Comprehensive Guide to Bobcat Zero Turn Mower Parts Diagram

For enthusiasts and professionals alike, maintaining and operating your landscaping equipment efficiently hinges on a thorough understanding of its individual elements. Each component plays a vital role in the overall performance, contributing to the machine’s functionality and longevity.

In this section, we will explore the intricate relationships among various mechanisms within the apparatus. Recognizing how each piece interacts not only enhances operational knowledge but also aids in troubleshooting and repair efforts.

Arming yourself with this knowledge is the ultimate step toward achieving optimal performance and ensuring that your investment stands the test of time. Join us as we delve into the essential components, their locations, and their purposes.

Understanding Bobcat Zero Turn Mowers

This section explores the mechanics and functionalities of high-performance landscaping equipment designed for efficient navigation and maneuverability. These machines are engineered to provide exceptional control, making them ideal for various tasks in outdoor maintenance and turf management.

Key Features

Advanced models incorporate various innovative elements that enhance user experience and productivity. Notable features often include precision steering systems, powerful engines, and ergonomic designs.

Maintenance Essentials

Regular upkeep is crucial for longevity and optimal performance. Essential maintenance tasks often involve checking fluid levels, inspecting blades, and ensuring all components are functioning smoothly.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 50 hours |

| Blade Sharpening | Every 25 hours |

| Filter Replacement | Every 100 hours |

Components of a Zero Turn Mower

Understanding the various elements that make up a contemporary lawn care machine is essential for effective maintenance and operation. Each component plays a critical role in ensuring efficiency and maneuverability, allowing users to achieve a pristine landscape with ease.

- Chassis: The frame serves as the foundational structure, supporting all other elements.

- Engine: This powerhouse drives the machine, providing the necessary horsepower for cutting grass and navigating terrain.

- Transmission: This system enables seamless movement and direction changes, crucial for intricate landscaping tasks.

- Deck: The cutting apparatus, typically adjustable, determines the height and quality of the cut.

- Wheels: These components are designed for superior traction and stability, allowing for smooth operation over various surfaces.

Additional features often include:

- Controls: User-friendly interfaces facilitate precision steering and speed adjustment.

- Seat: Ergonomically designed for comfort during extended use.

- Fuel System: Ensures efficient energy delivery, impacting overall performance.

Familiarity with these key elements enhances the user experience, ensuring the machine operates optimally and effectively meets the demands of lawn care.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the prolonged functionality and efficiency of any equipment. By prioritizing maintenance, users can significantly enhance the lifespan of their machinery, preventing unexpected breakdowns and costly repairs. This proactive approach not only safeguards the investment but also contributes to optimal performance over time.

Benefits of Consistent Care

Consistent maintenance yields a multitude of advantages. First and foremost, it helps identify and address minor issues before they escalate into major problems. Routine inspections allow operators to spot wear and tear, ensuring timely interventions. Moreover, maintaining clean and lubricated components enhances overall efficiency, leading to improved fuel consumption and reduced operational costs.

Strategies for Effective Maintenance

Implementing a structured maintenance plan is crucial. This includes scheduled cleaning, lubrication, and replacement of worn components. Utilizing manufacturer guidelines can provide a clear roadmap for necessary actions. Additionally, keeping detailed records of maintenance activities can aid in tracking performance and anticipating future needs, ensuring that equipment remains reliable and effective for years to come.

Common Issues with Bobcat Mowers

When it comes to maintaining high-performance landscaping equipment, operators often encounter various challenges that can hinder efficiency and productivity. Understanding these common problems is essential for effective troubleshooting and preventive maintenance. Below are some frequently reported issues that users might face.

Engine Performance Problems

One of the primary concerns is related to engine functionality. Operators may notice symptoms such as difficulty starting, irregular idling, or reduced power during operation. These issues can arise from several factors, including fuel quality, air filter blockages, or ignition system malfunctions. Regular inspections and timely replacements can mitigate these problems.

Hydraulic System Failures

Another critical area of concern is the hydraulic system. Leaks, sluggish response, or erratic movement often indicate underlying issues. Common culprits include worn hoses, loose connections, or low fluid levels. Addressing these problems promptly can prevent more severe damage and ensure smooth operation.

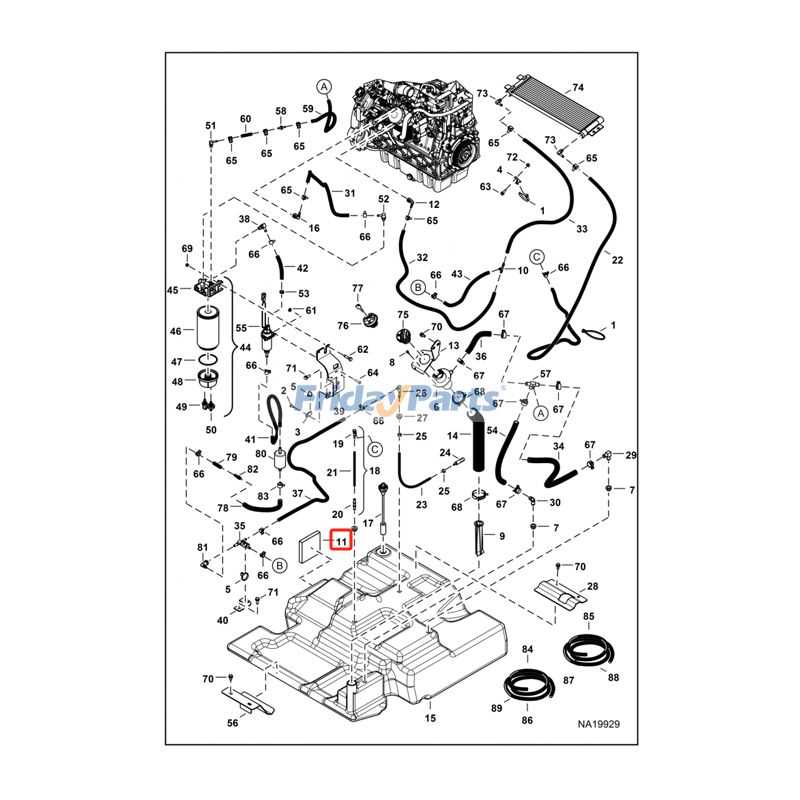

Parts Identification in Diagrams

Understanding the various components illustrated in technical drawings is essential for effective maintenance and repair. Each visual representation serves as a guide, allowing users to pinpoint specific elements and their functions within the overall system. This knowledge not only enhances operational efficiency but also aids in troubleshooting potential issues.

When examining these illustrations, it is crucial to recognize the following key aspects:

- Labels: Clear identifiers help distinguish each element, making it easier to refer to them in discussions or when ordering replacements.

- Symbols: Standardized graphics often represent specific functions or types of components, providing a universal language for understanding machinery.

- Color Coding: Different hues may indicate various categories or statuses of elements, enhancing clarity in complex assemblies.

To effectively utilize these visuals, follow these steps:

- Start by familiarizing yourself with the overall layout of the illustration.

- Identify and memorize the key labels and symbols used throughout the drawing.

- Cross-reference the visual with the service manual or parts list to confirm the specifics of each component.

In summary, mastering the art of interpreting technical illustrations can significantly streamline the maintenance process and ensure a deeper understanding of the machinery in question.

How to Replace Worn Parts

Maintaining your equipment’s performance is crucial for longevity and efficiency. When components show signs of wear, timely replacement can prevent further damage and ensure smooth operation. This guide outlines the necessary steps to effectively swap out old elements with new ones, promoting optimal functionality.

Before starting, gather the appropriate tools and replacement components. Always consult the manufacturer’s guidelines for specific details on the required items. Familiarize yourself with the layout of your equipment, as this will simplify the process and help avoid any unnecessary complications.

Begin by safely powering down the machine and disconnecting it from any power sources. Next, remove any protective coverings to access the worn components. Carefully detach the old parts, taking note of how they are connected to facilitate proper installation of the new items.

Once the worn components are removed, install the replacements, ensuring they fit snugly and are aligned correctly. After securing them, reassemble any protective coverings and reconnect the power source. Finally, conduct a thorough inspection to confirm everything is functioning as intended before returning the equipment to regular use.

Finding Authentic Replacement Parts

Ensuring the longevity and performance of your equipment relies heavily on sourcing genuine components. Identifying authentic replacements not only enhances functionality but also guarantees compatibility and durability. In this section, we will explore the best practices for locating reliable sources and verifying the authenticity of the items you intend to purchase.

Research Reputable Suppliers

Begin by seeking out established vendors who specialize in original components. Look for companies with positive reviews and a strong reputation in the industry. Checking their credentials and customer feedback can provide insight into their reliability.

Verify Product Authenticity

Once you’ve found potential suppliers, it’s crucial to confirm that the items they offer are genuine. Look for labels, serial numbers, or certification marks that indicate authenticity. Additionally, contacting the manufacturer directly can help ensure you are purchasing legitimate products.

Diagram Navigation Tips for Users

Understanding the layout of technical illustrations can greatly enhance your experience when maintaining or repairing machinery. Proper navigation through these visuals allows users to quickly locate components and grasp their relationships within the system.

Familiarize Yourself with Legends

Always start by reviewing any legends or keys provided. These tools clarify symbols and terminology used in the illustration, making it easier to understand the layout and connections.

Zoom In for Detail

Utilizing zoom features on digital platforms can reveal intricate details that are often overlooked. This close-up view assists in identifying smaller elements and can be crucial for accurate assembly or troubleshooting.

Upgrades for Enhanced Performance

Enhancing the efficiency and functionality of your outdoor equipment can significantly improve its overall performance. By investing in specific upgrades, you can elevate productivity, extend lifespan, and ensure a smoother operation. Below are some recommended modifications that can provide substantial benefits.

| Upgrade | Description | Benefits |

|---|---|---|

| High-Performance Blades | Replace standard blades with specialized designs for better cutting efficiency. | Improved cutting quality and reduced fuel consumption. |

| Advanced Suspension System | Install a premium suspension system for a smoother ride. | Increased comfort and better handling on uneven terrain. |

| Upgraded Engine | Consider a more powerful engine for enhanced performance. | Greater speed and torque for tougher tasks. |

| Enhanced Air Filtration | Upgrade to a high-efficiency air filter. | Improved engine performance and longevity. |

Safety Features of Bobcat Mowers

Ensuring operator safety is a top priority in modern landscaping equipment design. Advanced safety mechanisms are integrated to minimize risks during operation, providing users with peace of mind while handling powerful machinery. Understanding these features is crucial for safe and efficient usage.

Emergency Stop Mechanisms

One of the key safety innovations is the emergency stop system, which allows the operator to quickly halt all functions in case of an unexpected situation. This feature is typically activated by a simple lever or button, ensuring immediate response time. The accessibility of this control is vital, enabling users to act swiftly to prevent accidents.

Operator Presence Controls

Another important aspect is the operator presence control. This technology requires the user to maintain contact with designated controls to keep the machine operational. If the operator steps away or loses grip, the equipment automatically shuts off, significantly reducing the chance of injury. Such mechanisms are designed to promote safe handling and awareness of the working environment.

Benefits of Using Zero Turn Mowers

Employing a specialized lawn care machine offers numerous advantages that enhance efficiency and effectiveness in maintaining outdoor spaces. These benefits appeal to both residential and commercial users, making them a preferred choice for many landscapers.

- Increased Maneuverability: The unique design allows for sharp turns and agile movement around obstacles, making it ideal for complex landscapes.

- Time Efficiency: With faster speeds and superior handling, users can complete mowing tasks more quickly, freeing up time for other activities.

- Improved Cutting Precision: Enhanced control leads to cleaner lines and a more professional finish, elevating the appearance of lawns.

- Comfortable Operation: Ergonomically designed seats and controls reduce operator fatigue, making long mowing sessions more manageable.

- Versatility: These machines can easily adapt to various attachments and accessories, expanding their functionality for different tasks.

Overall, utilizing a specialized machine for lawn care significantly enhances the mowing experience, offering practical solutions for achieving a well-groomed landscape.

Frequently Asked Questions about Parts

This section addresses common inquiries regarding components and their maintenance. Understanding these elements is crucial for ensuring optimal performance and longevity of your equipment.

What should I do if a component is damaged?

If you notice any damage, it’s essential to replace the component immediately to avoid further issues. Consult the manual or a professional for guidance on compatible replacements.

How can I identify the correct component for my equipment?

To identify the right element, refer to your user manual or search online using the model number. This will help you find specifications and compatibility for your specific machine.