Comprehensive Guide to Zero Turn Mower Parts Diagram

In the realm of lawn maintenance, a particular type of equipment stands out for its efficiency and agility. These machines are designed to navigate tight spaces and execute sharp maneuvers with ease, making them a favorite among homeowners and professionals alike. However, to fully appreciate their functionality, it’s crucial to explore the intricate elements that enable their performance.

Each of these machines is comprised of various components, each playing a vital role in ensuring optimal operation. From the engine to the cutting blades, understanding how these elements interact can lead to better maintenance practices and improved longevity. A comprehensive overview of these components provides insights into the machinery’s capabilities and potential areas for enhancement.

Moreover, recognizing the relationship between the different sections can help users troubleshoot issues more effectively. This knowledge not only empowers operators but also promotes a deeper connection with the equipment they use. By delving into the specifics, one can unlock the full potential of these remarkable tools.

Understanding Zero Turn Mowers

The concept of highly maneuverable lawn care equipment has transformed the way enthusiasts and professionals approach landscaping. This specialized machinery, known for its agility and precision, offers unparalleled control over various terrains. With advanced steering systems and unique design features, it provides an efficient solution for maintaining expansive green spaces.

Key Features and Benefits

One of the most notable characteristics of this type of equipment is its ability to pivot on the spot. This function enables users to navigate around obstacles effortlessly, making it ideal for intricate landscapes. Additionally, the design often incorporates powerful engines that enhance productivity, allowing for quicker completion of tasks without compromising on quality.

Maintenance Considerations

Regular upkeep is essential to ensure longevity and optimal performance. Familiarity with the various components involved can greatly assist in troubleshooting and routine care. Understanding the functionality of each element not only aids in efficient operation but also extends the lifespan of the machine, ensuring that it remains a valuable asset in any landscaping arsenal.

Key Components of Zero Turn Mowers

Understanding the essential elements of these innovative lawn care machines is crucial for effective maintenance and operation. Each component plays a vital role in ensuring smooth functionality, enhancing performance, and providing optimal maneuverability across various terrains.

Steering System

The steering mechanism allows for exceptional agility and precision in navigation. Utilizing dual levers, this system enables operators to execute sharp turns with ease, making it ideal for landscaping tasks. Control and responsiveness are hallmarks of this design, facilitating a seamless mowing experience.

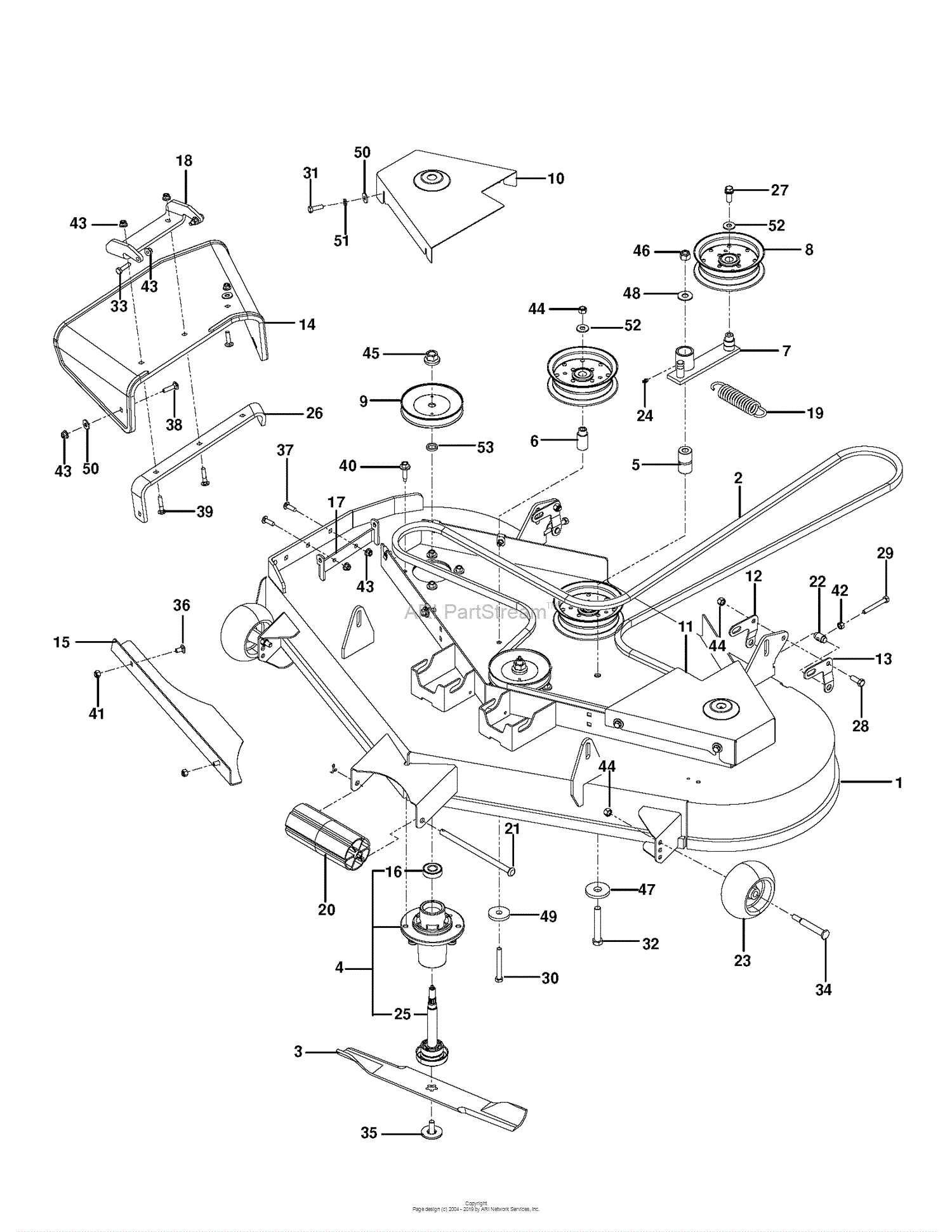

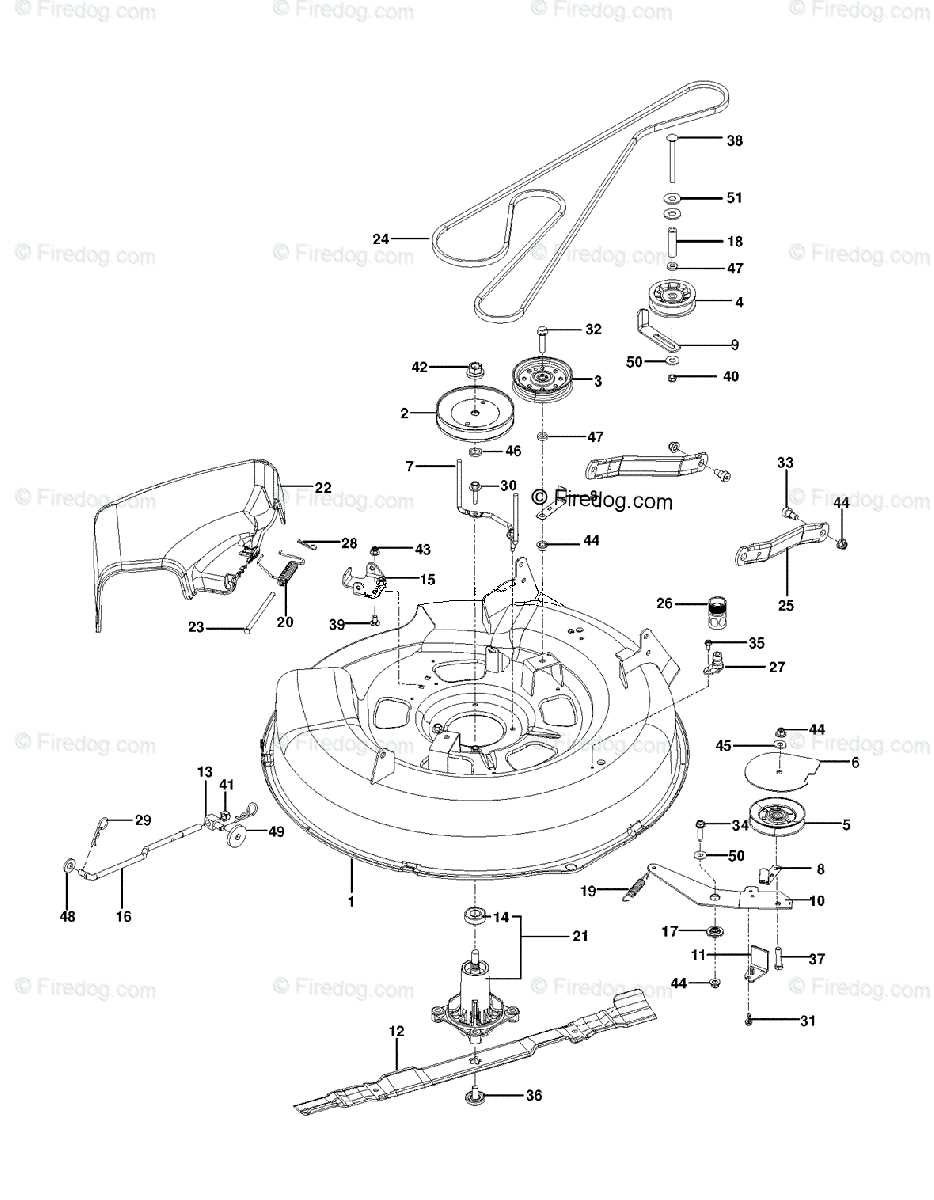

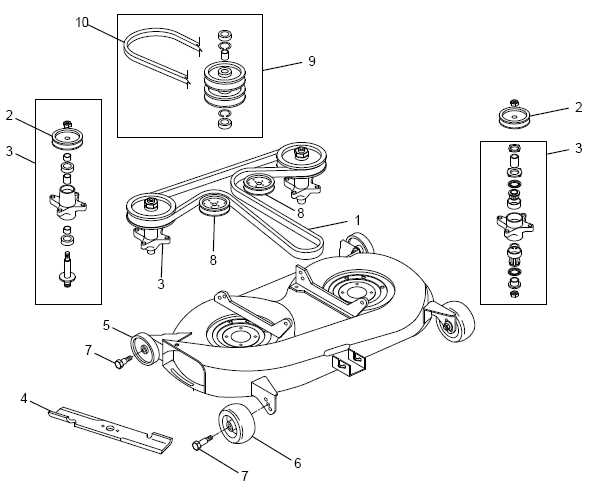

Cutting Deck

The cutting deck is a fundamental part responsible for the grass trimming process. Typically available in various widths, it influences the efficiency and quality of the cut. A well-designed deck ensures uniformity and minimizes clumping, allowing for a pristine finish on your lawn.

Benefits of Zero Turn Design

The innovative configuration of these grass maintenance machines offers numerous advantages that enhance efficiency and ease of use. By enabling operators to maneuver with exceptional precision, this design significantly improves the overall mowing experience.

Enhanced Maneuverability: One of the standout features of this design is its ability to navigate tight spaces and intricate landscapes. This flexibility allows users to work around obstacles, such as trees and flower beds, without difficulty.

Time Efficiency: The unique steering system enables faster operation, reducing the time required to complete lawn care tasks. Users can cover more ground in less time, making it an ideal choice for both residential and commercial applications.

Improved Comfort: Operators benefit from a comfortable seating position and ergonomic controls, minimizing fatigue during extended use. This focus on user experience promotes better results and higher satisfaction.

Precision Cutting: The design allows for tighter turns and closer trimming, resulting in a neater lawn finish. This level of detail is especially beneficial for maintaining high-quality landscapes.

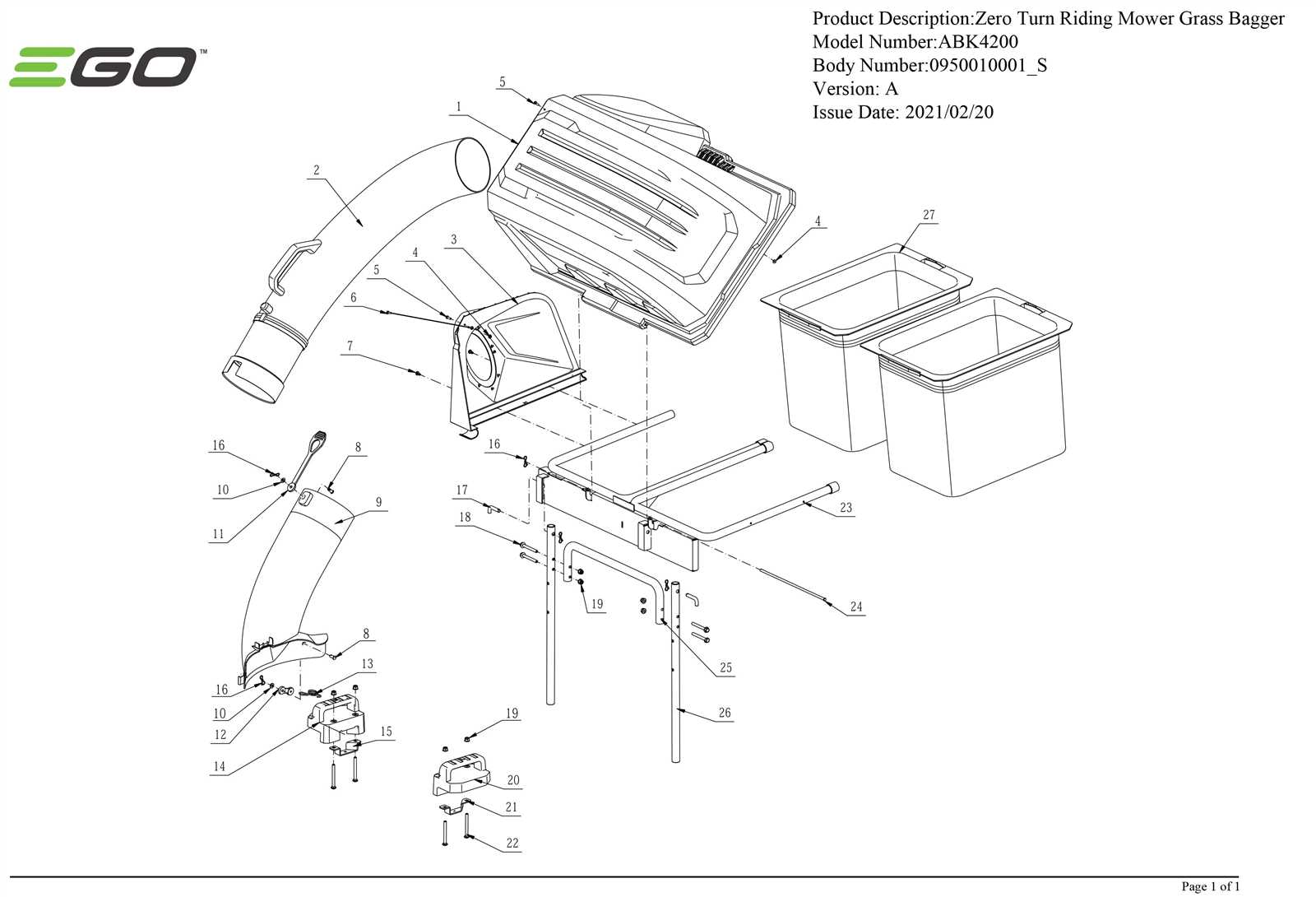

Versatility: Many models can accommodate various attachments, expanding their functionality beyond just cutting grass. This versatility allows users to tackle multiple tasks throughout the year, making it a worthwhile investment.

Common Parts in Lawn Care Equipment

Understanding the essential components of landscaping machinery is crucial for maintaining a well-groomed yard. These elements play a significant role in the overall functionality and efficiency of the equipment. Familiarity with these parts can help users ensure their tools remain in top condition, ultimately leading to better results in lawn maintenance.

Key Components

- Blades: Critical for cutting grass to the desired height, these sharp elements come in various shapes and sizes to accommodate different types of machinery.

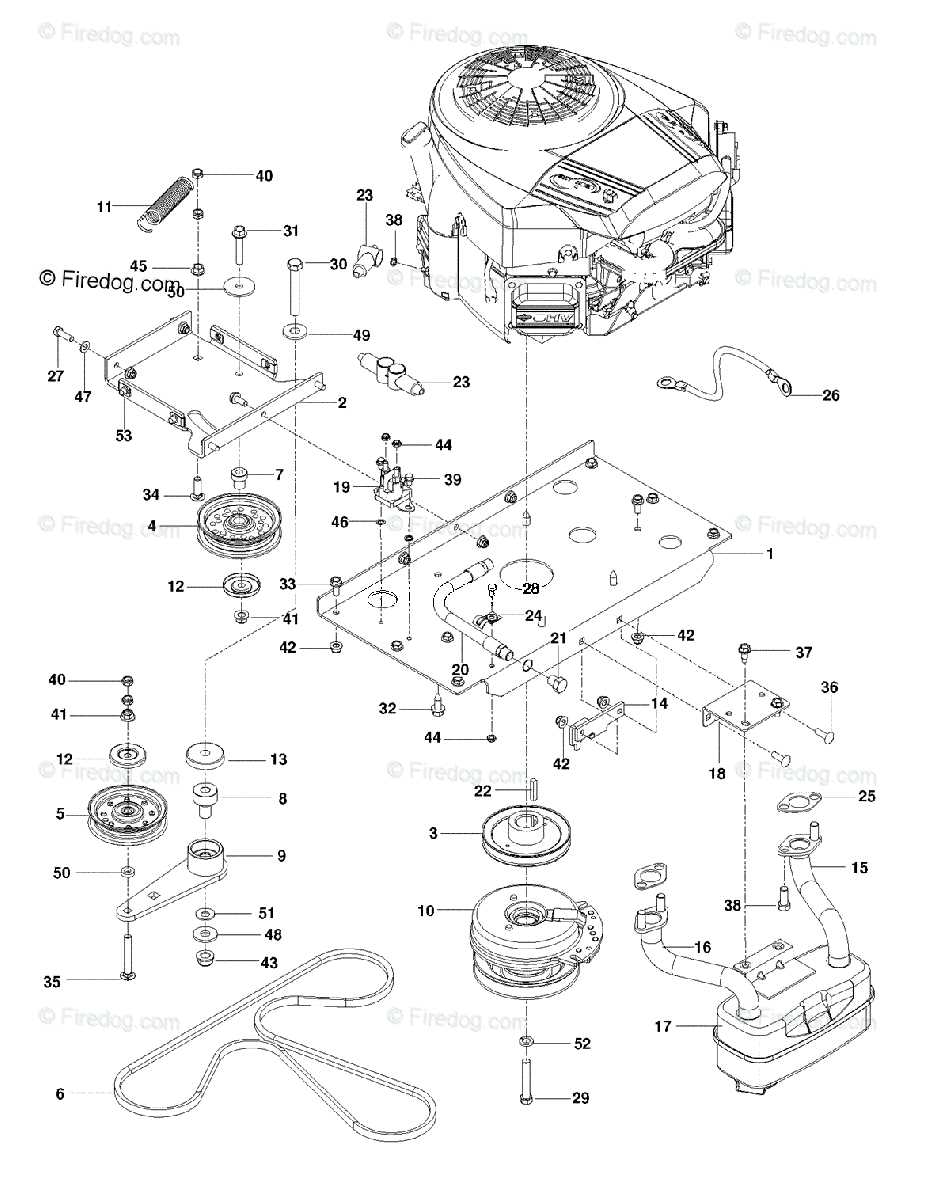

- Engines: The power source behind the equipment, available in gas or electric varieties, impacting performance and efficiency.

- Deck: The housing that contains the cutting mechanism, designed to provide durability and protect internal components.

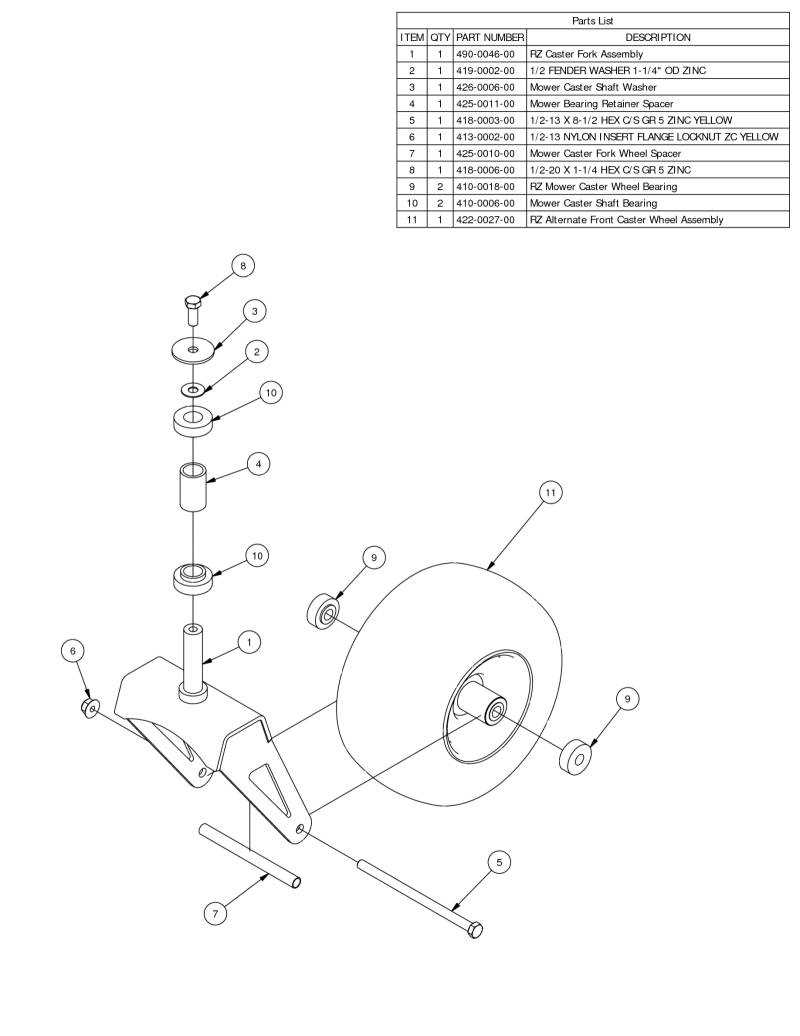

- Wheels: Essential for mobility, available in various sizes to navigate different terrains effectively.

- Controls: The user interface that allows for steering, speed adjustment, and various functions depending on the specific model.

Maintenance Essentials

- Regularly check and sharpen blades to ensure clean cuts.

- Change oil and filters according to manufacturer recommendations for optimal engine performance.

- Inspect belts and cables for wear to prevent mechanical failures.

- Keep wheels free from debris to ensure smooth movement.

- Clean the deck regularly to maintain efficiency and longevity.

By understanding these fundamental components and maintenance practices, users can enhance the performance and lifespan of their landscaping tools, leading to more effective lawn care results.

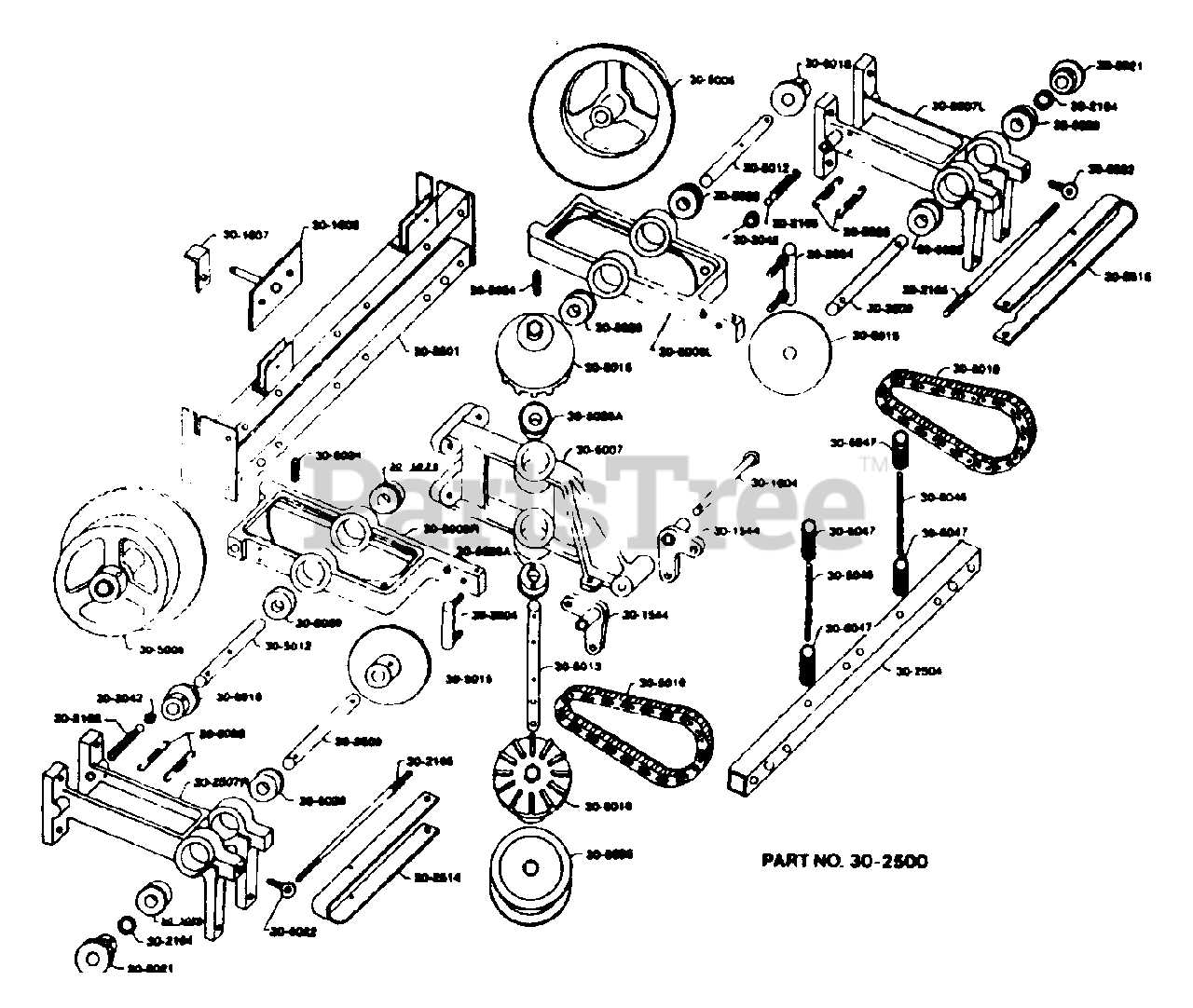

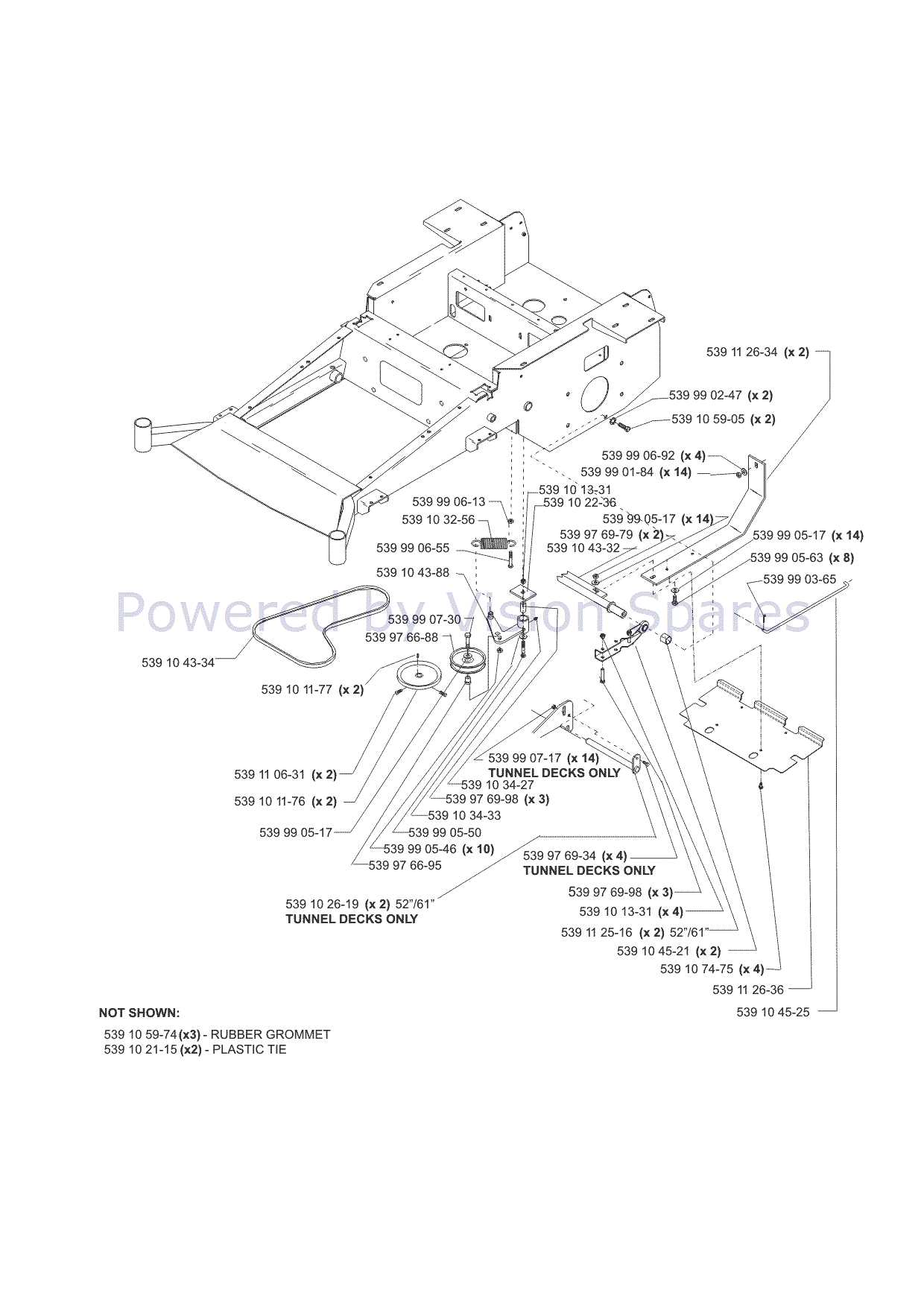

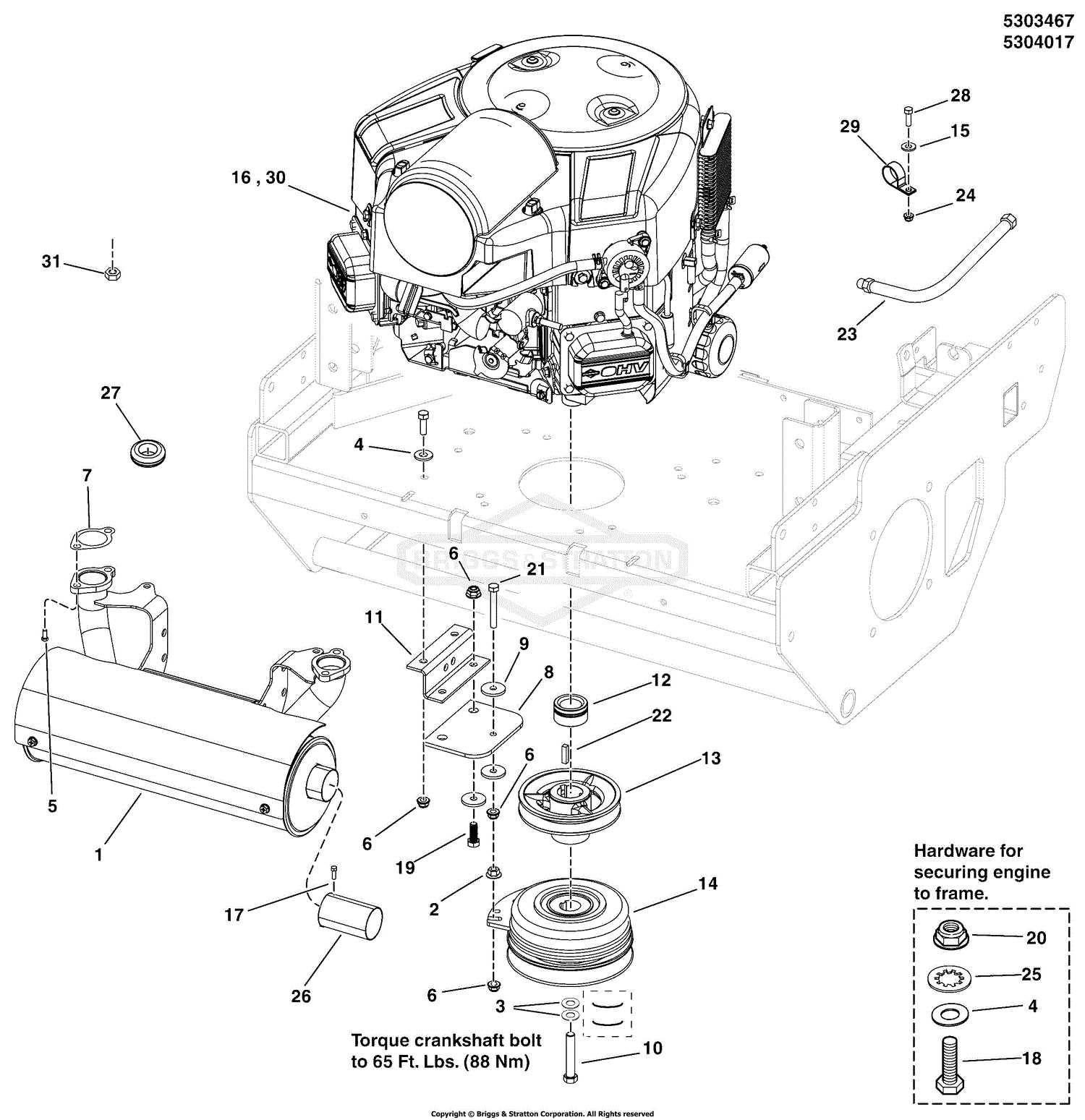

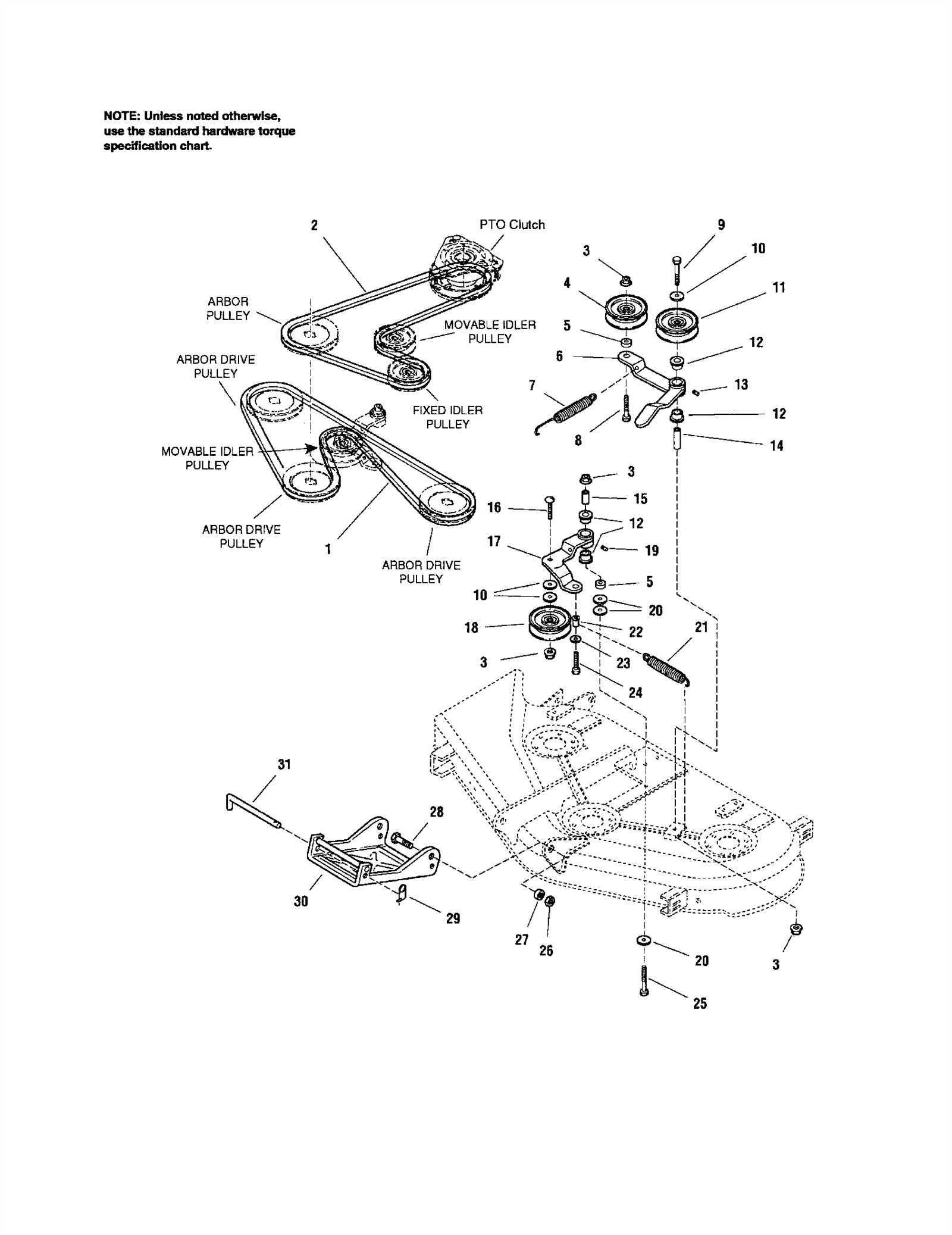

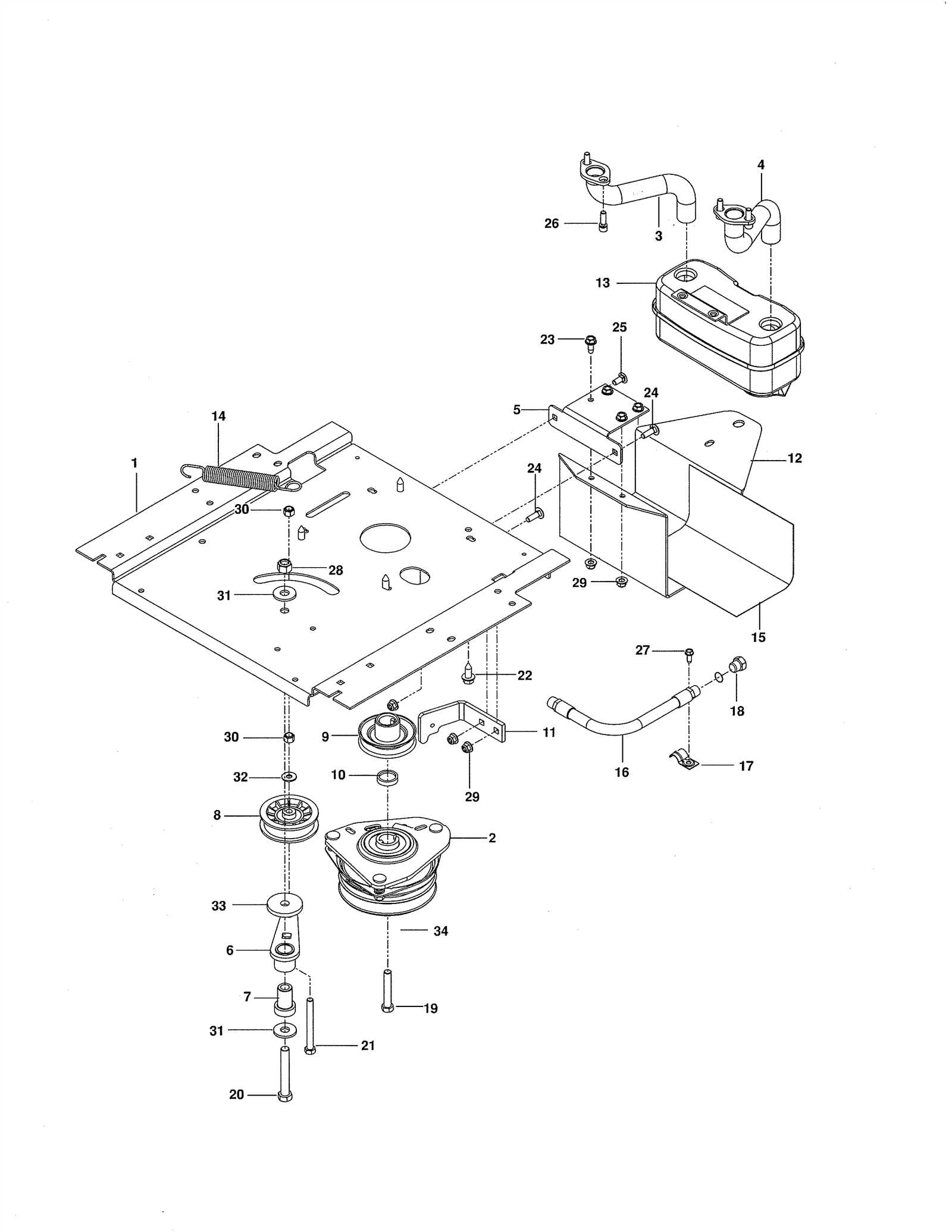

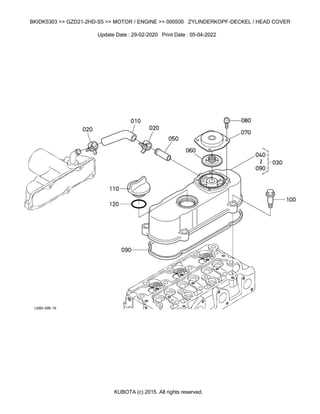

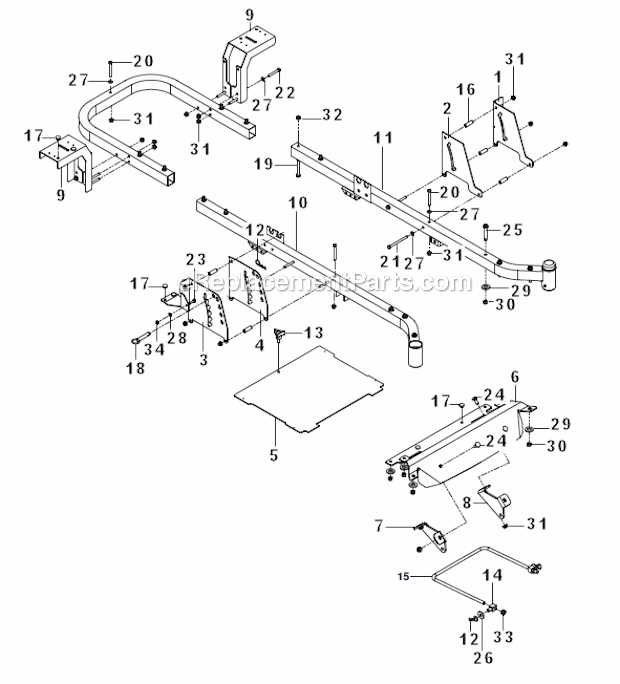

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair. These visuals provide a comprehensive overview of components, their arrangement, and connections. Familiarizing yourself with symbols and labeling can greatly enhance your ability to identify and source necessary elements.

Start with the legend: Most illustrations include a key that defines symbols used throughout. This is your roadmap to understanding the visual representation.

Identify major sections: Break down the diagram into smaller sections. Recognizing groupings can help you focus on specific areas without feeling overwhelmed.

Pay attention to numbering: Many illustrations feature numbers corresponding to a list of items. This aids in quickly locating and referencing the required components.

By mastering these techniques, you’ll ultimately enhance your ability to navigate complex schematics and streamline your repair processes.

Identifying Major Assembly Sections

Understanding the key components of a lawn care machine is essential for efficient maintenance and repair. This section focuses on the primary sections that make up the overall structure, helping users navigate through the intricacies of their equipment. By familiarizing oneself with these areas, users can enhance their operational efficiency and troubleshoot issues more effectively.

The main assembly is typically divided into several crucial segments, including the cutting mechanism, transmission system, and steering controls. Each segment plays a vital role in the functionality of the machine. Recognizing these sections allows operators to identify potential problems and perform necessary adjustments or replacements with confidence.

Moreover, a clear understanding of each assembly section aids in the disassembly and reassembly process, making it easier to manage repairs. Users should pay attention to the connections and interactions between these components to ensure optimal performance and longevity of their equipment.

Maintenance Tips for Longevity

To ensure the lasting performance of your landscaping equipment, regular upkeep is essential. This not only enhances efficiency but also prolongs the lifespan of your machinery. Implementing simple maintenance practices can make a significant difference in how well your equipment functions over time.

Regular Inspection

Conducting routine checks can help identify wear and tear early. Look for any loose components or signs of damage that could affect performance.

Cleaning and Lubrication

Keep the exterior and interior of your equipment clean to prevent buildup that can lead to issues. Additionally, regular lubrication of moving parts reduces friction and wear.

| Maintenance Task | Frequency |

|---|---|

| Inspect belts and cables | Monthly |

| Clean air filter | Every 25 hours |

| Change oil | Every 50 hours |

| Sharpen blades | Every 10 hours |

Common Issues and Troubleshooting

In the realm of lawn care equipment, encountering challenges is not uncommon. Understanding these typical problems can significantly aid in effective maintenance and ensure optimal performance. By identifying symptoms early, users can prevent further complications and enhance the longevity of their machinery.

Frequently Encountered Problems

Many users face similar issues when operating their equipment. Below is a table summarizing some of the most prevalent challenges along with possible solutions:

| Issue | Potential Cause | Recommended Action |

|---|---|---|

| Engine won’t start | Empty fuel tank | Refill with fresh fuel |

| Uneven cutting | Worn blades | Sharpen or replace blades |

| Excessive vibration | Loose components | Tighten bolts and screws |

Maintenance Tips

Regular upkeep is essential to avoid these issues. Check fluid levels, inspect belts, and clean filters frequently to maintain peak functionality. By adopting a proactive approach, operators can mitigate problems and enjoy a smoother experience.

Aftermarket vs. Original Parts

The choice between alternative and manufacturer-specific components can significantly impact performance and longevity. Each option presents its own set of advantages and potential drawbacks, making it essential for users to consider their specific needs and preferences.

Original components are designed by the original equipment manufacturer and often guarantee compatibility and reliability. They may come with warranties and support, which can offer peace of mind for users concerned about quality and fit.

On the other hand, aftermarket options typically provide a wider range of prices and choices. Many users find them appealing due to cost-effectiveness and the availability of specialized features that might not be present in original offerings. However, quality can vary significantly, so thorough research is crucial.

Replacing Worn Out Components

Maintaining optimal performance requires periodic updates of aged elements in your equipment. Regularly assessing and substituting these components ensures efficiency and longevity, preventing potential breakdowns during use. Addressing wear and tear promptly can save both time and resources.

Identifying Worn Components

Begin by examining the key sections of your machine for signs of deterioration. Look for unusual noises, decreased performance, or visible damage. Components such as belts, blades, and filters often require attention as they endure significant stress.

Steps for Replacement

Once you’ve identified the affected items, follow these steps for replacement:

- Gather Tools: Ensure you have the necessary tools for disassembly.

- Carefully Remove: Take out the worn components, following the manufacturer’s guidelines.

- Install New Parts: Position the new elements precisely and securely.

- Test Performance: After installation, check for proper operation before resuming regular use.

By staying proactive in replacing outdated components, you enhance the functionality and durability of your equipment.

Tools Needed for Repair Work

When undertaking maintenance or repair tasks on specialized machinery, having the right instruments is crucial for efficiency and effectiveness. A well-equipped toolkit not only speeds up the process but also enhances the quality of the repairs performed. Below is a comprehensive list of essential tools to consider for your next project.

Essential Hand Tools

- Wrenches (adjustable and socket)

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Torque wrench

- Hammers (rubber and claw)

Power Tools for Efficiency

- Drill and drill bits

- Impact wrench

- Angle grinder

- Reciprocating saw

- Air compressor (for pneumatic tools)

Equipping yourself with these tools will ensure that you are prepared for any repair challenge that may arise, making the process smoother and more manageable.

Safety Precautions During Maintenance

Ensuring safety while performing maintenance tasks is crucial to prevent accidents and injuries. Following appropriate guidelines and using protective equipment can significantly reduce risks associated with mechanical upkeep.

- Always disconnect the power source before beginning any work.

- Wear suitable personal protective equipment, including gloves and safety goggles.

- Make sure the equipment is on a flat surface to avoid any unintended movements.

- Keep the workspace clean and free of obstacles to prevent trips and falls.

- Read the manufacturer’s instructions thoroughly before starting any repairs.

By adhering to these safety measures, individuals can ensure a secure environment while maintaining their equipment.

Resources for Parts and Support

Accessing reliable resources for maintenance and repair components is crucial for optimal performance and longevity of your equipment. Whether you’re looking for technical assistance or specific items, various platforms can provide valuable information and support to ensure your machine operates smoothly.

Online Retailers

Numerous online retailers specialize in selling components for various types of machinery. Websites offer extensive catalogs, detailed descriptions, and user reviews that can help you make informed decisions. It’s advisable to compare prices and check for warranties or return policies.

Community Forums

Engaging with online communities can yield insights from experienced users who share tips, recommendations, and troubleshooting advice. These forums are excellent for discussing common issues and discovering alternative solutions, enriching your knowledge base.