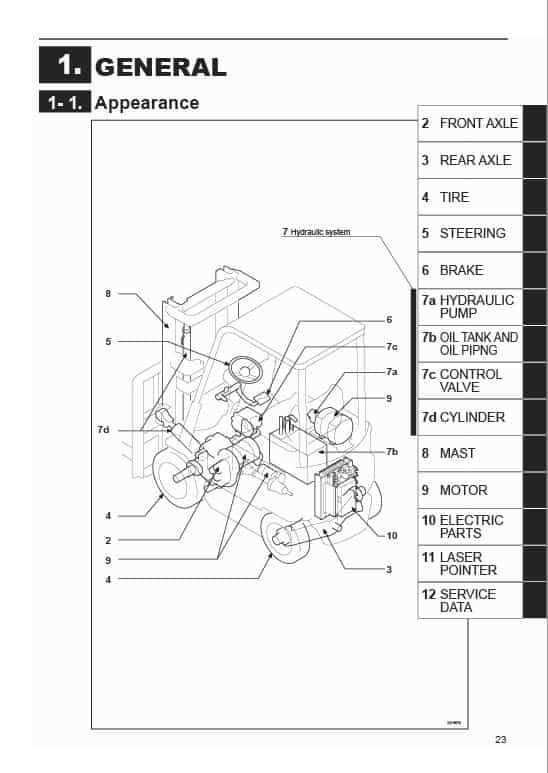

Mitsubishi Forklift Parts Diagram

Efficient operation and maintenance of industrial machinery require a clear understanding of its internal configuration. Each machine is made up of various crucial elements that interact to perform specific tasks. By studying the layout of these parts, operators can ensure that everything functions as expected, minimizing downtime and preventing costly repairs.

Proper identification and organization of these components are vital for quick troubleshooting and smooth repairs. When you are familiar with how each part fits together, finding and replacing damaged components becomes much easier. This knowledge also helps in ensuring that every piece is working in harmony, improving overall efficiency.

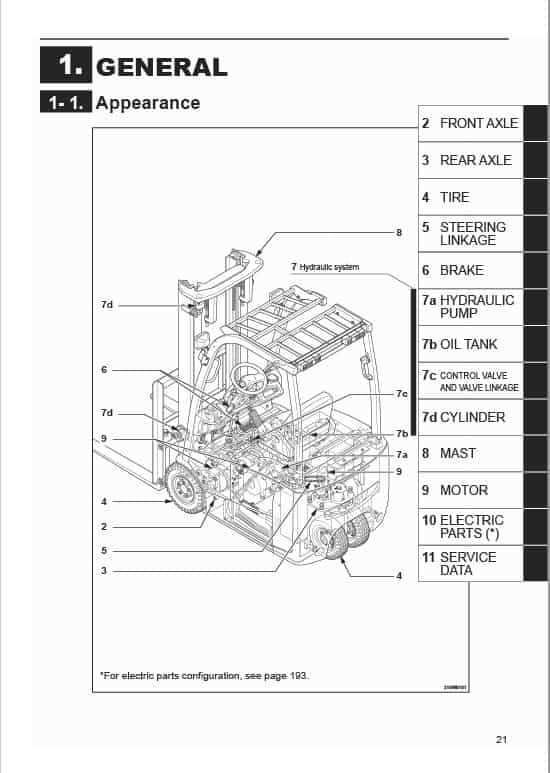

The layout of these systems typically includes a mix of mechanical and electrical parts, each contributing to the machine’s effectiveness. In-depth diagrams provide visual clarity, helping technicians quickly pinpoint the source of any issues. Whether you’re dealing with a malfunction or conducting routine maintenance, having access to a detailed representation of the system can make a significant difference.

Mitsubishi Forklift Parts Overview

Understanding the key components of industrial lifting equipment is essential for optimal performance and maintenance. Each machine is composed of various elements that contribute to its functionality, durability, and safety. This section provides a detailed overview of the critical components found in such equipment, helping to ensure that users can identify, troubleshoot, and maintain these systems effectively.

The following table outlines some of the primary components that are vital for the operation and longevity of industrial lifting machines:

| Component | Description | Function |

|---|---|---|

| Hydraulic System | Includes pumps, valves, and cylinders | Controls lifting and lowering of the load |

| Powertrain | Consists of the engine and transmission | Transfers power to drive the vehicle |

| Steering Mechanism | Steering wheel or joystick system | Allows maneuverability and precise movement |

| Lift Mast | Vertical structure for lifting loads | Supports and raises the load |

| Chassis | Base frame of the vehicle | Supports the entire structure and components |

| Battery or Fuel System | Electric or internal combustion engine | Provides power for operation |

Types of Mitsubishi Forklifts

There are several categories of material handling machines designed to meet diverse operational needs. These machines come in various configurations, each offering specific advantages depending on the type of work required. From compact, maneuverable models to heavy-duty machines, the selection is vast, ensuring that every warehouse or industrial environment can find the perfect match for its demands.

Electric models are ideal for indoor environments, offering quiet and emission-free operation. These machines excel in areas where clean air and minimal noise are priorities. They typically provide efficient, low-maintenance solutions with impressive lifting capacities for smaller loads.

Internal combustion engine models are built for tough outdoor applications. These machines are robust and capable of handling heavier loads over uneven terrain, making them suitable for construction sites and large warehouses. They tend to operate with more power but also require regular maintenance to ensure optimal performance.

Rough terrain models are designed for off-road operations. They feature larger wheels and more durable frames, enabling them to navigate challenging environments. These machines are indispensable in industries where uneven surfaces are common, such as in forestry, agriculture, and large construction projects.

Each type brings its own unique set of features, tailored to specific tasks, ensuring greater efficiency and safety in daily operations.

Common Parts of Forklift Systems

In industrial machinery, various components work in unison to ensure smooth operation and safety. These essential elements are integral to the functionality and performance of the vehicle, each serving a specific purpose that contributes to its overall efficiency. Understanding these components is crucial for maintenance and troubleshooting, as well as for optimizing operational longevity.

Drive and Transmission Systems

The drive and transmission systems are fundamental to the vehicle’s mobility. They consist of motors, gearboxes, and related assemblies that transfer power from the engine to the wheels. These systems are responsible for controlling speed, direction, and power distribution, ensuring the vehicle can navigate diverse work environments effectively.

Lift Mechanism

The lift mechanism is a key feature, allowing the vehicle to raise and lower loads with precision. Comprising hydraulic cylinders, chains, and lifting arms, this system provides the necessary force and stability to handle varying weights. Proper maintenance of the lift system ensures safe load handling and prevents operational failures.

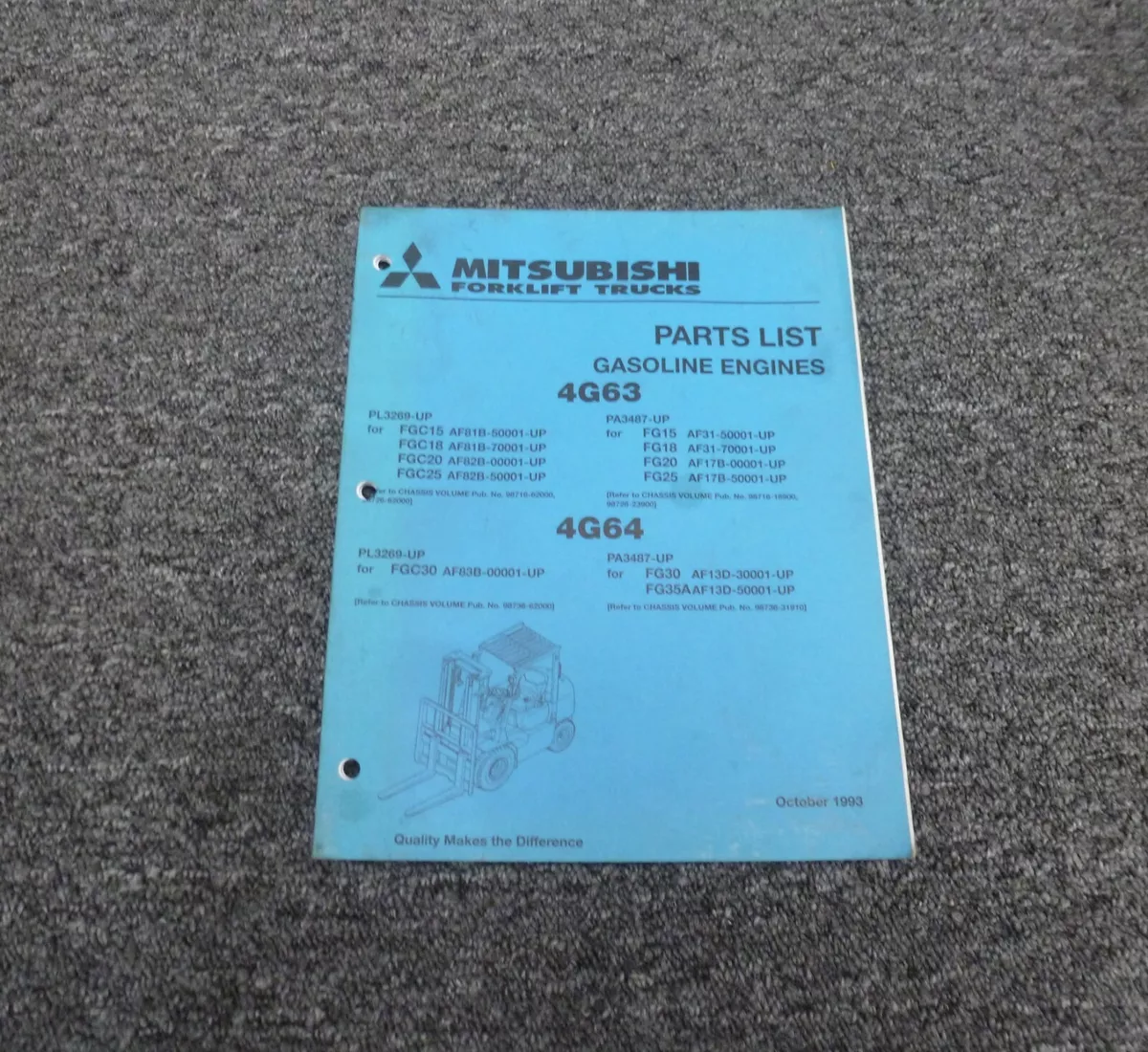

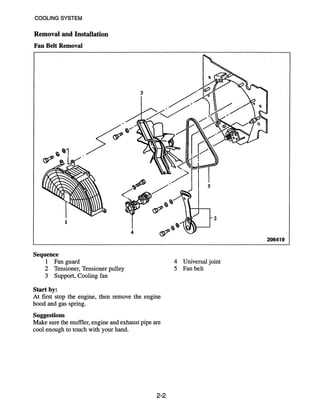

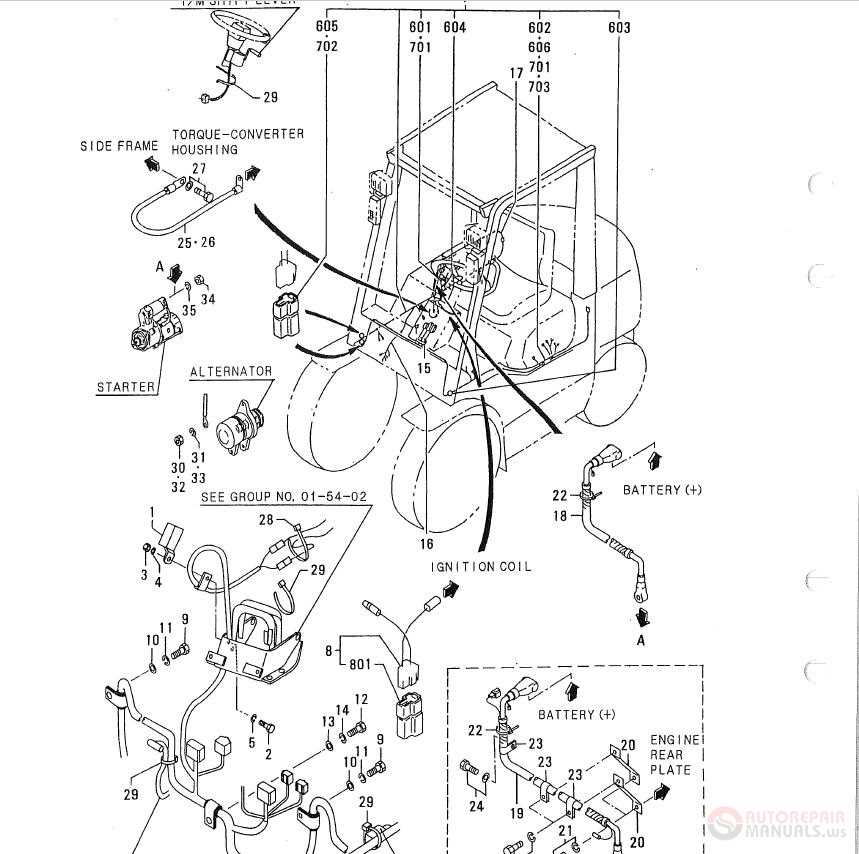

Engine Components in Mitsubishi Models

The engine is the heart of any industrial vehicle, providing the necessary power to keep operations running smoothly. In various models, the engine assembly consists of several key elements that work in tandem to ensure optimal performance. Understanding these components helps in maintaining the machinery and extending its lifespan. This section covers the crucial engine parts and their functions, offering insight into the mechanics that drive these robust machines.

Key Engine Elements

Industrial machinery relies on a variety of engine components that play specific roles. These parts range from power-producing elements to control mechanisms, all of which contribute to the vehicle’s efficiency. Below is a breakdown of the essential components commonly found in these machines:

| Component | Function |

|---|---|

| Crankshaft | Converts linear motion into rotational motion to drive the vehicle. |

| Camshaft | Controls the opening and closing of the engine’s intake and exhaust valves. |

| Timing Belt | Synchronizes the rotation of the crankshaft and camshaft for precise valve timing. |

| Fuel Injector | Delivers fuel to the engine’s combustion chamber for efficient operation. |

| Alternator | Generates electrical power to charge the battery and power electrical systems. |

Additional Essential Components

Other vital engine components, such as the intake manifold, exhaust system, and cooling system, further enhance the vehicle’s performance. Each part plays a specific role in ensuring that the engine operates at peak efficiency, providing the necessary power and reliability for heavy-duty tasks.

Hydraulic System Breakdown

The hydraulic system is a critical component in machinery that relies on fluid power to perform various tasks. It consists of various interconnected parts that work together to generate, control, and direct fluid flow. A breakdown in any part of this system can lead to a complete loss of function, affecting the machine’s overall performance. Understanding the common issues and maintenance practices is essential for keeping the system running efficiently.

Common Issues in Hydraulic Systems

Several factors can cause failures in the hydraulic circuit, ranging from wear and tear of seals to contamination of the fluid. Leaks are one of the most common problems, often caused by damaged hoses or connectors. Fluid contamination can lead to poor system performance and even damage to sensitive components such as pumps and valves. Understanding these potential problems can help prevent more significant damage.

Maintenance Tips

Regular maintenance is crucial for the longevity and efficiency of the hydraulic system. Periodically checking fluid levels and replacing filters can significantly reduce the risk of contamination. Also, inspecting hoses and seals for any signs of wear will help avoid potential leaks and other complications.

| Component | Common Failure | Solution |

|---|---|---|

| Hydraulic Pump | Low pressure output | Check for wear and tear, replace if necessary |

| Hoses and Fittings | Leaks and cracks | Inspect regularly, replace damaged parts |

| Seals | Fluid leakage | Replace damaged seals immediately |

| Hydraulic Fluid | Contamination | Change fluid and replace filters as part of routine maintenance |

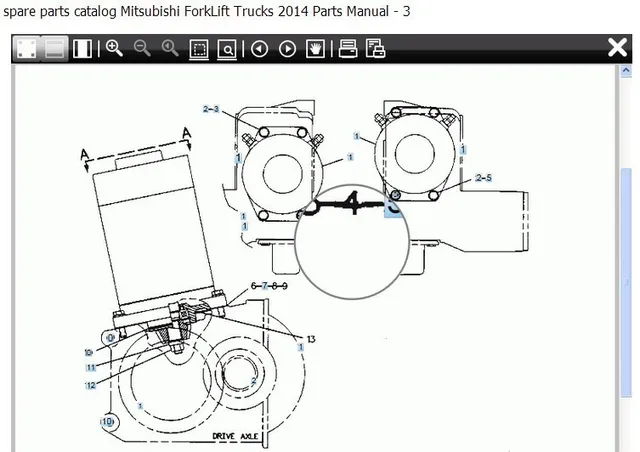

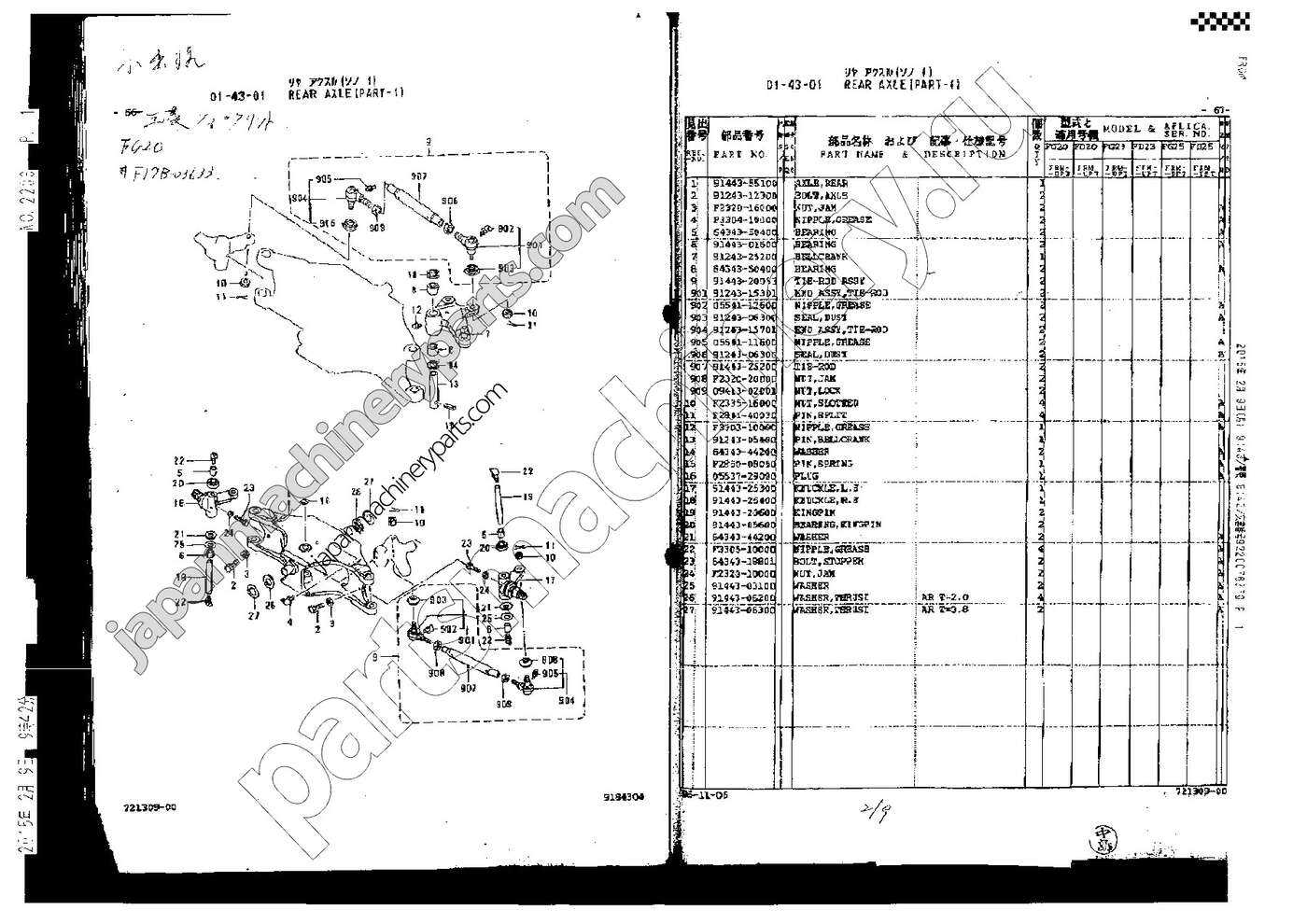

Transmission and Drive Assembly

The transmission and drive components form the essential link between the power source and the wheels, allowing for the efficient movement of industrial machinery. This system is responsible for converting the engine’s power into mechanical force that propels the vehicle. The assembly includes various elements such as gears, shafts, and drive mechanisms, all working together to ensure smooth operation across different speeds and directions.

Key Components

The primary components involved in this assembly are the gearbox, drive shafts, and differential. The gearbox plays a critical role in altering the torque and speed provided by the engine, enabling the vehicle to move at different speeds based on the operator’s requirements. The drive shafts transfer the power from the gearbox to the wheels, while the differential allows for smooth turning by distributing power to the wheels at varying speeds.

Maintenance and Troubleshooting

Regular maintenance of the transmission and drive assembly is vital for ensuring optimal performance. Lubrication is essential to reduce friction and wear on components, while periodic inspections help identify potential issues such as leaks, damaged seals, or worn-out gears. Addressing these concerns promptly can extend the lifespan of the entire system and improve the efficiency of the vehicle.

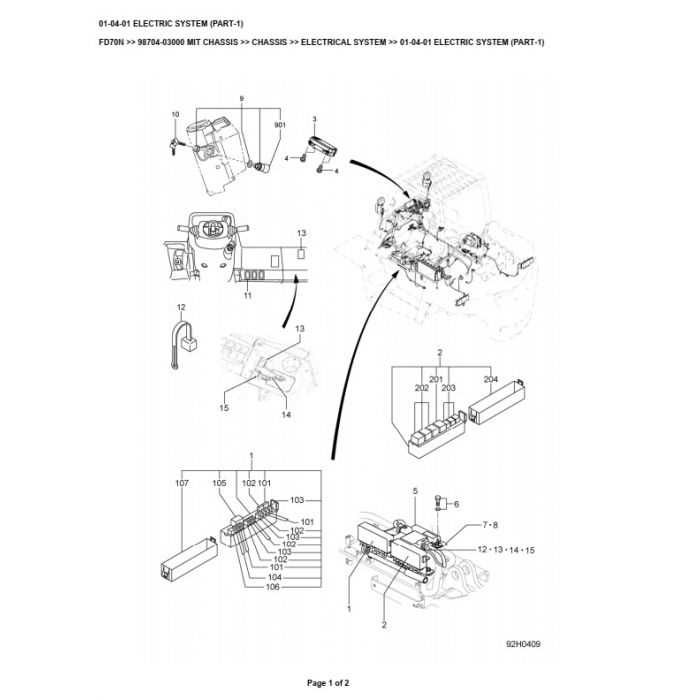

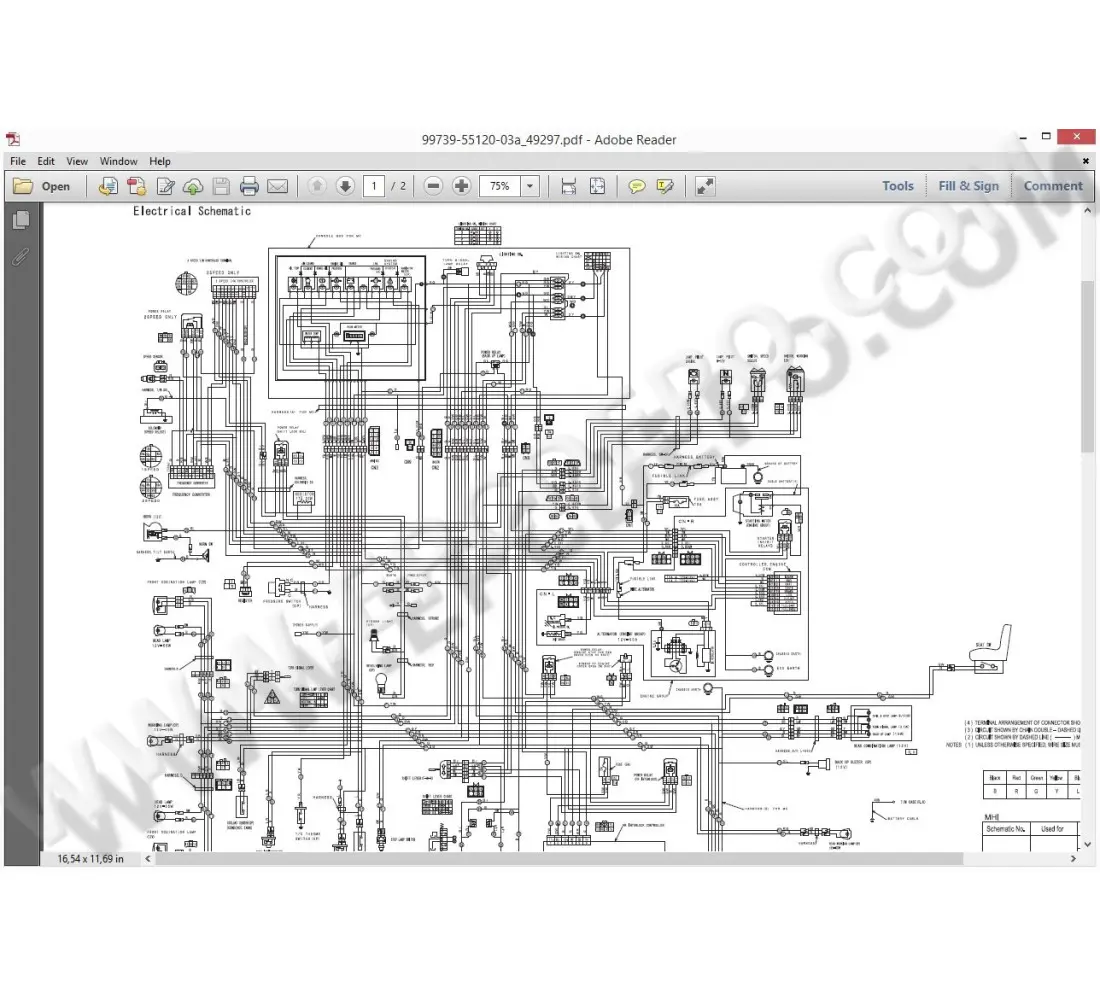

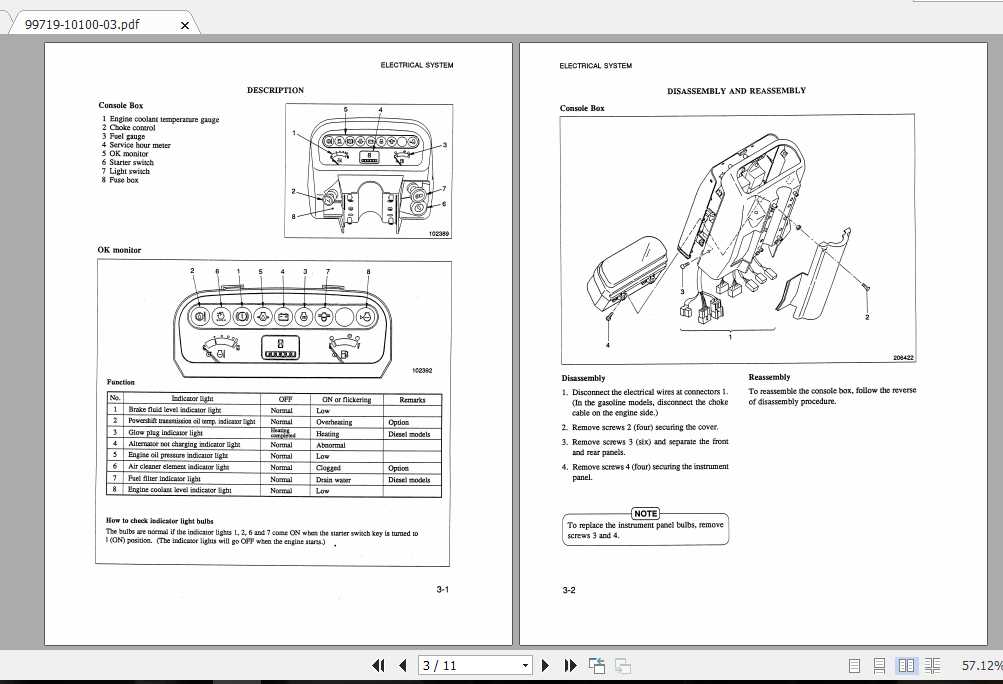

Electrical Wiring and Components

The electrical system in any industrial vehicle plays a crucial role in its overall functionality. It includes a network of wires, connectors, and various components that work together to ensure smooth operation. Proper understanding and maintenance of this system are essential for ensuring efficiency, safety, and longevity of the machine.

Key Electrical Components

The system is made up of several key components that work in harmony to control the vehicle’s functions. These include the battery, alternator, fuses, and relays. Each part has a specific function, such as supplying power, regulating voltage, or protecting circuits from overloads. It is important to check the condition of these elements regularly to avoid sudden failures.

Wiring Connections

The wiring itself is designed to carry electrical signals and power to various parts of the machine. Well-organized wiring ensures that power flows correctly and safely to different components. Over time, wires can wear out, become loose, or corrode, which may lead to performance issues. Ensuring proper insulation and tight connections is key to maintaining a reliable system.

Forklift Tires and Wheels

In any industrial setting, the role of the tires and wheels is crucial for efficient mobility and stability. These components bear the weight and ensure smooth movement on various surfaces, providing the necessary traction to maneuver heavy loads with precision.

Wheels are designed to endure constant stress and wear while supporting the machinery’s weight. They come in various types, including solid and pneumatic, each offering distinct benefits depending on the working environment. Solid wheels are durable and require less maintenance, while pneumatic ones offer a smoother ride and better shock absorption on uneven terrain.

Tires, on the other hand, are essential for gripping the ground and ensuring proper handling. The selection of tires directly impacts the safety and performance of the vehicle. Pneumatic tires are more suitable for outdoor operations, while solid tires are ideal for indoor or high-capacity environments. Understanding the requirements of specific tasks helps determine the best combination of wheels and tires for optimal results.

Battery and Charging Systems

The energy storage and replenishment systems are vital components for any electric-powered machinery. These systems ensure that the vehicle remains operational by providing the necessary power and maintaining battery life. The reliability and efficiency of these systems play a crucial role in the overall performance and longevity of the equipment.

Battery technology has advanced significantly in recent years, with modern batteries offering greater capacity and faster charging times. The correct maintenance of these power sources is essential to avoid disruptions in usage and maximize efficiency.

Lift Mechanism Parts

The lift system of any material handling vehicle consists of various components that work in unison to ensure the safe and efficient elevation and lowering of loads. These essential elements are responsible for providing the necessary mechanical advantage and stability, whether for lifting, tilting, or securing items at different heights. Understanding the function and interaction of these components is crucial for maintenance and operational efficiency.

Hydraulic cylinders play a pivotal role in the lifting process, utilizing pressurized fluid to generate the force needed for vertical movement. These components are designed to withstand significant pressure, ensuring smooth and controlled motion. Additionally, chains or ropes may be employed to support the lifting action, working in tandem with the cylinders to provide a balanced lift.

Other critical parts, such as the lift frame and mast, provide structural support to the entire system, offering a solid base for lifting operations. The fork carriage and tine assembly are equally important, as they are responsible for directly handling and positioning the load. Each component’s durability and proper functioning are essential for minimizing downtime and ensuring safe handling procedures.

Maintenance Tips for Forklift Parts

Proper care and regular upkeep of essential machinery components are critical to ensuring optimal performance and longevity. Routine inspections, timely repairs, and preventive measures help minimize breakdowns and improve efficiency. By focusing on the most crucial components, operators can extend the life of the equipment and reduce maintenance costs over time.

Key Areas to Inspect

Regular checks on specific areas can prevent common malfunctions. Focus on the following elements:

| Component | Inspection Frequency | Common Issues | Maintenance Tips |

|---|---|---|---|

| Hydraulic System | Every 500 hours | Leaks, low fluid levels | Ensure proper fluid levels, check for leaks, and clean filters. |

| Drive Motor | Every 1,000 hours | Overheating, loss of power | Check for dust buildup, lubricate components, and monitor temperature. |

| Brakes | Every 200 hours | Worn pads, poor response | Inspect for wear, replace pads as needed, and check fluid levels. |

Preventive Actions for Longevity

Regular maintenance prevents minor issues from becoming major problems. Clean and lubricate moving parts frequently to avoid wear and tear. Always use manufacturer-recommended fluids and components for replacement to ensure compatibility and efficiency. Training operators to spot early signs of trouble can also help reduce downtime and repair costs.

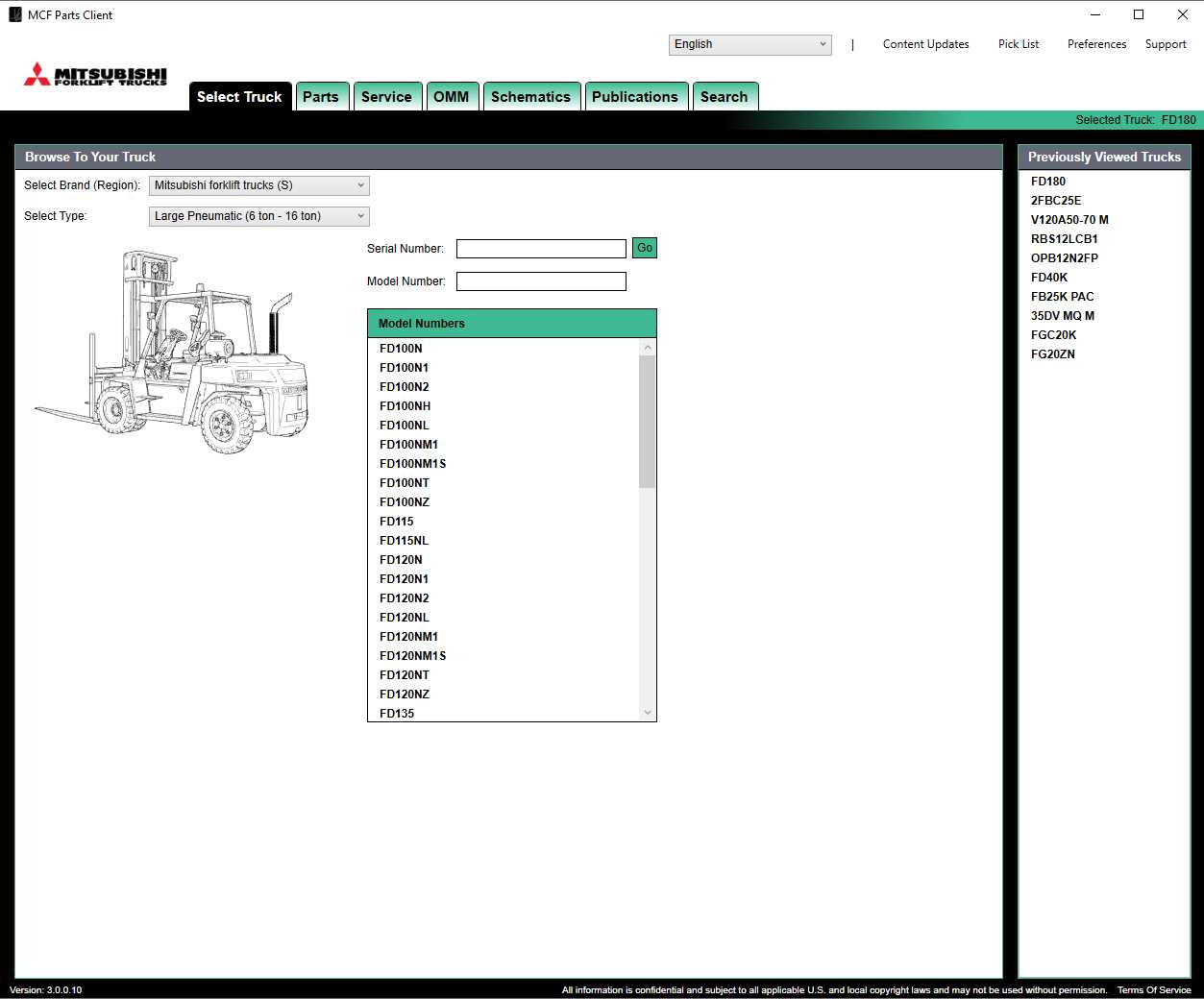

Where to Find Genuine Mitsubishi Parts

When searching for reliable components for your heavy-duty machinery, it’s important to source them from trusted and certified suppliers. Genuine replacement items are essential for ensuring long-term performance and avoiding costly repairs. These high-quality alternatives are specifically designed for your equipment, offering durability and efficiency. Here’s where you can find the authentic replacements you need.

| Source | Description |

|---|---|

| Authorized Dealers | Dealers with official agreements provide the most reliable and genuine products. They are equipped with expert knowledge and the latest inventory. |

| Certified Online Retailers | Online platforms with recognized certifications offer a wide range of genuine components. Make sure they have a solid reputation for authenticity and customer service. |

| Manufacturer’s Direct Sales | Purchasing directly from the original manufacturer guarantees authenticity and often provides support and warranty services for the items. |

| Specialized Repair Centers | Many repair facilities collaborate with authorized distributors, allowing customers to obtain authentic replacements through their services. |