Understanding the Motorcycle Clutch Parts Diagram

In the intricate world of two-wheeled machines, the functionality of various components is crucial for smooth operation and performance. This section explores the essential elements that facilitate power transfer, highlighting their roles and interactions.

Visual representation of these components provides a clearer understanding of their arrangement and function. By delving into the relationships among these vital elements, enthusiasts and mechanics alike can enhance their knowledge and skills.

Ultimately, a comprehensive grasp of these mechanisms not only aids in maintenance but also fosters a deeper appreciation for the engineering behind these remarkable vehicles. With clarity on their design and purpose, riders can ensure optimal performance and longevity.

Understanding Motorcycle Clutch Mechanics

This section explores the intricate workings behind the mechanism that enables seamless gear shifting in two-wheeled vehicles. By examining the components involved and their interactions, we gain insight into how power is transmitted from the engine to the wheels effectively.

Key Components Involved

- Friction Discs

- Pressure Plate

- Release Mechanism

- Spring System

How It Functions

- The engine generates power, which is directed towards the transmission.

- The friction discs engage and disengage to control this power flow.

- The pressure plate applies force to ensure smooth operation.

- The release mechanism allows for precise control during gear changes.

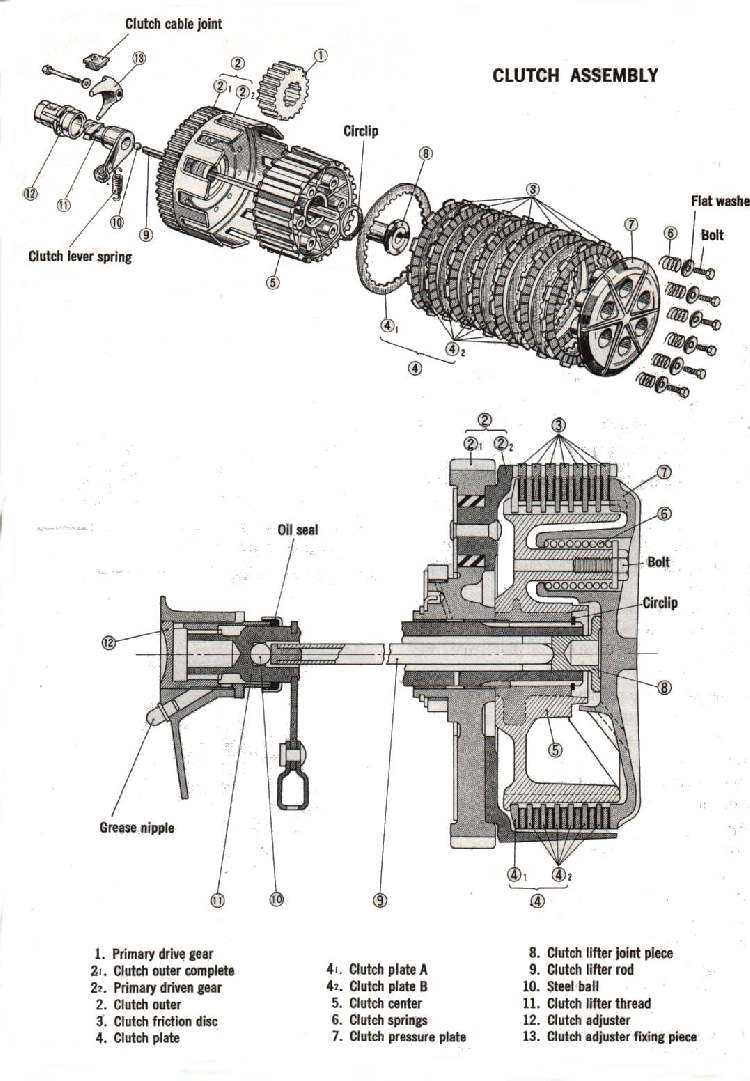

Components of a Clutch System

The functionality of a transmission mechanism relies on several essential elements that work together seamlessly. Understanding these components is crucial for effective maintenance and operation.

- Friction Discs: These components create the necessary grip to engage or disengage power transmission.

- Pressure Plate: This element applies force to the friction discs, ensuring proper engagement.

- Release Mechanism: It allows for the disconnection of the drive, enabling smooth gear changes.

- Flywheel: This part serves as a stable surface for engagement and helps maintain rotational momentum.

- Hydraulic or Cable Actuator: This mechanism facilitates the engagement and disengagement process.

Each of these elements plays a vital role in the overall efficiency and performance of the system, ensuring smooth operation and longevity.

Function of Each Clutch Part

This section explores the essential components of a transmission system and their respective roles in facilitating smooth engagement and disengagement of power between the engine and the wheels. Understanding how each element contributes to overall performance is crucial for effective maintenance and operation.

Key Components

| Component | Function |

|---|---|

| Friction Plate | Enables power transfer by creating friction against the pressure plate. |

| Pressure Plate | Holds the friction plate against the flywheel, maintaining connection. |

| Release Mechanism | Disengages the friction plate when the lever is activated. |

| Flywheel | Provides a surface for the friction plate to grip, storing rotational energy. |

Operational Significance

Each element works in harmony to ensure efficient transmission performance. When any component malfunctions, it can significantly affect the vehicle’s handling and responsiveness.

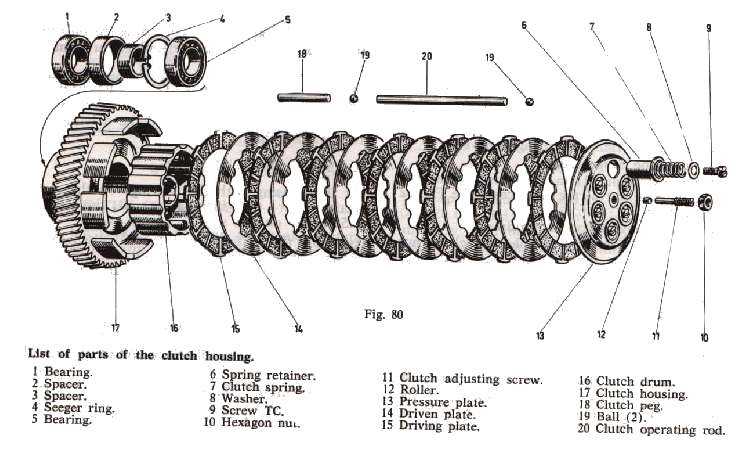

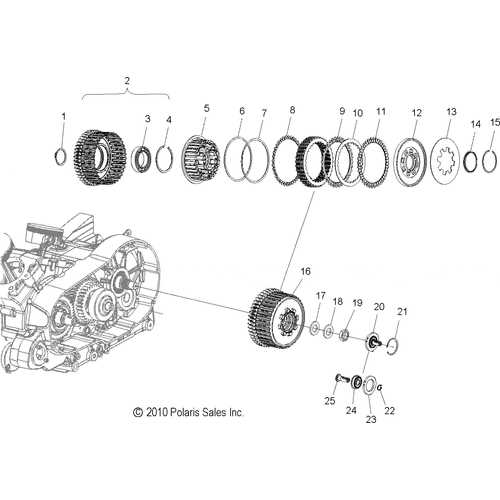

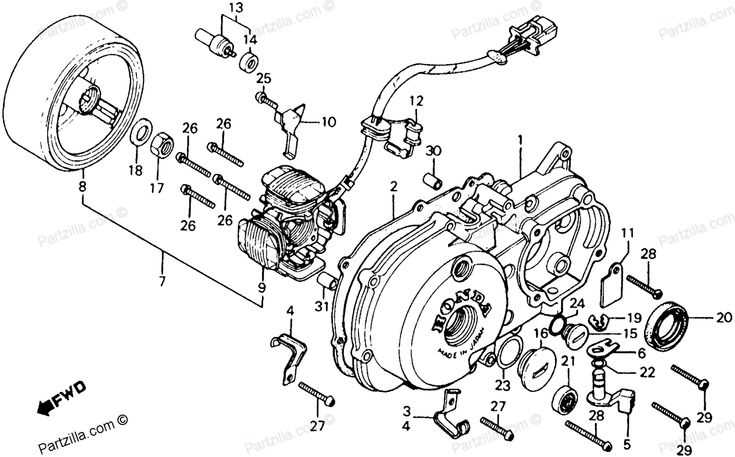

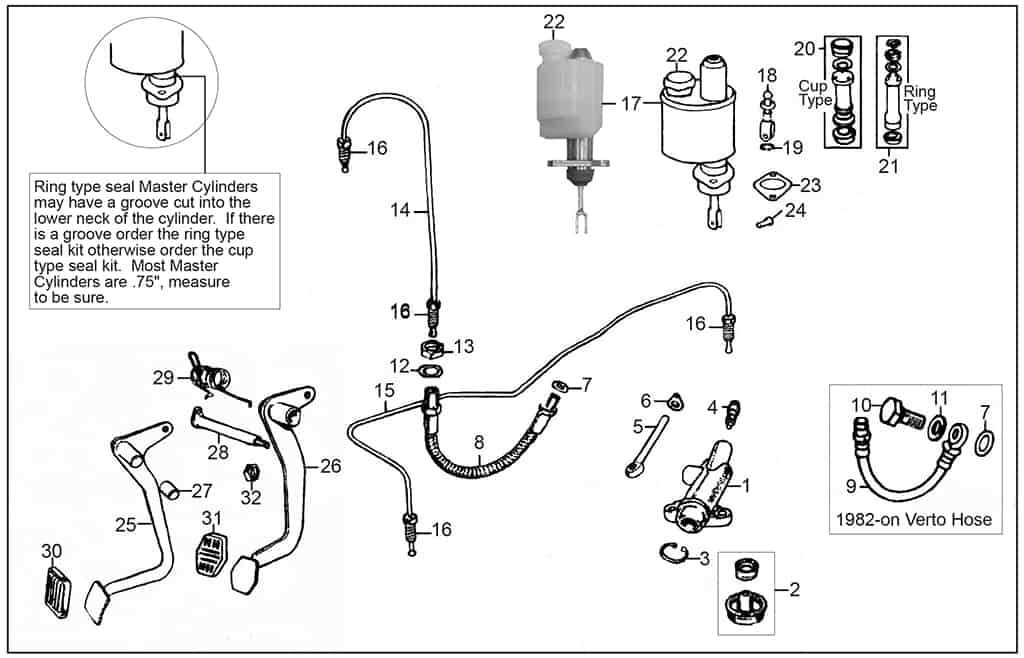

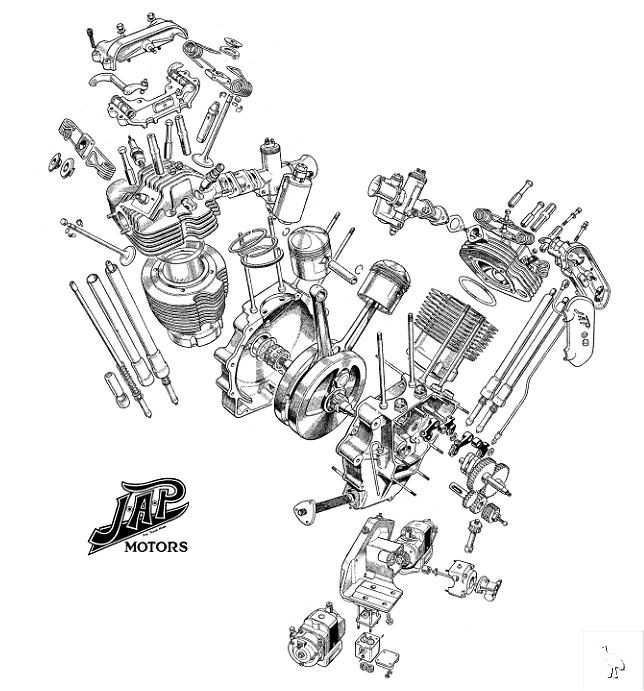

Visual Guide to Clutch Assembly

This section offers a comprehensive overview of the key components involved in the engagement and disengagement mechanism, essential for smooth operation. Understanding the configuration and function of each element is crucial for effective maintenance and troubleshooting.

Key Components

At the heart of this mechanism lies a series of interdependent elements that work together. These include the friction disks, springs, and a housing that secures the entire assembly. Each component plays a vital role in ensuring optimal performance and responsiveness.

Assembly Overview

When assembling the system, it’s important to follow the correct sequence to prevent any operational issues. Carefully aligning the components not only guarantees functionality but also enhances durability. Proper installation is the ultimate key to achieving a reliable setup.

Common Issues with Clutch Parts

Understanding the frequent challenges associated with engagement mechanisms is crucial for optimal performance. Various factors can lead to subpar functionality, affecting overall vehicle operation and safety. Identifying these issues can help in maintaining efficiency and prolonging the lifespan of the system.

Worn Components

Degradation of crucial elements often results from regular usage. Over time, friction surfaces may wear out, leading to difficulty in engagement or slipping. Regular inspections can prevent further damage and ensure seamless operation.

Hydraulic Problems

Fluid leaks and air in the hydraulic lines can significantly impact responsiveness. Addressing these issues promptly is essential to restore proper functioning and avoid more serious complications that could arise from neglect.

Maintenance Tips for Clutch Longevity

Ensuring the durability of your vehicle’s engagement system requires regular attention and care. Implementing specific maintenance practices can significantly extend its lifespan and enhance performance, reducing the risk of costly repairs.

Regular Inspections

Frequent evaluations are crucial. Look for signs of wear and tear, including unusual noises or changes in responsiveness. Addressing small issues early can prevent larger problems later.

Proper Lubrication

Maintaining optimal lubrication is essential for smooth operation. Use the recommended type of lubricant and check levels regularly to prevent friction-related damage.

| Tip | Description |

|---|---|

| Inspect Often | Check for signs of wear and listen for unusual sounds. |

| Keep Clean | Ensure the surrounding area is free from dirt and debris. |

| Adjust Tension | Maintain proper tension settings for optimal function. |

| Use Quality Fluids | Always opt for high-grade lubricants recommended by the manufacturer. |

Choosing the Right Clutch Components

Selecting the appropriate elements for your transmission system is crucial for optimal performance. The right choices can enhance efficiency and responsiveness, leading to a smoother ride.

Factors to Consider

- Material Quality: Ensure durability and longevity.

- Compatibility: Match components with your specific model.

- Performance Needs: Assess your riding style and conditions.

Types of Components

- Friction Discs

- Pressure Plates

- Release Mechanisms

By evaluating these factors and types, you can delve into the ultimate choices that best suit your needs, ensuring an effective and reliable setup.

Clutch Adjustment Techniques Explained

Achieving optimal performance in your two-wheeled vehicle often hinges on precise tuning of the engagement system. Understanding various methods to fine-tune this mechanism can greatly enhance ride quality and responsiveness.

Here are some key techniques to consider:

- Free Play Adjustment: Ensuring the correct amount of slack in the cable or mechanism is essential for smooth operation.

- Spring Tension Modification: Adjusting the tension of the springs can alter the engagement feel, providing a more responsive experience.

- Lever Position Change: Modifying the position of the lever can improve comfort and accessibility for the rider.

Implementing these techniques can lead to a more enjoyable and controlled ride, ultimately contributing to a better overall experience.

How Clutch Design Impacts Performance

The design of the disengagement mechanism plays a crucial role in the overall functionality and responsiveness of a two-wheeled vehicle. Various configurations can influence not only the efficiency of power transfer but also the rider’s control over acceleration and deceleration. Understanding these dynamics is essential for optimizing performance and enhancing the riding experience.

Key Design Elements

Several factors contribute to the effectiveness of this mechanism. Material choice significantly affects durability and heat resistance, while the spring tension influences the effort required for engagement. A well-engineered system allows for smoother transitions, providing the rider with greater confidence during maneuvers.

Performance Implications

When designed thoughtfully, the mechanism can enhance not only speed but also stability. For instance, a balanced assembly reduces vibrations, leading to a more comfortable ride. Additionally, advanced designs can improve responsiveness, enabling quick adjustments that are vital in competitive settings. Ultimately, the right configuration can transform the interaction between rider and machine, elevating the entire experience.

Upgrading Motorcycle Clutch Parts

Enhancing the performance of your two-wheeled machine can significantly improve your riding experience. By focusing on specific components of the transmission system, you can achieve better responsiveness, smoother shifts, and increased durability. This process not only boosts overall efficiency but also contributes to the longevity of your vehicle.

Benefits of Upgrading

Investing in superior components can lead to a remarkable transformation in handling and acceleration. High-quality replacements often offer enhanced friction characteristics and improved heat resistance. As a result, riders can enjoy a more exhilarating experience while maintaining control under various conditions.

Choosing the Right Components

When selecting new elements for your setup, consider factors such as compatibility, material quality, and design features. Aftermarket options may provide additional benefits compared to factory-installed equivalents. Pay attention to reviews and recommendations to ensure that your upgrades align with your riding style and performance goals.

Ultimately, thoughtful enhancements can elevate your machine’s capabilities, making every ride more enjoyable and engaging.

DIY Clutch Repair Basics

Understanding the fundamentals of maintaining your ride’s engagement mechanism can enhance performance and prolong its lifespan. With the right tools and knowledge, you can tackle common issues and ensure a smooth operation. This guide will help you navigate through essential techniques and troubleshooting steps.

Preparation is crucial before starting any repair. Gather necessary tools, including wrenches, screwdrivers, and a clean workspace. Familiarize yourself with the specific components involved to avoid confusion during the process.

One common issue is slipping. If you notice a lack of responsiveness, check for wear and tear on the essential elements. Replacing worn components can dramatically improve functionality. Additionally, ensure that the adjustment mechanism is properly set to allow optimal engagement.

Regular maintenance is key. Clean the parts periodically to prevent debris buildup that can lead to performance issues. Checking fluid levels and replacing them when necessary can also make a significant difference in efficiency.

By following these basic guidelines, you can confidently tackle repairs and ensure your machine remains in top shape. Remember, a well-maintained system not only enhances performance but also contributes to safety on the road.