Dixon ZTR Mower Parts Diagram Overview

When it comes to maintaining your outdoor space, the functionality of your machinery is crucial. A deep comprehension of the various elements that contribute to the overall operation can enhance performance and longevity. This section aims to demystify the intricate layout of these essential tools, providing valuable insights into their assembly and functionality.

Every piece of equipment is comprised of numerous components, each playing a pivotal role in ensuring smooth operation. By exploring the relationships between these elements, users can better troubleshoot issues and optimize maintenance routines. This knowledge empowers individuals to make informed decisions regarding repairs and replacements, ultimately leading to a more efficient lawn care experience.

In this exploration, we will break down the specific features and arrangements of these critical components. Whether you are a seasoned operator or a novice enthusiast, understanding how each part interacts within the whole system can significantly improve your ability to care for your lawn effectively. Join us as we delve into the detailed structure of your favorite outdoor machinery.

Dixon ZTR Mower Overview

This section offers a comprehensive understanding of a renowned line of garden maintenance equipment designed for efficiency and ease of use. These machines are engineered to provide exceptional maneuverability and cutting performance, making them ideal for both residential and commercial landscapes. Users can expect a blend of durability and innovation that ensures a pristine lawn with minimal effort.

Key Features

These innovative tools are equipped with a variety of features that enhance their functionality. Hydrostatic transmission allows for seamless speed adjustments, while the robust cutting deck ensures a clean and precise trim. Additional functionalities include adjustable seating and ergonomic controls, providing comfort during extended use.

Maintenance and Care

Regular upkeep is essential for maximizing the lifespan and performance of these machines. It is advisable to routinely check oil levels, sharpen blades, and clean the undercarriage to prevent debris buildup. Following the manufacturer’s recommendations for service intervals will help maintain optimal operation.

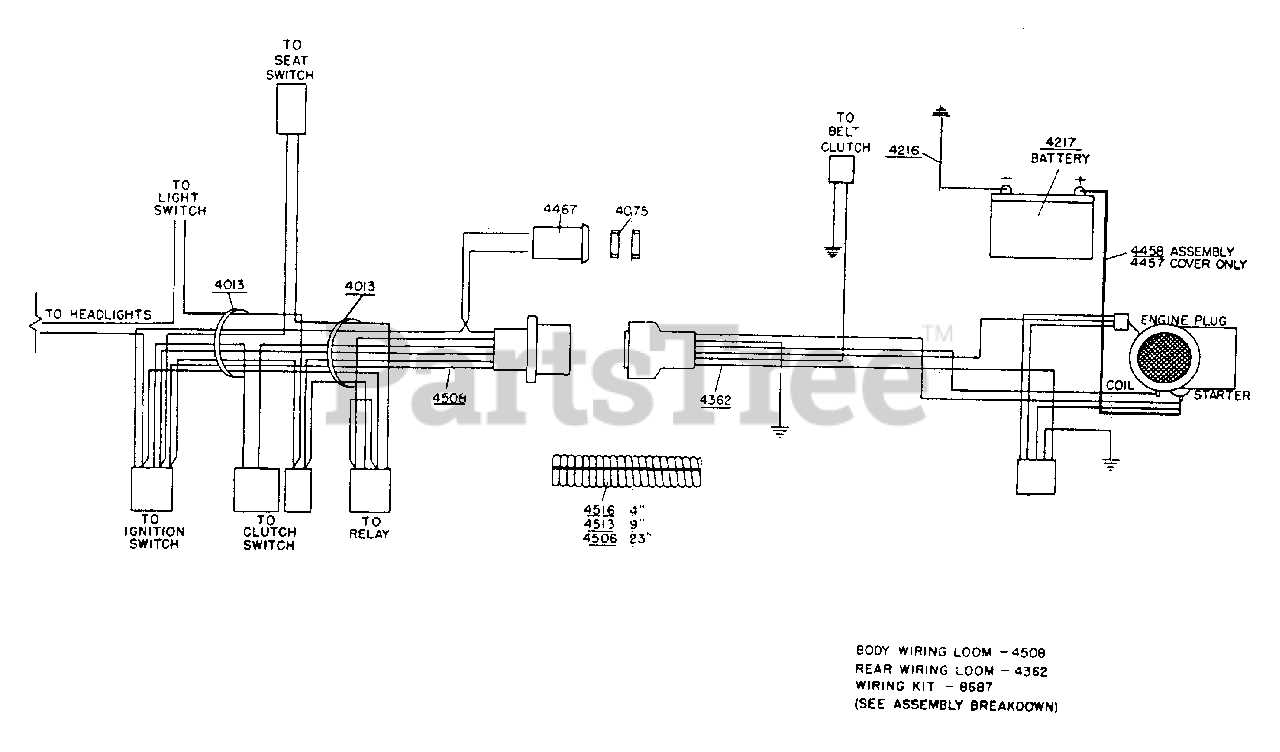

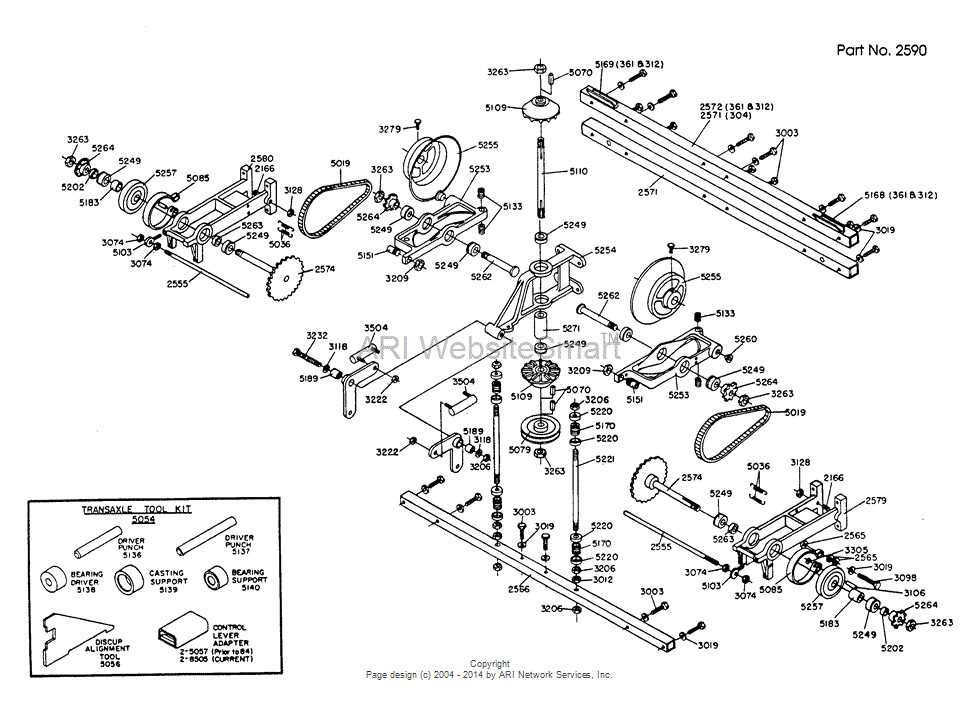

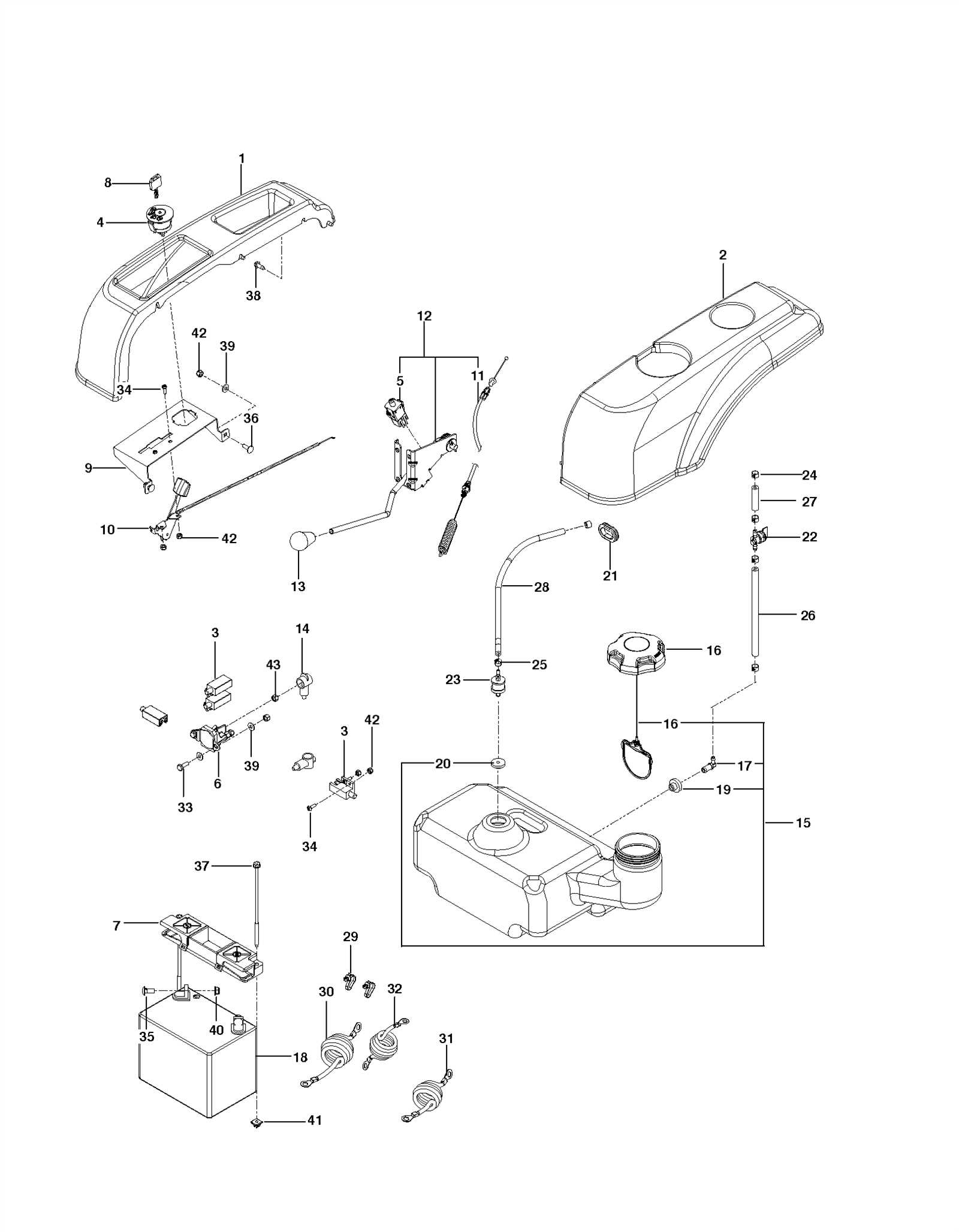

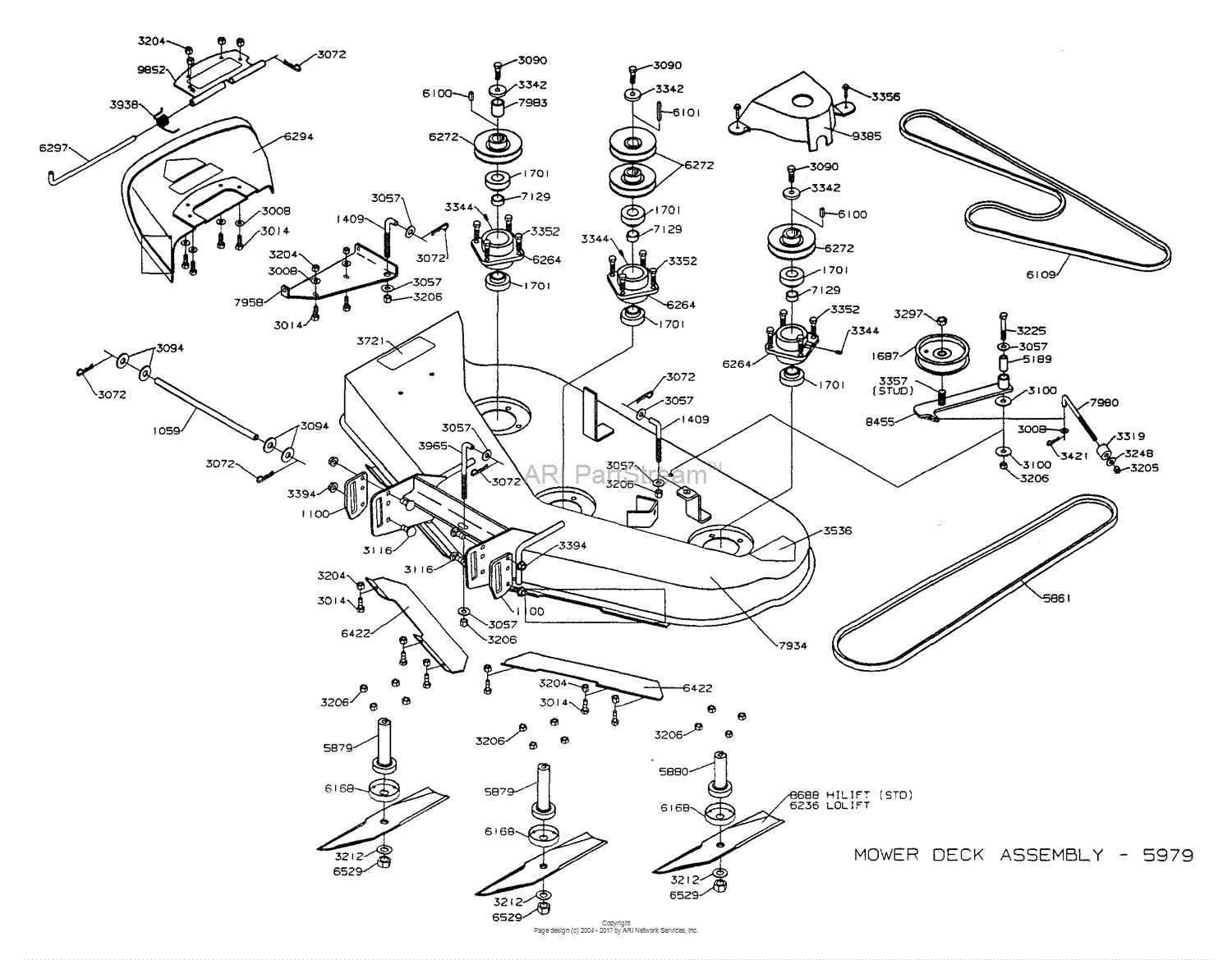

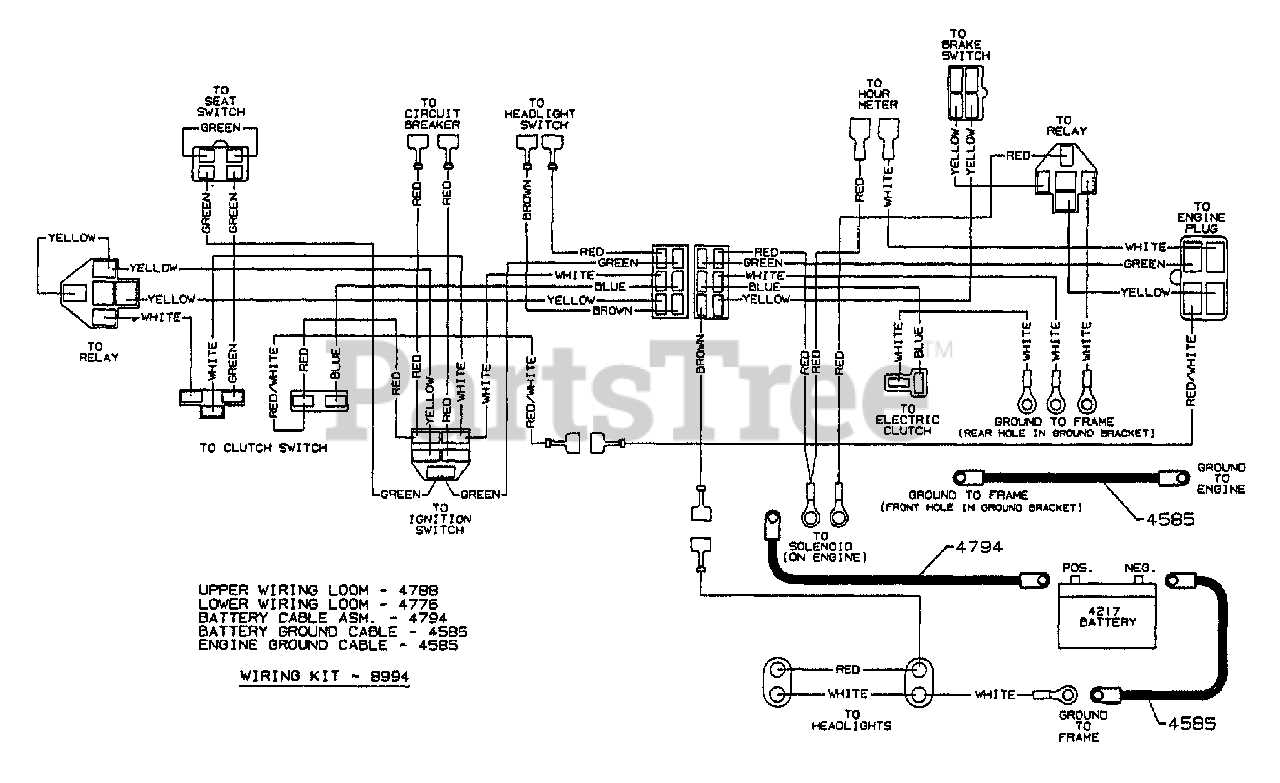

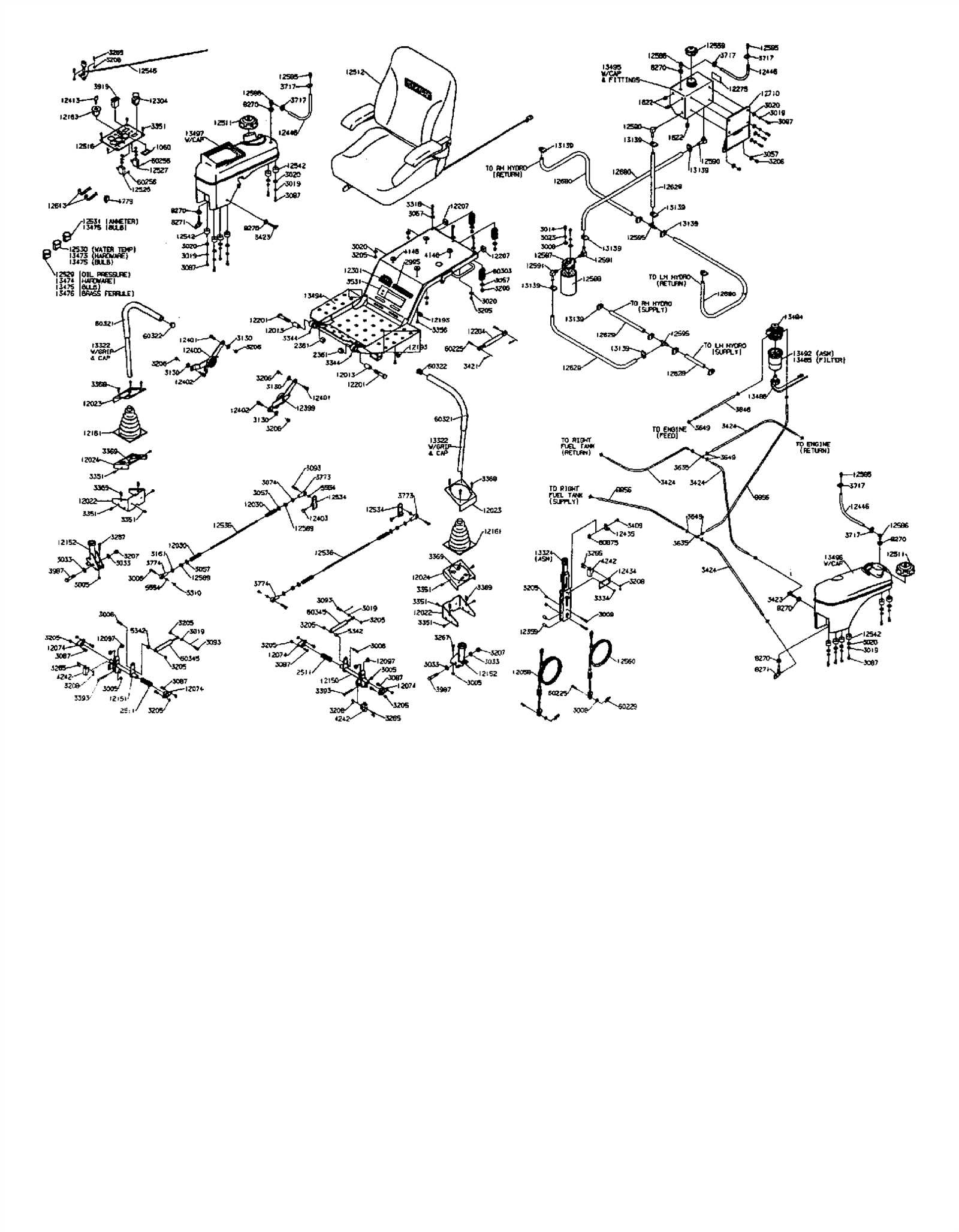

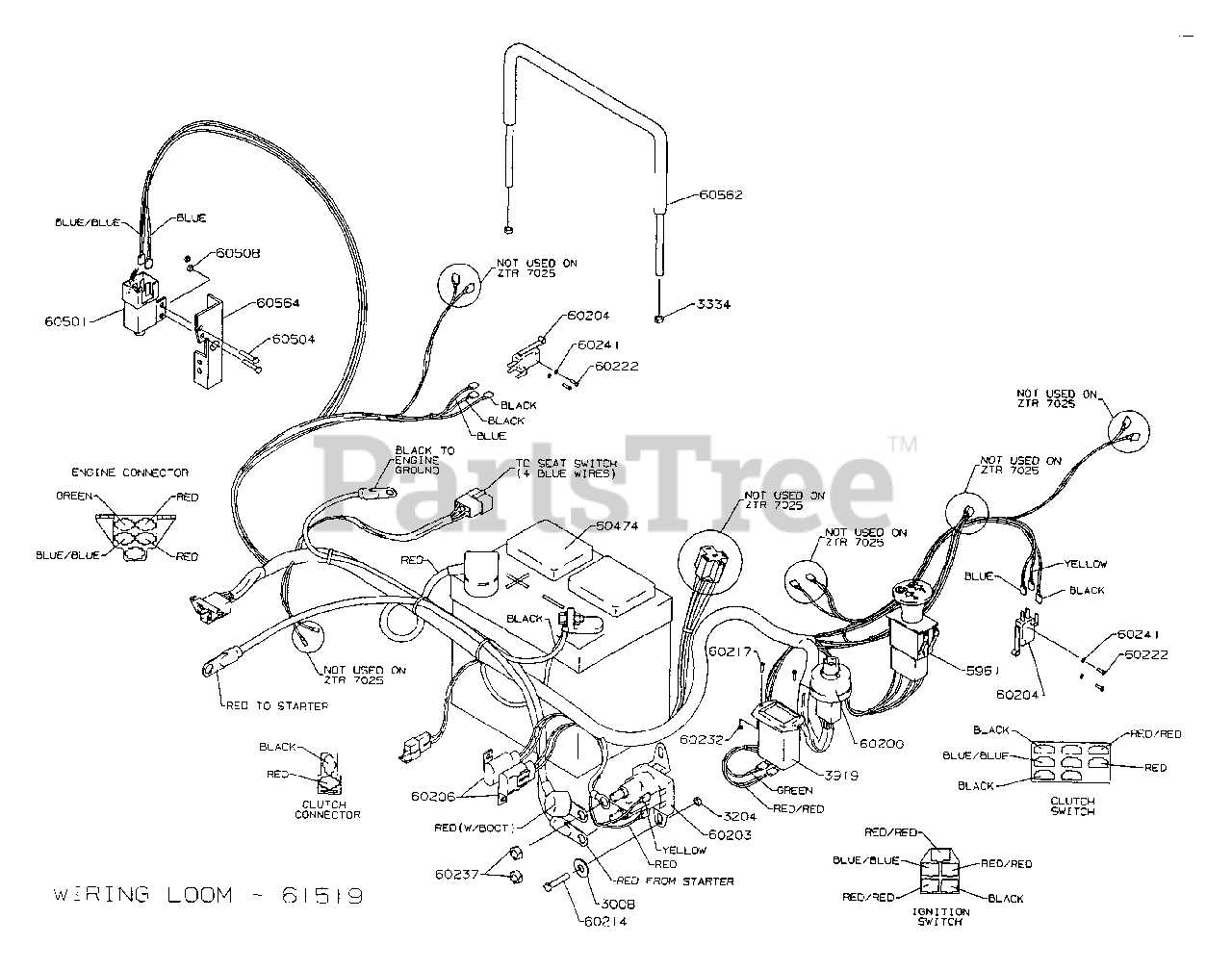

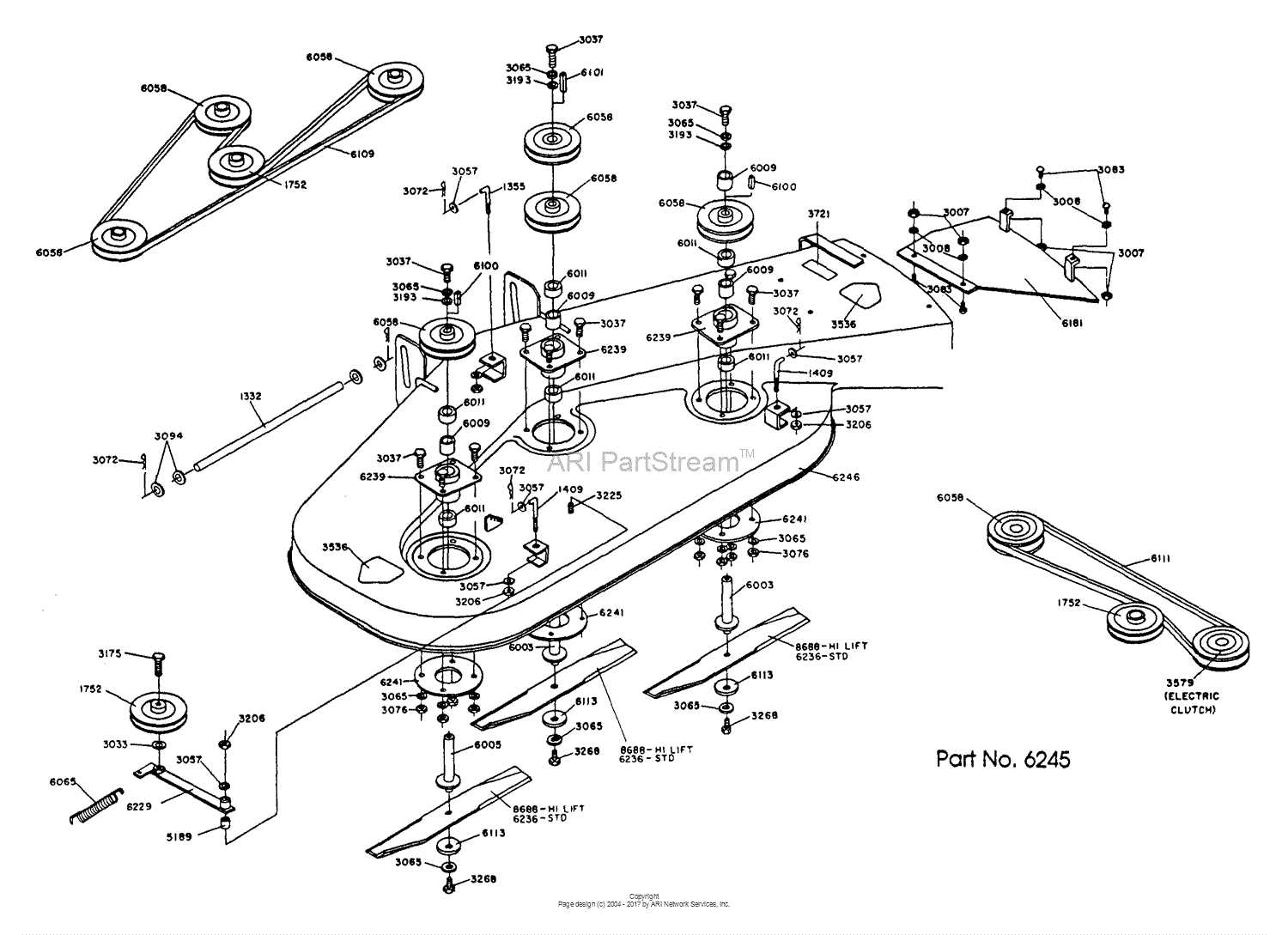

Importance of Parts Diagrams

Understanding the layout and components of any machinery is essential for effective maintenance and repair. Visual representations help users quickly identify specific elements, facilitating a smoother troubleshooting process and minimizing downtime.

Enhanced Understanding

Visual aids allow users to grasp the complexity of a machine more easily. By presenting a clear overview, these illustrations can help individuals, whether seasoned technicians or novices, to pinpoint the exact location and function of each component.

Efficient Repairs

When encountering issues, having a clear visual reference is invaluable. It streamlines the repair process, ensuring that all necessary elements are considered, thus enhancing overall efficiency and effectiveness in restoring functionality.

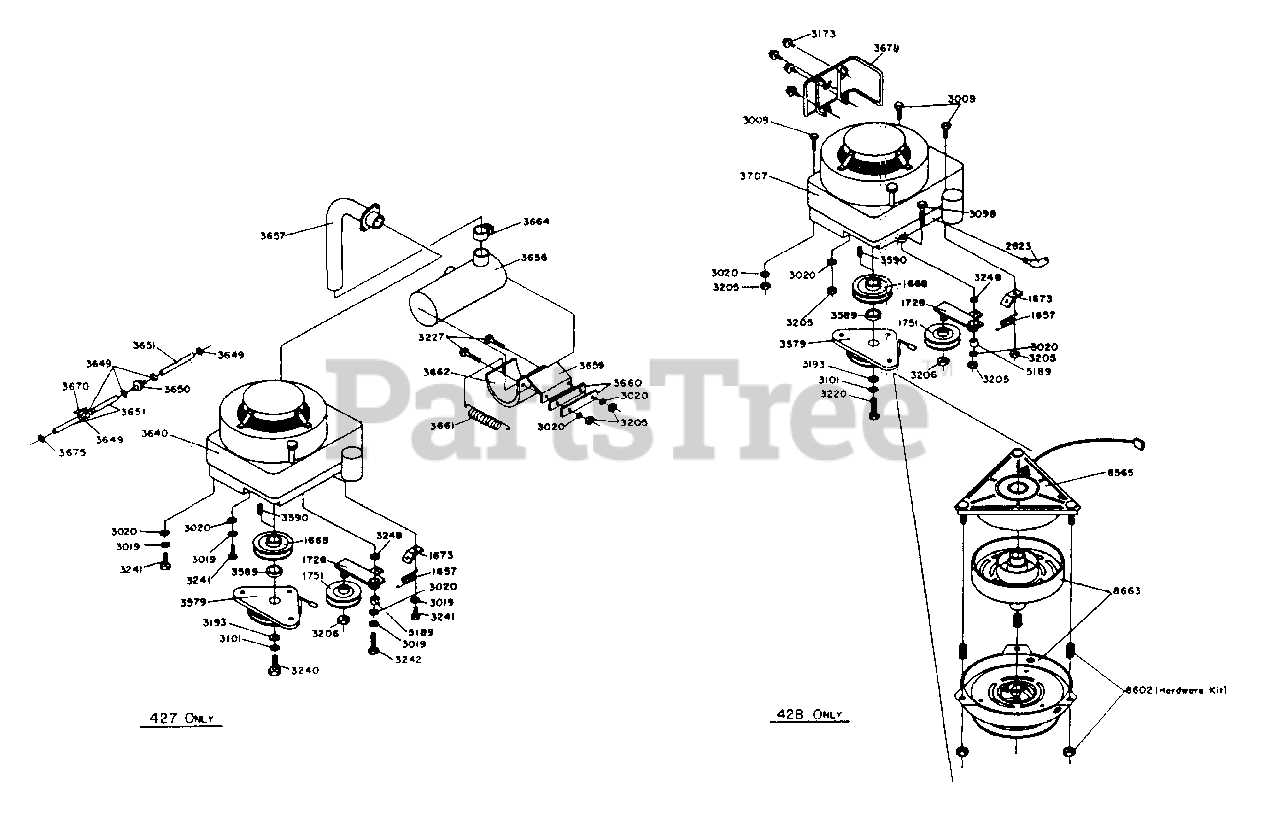

Key Components of Dixon Mowers

Understanding the essential elements that contribute to the functionality of these machines is crucial for optimal performance. Each component plays a significant role in ensuring efficiency and reliability during operation. From the power source to the cutting system, every part is designed with precision to enhance the user experience.

The engine serves as the heart, providing the necessary power to drive the entire system. Transmission elements facilitate smooth movement and speed adjustments, while the deck configuration is pivotal for achieving a clean and even cut. Additionally, wheels and tires impact maneuverability, allowing users to navigate various terrains with ease.

Regular maintenance of these key components not only extends the lifespan of the equipment but also ensures it operates at peak efficiency. Familiarity with each element allows operators to diagnose issues quickly and make informed decisions regarding repairs or replacements.

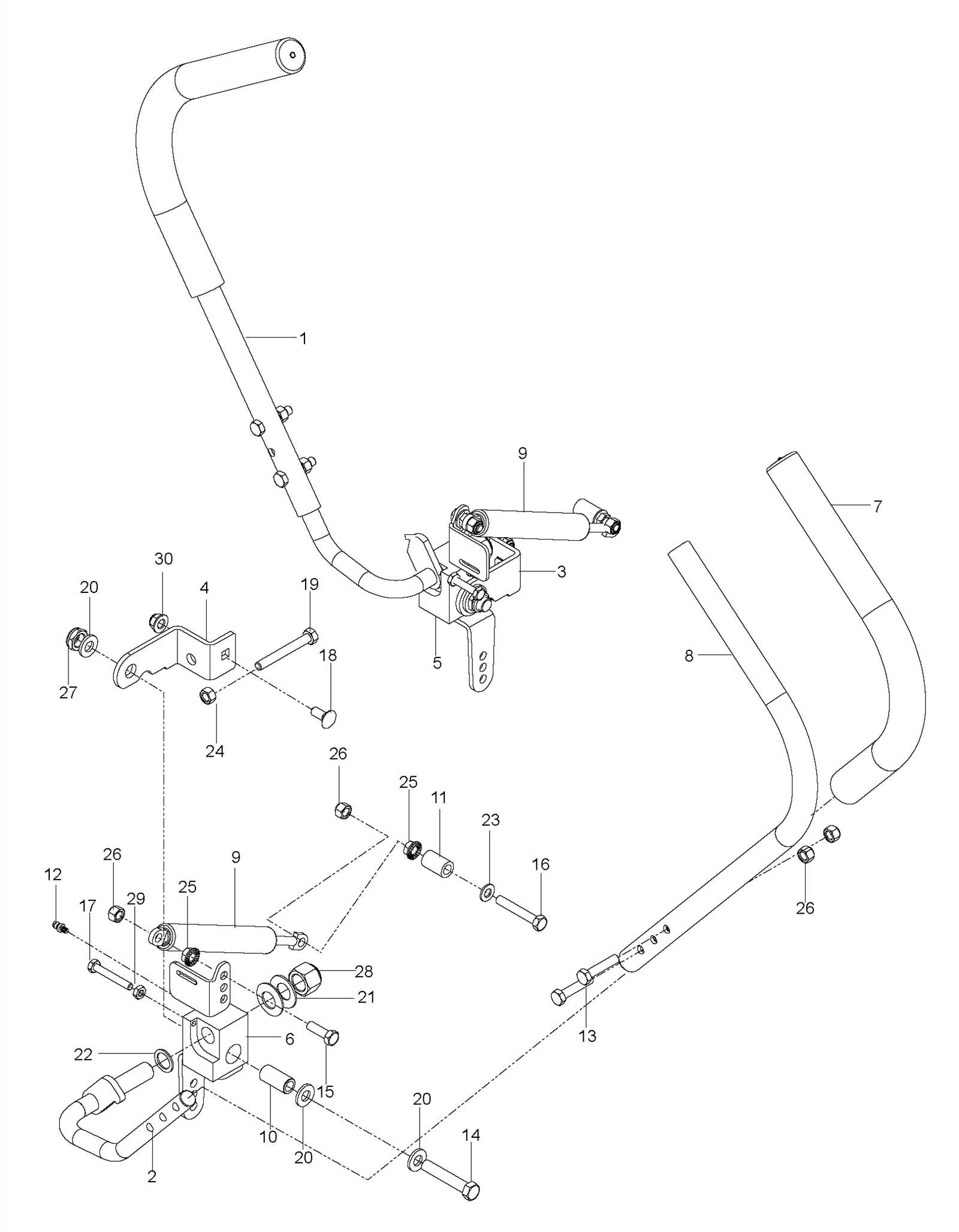

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. These illustrations serve as a roadmap, guiding you through various elements and their interconnections. By familiarizing yourself with the layout and symbols used, you can easily identify the necessary items and their placements.

First, start by examining the overall layout. This gives you a sense of the assembly and how individual elements fit together. Look for labels and numbers that indicate specific components, which can aid in locating them in a parts catalog.

Next, pay attention to any accompanying legend or key. This will clarify any symbols used in the illustration, ensuring you interpret the information correctly. Additionally, be aware of any directional arrows or lines that indicate movement or flow, as these often denote functionality.

Finally, always cross-reference the visual guide with the actual components. This hands-on approach reinforces your understanding and helps in identifying any discrepancies or needs for replacement. By following these steps, you will ultimately enhance your ability to manage repairs efficiently.

Common Issues with Mower Parts

Maintaining outdoor cutting equipment is essential for optimal performance and longevity. However, various challenges can arise with components, affecting functionality and efficiency. Understanding these common issues can help in identifying problems early and ensuring proper care.

Frequent Problems

Several issues may frequently occur with different components. Below are some of the most common challenges faced by users:

| Issue | Description | Potential Solution |

|---|---|---|

| Wear and Tear | Parts can degrade over time due to constant usage, leading to reduced performance. | Regular inspections and timely replacements are crucial. |

| Blockages | Debris accumulation can obstruct functionality, resulting in inefficient operation. | Routine cleaning and maintenance can help prevent this. |

| Misalignment | Components may become misaligned, causing uneven cutting or vibration. | Check alignment periodically and adjust as needed. |

Maintenance Tips

To mitigate these issues, regular maintenance is essential. Establishing a routine that includes inspections, cleaning, and necessary adjustments can significantly extend the lifespan of the equipment. Additionally, using high-quality replacement components can prevent frequent breakdowns and enhance overall performance.

Identifying Replacement Parts

Understanding how to pinpoint the necessary components for your equipment is crucial for effective maintenance and repair. Recognizing the specific elements that require attention can significantly enhance performance and longevity.

To streamline the identification process, follow these steps:

- Consult the User Manual: Always refer to the manual provided by the manufacturer. It contains essential information about components and their specifications.

- Examine the Equipment: Conduct a thorough inspection to locate any damaged or worn elements. Take note of the part numbers if visible.

- Utilize Online Resources: Various websites offer extensive databases for identifying components. Enter model information to find exact matches.

Here are some helpful tips:

- Take Photos: Documenting the current state of your equipment can assist in reassembly and help identify parts more easily.

- Join Online Forums: Engaging with communities can provide insights and advice from fellow users who may have faced similar challenges.

- Keep a Parts List: Maintaining a list of identified components can simplify future repairs and replacements.

By following these guidelines, you can efficiently identify the elements needed to keep your equipment in optimal condition.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for maximizing the lifespan of your outdoor equipment. Adopting a few simple practices can enhance performance and prevent unexpected breakdowns, ensuring your machine operates smoothly for years to come.

Routine Checks

Conducting frequent inspections is vital. Look for signs of wear and tear, such as frayed belts or loose components. Ensuring that all parts are secure and in good condition can prevent larger issues down the road. Regularly clean any debris or buildup that may accumulate, especially around moving parts, to maintain optimal efficiency.

Fluid Maintenance

Keep an eye on all necessary fluids. Regularly change oil and filters to ensure your engine runs smoothly. Check coolant levels and hydraulic fluids to prevent overheating and maintain hydraulic efficiency. An annual fluid check can save you from costly repairs and improve performance.

Where to Purchase Parts Online

Finding reliable sources for acquiring components online can streamline your maintenance and repair tasks. Various platforms offer an extensive selection, catering to different needs and budgets. Below is a guide to help you navigate these options effectively.

| Website | Special Features |

|---|---|

| Amazon | Wide variety, user reviews, fast shipping |

| eBay | Competitive pricing, auction options, used items |

| Specialty Retailers | Expert advice, specific brands, customer service |

| Manufacturer Websites | Original quality, latest models, warranty options |

Exploring these resources will help you find what you need quickly and efficiently, ensuring your equipment remains in optimal condition.

Understanding Mower Specifications

When it comes to maintaining a lawn care machine, familiarity with its technical details is essential. Knowing the specifications can greatly enhance performance, durability, and efficiency. This section will delve into the key elements that define a machine’s capabilities and functionalities.

Here are some crucial aspects to consider:

- Engine Power: The horsepower or kilowatts indicate how powerful the machine is, affecting its ability to handle various terrains.

- Cutting Width: This measurement reflects the breadth of the cutting deck, influencing the time it takes to cover a given area.

- Fuel Capacity: Understanding how much fuel the machine can hold will help in planning long mowing sessions without frequent refueling.

- Weight: Heavier machines may offer more stability, while lighter ones can be easier to maneuver.

- Blade Type: Different blade designs impact the quality of the cut and the type of grass that can be effectively managed.

- Drive System: Knowing whether a machine is belt-driven, chain-driven, or uses another mechanism can affect maintenance and operation.

By grasping these specifications, users can make informed choices regarding maintenance and enhancements, ensuring optimal performance for their equipment.

Comparing Dixon Models and Parts

This section explores the variations among different models and their respective components, highlighting key features and design philosophies that cater to diverse needs. By examining these aspects, users can make informed choices based on performance, durability, and functionality.

Model Features

Each version presents unique characteristics that enhance user experience. Performance metrics, such as speed and efficiency, vary significantly, influencing suitability for various tasks. Additionally, ergonomic design is crucial for comfort during prolonged use, making some models more appealing to specific users.

Component Compatibility

Understanding the interchangeability of components is vital for maintenance and upgrades. Certain versions may share parts, simplifying repairs and enhancing longevity. Identifying these relationships can ultimately lead to improved operational efficiency and cost savings.

DIY Repairs vs. Professional Help

When it comes to fixing machinery, individuals often face the choice between tackling repairs themselves or seeking expert assistance. Each approach has its own set of advantages and potential drawbacks that can influence the decision-making process.

Advantages of DIY Repairs

- Cost savings: Handling repairs independently can significantly reduce expenses.

- Skill development: Gaining hands-on experience enhances one’s mechanical skills.

- Flexibility: Repairs can be performed at one’s convenience, without waiting for a technician.

Benefits of Professional Assistance

- Expertise: Professionals bring specialized knowledge and experience, ensuring effective repairs.

- Time efficiency: Hiring a technician can save time, particularly for complex issues.

- Warranty protection: Professional repairs may help maintain manufacturer warranties.

Ultimately, the decision should consider the specific situation, available resources, and personal comfort with mechanical tasks.

Safety Precautions During Repairs

When undertaking maintenance on outdoor machinery, adhering to safety guidelines is crucial to prevent accidents and ensure a secure working environment. Understanding and implementing these precautions can significantly reduce the risk of injuries while enhancing the efficiency of the repair process.

Proper Gear and Environment

Before starting any work, it is essential to equip yourself with appropriate safety gear. This includes gloves, goggles, and sturdy footwear to protect against potential hazards. Additionally, ensure that the workspace is well-lit and free from clutter to minimize risks associated with slips, trips, and falls.

Disconnect and Inspect

Always disconnect the power source before beginning any repairs. This step is vital to prevent accidental activation of the equipment. Once disconnected, take the time to inspect tools and components for wear or damage. Using well-maintained tools not only promotes safety but also enhances the effectiveness of your repair tasks.

Customer Support for Dixon Products

Providing exceptional assistance to customers is a cornerstone of any reputable brand. Ensuring that users have access to reliable resources, knowledgeable staff, and prompt solutions enhances their overall experience. The commitment to customer satisfaction includes various avenues for support, whether it be troubleshooting issues, sourcing components, or addressing general inquiries.

Available Support Channels

Customers can reach out through multiple channels tailored to their preferences. Options typically include phone support, where representatives are ready to answer queries, as well as online resources, such as comprehensive FAQs and instructional materials. Additionally, email support provides a convenient method for more detailed inquiries, allowing customers to receive thorough responses at their convenience.

Resources for Assistance

To empower users in maintaining their equipment, many brands offer an extensive array of resources. These can include detailed guides, troubleshooting manuals, and video tutorials. Access to a community forum can also be invaluable, enabling users to connect with one another, share experiences, and find solutions collaboratively. Overall, the focus remains on fostering a positive relationship between the brand and its users through accessible and effective support.