operation. |

Importance of Parts Diagrams

Understanding the components of a mechanical system is essential for maintenance and repair. Visual representations of these elements play a crucial role in ensuring that users can identify, locate, and replace parts effectively. Such illustrations serve as a guide, making complex systems more approachable and manageable.

Benefits of Visual Representations

- Enhanced Clarity: Visual aids simplify intricate layouts, allowing users to grasp the overall structure easily.

- Efficient Troubleshooting: By pinpointing specific elements, users can quickly identify issues and implement solutions.

- Time-Saving: A clear visual reference reduces the time spent searching for components, speeding up the repair process.

Application in Maintenance

- Guided Repairs: Step-by-step visuals guide users through the repair process, minimizing errors.

- Inventory Management: Clear representations help in tracking which components are in stock or need replacement.

- Educational Tool: Visuals are invaluable for training new technicians, providing them with an accessible way to learn about system components.

Common Issues with Mercury 90 Elpto

This section addresses frequent problems encountered with a specific outboard engine model, emphasizing key areas that may require attention. Understanding these issues can help ensure better performance and longevity of the engine.

Engine Performance Issues

- Difficulty starting the engine

- Unusual noises during operation

- Loss of power under load

Fuel System Concerns

- Clogged fuel filters leading to reduced flow

- Inconsistent fuel supply causing stalling

- Leaking fuel lines resulting in safety hazards

Addressing these common problems promptly can enhance overall functionality and reduce repair costs.

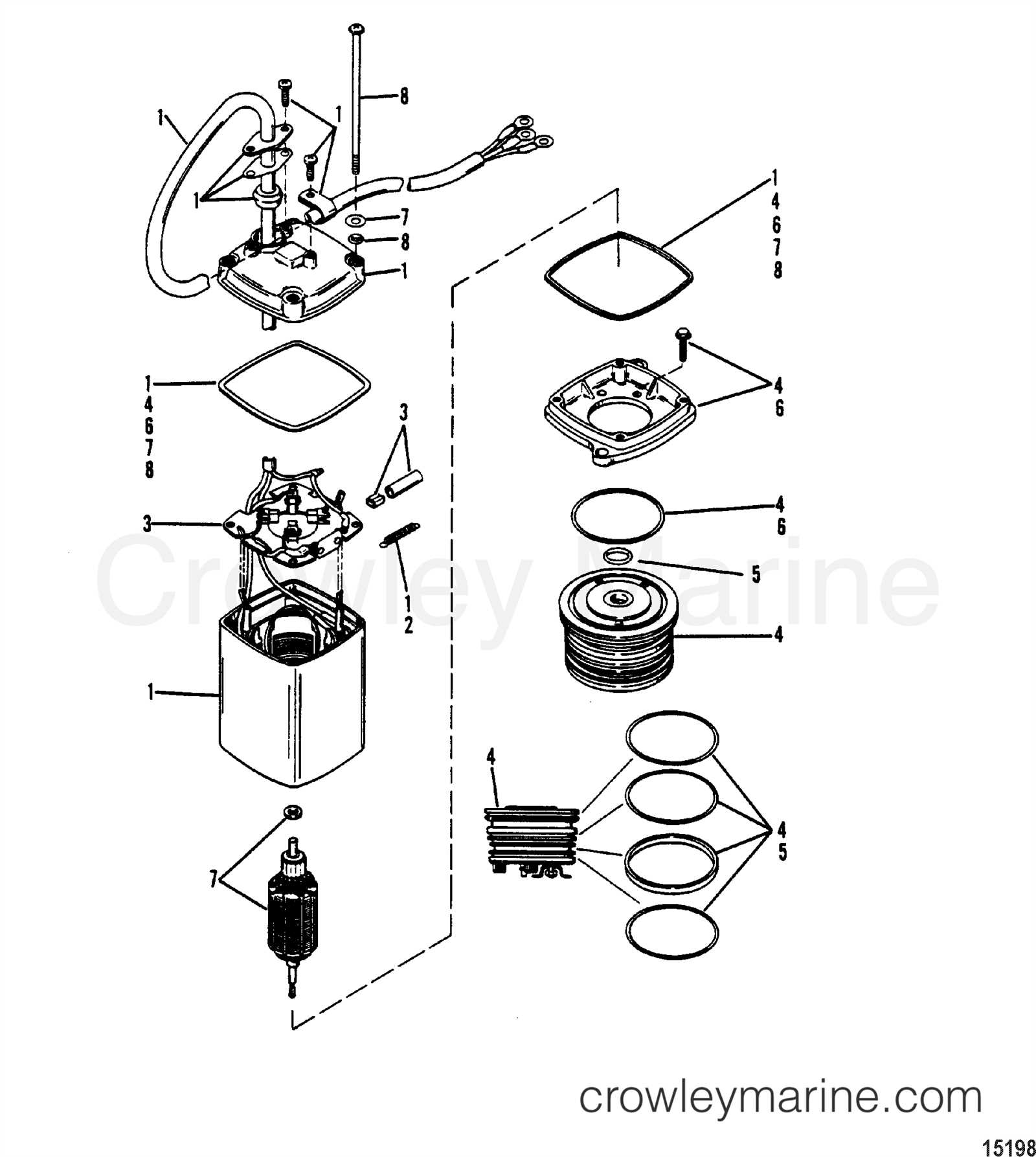

How to Read a Parts Diagram

Understanding an illustration that depicts components is essential for effective maintenance and repairs. This visual representation helps users identify and locate individual elements within a system. Familiarity with these visuals can enhance your repair experience significantly.

To effectively interpret these illustrations, consider the following steps:

- Identify the Key: Most illustrations include a legend that defines symbols and numbers. Review this section first.

- Examine the Layout: Observe how components are arranged. Groupings often indicate related parts.

- Follow the Connections: Lines and arrows show how parts interact. Understanding these relationships is crucial for troubleshooting.

- Check Reference Numbers: Each component typically has a unique identifier. Use these numbers for ordering replacements or consulting manuals.

By following these guidelines, you can delve deeper into the intricacies of your system, leading to the ultimate success in repairs and enhancements.

Essential Tools for Maintenance

Proper upkeep of any mechanical equipment requires a variety of specialized instruments. These tools not only facilitate routine checks but also ensure that any necessary repairs can be executed efficiently. Having the right equipment at your disposal can make a significant difference in both the ease and effectiveness of maintenance tasks.

Basic Hand Tools

Start with a set of essential hand tools that will cover most basic repairs:

- Screwdrivers (flathead and Phillips)

- Wrenches (adjustable and fixed)

- Pliers (needle-nose and standard)

- Socket set

- Hammer

Specialized Equipment

In addition to hand tools, certain specialized instruments can enhance your maintenance capabilities:

- Torque wrench for accurate tightening

- Multimeter for electrical diagnostics

- Oil filter wrench for easier maintenance

- Compression tester for engine assessment

- Safety gear (gloves, goggles, etc.)

Investing in these tools will ensure that you are well-prepared for any maintenance challenge that arises, helping to prolong the lifespan and performance of your machinery.

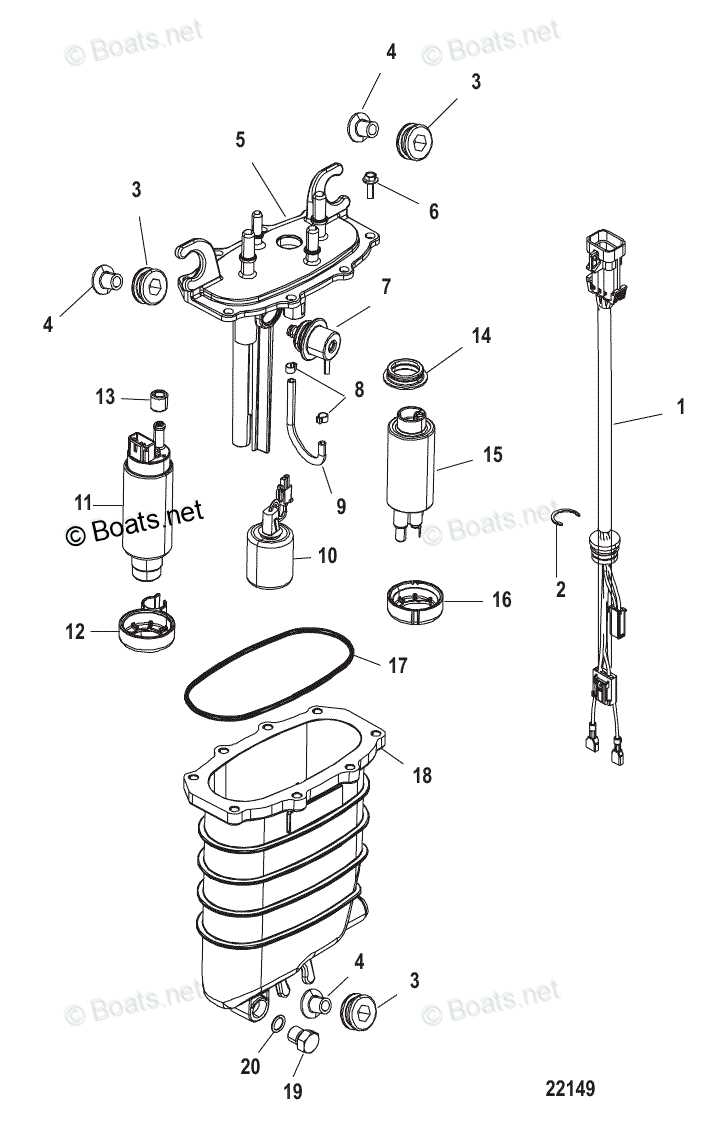

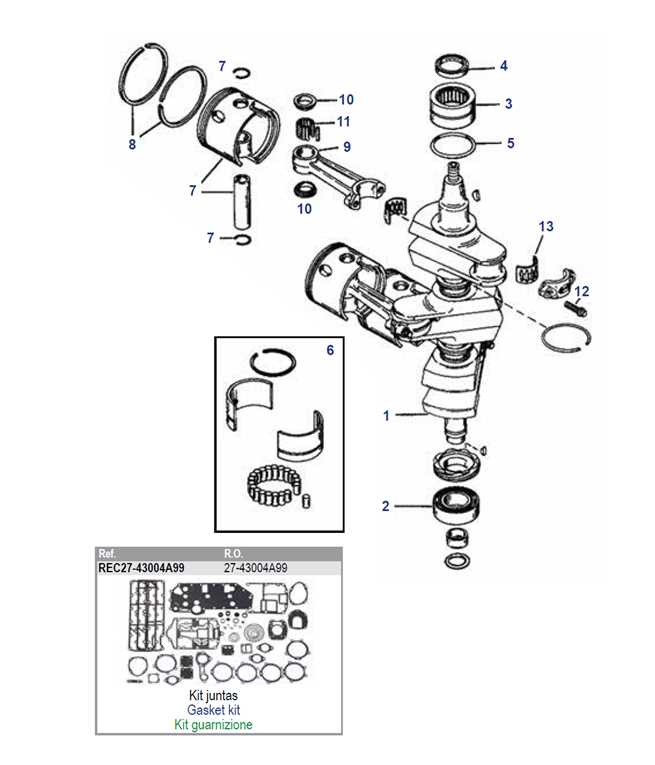

Identifying Key Engine Parts

Understanding the essential components of a marine engine is crucial for effective maintenance and troubleshooting. Each element plays a significant role in ensuring the overall performance and reliability of the system. By recognizing these critical elements, operators can enhance their skills in managing and optimizing engine function.

- Powerhead: This is the central unit housing the cylinders and associated mechanisms that generate thrust.

- Lower Unit: This section connects to the propeller and is responsible for transmitting power from the engine to the water.

- Fuel System: Comprising the fuel tank, lines, and injectors, this system ensures that the engine receives the right amount of fuel for optimal combustion.

- Ignition System: This includes spark plugs and coils, responsible for initiating the combustion process within the engine.

- Cooling System: Essential for regulating temperature, this system prevents overheating through the circulation of coolant or water.

Familiarity with these components not only aids in troubleshooting but also enhances the ability to perform routine checks and maintenance effectively. Proper identification can lead to timely repairs and extended engine life.

Step-by-Step Repair Guide

This section aims to provide a comprehensive approach to fixing common issues related to marine engines. By following the outlined steps, you can enhance your skills and ensure the longevity of your equipment. Each phase of the process is detailed to facilitate a smoother repair experience.

Preparation and Tools Needed

Before beginning the repair, gather the necessary tools and materials. Ensuring you have everything at hand will help streamline the process and avoid interruptions.

| Tool/Material | Description |

|---|---|

| Wrench Set | For loosening and tightening various components. |

| Screwdriver Set | Essential for removing screws and securing parts. |

| Oil and Lubricants | To ensure smooth operation of moving parts. |

| Cleaning Supplies | To keep surfaces clean and free of debris. |

Step-by-Step Procedure

Follow these detailed steps to effectively address the issues you may encounter:

- Begin by disconnecting the power source to prevent any accidental starts.

- Carefully remove the cover and inspect all accessible components for wear and damage.

- Clean all parts using appropriate cleaning supplies to remove dirt and grime.

- Replace any worn or damaged components, ensuring they are compatible with your system.

- Reassemble the engine carefully, ensuring all screws and bolts are tightened to the manufacturer’s specifications.

- Reconnect the power source and conduct a thorough test to ensure everything operates smoothly.

By adhering to this guide, you can confidently tackle repairs and maintain your marine engine in optimal condition.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process if you know where to look. There are various sources, each offering unique advantages that cater to different needs and budgets. Below are some effective options to consider.

- Authorized Dealers:

These outlets specialize in specific brands and often provide the highest quality items. They can ensure compatibility and offer warranties on their products.

- Online Retailers:

Numerous websites specialize in selling various components. These platforms typically offer competitive prices and a wide selection.

- Local Marine Supply Stores:

These establishments usually carry a range of items suitable for various equipment. Visiting in person allows for immediate assistance and advice from knowledgeable staff.

- Second-Hand Marketplaces:

Websites and apps dedicated to used goods can be a cost-effective way to find what you need. Just ensure to verify the condition of the items before purchasing.

- Specialty Forums and Communities:

Engaging with online groups can yield valuable recommendations and potential sources for hard-to-find components. Members often share insights on where to buy items at reasonable prices.

Exploring these options can help ensure you find the right components for your needs, whether you’re looking for new, used, or hard-to-find items.

Tips for Preventive Maintenance

Regular upkeep is essential for ensuring the longevity and performance of your equipment. By adopting a proactive approach to maintenance, you can prevent potential issues before they escalate into costly repairs. This section outlines key strategies to keep your machinery in optimal condition.

Regular Inspections

- Conduct routine visual checks for signs of wear and tear.

- Inspect critical components, ensuring they are securely fastened and free from corrosion.

- Listen for unusual noises during operation, which may indicate underlying problems.

Scheduled Maintenance

- Establish a maintenance calendar to track essential service intervals.

- Replace filters and fluids as recommended by the manufacturer.

- Lubricate moving parts regularly to reduce friction and wear.

By implementing these practices, you can enhance the reliability and efficiency of your equipment, ultimately saving time and resources in the long run.

Impact of Quality Parts on Performance

The caliber of components utilized in machinery significantly influences overall efficiency and reliability. High-quality elements ensure optimal functionality, reducing the risk of malfunctions and enhancing the lifespan of the equipment.

Durability is a key factor; superior materials withstand wear and tear, ultimately leading to fewer repairs and replacements. This not only saves time but also minimizes costs associated with maintenance.

Furthermore, precision in manufacturing plays a critical role in performance. Well-crafted components fit together seamlessly, promoting smooth operation and reducing friction, which can lead to increased speed and improved fuel efficiency.

In conclusion, investing in premium-quality components is essential for achieving the ultimate performance of any machinery, ensuring it operates at its best for longer periods.

Resources for Mercury Outboard Owners

For enthusiasts and operators of outboard engines, having access to reliable information and tools is essential for optimal performance and maintenance. This section provides valuable resources to enhance your experience and ensure longevity for your watercraft.

- Owner’s Manuals: Comprehensive guides specific to your model can help navigate maintenance and troubleshooting.

- Online Forums: Engaging with communities allows for sharing experiences and gaining insights from fellow users.

- Video Tutorials: Visual guides on platforms like YouTube can simplify complex repairs and upkeep tasks.

- Local Dealers: Authorized retailers offer expert advice and can source genuine components for your engine.

- Maintenance Logs: Keeping a detailed record of services can help track performance and plan future care.

Utilizing these resources can ultimately empower you to maintain and enhance your outboard’s efficiency and reliability.