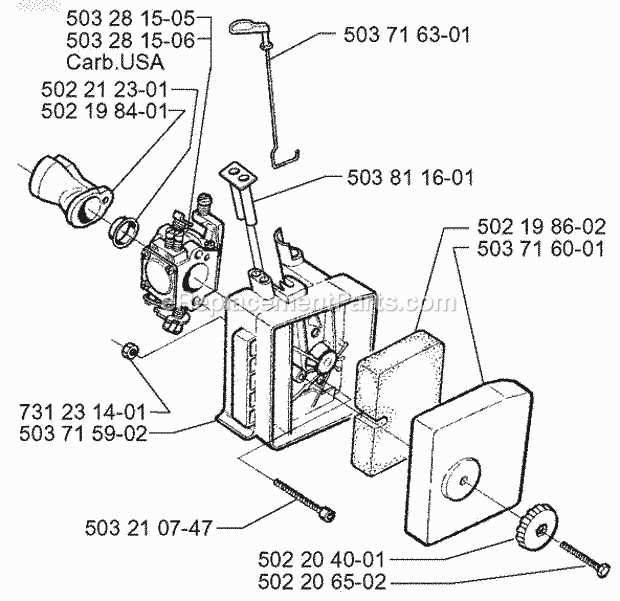

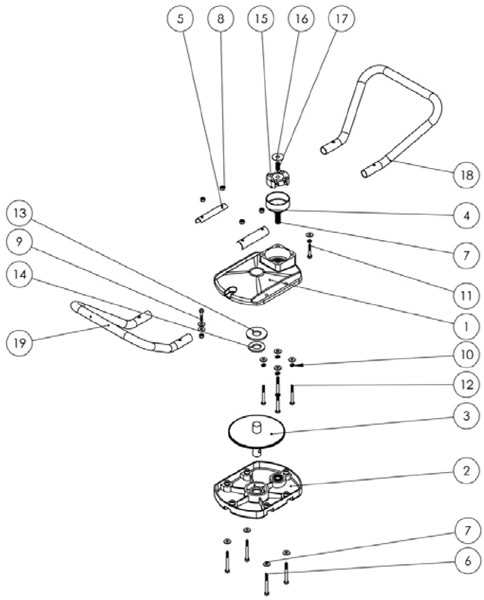

Jiffy Model 30 Carb Parts Overview

The functionality of a mechanical system often relies on the intricate arrangement of its smaller elements. Each part plays a crucial role in ensuring the smooth operation and efficiency of the entire unit. Understanding the structure and layout of these elements can significantly improve troubleshooting and maintenance efforts.

In this section, we will explore the key components that contribute to the overall performance of the system. By delving into the specifics, we aim to provide clarity on how each piece interacts within the mechanism, enhancing both your understanding and ability to address potential issues effectively.

Detailed knowledge of these elements is essential for anyone looking to maintain or repair such systems. With the right approach, even complex setups can be easily navigated, ensuring long-term reliability and optimal functioning.

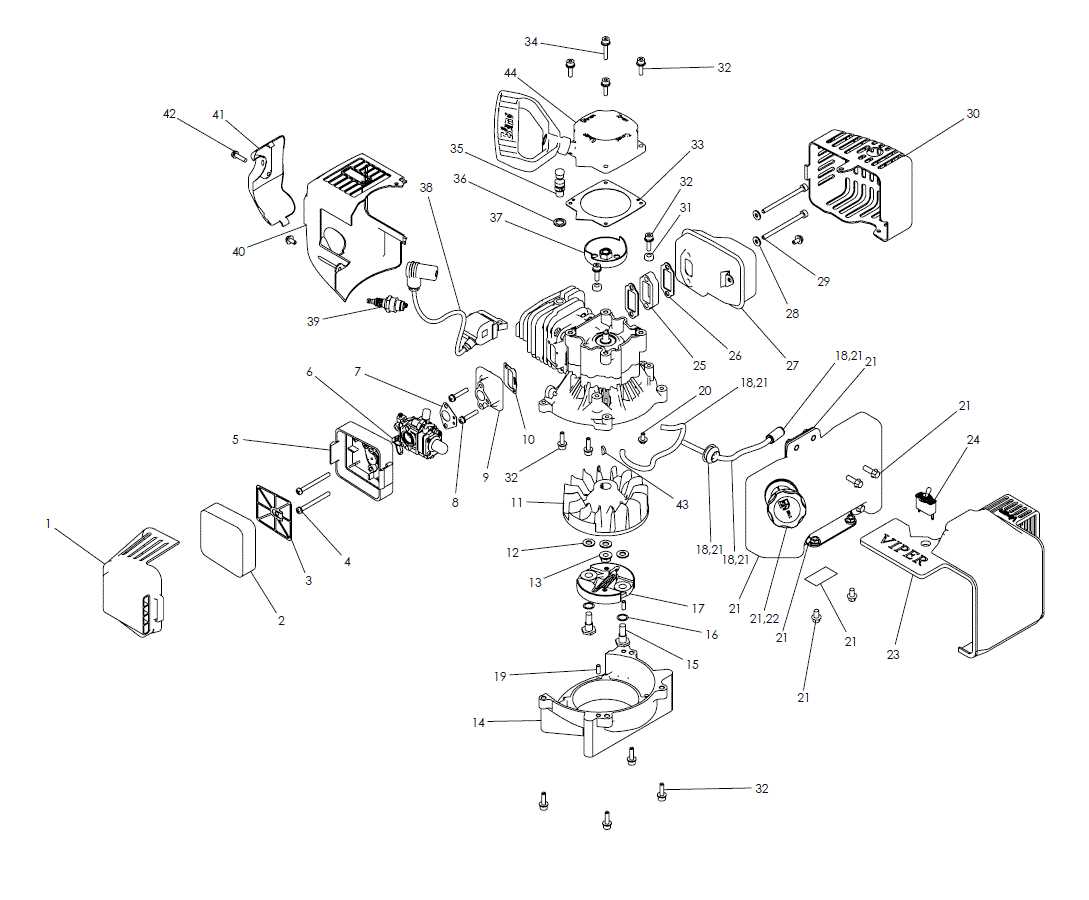

Jiffy Model 30 Carburetor Overview

The fuel-mixing component in this engine plays a crucial role in ensuring optimal performance. It regulates the mixture of air and fuel, which directly affects the efficiency of the machine during operation. This system is designed to ensure smooth and consistent power delivery, which is essential for achieving reliable performance in various conditions.

The component’s functionality relies on several internal mechanisms that work together to maintain balance. Proper maintenance and understanding of how these elements interact are key to ensuring long-term durability and consistent output.

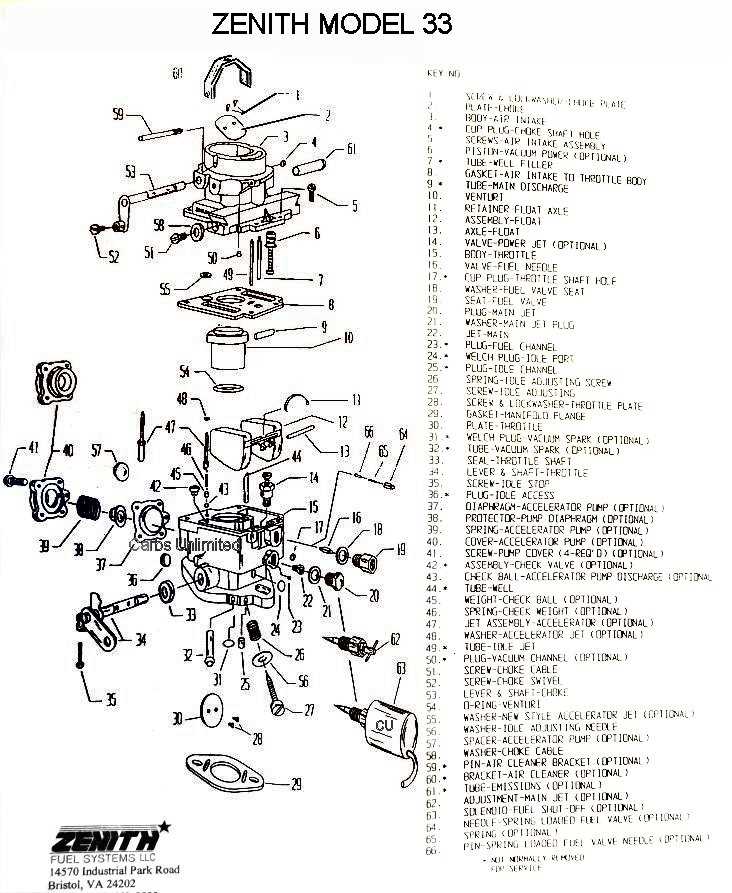

Essential Components of the Jiffy Model 30 Carburetor

The engine’s fuel delivery system relies on several key components that work together to ensure optimal performance. Each part has a specific role in regulating the flow of fuel and air to the engine, making the system efficient and reliable in various conditions.

- Float Chamber: A crucial section that helps maintain the correct fuel level, ensuring consistent flow to the engine.

- Needle Valve: This small mechanism regulates the fuel intake, opening and closing as needed to control the flow.

- Throttle Plate: By adjusting the amount of air entering the system, this component directly influences engine speed and response.

- Venturi: A narrow passage that increases airspeed and creates the necessary vacuum to draw fuel into the mix.

- Jets

How to Identify Carburetor Parts Correctly

Understanding the individual components of a carburetor is essential for maintaining engine performance. By familiarizing yourself with the key elements, you can ensure that the equipment operates smoothly and avoid common issues caused by worn or damaged elements.

To properly identify the different sections and pieces, it is important to recognize their shape, size, and function within the mechanism. Each component has a specific role, whether it regulates airflow, fuel delivery, or maintains pressure balance. Paying close attention to small details like screws, gaskets, and valves can help prevent misidentification.

Examine the structure: Start by observing the layout and connections between different parts. Notice how fuel is directed and controlled through the system, which will guide you in identifying individual sections more effectively.

Use reference materials: Diagrams or manuals can provide visual guidance, showing where each element fits within the

Common Issues in Jiffy Model 30 Carburetors

Small engines often face a variety of performance issues, many of which stem from fuel delivery problems. Understanding the potential causes behind these issues can help address malfunctions and restore proper operation. Key areas of concern usually revolve around fuel flow, air intake, and mechanical wear.

Fuel Blockages: Dirt or debris can accumulate, restricting fuel flow and causing the engine to stall or run inconsistently. Regular cleaning and checking for obstructions can prevent these issues.

Air Intake Problems: Improper air-fuel mixture ratios often lead to inefficient combustion. This can cause the engine to idle poorly or lose power during operation. Ensuring air filters are clean and properly installed is crucial.

Worn Components: Over time, parts like gaskets and seals can degrade, leading to leaks or inefficiencies in fuel and air management. Replacing worn-out parts is necessary to maintain engine performance.

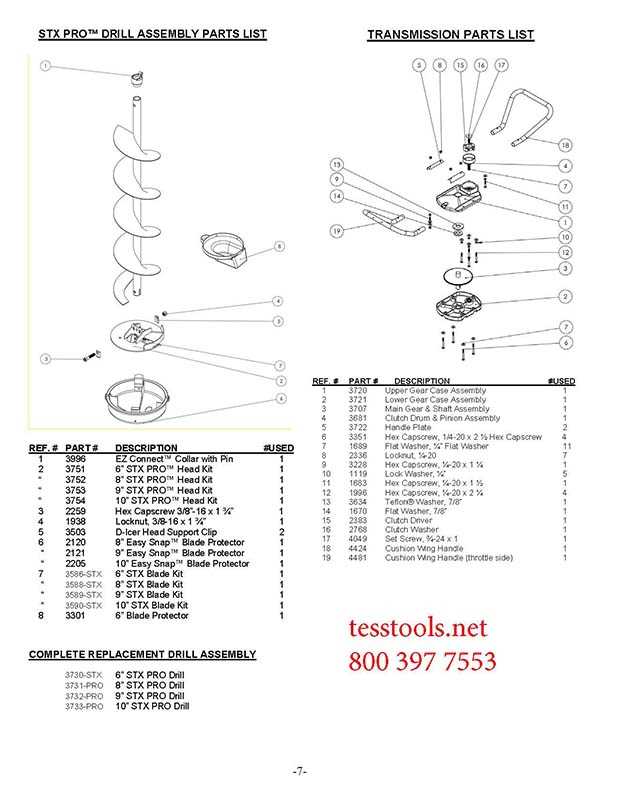

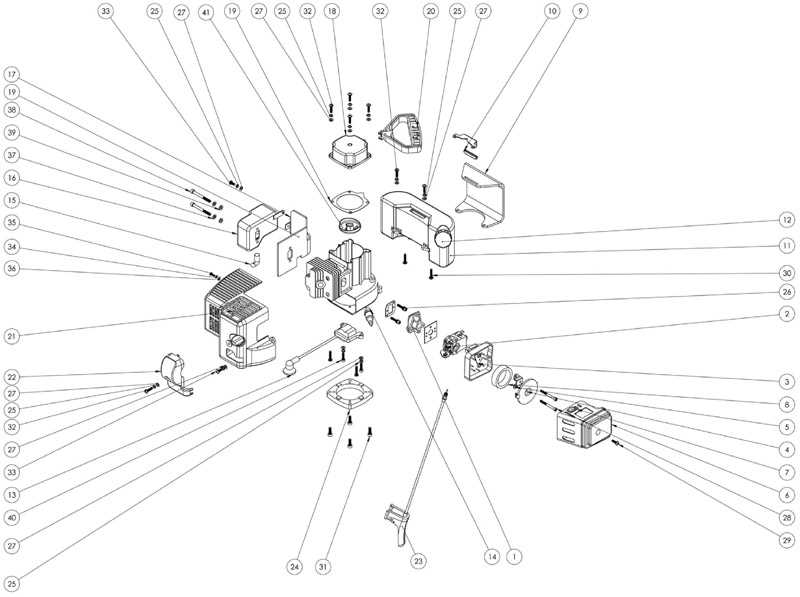

Steps for Disassembling the Jiffy Model 30 Carb

Maintaining proper functionality of your equipment requires a systematic approach to disassembly. Carefully following each step ensures safe and efficient work, avoiding potential damage to delicate components. Below are the essential steps to disassemble the mechanism safely and prepare it for cleaning or repair.

Necessary Tools and Preparation

- Gather a set of screwdrivers, wrenches, and a clean workspace.

- Ensure the engine is off, cooled down, and the fuel supply is disconnected.

- Have a container ready to collect small parts and screws.

Disassembly Process

- Begin by removing the protective cover and access screws to expose the core mechanism.

- Carefully detach the linkages and hoses connected to the

Cleaning Tips for Jiffy Model 30 Carburetor

Maintaining optimal performance of your equipment requires regular attention to its fuel delivery system. Properly cleaning the components can prevent issues and ensure smooth operation. This section provides essential advice for effectively restoring cleanliness to your device’s fuel system.

Preparation is Key: Before starting the cleaning process, gather all necessary tools and cleaning solutions. Having everything on hand will streamline the task and make it more efficient.

Disassemble Carefully: Take your time when disassembling the fuel delivery unit. Make sure to keep track of all components to avoid losing any small pieces. A clean workspace will help you stay organized.

Use Appropriate Cleaning Solutions: Opt for a high-quality cleaner that is specifically formulated for fuel systems. Avoid using harsh chemicals that may damage the components. Always follow the manufacturer’s guidelines for cleaning products.

Thoroughly Clean All Components: Use a soft brush and lint-free cloth to remove any residue from the parts. Pay special attention to small passages and openings, as these areas can easily become clogged.

Inspect for Damage: While cleaning, examine each component for wear and tear. Replace any damaged pieces to maintain the integrity of the system.

Reassemble with Care: After cleaning and inspecting, carefully reassemble the components in the correct order. Ensure that all parts are securely fastened to prevent leaks or malfunctions.

Test After Maintenance: Once everything is back in place, conduct a test run to ensure that the system is functioning correctly. Monitor for any irregularities that may indicate further issues.

How to Rebuild Your Jiffy Model 30 Carburetor

Restoring the functionality of your essential equipment requires careful attention to detail and a methodical approach. This process ensures optimal performance and longevity of the machinery. Here’s a step-by-step guide to effectively refurbish the fuel delivery component of your device.

- Gather Required Tools and Materials:

- Wrench set

- Screwdrivers (flathead and Phillips)

- Cleaning solvent

- Replacement seals and gaskets

- Compressed air

- Disassemble the Unit:

- Begin by removing the component from the machine.

- Carefully unscrew all fasteners and detach any connections.

- Take note of the arrangement for reassembly.

- Clean Each Part:

- Use the cleaning solvent to remove dirt and residue.

- Utilize compressed air to clear out any clogs.

- Inspect each component for wear or damage.

- Replace Worn Parts:

- Install new seals and gaskets where necessary.

- Ensure that all replacement items fit properly.

- Reassemble the Unit:

- Follow your notes to reattach all components.

- Tighten fasteners securely, but avoid over-tightening.

- Test for Functionality:

- Reinstall the unit back into the machinery.

- Start the equipment and observe for any irregularities.

- Make adjustments as needed to ensure smooth operation.

By following these steps, you can ensure that your device operates at peak efficiency, enhancing its overall performance and lifespan.

Troubleshooting Guide for Carburetor Problems

Understanding and resolving issues related to the fuel delivery system is essential for optimal engine performance. This section provides insights into common challenges and their solutions, helping you maintain efficiency and reliability.

One frequent problem is poor engine start-up. This may occur due to insufficient fuel reaching the combustion chamber. Check for clogs in the fuel line and ensure the fuel is clean and fresh.

Another common issue is erratic idling or stalling. This can result from incorrect adjustments or air leaks in the intake system. Inspect gaskets and seals for wear and ensure proper tuning of the system.

Furthermore, a rough running engine can indicate fuel mixture problems. If the mixture is too rich or too lean, adjustments may be necessary. Using a tuning tool can assist in achieving the right balance.

Lastly, pay attention to unusual noises or vibrations. These could signify mechanical wear or damage. Conduct a thorough inspection to identify any loose components or signs of deterioration.

Where to Find Carburetor Replacement Parts

Locating suitable components for your fuel mixing device can be straightforward if you know where to look. Various options are available, ranging from online retailers to local shops that specialize in engine equipment. Identifying reliable sources is crucial to ensure the quality and compatibility of the items you need.

Here are some common places to search for suitable replacements:

Source Description Online Retailers Websites that specialize in engine parts often have a wide selection and competitive prices. Local Hardware Stores Many local stores carry basic engine components and can help you find what you need. Specialty Shops Stores focusing on outdoor power equipment usually stock specific items and offer expert advice. Manufacturer Websites Visiting the official websites of manufacturers can provide direct access to authentic components. Second-hand Markets Online platforms and local flea markets can yield good deals on used parts, but quality should be verified. Maintenance Tips for Long-lasting Carburetor Performance

Ensuring the optimal function of your fuel delivery system is essential for the longevity of your engine’s performance. Regular upkeep not only enhances efficiency but also prevents costly repairs. Here are some essential practices to help maintain peak operation.

Regular Cleaning

- Perform a thorough cleaning every few months to remove dirt and residue.

- Use a specialized cleaner to dissolve stubborn deposits without causing damage.

- Inspect all components for wear and replace any that show signs of deterioration.

Proper Storage

- Store your equipment in a cool, dry place to prevent moisture buildup.

- Always drain fuel before long-term storage to avoid varnishing.

- Use a fuel stabilizer to maintain fuel quality and protect against degradation.

Implementing these strategies will greatly enhance the efficiency and lifespan of your fuel delivery system, ensuring reliable performance when you need it most.

- Gather Required Tools and Materials: