Understanding the Motorguide W55 Parts Diagram

When it comes to maintaining and optimizing the performance of your electric propulsion system, having a clear grasp of its various elements is essential. Each component plays a vital role in ensuring efficiency and reliability, enabling smooth navigation on the water. Familiarity with these parts not only aids in troubleshooting but also enhances overall user experience.

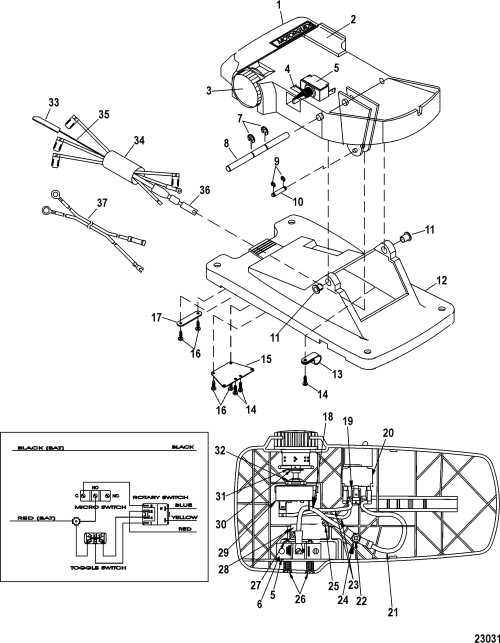

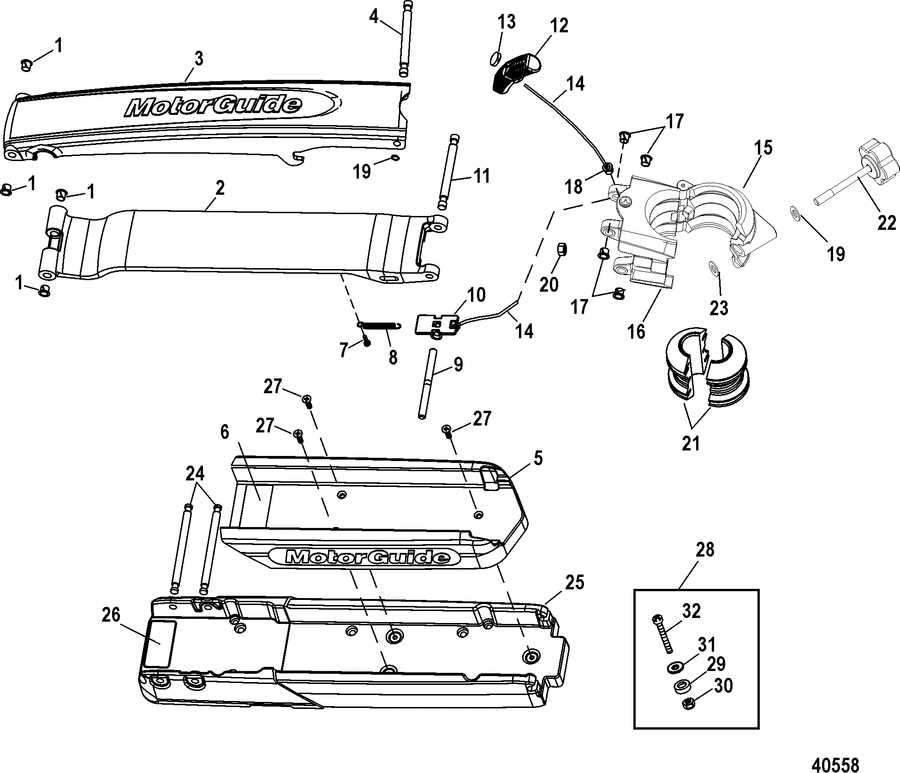

In this section, we will explore a detailed representation of the essential components that make up this technology. By breaking down each section, we aim to provide you with an informative reference that will assist in both maintenance and repair. Understanding how each piece interacts with the others is crucial for effective usage and longevity.

Whether you are a seasoned angler or a recreational boater, knowing the intricacies of your motor’s configuration can greatly enhance your time on the water. This knowledge empowers you to make informed decisions when it comes to repairs and upgrades, ensuring that your equipment remains in peak condition.

Understanding Motorguide W55 Components

In order to appreciate the functionality of electric propulsion systems, it is essential to familiarize oneself with the various elements that contribute to their operation. Each component plays a pivotal role, working in unison to ensure efficient performance on the water. A comprehensive understanding of these parts can enhance both maintenance practices and overall user experience.

Key Elements of the System

At the heart of any electric propulsion mechanism lies the motor, which converts electrical energy into mechanical motion. This is complemented by a series of connections and controls that allow users to manage speed and direction seamlessly. Additionally, propellers are crucial as they determine thrust and maneuverability, directly impacting how the vessel navigates through different water conditions.

Importance of Maintenance

Regular upkeep of these components is vital for longevity and efficiency. Over time, wear and tear can lead to performance degradation. Thus, inspecting and replacing parts as needed ensures that the system operates optimally. Understanding the role of each individual component aids in troubleshooting potential issues and enhances the overall reliability of the equipment.

Overview of W55 Parts Functionality

This section provides insight into the various components that contribute to the overall performance of the system. Each element plays a crucial role in ensuring efficient operation and reliability, catering to different operational needs and conditions.

The components work in harmony to enhance functionality, with specific roles that can significantly impact overall performance. Understanding these roles allows users to make informed decisions regarding maintenance and upgrades.

| Component | Function |

|---|---|

| Power Unit | Supplies energy for operation, converting electrical energy into mechanical force. |

| Steering Mechanism | Enables precise directional control, allowing for smooth navigation. |

| Propeller Assembly | Generates thrust to propel the system forward, designed for optimal efficiency. |

| Mounting Bracket | Secures the unit in place, providing stability during use. |

| Control Interface | Allows user interaction, enabling adjustments to speed and direction easily. |

By familiarizing oneself with these components and their functions, users can enhance their understanding and management of the entire system, leading to better performance and longevity.

Common Issues with W55 Components

Understanding the typical problems associated with certain components is essential for maintaining optimal performance. Many users encounter similar challenges that can hinder functionality and reduce efficiency. By identifying these common issues, individuals can take proactive measures to ensure their equipment operates smoothly.

Electrical Failures

One prevalent issue involves electrical malfunctions. Components may experience connectivity problems, leading to intermittent power loss or erratic performance. This can stem from corroded connectors or damaged wiring, necessitating thorough inspection and potential replacement to restore reliable operation.

Mechanical Wear and Tear

Mechanical parts are also prone to degradation over time. Regular use can result in excessive wear, which may cause components to become misaligned or fail altogether. Identifying signs of wear early, such as unusual noises or reduced efficiency, can prevent further damage and ensure longevity.

How to Access the Parts Diagram

Understanding the components of your equipment is essential for maintenance and repair. Accessing a visual representation of these elements can greatly assist in identifying parts and ensuring proper functionality. Here’s how you can obtain this valuable resource effectively.

Online Resources

The internet offers a wealth of information regarding various models and their respective components. Start by visiting manufacturer websites or authorized retailers, where you can often find downloadable resources. Search for your specific model to locate the relevant visual guides, which may be available in PDF format or as interactive tools.

User Manuals and Documentation

Importance of Regular Maintenance

Here are some key reasons why consistent maintenance is vital:

- Prolongs Lifespan: Routine care can significantly extend the life of machinery, saving money on replacements.

- Enhances Performance: Well-maintained equipment operates more efficiently, providing better results.

- Prevents Breakdowns: Regular checks can identify potential issues before they escalate into serious problems.

- Ensures Safety: Proper maintenance reduces the risk of accidents and ensures that equipment operates safely.

- Saves Costs: Investing time in maintenance can reduce long-term expenses related to repairs and replacements.

In conclusion, prioritizing routine maintenance is a proactive approach that yields numerous benefits, ensuring that machinery runs smoothly and effectively over time.

Identifying Replacement Parts Needed

When it comes to maintaining your equipment, recognizing the components that require substitution is essential for optimal performance. This process ensures that your machine operates smoothly and efficiently, preventing potential issues in the future. Here’s how to systematically determine what you need for repairs or upgrades.

Steps to Identify Components

- Review the User Manual: Start by consulting the manual that came with your device. It often contains valuable information about component specifications and troubleshooting guidelines.

- Inspect the Equipment: Conduct a thorough examination of your machine. Look for any signs of wear, damage, or corrosion that may indicate a need for replacement.

- Consult Online Resources: Utilize forums and websites dedicated to your device type. Users often share their experiences, providing insight into common issues and the parts that typically need replacement.

- Seek Professional Advice: If you’re uncertain, consider reaching out to a technician or a specialist. Their expertise can guide you in pinpointing exactly what you need.

Common Components to Check

- Electrical Connections: Ensure all wiring is intact and connections are secure.

- Propulsion Mechanisms: Look for signs of wear in propellers or motors that may affect performance.

- Mounting Brackets: Inspect for any damages that could compromise stability.

- Control Units: Check for responsiveness and any visible defects in the control systems.

Step-by-Step Repair Guide

This section provides a comprehensive guide to assist you in the repair process of your watercraft’s propulsion system. By following these detailed steps, you can effectively troubleshoot common issues and ensure optimal performance.

Begin by gathering all necessary tools and components. A well-organized workspace will make the process smoother and more efficient. Carefully review the manufacturer’s manual to familiarize yourself with the system’s layout and functions.

Next, identify the symptoms your equipment is exhibiting. Common issues may include unusual noises, lack of responsiveness, or electrical failures. Document these signs as they will help in diagnosing the problem accurately.

Once you have a clear understanding of the symptoms, proceed to disassemble the relevant sections. Take note of the order and orientation of each component, as this will be crucial for reassembly. Use labeled containers to keep small parts organized.

After disassembly, inspect each piece for wear and damage. Look for cracks, corrosion, or other signs of deterioration. Replace any faulty components with high-quality replacements to ensure longevity and reliability.

Before reassembling, clean all parts thoroughly. Remove any debris or residue that may hinder performance. Reassemble the system in the reverse order of disassembly, making sure all connections are secure and properly aligned.

Finally, conduct a series of tests to confirm that the repairs were successful. Monitor the system closely during initial use to catch any lingering issues early. Regular maintenance checks will help prolong the life of your equipment and keep it operating at peak efficiency.

Best Practices for Parts Installation

When it comes to assembling components of your equipment, following established guidelines can significantly enhance performance and longevity. Proper techniques not only ensure a smooth installation process but also minimize the risk of damage or malfunctions in the future. This section outlines key recommendations to optimize your setup.

| Practice | Description |

|---|---|

| Read the Manual | Always start by reviewing the manufacturer’s instructions to understand specific requirements and recommendations for your equipment. |

| Gather the Right Tools | Ensure you have all necessary tools on hand before beginning. Using the correct tools can prevent damage to components and make the process smoother. |

| Inspect Components | Check all items for any signs of wear or damage prior to installation. Replacing worn parts can prevent future issues. |

| Follow Sequential Steps | Adhere to the recommended order of assembly to ensure that each component fits correctly and functions as intended. |

| Ensure Proper Alignment | Double-check that all pieces are aligned properly before securing them. Misalignment can lead to operational problems. |

| Torque Specifications | Use a torque wrench to apply the correct amount of force when securing screws and bolts to avoid stripping or damaging threads. |

| Test Functionality | After installation, perform a thorough check to ensure everything is working correctly. Address any issues immediately. |

By adhering to these practices, you can achieve a successful installation that enhances the reliability and efficiency of your equipment.

Where to Purchase Genuine Parts

Finding authentic components for your equipment is crucial for ensuring optimal performance and longevity. Whether you’re looking to replace a worn-out piece or upgrade your setup, sourcing the right items from reliable vendors is essential.

Here are some recommended places to consider for your purchases:

- Official Retailers: Always start with authorized dealers who specialize in marine gear. They often carry a full range of genuine items and can provide expert advice.

- Online Marketplaces: Websites dedicated to boating accessories frequently offer a wide selection of original merchandise. Ensure you check seller ratings and reviews.

- Manufacturer’s Website: Directly purchasing from the brand’s online store guarantees you’re getting authentic items. It’s also a good way to find the latest products.

- Local Marine Supply Stores: Visiting a nearby shop can provide immediate access to components. Staff members can help you find exactly what you need.

- Boat Shows and Expos: Attending these events can connect you with suppliers who showcase genuine offerings and sometimes provide exclusive deals.

Remember, using authentic components not only enhances the efficiency of your equipment but also maintains safety standards. Make sure to verify the authenticity of any item before making a purchase.

Tips for Troubleshooting Electrical Issues

When dealing with electrical systems, encountering problems is not uncommon. Understanding how to systematically identify and resolve these issues can save time and enhance performance. The following tips offer a structured approach to diagnosing electrical failures, ensuring that you can get back to enjoying your equipment without unnecessary delays.

Step-by-Step Diagnosis

Begin by following a logical sequence to pinpoint the issue. Here’s a simple checklist to guide your troubleshooting process:

| Step | Action |

|---|---|

| 1 | Check for visible damage or wear on cables and connectors. |

| 2 | Test the power source to ensure it is functioning correctly. |

| 3 | Use a multimeter to check for continuity and voltage in circuits. |

| 4 | Inspect all fuses and circuit breakers for faults. |

| 5 | Consult any available manuals or technical documents for specific guidance. |

Common Issues and Solutions

Identifying frequent problems can also streamline your troubleshooting efforts. Here are some typical electrical issues along with potential remedies:

| Issue | Possible Solution |

|---|---|

| Device not powering on | Check connections and replace blown fuses. |

| Intermittent functionality | Inspect for loose wires or corroded terminals. |

| Excessive heat | Ensure proper ventilation and check for overloaded circuits. |

| Unusual noises | Look for obstructions and verify all components are securely fastened. |

Comparing W55 with Other Models

When evaluating different electric propulsion systems, it’s essential to consider the unique features and capabilities of each model. This analysis highlights the distinctions between a specific model and its competitors, focusing on performance, efficiency, and user experience. Understanding these differences can help users make informed choices based on their specific needs and preferences.

| Feature | Model A | Model B | Model C |

|---|---|---|---|

| Power Output | 55 lbs | 60 lbs | 50 lbs |

| Control Type | Hand Control | Foot Control | Remote Control |

| Battery Efficiency | High | Medium | High |

| Weight | 30 lbs | 35 lbs | 28 lbs |

| Price Range | $$ | $$$ | $ |

In summary, examining various models reveals significant differences in power, control options, and overall design. This comparative analysis provides valuable insights for users seeking the most suitable solution for their boating needs.

Resources for Further Assistance

When it comes to seeking help with specific equipment and components, having access to reliable resources can make all the difference. Various platforms and materials are available to assist users in understanding, repairing, or upgrading their devices effectively. Below are some valuable avenues to explore for guidance and information.

Online Forums and Communities

Participating in dedicated online forums can provide insights from fellow enthusiasts and experts. These communities often share personal experiences, troubleshooting tips, and advice on maintenance and improvements.

Manufacturer Support and Documentation

Directly reaching out to the manufacturer can yield official resources such as manuals and technical guides. These documents often contain detailed information about the equipment, including assembly instructions and maintenance protocols.

| Resource Type | Description |

|---|---|

| Online Forums | Platforms where users share experiences and solutions. |

| Manufacturer Documentation | Official manuals and guides provided by the maker. |

| Video Tutorials | Visual aids available on platforms like YouTube for hands-on guidance. |

| Local Repair Shops | Professional services that can assist with repairs and maintenance. |