Understanding Flail Mower Parts Diagram for Efficient Maintenance

The intricate design of modern cutting machinery plays a crucial role in its efficiency and functionality. A comprehensive exploration of these implements reveals how each element contributes to optimal performance. Recognizing the significance of every component allows operators and enthusiasts to appreciate the technology behind effective land management.

Each mechanism serves a specific purpose, from the driving systems to the rotating elements that engage with the vegetation. An in-depth look at these individual features not only enhances operational knowledge but also aids in maintenance and troubleshooting. This understanding is essential for ensuring longevity and reliability in various applications.

Furthermore, grasping the relationship between different sections can lead to improved techniques and better results in landscaping tasks. Whether for professional use or personal projects, familiarizing oneself with these components fosters confidence and proficiency in utilizing such equipment. Engaging with this information empowers users to maximize their resources effectively.

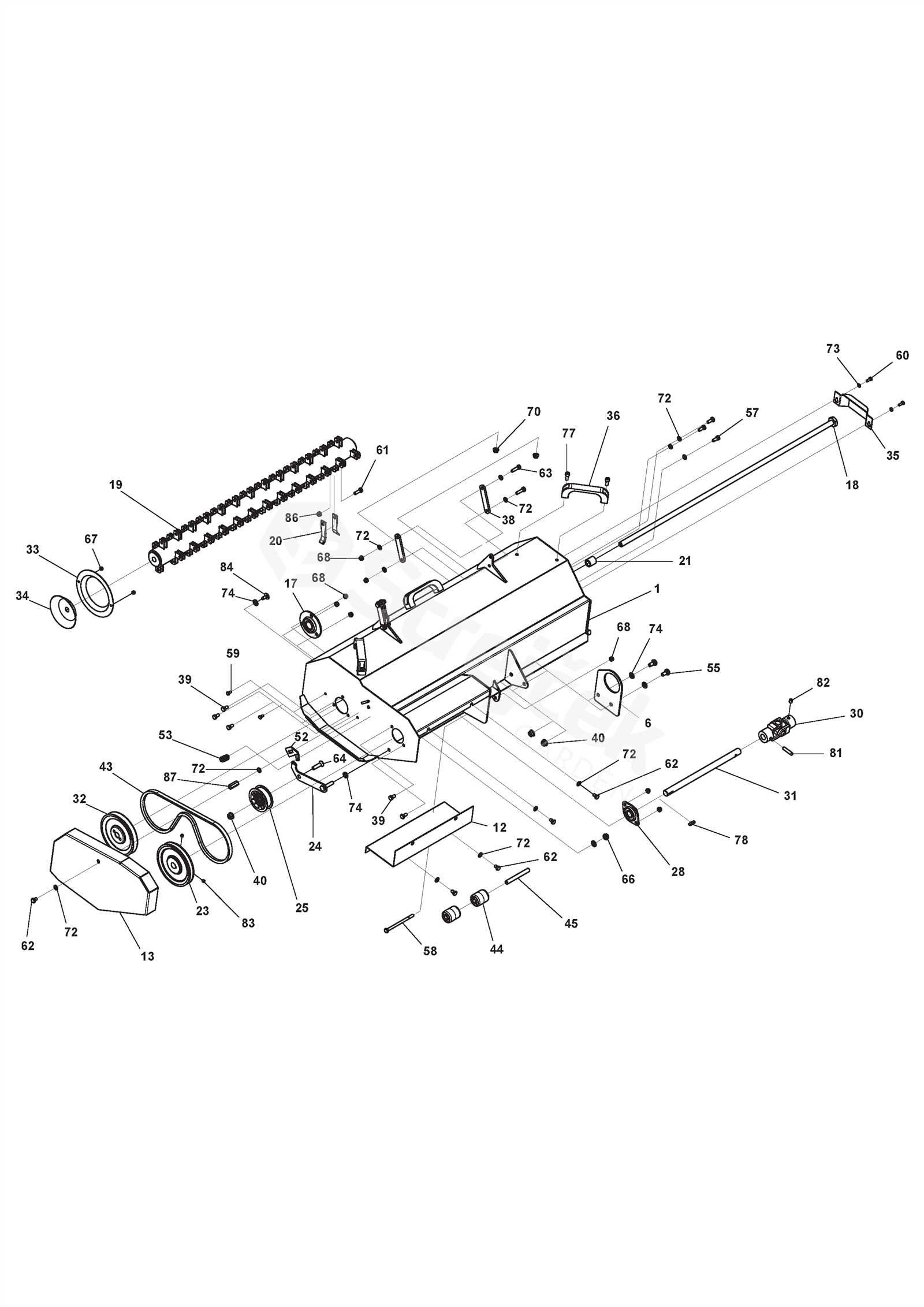

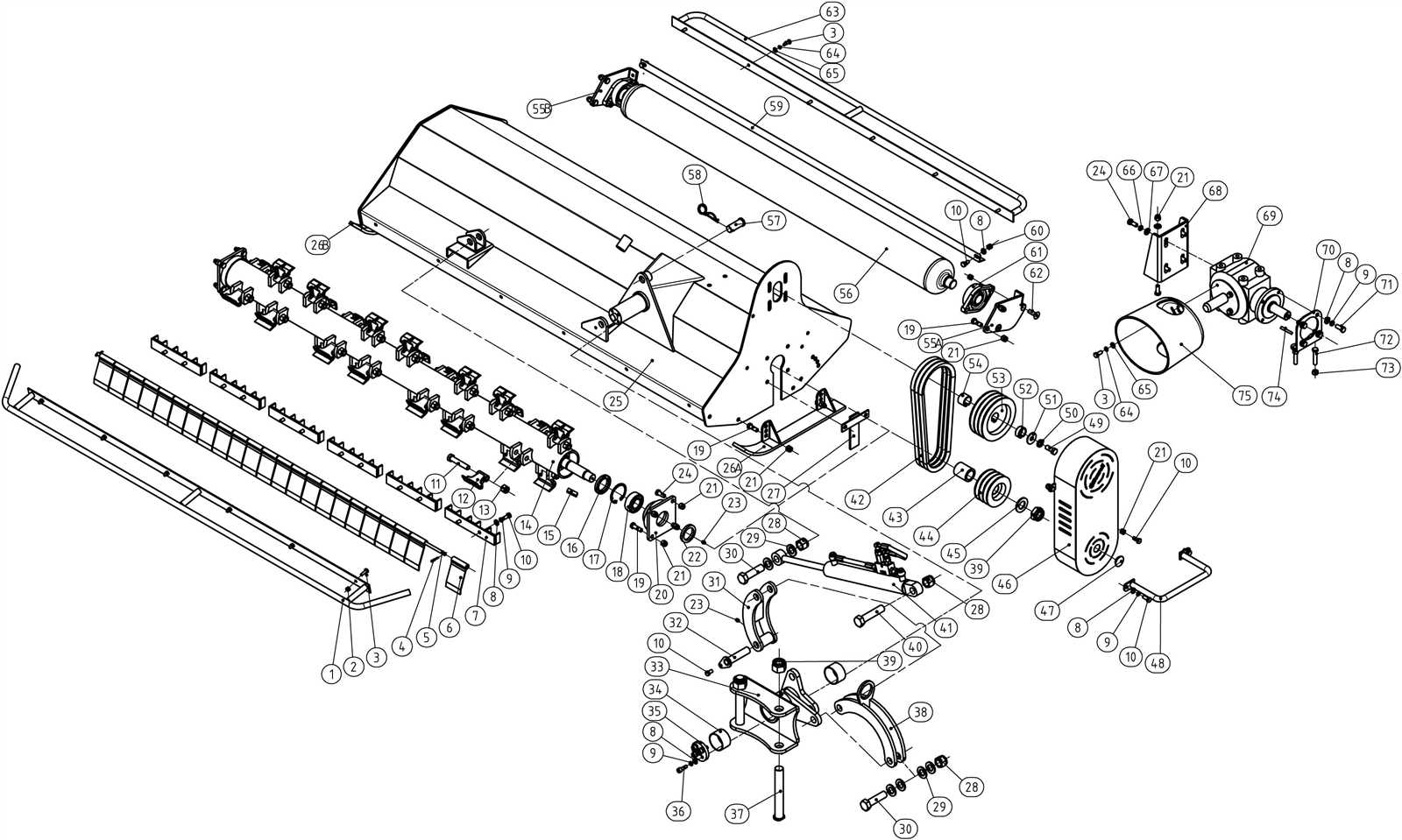

Understanding Flail Mower Components

The functionality of a cutting machine relies heavily on its various elements, each contributing to the overall efficiency and effectiveness of the equipment. A comprehensive grasp of these components enables users to optimize performance, ensure longevity, and facilitate maintenance.

Central to the operation is the cutting mechanism, which is designed to handle diverse types of vegetation with ease. This mechanism typically consists of sharp blades that rotate rapidly, effectively managing thick grass and brush. The design ensures a clean cut, promoting healthier growth in the long term.

Another critical element is the frame, which provides structural integrity and support. Constructed from durable materials, the frame must withstand rigorous use while maintaining stability during operation. A robust design minimizes vibrations, enhancing user comfort and control.

Additionally, the drive system plays a pivotal role in transmitting power from the engine to the cutting apparatus. This system is vital for achieving the desired speed and efficiency, ensuring that the machine can handle various terrains without compromising performance.

Finally, the collection system, often included, aids in managing the debris produced during cutting. Effective collection helps maintain a tidy workspace and reduces the need for additional clean-up after the job is done. Understanding these components not only aids in proper operation but also enhances troubleshooting and repair efforts when issues arise.

Essential Parts of Flail Mowers

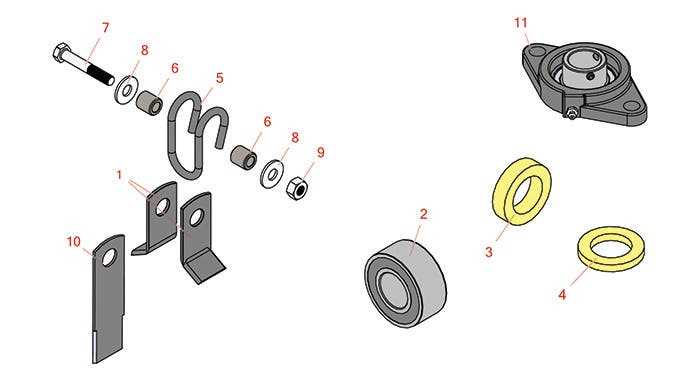

Understanding the fundamental components of this cutting equipment is crucial for efficient operation and maintenance. Each element plays a significant role in ensuring optimal performance, safety, and longevity of the machine. Below is a brief overview of the key elements that contribute to its functionality.

| Component | Description |

|---|---|

| Cutting Blades | Sharp, rotating elements responsible for trimming vegetation at various heights. |

| Housing | The protective casing that encloses the cutting mechanism, safeguarding it from debris. |

| Drive Shaft | A rotating rod that transmits power from the engine to the cutting assembly. |

| Support Frame | The sturdy structure that holds all components together, providing stability during operation. |

| Hitch | A connector that attaches the equipment to a vehicle, allowing for easy transportation. |

| Deck | The surface area underneath the cutting blades, designed to ensure efficient grass discharge. |

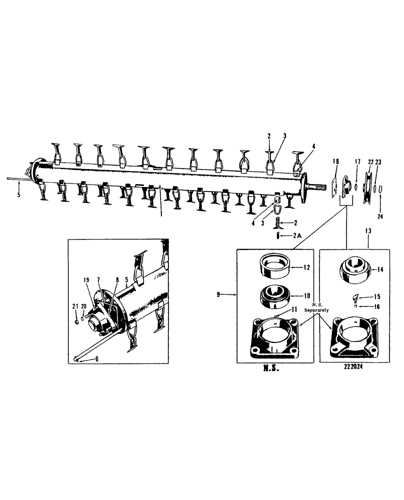

How Flail Mowers Operate

This section explores the operational principles of a specialized cutting tool used for maintaining vegetation. These machines employ a unique mechanism that enhances their efficiency in managing overgrown areas.

The core function revolves around rotating elements that engage with the ground cover, providing a precise and effective cutting action. The following components contribute to their overall performance:

- Cutting Blades: Sharp implements that tackle various types of foliage.

- Rotating Assembly: A dynamic system that ensures blades spin at high speeds.

- Power Source: Typically a combustion engine or electric motor that drives the cutting mechanism.

Operation involves several key steps:

- The power source activates the rotating assembly.

- As the assembly turns, the blades engage with the vegetation.

- Debris is shredded and dispersed evenly, enhancing the land’s appearance.

Overall, these machines are designed for robustness and versatility, allowing them to tackle diverse terrains and cutting tasks efficiently.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the prolonged functionality and efficiency of any mechanical equipment. By adhering to a consistent maintenance schedule, users can prevent premature wear and extend the lifespan of their machinery. This practice not only enhances performance but also minimizes the risk of unexpected breakdowns.

Key Benefits of Regular Upkeep

- Enhanced Performance: Routine inspections and servicing can significantly improve the operational efficiency of the equipment.

- Cost Savings: Preventive measures reduce the likelihood of major repairs, ultimately saving money in the long run.

- Safety Assurance: Proper maintenance ensures that the machinery operates safely, protecting users from potential hazards.

- Increased Resale Value: Well-maintained equipment typically retains higher resale value, appealing to potential buyers.

Essential Maintenance Practices

- Regularly check and replace worn components.

- Keep the machinery clean to prevent buildup that can hinder performance.

- Lubricate moving parts as per the manufacturer’s recommendations.

- Conduct seasonal inspections to address any issues proactively.

By implementing these practices, users can ensure their equipment remains reliable and efficient for many years, thereby maximizing their investment.

Identifying Common Wear and Tear

Understanding the signs of deterioration is crucial for maintaining the efficiency and longevity of your equipment. Over time, various components can experience stress and damage due to regular use, environmental factors, and general wear. Recognizing these indicators early can prevent more significant issues and ensure optimal performance.

One of the most common signs of wear is uneven cutting performance. This can manifest as patchy results in the field, indicating that certain blades may be dull or damaged. Additionally, you might notice unusual vibrations or noise during operation, which can suggest misalignment or loose fittings. Regular inspections of moving parts are essential to catch these problems before they escalate.

Another area to monitor is the accumulation of debris and residue on critical components. Build-up can lead to overheating or reduced efficiency, impacting the overall functionality. Checking for rust or corrosion is also vital, as these can weaken structures and lead to failure. Keeping an eye on these aspects will help you maintain your equipment effectively.

Lastly, be aware of any changes in fluid levels or leaks around hydraulic systems. Such issues can signal a need for immediate attention to prevent operational breakdowns. By staying vigilant and addressing wear promptly, you can prolong the life of your machinery and enhance its performance.

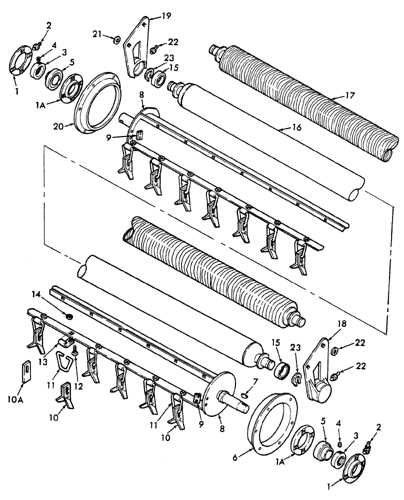

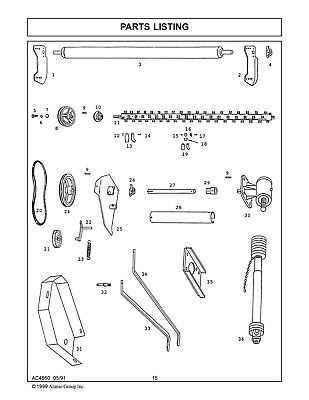

Choosing the Right Flail Blades

Selecting the appropriate cutting elements is crucial for achieving optimal performance and efficiency in landscaping and agricultural tasks. The right choice not only affects the quality of the cut but also influences the overall longevity and maintenance of the equipment.

When considering cutting elements, it’s important to evaluate the material and design. Blades made from high-carbon steel tend to offer superior durability and edge retention, making them suitable for tougher vegetation. Conversely, lightweight options may be more effective for lighter tasks, providing a balance between performance and maneuverability.

The shape and length of the blades also play a significant role. Longer, more angled designs can enhance cutting ability in dense underbrush, while shorter blades might provide more control in precise applications. Additionally, the specific requirements of the terrain being managed should guide your selection, as different environments may demand varying blade characteristics.

Finally, consider compatibility with your equipment. Ensure that the chosen cutting elements fit properly and align with your machine’s specifications. This attention to detail will not only maximize efficiency but also minimize wear and tear on the unit, ensuring reliable operation for years to come.

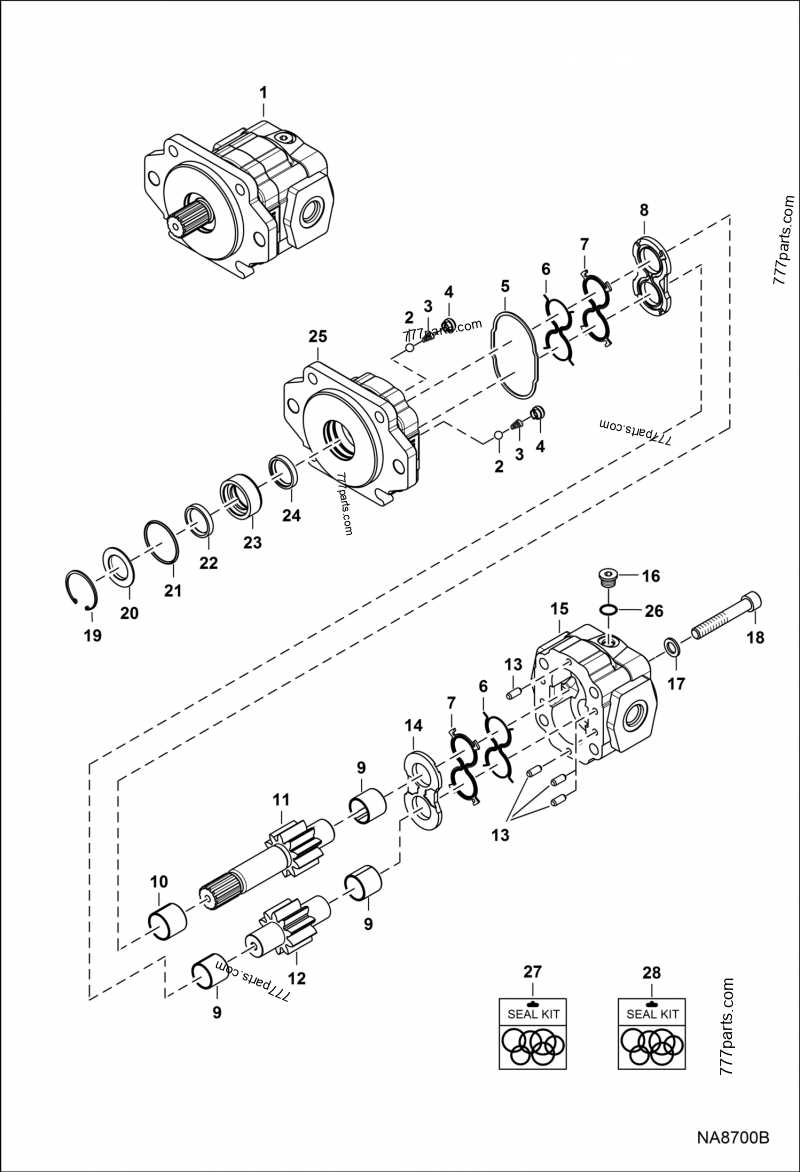

Gearbox Functionality Explained

The gearbox is a critical component that facilitates the transfer of power within various machinery. By converting rotational motion and adjusting torque, it ensures optimal performance and efficiency in operations. Understanding its role is essential for anyone involved in the maintenance or operation of these machines.

How Gearboxes Operate

At its core, a gearbox consists of a series of gears that interlock to manage the speed and force generated by the engine. When the engine turns, it drives the input shaft, which rotates the gears. The arrangement and size of these gears dictate the output speed and torque. This allows for precise control over the machine’s capabilities, enabling it to handle different tasks effectively.

Importance of Gear Ratios

Gear ratios play a pivotal role in determining the performance characteristics of a machine. By selecting appropriate gear combinations, operators can enhance efficiency for specific applications. A lower gear ratio increases torque, making it suitable for tasks requiring power, while a higher ratio allows for greater speed, ideal for lighter operations. This adaptability underscores the importance of understanding gearbox functionality in achieving desired results.

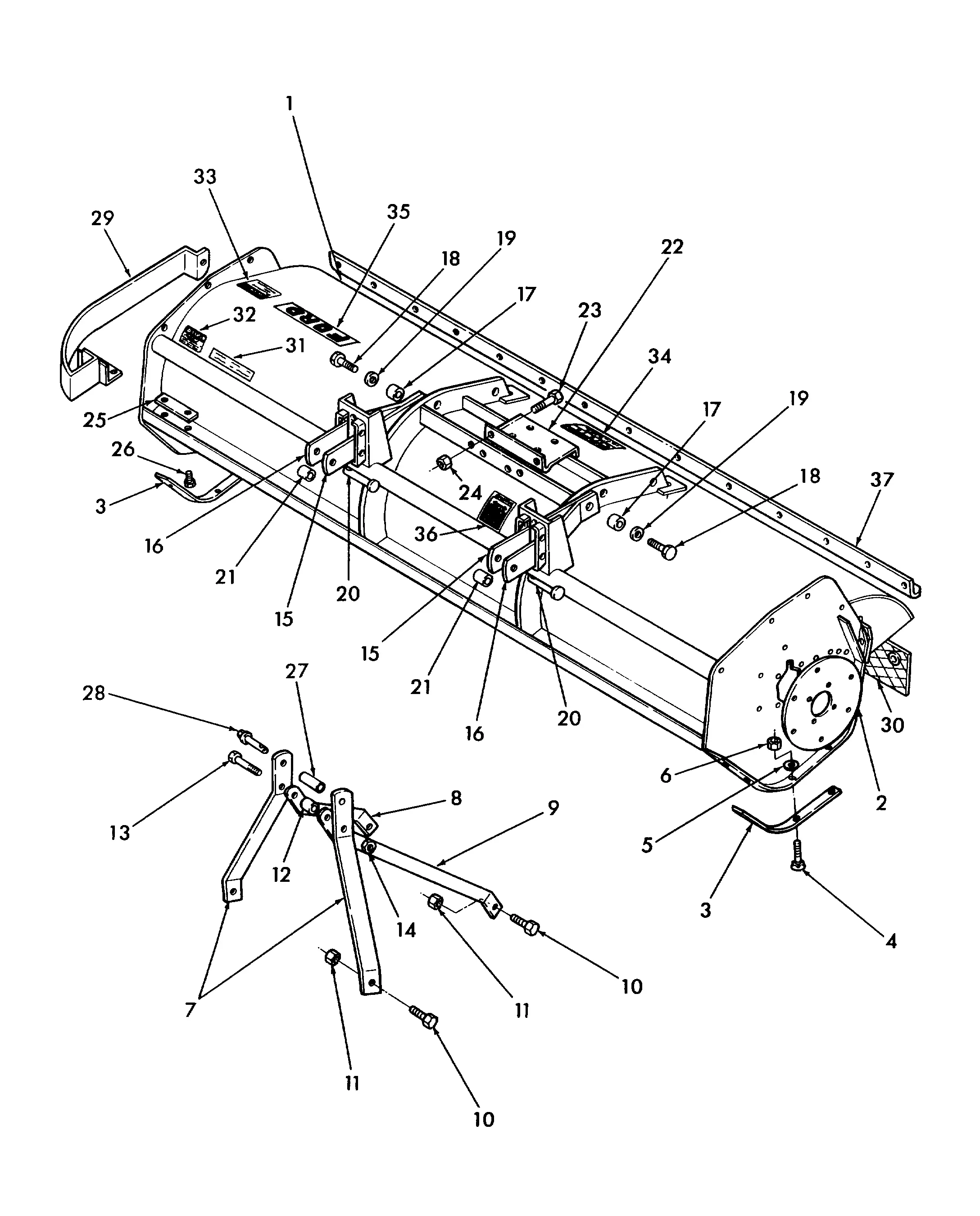

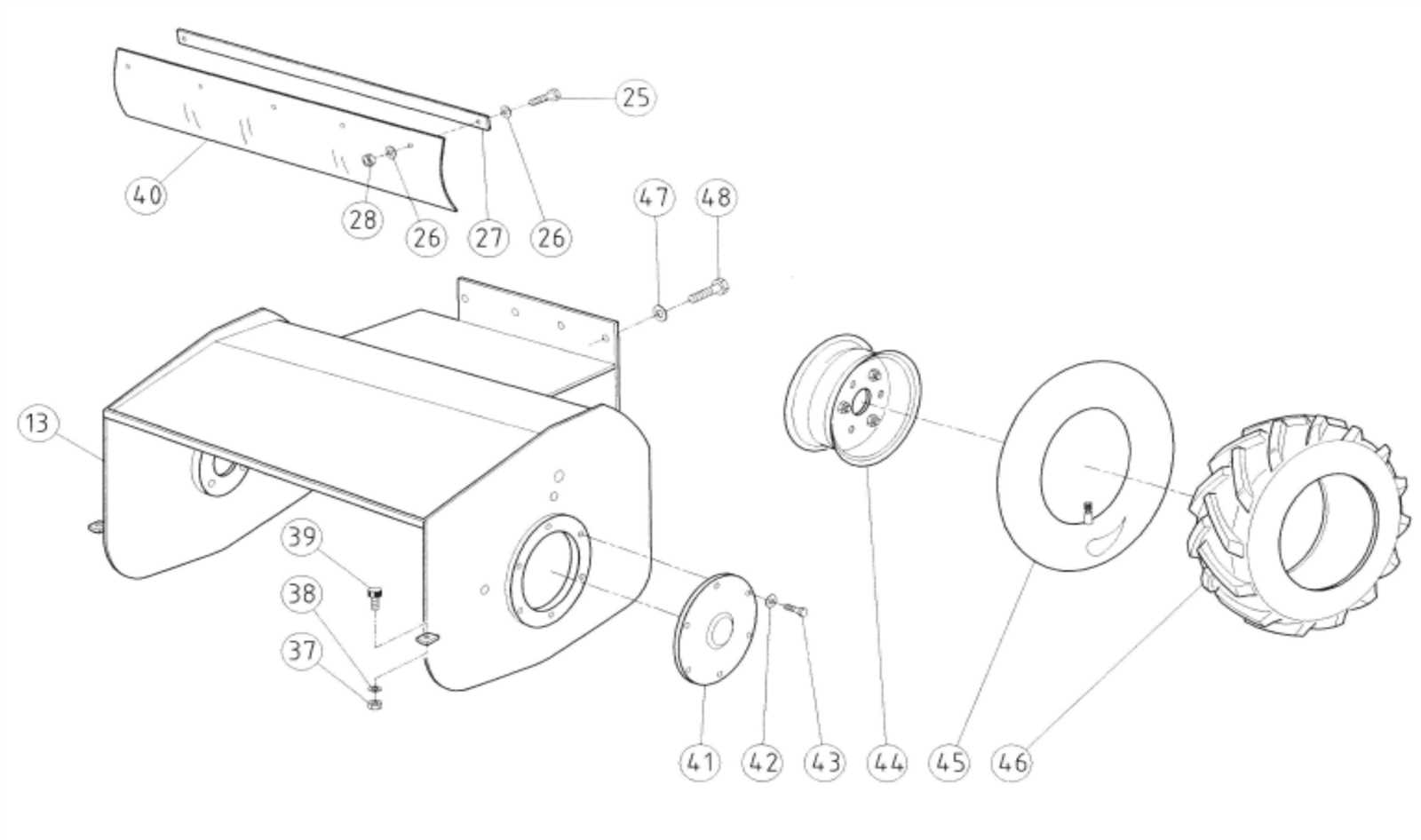

Exploring the Frame Structure

The frame of a cutting machine serves as its backbone, providing essential support and stability during operation. This component is crucial for maintaining alignment and ensuring the longevity of the entire system. A robust frame not only enhances performance but also contributes to safety and durability in challenging environments.

Design and Material play a vital role in the effectiveness of the structure. High-quality materials are chosen to withstand the rigors of outdoor use, reducing wear and tear over time. The engineering of the frame often incorporates specific shapes and reinforcements, aimed at distributing stress evenly and minimizing the risk of deformation.

Furthermore, the assembly of the frame is engineered to facilitate easy access for maintenance and repairs. This accessibility is essential for users to keep their equipment in optimal condition, ultimately extending its operational life. Understanding the intricacies of the frame design empowers operators to make informed choices regarding their equipment and its upkeep.

Hydraulic System Overview

The hydraulic system serves as a vital mechanism in various machinery, providing the necessary force and control for effective operation. Understanding its components and functionality is crucial for optimizing performance and ensuring reliability.

At its core, the hydraulic system operates through the principles of fluid dynamics, utilizing pressurized liquids to transmit power. The key elements of this system include:

- Hydraulic Fluid: The medium that transfers energy throughout the system, ensuring efficient power delivery.

- Pump: The component responsible for generating fluid flow and creating pressure within the system.

- Actuators: Devices that convert hydraulic energy into mechanical movement, enabling tasks to be performed.

- Valves: Essential for controlling the direction and flow of the hydraulic fluid, allowing for precise operation.

- Reservoir: A storage tank that holds the hydraulic fluid, maintaining the system’s functionality and performance.

Maintenance and troubleshooting of the hydraulic system are critical for preventing failures. Common practices include:

- Regularly checking fluid levels and quality.

- Inspecting hoses and connections for leaks or damage.

- Testing the pump and valves for proper operation.

- Replacing filters to ensure clean fluid circulation.

By understanding these components and practices, operators can enhance the efficiency and longevity of their hydraulic systems, ensuring smooth operation across a variety of applications.

Safety Features in Flail Mowers

Ensuring safety during operation is a paramount concern for any piece of equipment designed for vegetation management. Various protective elements are integrated into machinery to minimize risks and enhance the user experience. Understanding these features can help operators make informed decisions and maintain a secure working environment.

Key Safety Elements

- Emergency Stop Switch: A crucial feature that allows for immediate cessation of operations in case of an emergency.

- Protective Guards: Shields that prevent debris from flying towards the operator, reducing the risk of injury.

- Safety Interlocks: Mechanisms that ensure the machine only operates under safe conditions, such as when the operator is in the correct position.

- Operator Presence Control: This feature ensures the equipment shuts down if the operator leaves their designated area.

Maintenance and Inspection

Regular maintenance and thorough inspections are essential for keeping safety features functional. Operators should:

- Check the emergency stop mechanism frequently to ensure it is working correctly.

- Inspect protective guards for damage or wear.

- Test safety interlocks before each use to confirm they are operational.

- Keep the operator area free from hazards to maintain safe working conditions.

By prioritizing these safety measures, operators can significantly reduce risks and enhance their overall experience while using this type of machinery.

Repairing Damaged Components

Maintaining the functionality of machinery often requires attention to damaged elements. Identifying and addressing wear and tear can significantly extend the lifespan of equipment. This section outlines essential methods for restoring compromised components to ensure optimal performance.

Assessing Damage

Before proceeding with repairs, a thorough evaluation of the affected areas is crucial. Inspect each element for signs of wear, such as cracks, dents, or rust. This initial assessment will help determine whether the component can be repaired or needs replacement. Documenting the condition with photographs can aid in planning the restoration process.

Restoration Techniques

Depending on the extent of the damage, various techniques can be employed. Welding is effective for structural repairs, while grinding can eliminate surface imperfections. For minor abrasions, patching with suitable materials may suffice. Always ensure that any repair maintains the integrity and functionality of the original design.

Upgrading Your Mower Parts

Enhancing the functionality and performance of your equipment can lead to more efficient operations and improved results. By focusing on key components, you can significantly boost efficiency and durability. This section will explore essential upgrades to consider for optimal performance.

Benefits of Upgrading

Investing in higher-quality components can result in improved reliability and longevity. Enhanced materials often mean less wear and tear, which translates to reduced maintenance costs over time. Furthermore, modern innovations can offer better performance, making your tasks easier and quicker.

Key Components to Consider

| Component | Description | Benefits |

|---|---|---|

| Blades | High-performance cutting tools | Sharper edges, cleaner cuts |

| Belts | Durable, reinforced drive belts | Increased power transfer, less slippage |

| Engines | Upgraded engine options | More horsepower, better fuel efficiency |

| Wheels | All-terrain wheel sets | Improved traction and maneuverability |

By focusing on these essential enhancements, you can elevate the capabilities of your equipment, ensuring it meets your needs effectively and efficiently.

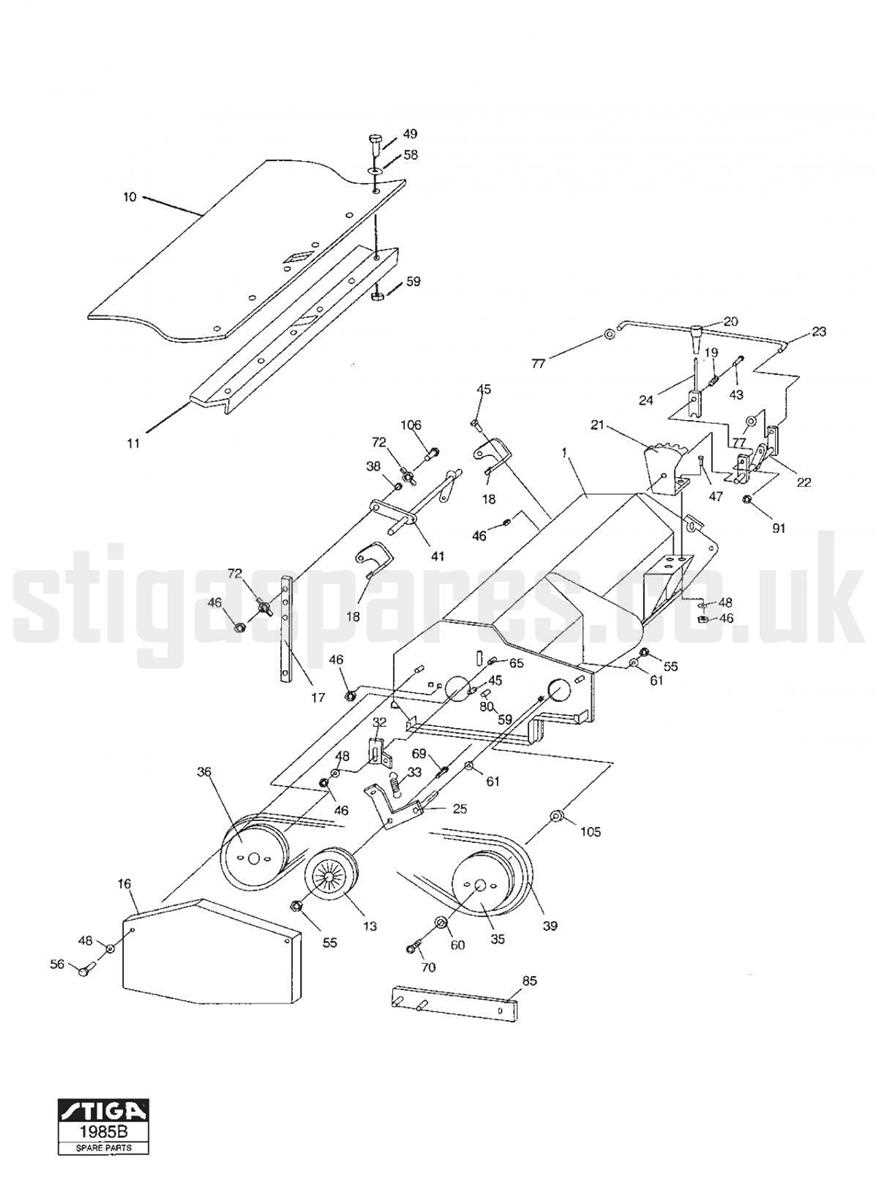

Flail Mower Assembly Instructions

When it comes to putting together your cutting device, following a clear set of guidelines is essential for ensuring proper functionality and safety. This section provides a comprehensive approach to assembling your equipment, allowing for a smooth and efficient process. With the right techniques, you can ensure optimal performance and longevity of your tool.

Preparation Steps

Before starting the assembly, gather all necessary components and tools. This includes blades, housing, and any fasteners. Lay everything out in an organized manner to facilitate a streamlined workflow. Additionally, consult the manufacturer’s manual for any specific instructions or recommendations that pertain to your particular model.

Assembly Process

Begin by securely attaching the housing to the frame, ensuring all bolts are tightened adequately. Next, position the cutting elements in their designated slots, making sure they are aligned correctly. Utilize appropriate fasteners to secure them in place, maintaining a balance for optimal operation. Once all components are connected, double-check each connection for stability. Finally, perform a safety check to ensure everything is properly assembled before use.