Minn Kota Trolling Motor Parts Diagram Explained

When it comes to enhancing your aquatic adventures, the efficiency of your vessel’s propulsion mechanism plays a crucial role. A comprehensive grasp of its components can significantly improve performance and longevity. Knowing how each element interacts allows for better maintenance and quicker troubleshooting.

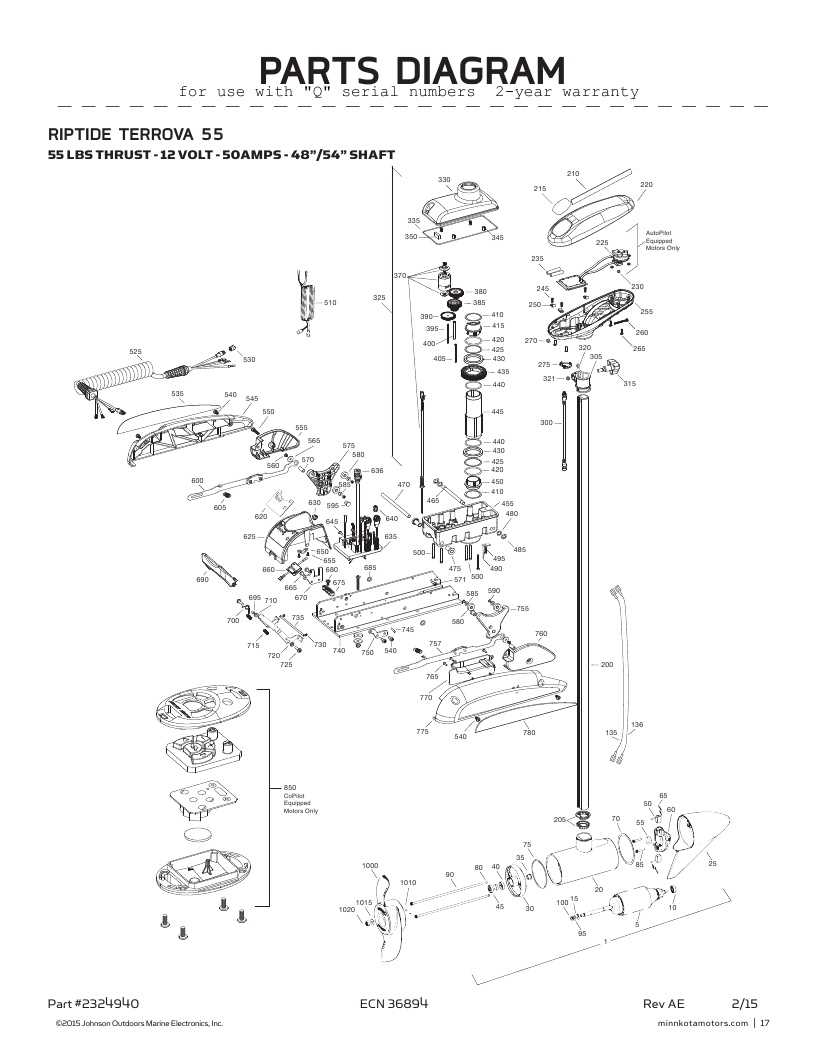

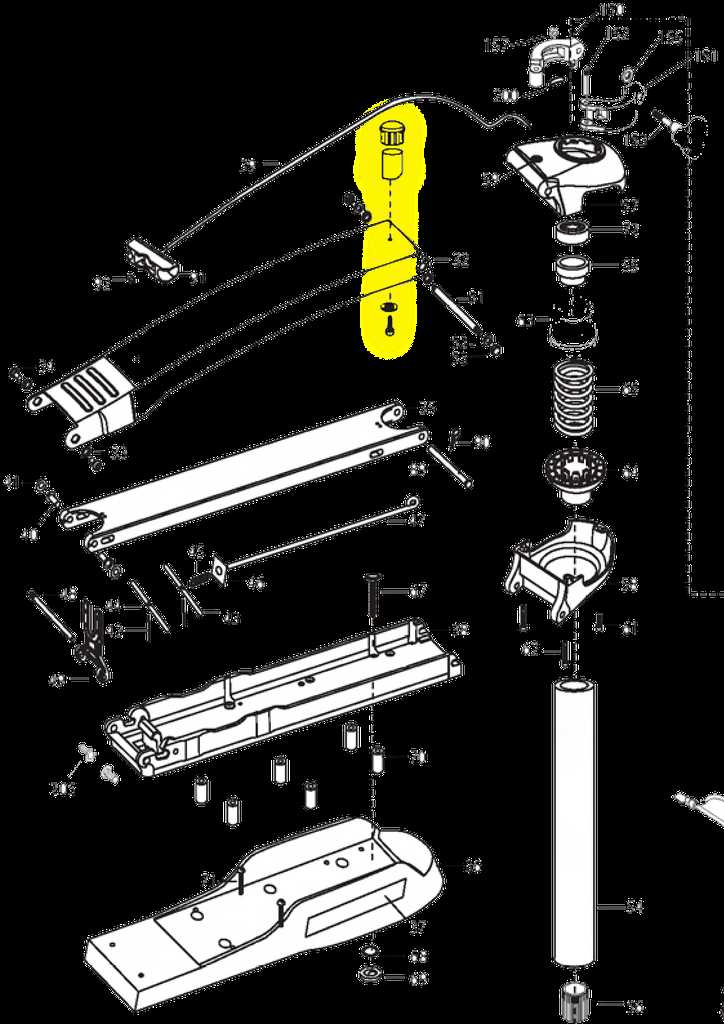

Visual representations of these essential components serve as invaluable tools for both novices and experienced users. They provide clarity in identifying parts and understanding their functions within the larger system. This knowledge is not only beneficial for repairs but also enhances overall familiarity with the equipment.

In this section, we will delve into the intricate details of the propulsion system, exploring how each piece contributes to the ultimate boating experience. By familiarizing yourself with these elements, you’ll be well-equipped to ensure your vessel remains in optimal condition.

Minn Kota Trolling Motors Overview

This section provides an insight into the various electric propulsion systems designed for enhancing the fishing experience. These systems are engineered for efficiency, reliability, and ease of use, making them essential tools for anglers.

Key Features

Modern electric propulsion systems offer advanced technology, including variable speed control, wireless connectivity, and battery management features. These innovations ensure that users can navigate waterways smoothly while maintaining optimal performance.

Applications

These propulsion systems are ideal for both freshwater and saltwater environments, catering to recreational and professional anglers alike. Their versatility allows for a range of activities, from leisurely outings to competitive fishing events.

Understanding Trolling Motor Components

Exploring the various elements that comprise an electric propulsion device reveals the intricate design and functionality behind these essential tools for navigating waterways. Each component plays a critical role in ensuring smooth operation and efficiency, contributing to a seamless experience on the water.

At the heart of the device lies the power source, which provides the necessary energy to drive the system. Coupled with a control mechanism, this allows users to adjust speed and direction with ease. The assembly also features a propeller, which translates the energy into movement, ensuring optimal performance based on the vessel’s requirements.

Furthermore, structural elements such as the shaft and mount are vital, offering stability and support during operation. These components are engineered to withstand various environmental conditions, ensuring durability and longevity. Understanding these features is essential for effective maintenance and enhancing overall performance during aquatic adventures.

Importance of Maintenance and Care

Regular upkeep and attention are essential for ensuring optimal performance and longevity of aquatic propulsion devices. Neglecting these aspects can lead to reduced efficiency and potential failures, which may disrupt your aquatic activities.

To effectively maintain your equipment, it is crucial to understand the various components that require attention. Below is a table highlighting key maintenance tasks and their significance:

| Maintenance Task | Importance |

|---|---|

| Cleaning | Prevents buildup of debris and corrosion, ensuring smooth operation. |

| Inspection | Identifies wear and tear early, allowing for timely replacements. |

| Lubrication | Reduces friction between moving parts, enhancing performance. |

| Battery Care | Ensures reliable power supply and extends battery lifespan. |

Investing time in maintenance will ultimately enhance the reliability and efficiency of your equipment, allowing for more enjoyable and trouble-free experiences on the water.

Common Issues with Trolling Motors

Electric propulsion systems for boats can encounter various challenges that affect their performance and reliability. Understanding these common problems can help users maintain their equipment effectively and ensure a smoother experience on the water.

Power and Performance Problems

One frequent issue is inconsistent power delivery, which may stem from battery malfunctions or poor connections. Users should regularly check the battery voltage and inspect cables for corrosion or damage to avoid performance drops.

Noise and Vibration Concerns

Unusual sounds or vibrations often indicate mechanical issues. Loose components or wear and tear on the propeller can lead to increased noise levels. Regular maintenance and inspections can help identify these concerns early, preventing more significant damage.

How to Identify Part Numbers

Understanding the identifiers associated with various components can streamline the maintenance and repair processes for any equipment. These identifiers often provide critical information about compatibility and specifications, making it easier to find the exact replacements needed. Mastering the identification of these numbers can save time and ensure optimal performance of your gear.

Decoding the Identification System

Manufacturers typically use a structured approach when assigning identifiers, which may include a combination of letters and numbers. Familiarizing yourself with the format can help in deciphering the specifications tied to each component. It’s important to consult the user manual or manufacturer’s website to grasp the specific coding used for your equipment, as variations can exist across different brands.

Utilizing Online Resources

Numerous online platforms offer databases where you can search for specific identifiers. These resources can provide comprehensive details about compatibility, alternative options, and even pricing. Engaging with forums or communities focused on similar equipment can also yield valuable insights into identifying the right components efficiently.

Diagram Types and Their Uses

Visual representations play a crucial role in understanding complex systems and components. By categorizing these illustrations, we can streamline the learning process and enhance comprehension. Various types of schematics serve specific purposes, catering to different audiences and needs.

Common Types of Visual Representations

- Schematic Diagrams: These provide a simplified representation of a system, focusing on the relationships between components rather than their physical appearance. They are ideal for engineers and technicians.

- Block Diagrams: Useful for illustrating the overall structure of a system, these diagrams break down functions into blocks. They are often employed in presentations to communicate ideas quickly.

- Wiring Diagrams: These detailed illustrations show the connections and pathways between electrical components. They are essential for troubleshooting and installation tasks.

Applications in Various Fields

- Engineering: Professionals rely on these visuals to design and analyze systems effectively.

- Education: Instructors use them as teaching aids to convey complex concepts clearly.

- Maintenance: Technicians refer to them for guidance during repairs, ensuring accurate and efficient work.

Electric vs. Manual Components

This section explores the differences between powered and hand-operated elements commonly found in marine propulsion systems. Each type has its unique characteristics, advantages, and potential drawbacks, making them suitable for different applications and user preferences.

Electric components offer enhanced convenience and efficiency, allowing for effortless control and operation. These systems typically feature advanced technology that can improve performance and responsiveness, catering to modern boating needs.

In contrast, manual components emphasize simplicity and reliability. They often require more physical effort, but many users appreciate the direct connection to their vessel and the straightforward nature of operation. Additionally, these elements can be easier to maintain in remote areas.

Ultimately, the choice between electric and manual systems depends on individual requirements, such as intended usage, budget, and personal preference. Understanding the strengths and weaknesses of each type can help users make informed decisions.

Replacement Parts Availability and Options

When it comes to maintaining your aquatic propulsion system, understanding the availability and variety of replacement components is crucial. Access to high-quality substitutes ensures optimal performance and longevity of your equipment.

Numerous suppliers offer an extensive selection of items, allowing users to find what they need efficiently. Here are some key considerations when looking for replacement components:

- Original Equipment Manufacturer (OEM) vs. Aftermarket: Determine whether to choose original components for guaranteed compatibility or explore aftermarket options that may provide cost savings.

- Quality Assurance: Always check for warranties and reviews to ensure that the selected replacements meet high-quality standards.

- Compatibility: Verify that the components are designed for your specific model to avoid installation issues.

- Supplier Reputation: Research the suppliers’ credibility and customer feedback to ensure reliable service and support.

Moreover, various online platforms and local retailers provide resources for easily locating and purchasing these items. Many offer detailed catalogs, enhancing the shopping experience and facilitating informed choices.

By considering these factors, users can effectively navigate the marketplace and select the most suitable replacements for their aquatic propulsion needs.

Tools Needed for Repairs

When it comes to maintaining and fixing your equipment, having the right tools is essential for a smooth process. Each component may require specific instruments to ensure effective repairs and longevity. A well-equipped workspace not only simplifies the task but also enhances precision and safety.

Basic Hand Tools: Start with a set of screwdrivers, wrenches, and pliers. These fundamental tools are crucial for loosening and tightening various connections. Ensure that you have both flathead and Phillips screwdrivers to accommodate different types of screws.

Specialized Equipment: Depending on the complexity of the repairs, you might need additional tools like a multimeter for electrical diagnostics or a torque wrench for specific tightening requirements. Having these specialized instruments on hand can save time and prevent damage to components.

Cleaning Supplies: Regular maintenance includes cleaning, so gather items like brushes, rags, and cleaning solvents. Keeping your equipment clean is vital for optimal performance and longevity.

Safety Gear: Don’t forget to wear appropriate safety gear, such as gloves and goggles. Protecting yourself during repairs should always be a priority to prevent injuries.

By ensuring you have the right tools and equipment at your disposal, you can tackle repairs efficiently and effectively, leading to improved performance and reliability.

Step-by-Step Repair Instructions

This section provides a comprehensive guide for effectively addressing common issues that may arise with your aquatic propulsion device. By following these structured instructions, you can restore functionality and ensure optimal performance. Whether you’re dealing with electrical malfunctions, mechanical wear, or any other concerns, the steps outlined here will assist you in the repair process.

Preparation

- Gather necessary tools: screwdriver, wrench, multimeter, and replacement components.

- Ensure a clean and safe working environment.

- Disconnect the device from the power source.

Repair Process

- Inspect the Unit: Examine the exterior for signs of damage or wear.

- Check Electrical Connections: Use a multimeter to test wires and terminals for continuity.

- Replace Worn Components: Remove damaged parts and install new ones, ensuring proper alignment.

- Reassemble the Device: Carefully put all components back together, following the reverse order of disassembly.

- Test Functionality: Reconnect to power and conduct a thorough test to verify repairs.

Upgrading Your Trolling Motor

Enhancing your aquatic propulsion system can significantly improve your boating experience. By incorporating advanced components, you can achieve better performance, efficiency, and control on the water.

- Consider replacing the battery with a higher capacity model for extended outings.

- Upgrade the propeller to improve speed and maneuverability.

- Install a more advanced control system for enhanced responsiveness.

Additionally, it’s wise to evaluate the overall construction and weight of your setup. A lighter design can contribute to better handling and reduced strain on the system.

- Research compatible upgrades tailored to your specific needs.

- Ensure all components are compatible with existing equipment.

- Consult experts if uncertain about installation procedures.

Ultimately, investing in quality enhancements can lead to a more enjoyable and efficient experience on the water.

Safety Tips When Working on Motors

When engaging in maintenance or repairs on any machinery, prioritizing safety is essential to prevent accidents and injuries. Following specific guidelines can ensure a secure working environment, allowing for efficient and effective tasks.

Preparation Before Starting

- Wear appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Ensure your workspace is clean and well-lit.

- Familiarize yourself with the equipment’s manual and safety instructions.

During Maintenance

- Always disconnect power sources before beginning work.

- Keep tools organized and within reach to avoid unnecessary movement.

- Be cautious of sharp edges and hot surfaces.

Resources for Further Learning

Exploring a variety of materials can enhance your understanding of aquatic propulsion systems and their components. A well-rounded approach includes manuals, online forums, and instructional videos that provide insights into functionality and maintenance.

Books and Manuals: Look for comprehensive guides that cover both basic and advanced topics related to propulsion technology. These resources often include troubleshooting tips and detailed instructions.

Online Forums: Engaging with communities of enthusiasts can offer practical advice and shared experiences. These platforms allow you to ask questions and gain valuable knowledge from seasoned users.

Video Tutorials: Visual learners may benefit from step-by-step guides available on platforms like YouTube. These tutorials can clarify complex procedures and demonstrate best practices.

Manufacturer Websites: Official sites often provide downloadable resources, including product manuals and FAQs, which are crucial for understanding specific models and their unique features.

By utilizing these resources, you can delve deeper into the subject and gain the ultimate understanding necessary for effective operation and care.