Bush Hog Mower Parts Diagram

In the realm of lawn maintenance, having a comprehensive grasp of the machinery’s internal elements is essential for optimal performance. Recognizing how each component interacts can greatly enhance efficiency and ensure long-lasting functionality. This section delves into the intricacies of a specific type of cutting apparatus, providing valuable insights into its construction and design.

Maintenance and repairs are crucial for extending the lifespan of any outdoor equipment. By familiarizing oneself with the arrangement of various elements, operators can swiftly identify issues and implement effective solutions. This knowledge not only contributes to smoother operations but also fosters a sense of confidence when handling the machinery.

Moreover, understanding the layout of the components can assist users in selecting suitable replacements and performing upgrades. As technology advances, newer designs may offer improved performance and durability. Thus, exploring the essential features of such equipment is a worthwhile endeavor for anyone dedicated to maintaining their outdoor spaces.

This section provides a comprehensive overview of the essential elements that comprise a typical grass-cutting machine. Each component plays a vital role in ensuring efficient operation and maintenance. Understanding these elements is crucial for both novice and experienced users looking to enhance their knowledge and manage their equipment effectively.

- Overview of Cutting Machinery

This section outlines the various types of cutting devices and their applications in landscaping and agricultural settings.

- Engine Functions

Detailing the importance of the engine in providing the necessary power for operation, along with maintenance tips.

- Cutting Deck Description

Explaining the significance of the cutting deck’s design and how it influences performance and grass quality.

- Blades and Their Types

Discussing various blade designs and their impact on cutting efficiency and grass types.

- Transmission System Insights

Describing how the transmission system transfers power from the engine to the wheels and blades, affecting speed and control.

- Wheel and Tire Specifications

Examining the role of wheels and tires in maneuverability and stability on different terrains.

- Chassis Structure

Highlighting the importance of a robust chassis in supporting various components and ensuring durability.

- Safety Features

Reviewing essential safety mechanisms that protect users during operation.

- Electrical Systems Overview

Detailing the electrical components that power lights, ignition systems, and other features.

- Maintenance Practices

Providing insights into routine maintenance tasks to prolong the lifespan of the machine.

- Common Issues and Troubleshooting

Listing frequent problems encountered with cutting devices and their potential solutions.

Key Parts of a Bush Hog Mower

The efficiency and functionality of a cutting tool rely heavily on its essential components. Understanding these elements can greatly enhance maintenance and performance, ensuring optimal operation in various conditions.

Below are some crucial elements that contribute to the overall effectiveness of this equipment:

- Deck: The robust structure that houses the blades, providing stability and support during operation.

- Blades: Sharp cutting edges that perform the actual trimming, available in various shapes and sizes for different tasks.

- Spindle: The rotating mechanism that drives the blades, crucial for achieving the desired cutting speed.

- Gearbox: This component transmits power from the engine to the blades, allowing for efficient operation.

- Wheels: Essential for mobility, enabling the tool to navigate various terrains effortlessly.

- Safety Guards: Protective barriers that ensure safe operation by preventing debris from flying out during use.

Familiarizing oneself with these vital components aids in effective maintenance and troubleshooting, ultimately extending the lifespan of the equipment.

Identifying Mower Blade Types

Understanding the various blade configurations is essential for optimizing the performance of cutting equipment. Different designs serve distinct purposes, influencing the efficiency and effectiveness of the cutting process. Recognizing these variations can significantly enhance your experience and results when maintaining your landscape.

Common Blade Designs

Several typical blade types are prevalent, each engineered for specific tasks. Standard blades are designed for general use, providing a balanced cut for various grass types. In contrast, high-lift blades are ideal for lifting clippings away from the cutting deck, promoting better airflow and preventing clogging.

Specialized Blade Options

For those looking for enhanced performance, mulching blades excel at finely chopping grass clippings, allowing for better decomposition and nutrient return to the soil. Meanwhile, rough-cut blades are tailored for tackling taller, thicker vegetation, making them suitable for overgrown areas.

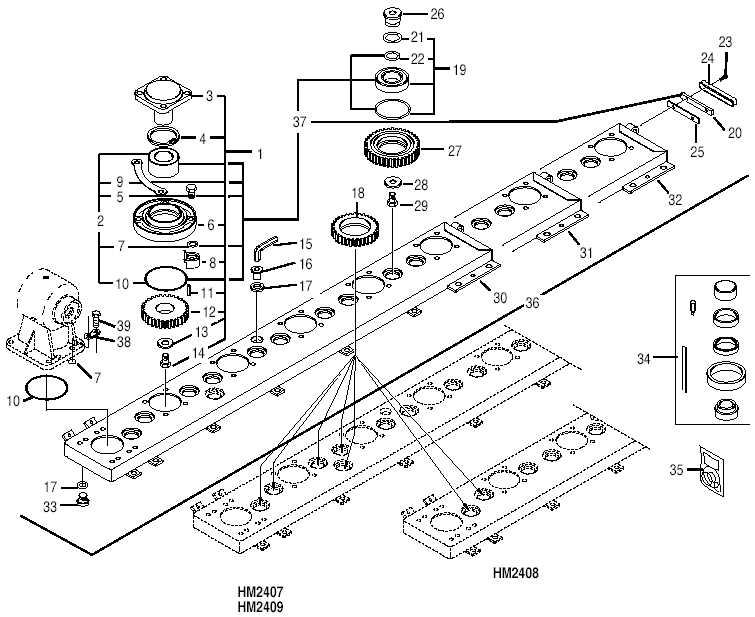

Importance of Gear Assembly

The gear assembly plays a crucial role in the functionality of various machinery, serving as the backbone that enables efficient power transmission and operational effectiveness. This component ensures that the rotational motion generated by the engine is effectively transferred to the necessary mechanisms, allowing the equipment to perform its intended tasks.

Understanding the significance of the gear assembly is essential for proper maintenance and operation. A well-functioning gear system contributes to improved performance, enhanced longevity, and reduced wear and tear on other components. Moreover, it aids in optimizing energy consumption, which can lead to cost savings over time.

Regular inspection and maintenance of the gear assembly can prevent potential issues that may arise due to wear, misalignment, or lubrication deficiencies. By prioritizing the health of this assembly, operators can ensure their machinery operates smoothly and efficiently, minimizing downtime and maximizing productivity.

Maintenance of Drive Belts

Regular upkeep of the drive belts is essential for the efficient operation of your equipment. Proper care not only extends the lifespan of the belts but also enhances overall performance. Understanding the maintenance procedures can help prevent unnecessary breakdowns and ensure smooth functionality.

Inspection

Conducting regular inspections is crucial. Look for signs of wear or damage, such as cracks, fraying, or glazing. An early assessment can save time and resources in the long run. Here are some key points to check:

- Inspect for visible wear patterns.

- Check tension levels to ensure proper fit.

- Look for signs of slipping or noise during operation.

Replacement and Adjustment

If you notice significant damage or if the belts are worn beyond usability, replacement is necessary. Proper tension adjustment is also vital to maintain optimal performance. Follow these steps for effective replacement:

- Disconnect the power source for safety.

- Remove the old belt carefully.

- Install the new belt, ensuring it is aligned correctly.

- Adjust the tension according to the manufacturer’s specifications.

- Reconnect the power and test the equipment.

Fuel System Overview

The fuel system is a critical component in any engine-driven machinery, responsible for delivering the necessary fuel to ensure efficient operation. This system typically consists of various elements that work together to store, filter, and transport fuel to the engine, allowing it to function optimally. Understanding the basics of this system can greatly aid in maintaining performance and longevity.

Key Components

Central to the fuel system are several vital components, including the fuel tank, fuel pump, and fuel filter. The fuel tank stores the fuel required for operation, while the fuel pump ensures that fuel is effectively transported from the tank to the engine. Additionally, the fuel filter plays a crucial role in removing impurities, preventing clogging and ensuring a steady fuel supply.

Importance of Maintenance

Regular maintenance of the fuel system is essential to avoid issues such as fuel leaks and engine performance problems. Keeping the fuel tank clean and ensuring that the pump and filter are functioning properly can enhance efficiency and reduce the likelihood of costly repairs. Proper care contributes significantly to the overall health of the machinery.

Electrical Components Explained

The functioning of machinery relies heavily on various electrical elements that ensure smooth operation and reliability. Understanding these components is crucial for anyone involved in maintenance or repair, as they play a vital role in the overall efficiency of the equipment.

Power Supply: This component serves as the primary source of energy for the machine, converting electrical energy into usable power. It is essential for providing consistent voltage levels to keep all systems operational.

Switches: These devices control the flow of electricity, allowing users to turn the equipment on or off as needed. They can be simple toggles or complex circuit breakers that prevent overload.

Sensors: Equipped with the ability to detect various conditions, sensors play a significant role in automating functions and ensuring safety. They can monitor temperature, pressure, and other critical parameters, providing real-time feedback to the operator.

Wiring Harness: This assembly of wires connects different electrical components, facilitating the transfer of power and signals throughout the machine. A well-organized harness is crucial for efficient performance and ease of troubleshooting.

Relays: These electromagnetic switches control larger currents with lower power signals, making them essential for activating high-power components without direct manual intervention.

By familiarizing oneself with these electrical components, users can enhance their understanding of how their machinery operates, leading to more effective maintenance and troubleshooting practices.

Understanding Hydraulic Systems

Hydraulic systems play a crucial role in various machinery, providing the necessary force for efficient operation. By utilizing fluid power, these systems convert energy into motion, enabling complex tasks to be performed with relative ease. Understanding the fundamentals of hydraulic technology can significantly enhance maintenance and operational efficiency.

Key Components of Hydraulic Systems

A hydraulic system consists of several essential elements that work together to facilitate fluid movement and pressure management:

- Hydraulic Fluid: The medium through which power is transmitted, typically oil, which also lubricates components.

- Pump: Converts mechanical energy into hydraulic energy, creating flow within the system.

- Actuators: Devices such as cylinders and motors that convert hydraulic energy back into mechanical energy.

- Valves: Control the flow and direction of hydraulic fluid, ensuring proper function and safety.

Benefits of Hydraulic Systems

The advantages of utilizing hydraulic technology include:

- High Power Density: Hydraulic systems can produce a large amount of power relative to their size.

- Precision Control: These systems allow for accurate movement and positioning, crucial for various applications.

- Versatility: Hydraulics can be adapted for numerous tasks across different industries.

- Durability: With proper maintenance, hydraulic systems can operate effectively for many years.

Common Replacement Parts

Regular maintenance of equipment is crucial for optimal performance. Over time, certain components may wear out and require substitution to ensure smooth operation. Understanding which elements commonly need replacement can help you maintain efficiency and extend the lifespan of your machinery.

Essential Components for Maintenance

Blades: Sharp blades are vital for effective cutting. Dull or damaged blades can lead to uneven results and may stress the engine. It’s advisable to inspect and replace blades periodically to maintain optimal cutting performance.

Drive Belts and Cables

Drive belts: These are essential for transferring power from the engine to the cutting mechanism. Worn or frayed belts can slip, causing reduced functionality. Regular checks and timely replacement can prevent performance issues. Additionally, cables that control various functions may also require occasional substitution to ensure precise operation.

Troubleshooting Mower Issues

Identifying and resolving operational problems can significantly enhance the efficiency and longevity of your cutting equipment. Various issues may arise, ranging from mechanical failures to performance deficiencies. This section provides insight into common complications and practical solutions to ensure smooth operation.

Common Symptoms and Solutions

When the machine fails to start, check the fuel level and battery condition. A lack of fuel or a dead battery is often the culprit. If the equipment starts but runs poorly, inspect the air filter and spark plug for blockages or wear. Replacing these components can restore optimal performance.

Maintenance Tips

Regular maintenance is essential for preventing issues. Ensure to clean the blades frequently to avoid grass buildup, which can hinder cutting efficiency. Additionally, lubricate moving parts as recommended in the owner’s manual to minimize wear. Adopting these practices can help avoid many common problems and extend the lifespan of your equipment.

Assembly and Disassembly Tips

When working on machinery, understanding the assembly and disassembly process is crucial for maintenance and repairs. Proper techniques can ensure a smooth operation and prolong the lifespan of your equipment. This section provides essential strategies to facilitate these processes effectively.

Preparation is Key: Before starting, gather all necessary tools and materials. Ensure you have a clean workspace to avoid losing small components. Organizing parts in a logical order can save time and prevent confusion during reassembly.

Documenting the Process: Take pictures or notes as you disassemble the equipment. This documentation serves as a valuable reference for correctly reassembling it later. Additionally, labeling parts can help identify their placement and orientation.

Follow a Systematic Approach: Start by removing larger components first, gradually working towards smaller ones. This method reduces the risk of damaging fragile parts. When reassembling, reverse the order of disassembly, ensuring each piece fits snugly and securely.

Use Proper Techniques: Apply gentle pressure when disconnecting parts to avoid bending or breaking them. If a component is stuck, avoid using excessive force. Instead, use appropriate lubricants or tools designed for loosening tight fittings.

Safety Precautions: Always prioritize safety by wearing protective gear and ensuring the equipment is powered down before beginning. Keeping a well-lit and organized workspace reduces the risk of accidents and injuries.

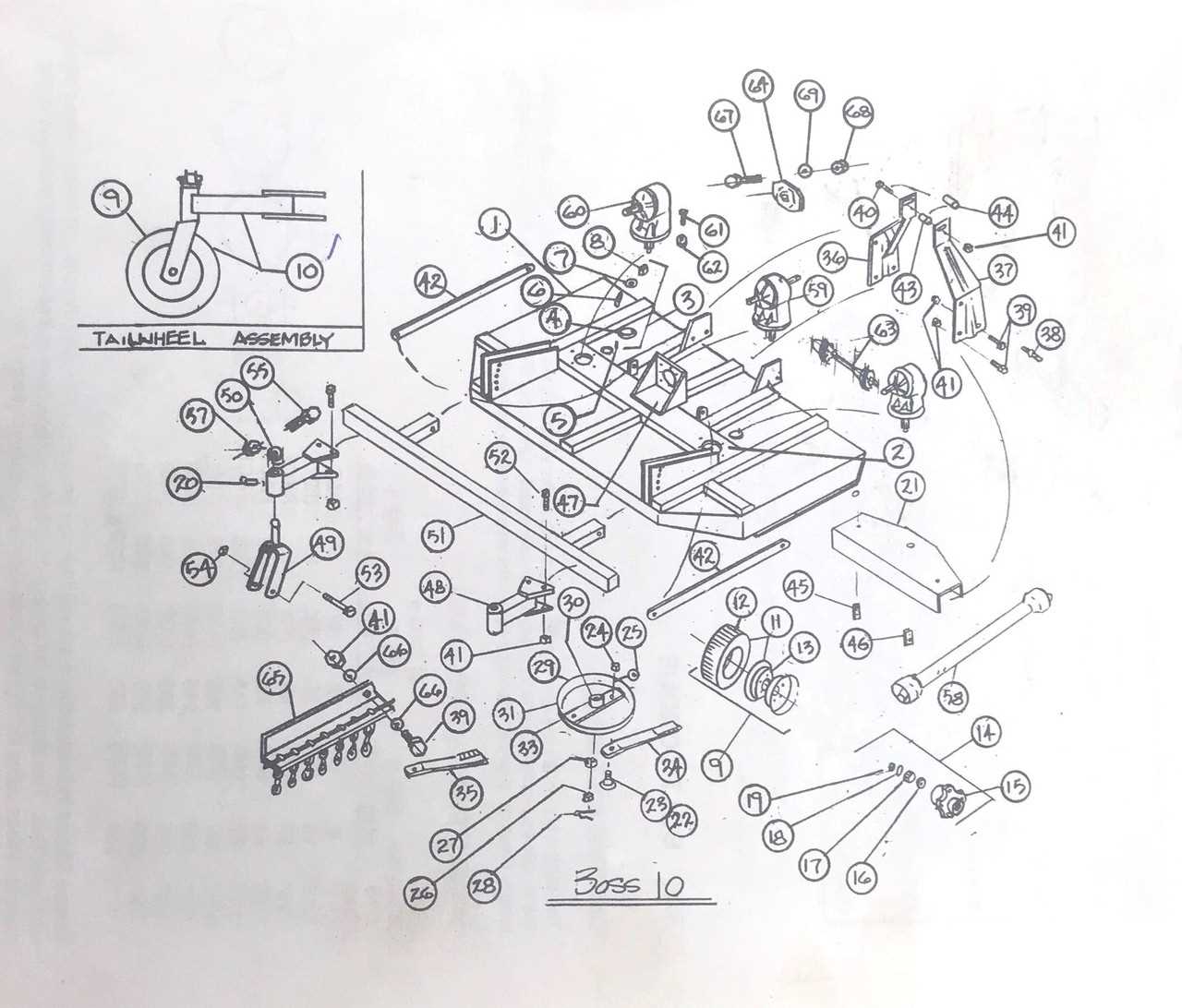

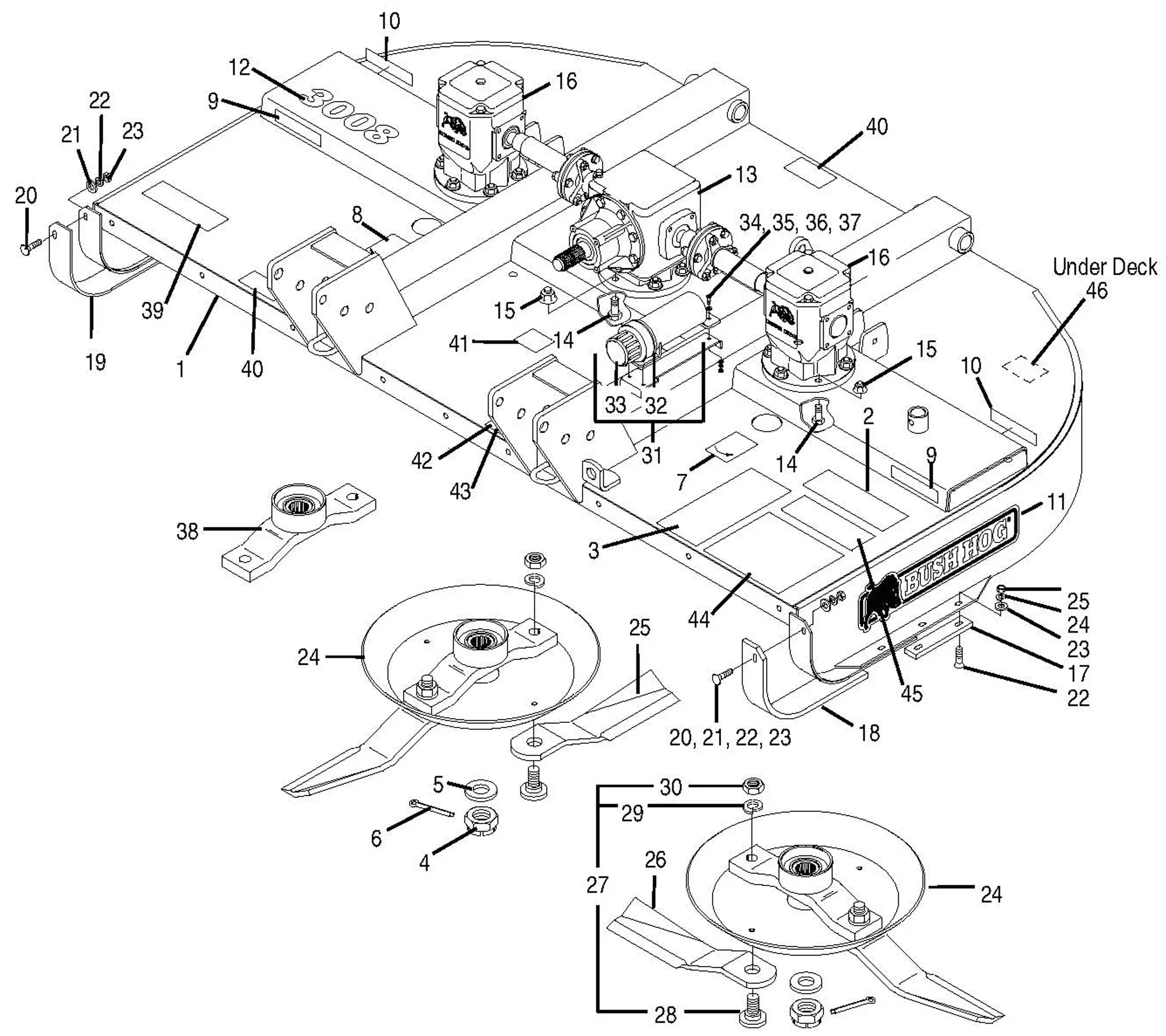

Parts Diagram Interpretation

Understanding the layout of components is crucial for effective maintenance and repair of machinery. A visual representation that outlines the various elements helps users identify each part’s role and location, facilitating smoother operations. This insight is essential for anyone looking to ensure optimal functionality.

Interpreting these visuals requires careful attention to detail. Each symbol or number typically corresponds to a specific element, providing guidance on assembly or disassembly. By familiarizing oneself with these representations, operators can navigate the intricacies of their equipment more efficiently.

Additionally, recognizing the relationships between different components can enhance troubleshooting efforts. When issues arise, a clear understanding of how parts interact allows for quicker diagnostics and targeted repairs. Thus, mastering the interpretation of these visuals is an invaluable skill for any equipment user.