Understanding the Parts Diagram for Swisher Rough Cut Mowers

Maintaining outdoor machinery requires a comprehensive grasp of its vital elements. Knowing how each component functions can significantly enhance the performance and longevity of your equipment. This section delves into the intricate arrangement of essential parts, providing clarity and insight into their roles.

With a focus on the operational efficiency, recognizing the interconnections between various segments is crucial. An organized overview of these elements not only aids in troubleshooting but also facilitates informed decision-making when it comes to repairs or upgrades. Mastery of this knowledge empowers users to tackle maintenance tasks with confidence.

In the following discussion, we will explore a detailed representation of these critical elements. By examining their configurations, you will gain a deeper understanding of how to optimize your machinery’s functionality, ensuring it performs at its best for all your outdoor tasks.

Understanding Swisher Mower Components

To effectively maintain and operate a landscape management tool, it’s essential to grasp the various elements that contribute to its functionality. Each component plays a pivotal role, ensuring smooth operation and optimal performance. Recognizing the significance of these parts can enhance user experience and prolong the equipment’s lifespan.

In this section, we will delve into the key elements of such tools, detailing their functions and how they interact with one another. This knowledge will empower users to troubleshoot issues and carry out necessary maintenance.

| Component | Description | Function |

|---|---|---|

| Engine | The power source for the machine. | Drives the cutting mechanism and provides mobility. |

| Deck | The housing that encases the cutting mechanism. | Supports the blades and directs grass clippings. |

| Blades | Sharp metal edges responsible for cutting. | Trim grass to the desired height. |

| Wheels | Round components that facilitate movement. | Allow the tool to traverse various terrains. |

| Handle | Control interface for operation. | Enables steering and adjusting speed. |

Understanding these components and their respective functions can significantly enhance the overall experience, ensuring effective usage and maintenance. Users equipped with this knowledge can make informed decisions regarding repairs and upgrades, ultimately leading to better outcomes in their landscaping tasks.

Key Features of Rough Cut Mowers

When considering a machine designed for handling tough vegetation, several important characteristics come into play. These features not only enhance performance but also ensure durability and ease of use, making the equipment ideal for various outdoor tasks.

Powerful Engine: A robust engine is essential for tackling dense undergrowth. The higher horsepower ratings allow for efficient operation, ensuring that even the toughest brush can be managed with ease.

Wide Cutting Deck: The expansive cutting area minimizes the number of passes required, increasing productivity. This design is particularly beneficial for large areas where time efficiency is crucial.

Heavy-Duty Construction: Built with rugged materials, these machines are designed to withstand harsh conditions. Their sturdy frames and components contribute to longevity, reducing the need for frequent repairs.

Adjustable Cutting Height: Flexibility in cutting height allows users to adapt to different types of terrain and vegetation. This feature enables precise control over the desired outcome, whether it’s a clean finish or a more natural look.

Easy Maneuverability: Designed for ease of use, these devices often come with features that enhance maneuverability, such as responsive steering and a compact design, allowing users to navigate tight spaces effortlessly.

Safety Features: Modern equipment prioritizes user safety. With protective measures in place, such as automatic shut-off mechanisms and durable shielding, operators can work with confidence.

In summary, these essential attributes create a powerful tool for land management, ensuring efficiency, durability, and safety for users tackling demanding outdoor projects.

Importance of Proper Maintenance

Ensuring optimal performance of equipment is crucial for longevity and efficiency. Regular upkeep not only enhances functionality but also minimizes the likelihood of unexpected failures. Neglecting this essential aspect can lead to significant issues that may compromise both productivity and safety.

Enhancing Longevity

Consistent maintenance significantly extends the life of machinery. By regularly inspecting and servicing components, users can identify wear and tear before it escalates into more severe damage. This proactive approach reduces the need for costly replacements and downtime.

Improving Efficiency

Well-maintained equipment operates more effectively, providing better results while consuming less energy. Routine checks and timely repairs ensure that all parts function smoothly, contributing to overall performance. In turn, this efficiency translates into cost savings and enhanced productivity.

Common Issues with Mower Parts

Understanding the frequent challenges associated with lawn care machinery components is essential for effective maintenance and longevity. Various factors can lead to diminished performance, and recognizing these issues early can save both time and resources.

Frequent Challenges

- Wear and Tear: Components can degrade over time due to constant use, leading to reduced efficiency.

- Corrosion: Exposure to moisture can result in rust, compromising the integrity of metal parts.

- Improper Alignment: Misalignment can cause undue stress on parts, leading to accelerated failure.

Signs of Trouble

- Unusual noises during operation may indicate a problem with moving components.

- Decreased performance, such as uneven cutting or reduced power output, can signal underlying issues.

- Visible damage, such as cracks or bends in critical components, should be addressed promptly.

By staying vigilant and addressing these common issues, users can ensure their equipment remains in optimal working condition.

How to Identify Damaged Components

Recognizing compromised elements within machinery is essential for maintaining optimal performance and ensuring safety. Proper identification allows for timely repairs or replacements, thus prolonging the lifespan of the equipment.

Visual Inspection

Conducting a thorough visual examination can reveal a lot about the condition of various components. Look for the following signs:

- Cracks or Breaks: Inspect for visible fractures that may indicate structural failure.

- Corrosion: Check for rust or deterioration, especially on metal parts.

- Deformation: Look for bent or misshapen elements that could hinder functionality.

Functional Tests

In addition to visual checks, performing specific operational tests can help identify issues:

- Operational Sound: Listen for unusual noises during operation that could signal a problem.

- Performance Monitoring: Assess the efficiency of the machinery; decreased performance may point to faulty components.

- Response Check: Ensure that all controls and mechanisms respond properly; delays or malfunctions can indicate wear.

Swisher Parts Availability and Sources

Accessing essential components for outdoor equipment maintenance is crucial for ensuring optimal performance and longevity. Various suppliers and platforms offer a wide range of options, catering to different needs. Understanding where to find these items can significantly enhance the efficiency of your equipment upkeep.

Authorized Dealers and Retailers

One of the most reliable sources for components is through authorized dealers. These retailers provide genuine items that are specifically designed for compatibility and performance. Engaging with local distributors can often lead to personalized assistance and expert recommendations, ensuring that you obtain exactly what you need for your equipment.

Online Marketplaces and Specialty Websites

For those who prefer the convenience of online shopping, numerous specialty websites and marketplaces offer an extensive selection. These platforms often feature user-friendly search functions and detailed descriptions to help you identify the correct items. Additionally, customer reviews can provide insights into the quality and reliability of the components being purchased.

Researching and comparing options from various sources will enable you to make informed decisions, ensuring your equipment remains in top shape.

Step-by-Step Repair Process

When it comes to fixing your outdoor equipment, a systematic approach can make all the difference. This section will guide you through a comprehensive process to restore functionality and ensure longevity. Following these detailed steps will help you address common issues effectively, enabling you to enjoy reliable performance once again.

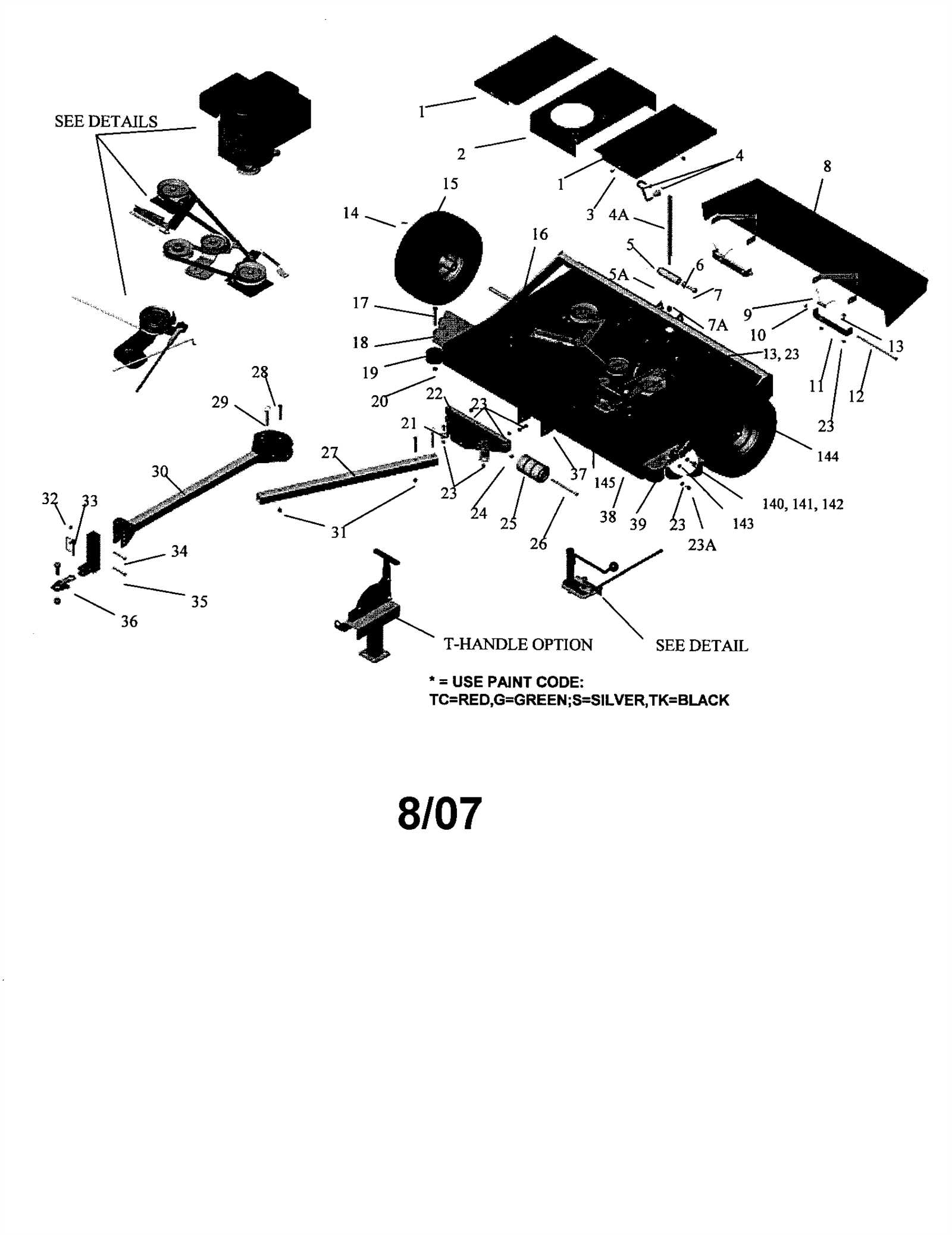

Start by gathering all necessary tools and replacement components. Having everything on hand minimizes downtime and enhances efficiency. Next, consult the maintenance manual or any available schematics to understand the assembly layout. This knowledge is crucial for a smooth disassembly and reassembly process.

Begin the repair by safely disconnecting power sources and removing any obstructive elements. Take care to document the order of disassembly, using photos or notes for reference. This will help you avoid confusion during reassembly. Inspect each part for wear or damage, paying close attention to areas that commonly experience stress.

Once the faulty components are identified, proceed with replacing them. Ensure that new parts fit correctly and are compatible with your equipment model. After installation, reassemble the unit in reverse order, referring to your earlier documentation as needed. Tighten all screws and fasteners securely to prevent future issues.

Finally, conduct a thorough test run to ensure everything functions as intended. Monitor for any unusual sounds or vibrations during operation. If any problems arise, revisit the previous steps to troubleshoot effectively. This meticulous approach not only resolves immediate concerns but also contributes to the overall maintenance of your equipment.

Tips for Safe Operation

Ensuring a secure and efficient experience while handling outdoor equipment is crucial for both the operator and the environment. Adhering to safety guidelines not only protects individuals but also enhances the performance of the machinery.

Pre-Operation Checks

- Inspect the equipment for any visible damages or wear before use.

- Ensure all safety guards and shields are in place and functioning properly.

- Check fluid levels, including fuel and oil, to prevent malfunctions.

- Confirm that all bolts and fasteners are tight to avoid operational hazards.

Safe Operating Practices

- Wear appropriate personal protective equipment, such as gloves and safety glasses.

- Keep bystanders at a safe distance during operation.

- Never operate the machinery on wet or uneven terrain to maintain stability.

- Be aware of your surroundings, including obstacles and potential hazards.

- Follow the manufacturer’s guidelines regarding operating speeds and techniques.

Enhancing Mower Performance Techniques

Optimizing the efficiency of grass cutting equipment involves a variety of strategies that ensure smooth operation and superior results. By focusing on maintenance, adjustments, and upgrades, users can significantly improve functionality and longevity.

Here are some effective techniques to elevate performance:

- Regular Maintenance: Establish a routine for cleaning and inspecting equipment to prevent buildup and wear.

- Blade Sharpening: Keep blades sharp to achieve clean cuts, reducing strain on the engine.

- Proper Tire Pressure: Check and maintain correct tire inflation to enhance traction and maneuverability.

- Engine Care: Regularly change oil and air filters to ensure optimal engine performance and fuel efficiency.

Additionally, consider the following upgrades:

- High-Performance Blades: Invest in quality blades designed for specific grass types or terrain for improved cutting efficiency.

- Powerful Engines: Upgrade to a more robust engine to handle larger jobs and tougher conditions.

- Advanced Deck Design: Look for models with innovative deck designs that enhance airflow and cutting capabilities.

Implementing these techniques will not only enhance the operation of your equipment but also ensure a more satisfying experience in lawn care.

Choosing the Right Replacement Parts

Selecting the appropriate components for your outdoor equipment is crucial for maintaining optimal performance and extending the lifespan of your machinery. Understanding the significance of quality, compatibility, and functionality can help you make informed decisions when it’s time to replace worn-out items.

Understanding Compatibility

Ensuring that new components fit seamlessly with your existing equipment is essential. Not all replacements are created equal; thus, it’s vital to verify specifications before making a purchase. Check the model number and any other relevant details to avoid mismatches that could lead to further issues.

Quality Over Cost

While it may be tempting to opt for the cheapest alternatives, investing in high-quality components can save you money in the long run. Durable materials and reliable brands often offer better performance and longevity, reducing the frequency of replacements and maintenance efforts. Prioritizing quality ensures that your machinery operates efficiently and safely.

By considering compatibility and quality, you can enhance the reliability of your outdoor tools and enjoy a more efficient working experience.

DIY vs. Professional Repairs

When it comes to maintaining equipment, individuals often face the decision of tackling repairs themselves or hiring a specialist. Both approaches have their merits and drawbacks, influencing not only the outcome but also the time and cost involved. Understanding the nuances between self-service and professional assistance can guide users in making informed choices.

Do-It-Yourself repairs offer the benefit of convenience and potential savings. With a bit of research and the right tools, enthusiasts can often address minor issues effectively. Engaging in hands-on fixes can also foster a sense of accomplishment and deepen one’s understanding of the equipment. However, without adequate expertise, there’s a risk of exacerbating problems or causing additional damage.

On the other hand, professional repairs bring experience and specialized knowledge to the table. Technicians are equipped to diagnose complex issues that may not be immediately apparent to the untrained eye. While this option may incur higher costs, it often results in faster and more reliable outcomes. Moreover, professionals typically offer warranties on their work, providing peace of mind for the owner.

Ultimately, the choice between DIY and professional services depends on the complexity of the repair, the individual’s skill level, and the urgency of the situation. Balancing cost, efficiency, and the potential for learning can help determine the best path forward.

Storing Your Mower Properly

Ensuring the longevity and efficiency of your equipment involves careful consideration during storage. Proper handling and maintenance before putting your machine away can prevent issues and extend its lifespan.

Follow these essential steps for effective storage:

- Clean Thoroughly: Remove any grass clippings, dirt, or debris. This helps prevent rust and corrosion.

- Check Fluids: Ensure that oil and fuel levels are appropriate. Consider draining old fuel to avoid clogs.

- Inspect Blades: Sharpen and clean the cutting edges to maintain performance for the next use.

- Remove the Battery: If applicable, store the battery in a cool, dry place, and ensure it’s charged to prevent degradation.

- Choose the Right Location: Store your machine indoors or under a cover to protect it from harsh weather conditions.

By adhering to these guidelines, you can ensure that your equipment remains in optimal condition and is ready for use when needed.