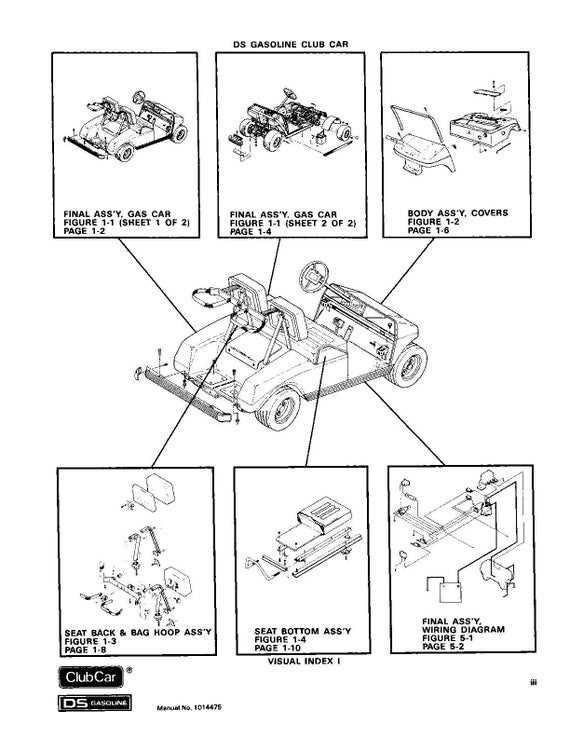

Overview of 1991 Club Car Parts Diagram

Understanding the configuration of various elements in mechanical systems is essential for proper maintenance and repair. This guide focuses on helping users navigate the layout of essential mechanisms, providing clarity for both beginners and experienced individuals. By examining the arrangement of different sections, the guide offers valuable insights into optimizing performance and ensuring long-term reliability.

Structural Composition plays a key role in how efficiently the system operates. Each segment must function in harmony with others, making it crucial to recognize the connections and interactions between them. Accurate knowledge of these details can significantly simplify any adjustments or replacements that may be required over time.

This resource serves as a comprehensive reference for locating specific components and understanding their functions within the broader mechanical framework. With this knowledge, tasks such as troubleshooting and improving functionality become much easier, ensuring that the system remains in top condition.

Comprehensive Overview of 1991 Club Car Components

This section provides a detailed analysis of the main elements that ensure the functionality and performance of the vehicle. These elements work together to deliver smooth operation and consistent reliability across various driving conditions.

Key Systems and Mechanisms

Each system plays a crucial role in the overall performance. Whether it’s the power unit responsible for propulsion or the control mechanisms that offer precise handling, these components are engineered to optimize efficiency and safety. The braking system, in particular, ensures secure stops, while the suspension provides stability on uneven surfaces.

Structural and Supportive Elements

The structural frame and supportive elements form the backbone of the vehicle, ensuring durability and protection. These components are designed to withstand long-term use while maintaining the integrity

Essential Parts for Optimal Performance

To maintain a high level of efficiency and ensure smooth operation, it’s important to focus on the key components that keep the vehicle running at its best. Proper maintenance and attention to detail can significantly extend the lifespan of your equipment while enhancing its functionality.

- Engine Components: Regular checks and timely replacements of core elements within the motor ensure consistent power delivery and reliability.

- Brake System: Maintaining the braking mechanism is essential for safety and control, ensuring effective stopping power when needed.

- Electrical System: The wiring and battery must be in top shape to avoid malfunctions, guaranteeing smooth operation of all systems.

- Suspension Elements: A well-maintained suspension ensures a comfortable and controlled ride, minimizing wear on other parts.

Regular upkeep of these areas will ensure your vehicle continues to perform efficiently, avoiding unnecessary breakdowns and costly repairs.

Understanding the Electrical System Layout

The electrical system plays a critical role in ensuring smooth functionality of various components in a vehicle. To comprehend its structure, it’s essential to explore the connections between the battery, wiring, and all key electrical elements. This section aims to provide a clear overview of how these components interact without diving into unnecessary complexity.

Key Components of the Electrical Setup

- Battery: The central power source for the entire electrical system, providing energy for all connected elements.

- Wiring: A network of wires ensures the delivery of electricity from the power source to each component.

- Switches: These control the activation of specific systems, like lighting or ignition.

Flow of Power Throughout the System

- Power is generated by

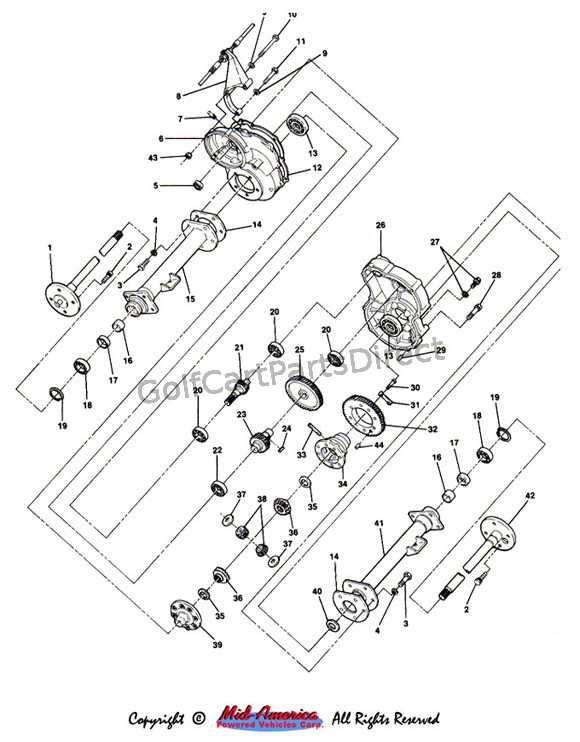

Key Features of the Suspension Assembly

The suspension system plays a crucial role in ensuring a smooth and stable ride by absorbing shocks and maintaining vehicle balance. Its design is centered on improving comfort, handling, and durability, allowing for better control over various terrains.

Shock absorbers and springs work in tandem to reduce vibrations and manage weight distribution. This cooperation helps the vehicle maintain optimal traction, even on uneven surfaces. The components are crafted to endure prolonged use while minimizing wear and tear.

The structural layout of the assembly is engineered to align with performance requirements, making it adaptable to different driving conditions. It ensures that the frame remains stable, reducing the impact felt by the occupants and protecting the vehicle from excessive strain.

Guide to Brake System Maintenance

Maintaining the braking system is crucial for ensuring optimal vehicle safety and performance. Proper care and regular inspections can prevent wear and ensure the system functions efficiently. This guide will provide key steps to help you understand how to maintain and service the brakes effectively.

- Inspection Frequency: Regularly check the condition of all components. Worn-out parts should be replaced to avoid safety risks.

- Brake Pads: Monitor the thickness of the pads. If they are too thin, it can lead to reduced braking power and damage to other elements.

- Fluid Levels: Check the brake fluid regularly. Low levels can result in reduced performance or even complete failure.

- Cleaning: Ensure that the braking system is clean from dirt and debris, which can affect

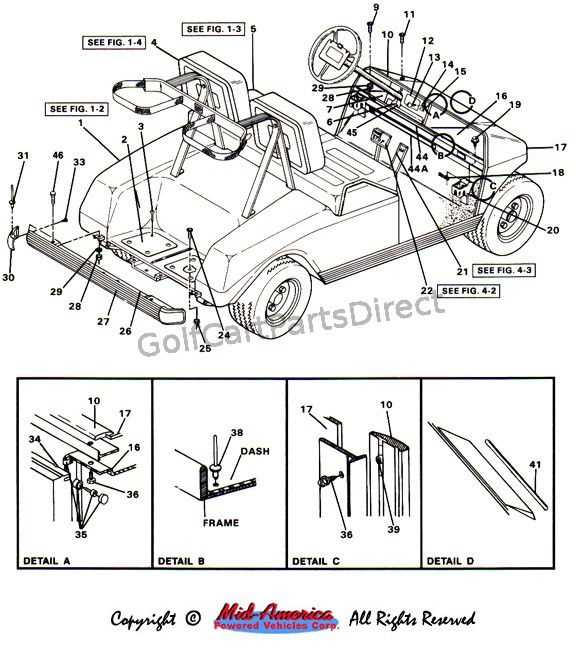

Chassis Diagram and Component Placement

The arrangement of essential elements within a vehicle’s structure is crucial for optimal functionality and performance. This section explores the layout of various components, emphasizing their respective positions and interconnections. Understanding this setup is vital for maintenance and repairs, ensuring that all parts work harmoniously together.

Key Structural Elements

- Frame: The foundational structure that supports all other components.

- Suspension: The system that absorbs shocks and provides stability.

- Axles: Rods that connect wheels, enabling movement.

- Steering Mechanism: The apparatus that allows for directional control.

- Braking System: The components responsible for slowing down or stopping.

Positioning and Functionality

- Frame: Positioned at the base, it serves as the core support.

- Suspension: Attached to the frame, it ensures a smooth ride by managing road irregularities.

- Axles: Fixed in place, they enable rotation of the wheels.

- Steering Mechanism: Located at the front, facilitating easy navigation.

- Braking System: Strategically placed for effective response to driver commands.

Proper knowledge of these placements aids in troubleshooting and repairs, enhancing the longevity and reliability of the vehicle.

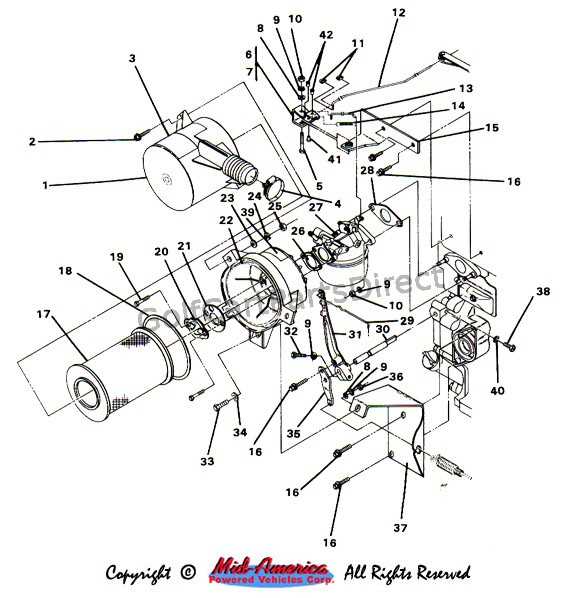

Engine System Breakdown and Functionality

The engine serves as the heart of any vehicle, responsible for generating power and enabling movement. Understanding its components and their respective roles is crucial for maintaining optimal performance. This section explores the various elements that comprise the engine system and their interrelated functions.

Key Components of the Engine System

- Crankshaft: Converts linear motion into rotational force.

- Pistons: Move up and down within the cylinders to create compression.

- Cylinders: Encloses the pistons and plays a vital role in the combustion process.

- Camshaft: Regulates the timing of valve openings and closings.

- Valves: Control the intake of air and fuel, as well as the exhaust of gases.

- Fuel System: Delivers the necessary fuel to the engine for combustion.

Functionality Overview

The engine operates through a series of controlled explosions within the cylinders. This process begins with the intake stroke, where air and fuel enter the cylinder. Next, the compression stroke occurs, compressing the mixture for optimal ignition. Following this, the power stroke is initiated, where the explosion pushes the piston down, ultimately rotating the crankshaft. Finally, the exhaust stroke expels the leftover gases, making way for a new cycle.

Each component plays a vital role in this intricate process, and a failure in one area can significantly impact overall performance. Regular maintenance and understanding of these systems can lead to enhanced longevity and efficiency.

Cooling Mechanism and Parts Overview

The cooling system is crucial for maintaining optimal temperature levels within the vehicle’s engine. This section provides an in-depth look at the essential components that work together to ensure efficient heat dissipation. Understanding these elements is vital for effective maintenance and troubleshooting.

At the core of the cooling mechanism is the radiator, which plays a significant role in transferring heat away from the engine. The coolant circulates through the engine, absorbing heat and then flowing to the radiator, where it is cooled by airflow. Additionally, the thermostat regulates the flow of coolant, ensuring that the engine reaches and maintains the ideal operating temperature.

Other key components include the water pump, which facilitates the circulation of coolant, and the cooling fan, which enhances airflow through the radiator. Hoses connect these parts, allowing for seamless coolant flow. Regular inspection and maintenance of these components are essential for preventing overheating and ensuring the longevity of the engine.

Fuel System Layout for 1991 Models

The fuel system of these specific vehicles is designed to ensure optimal performance and efficiency. Understanding its configuration is essential for proper maintenance and troubleshooting. This layout integrates various components that work together to deliver fuel to the engine smoothly, allowing for seamless operation under various conditions.

At the heart of this system lies the fuel tank, which stores the essential liquid. Connected to the tank is the fuel pump, responsible for drawing fuel and delivering it through the fuel lines. These lines are carefully routed to minimize potential leaks and ensure a steady flow. Additionally, fuel filters play a crucial role in keeping contaminants at bay, protecting the engine from harmful particles.

Moreover, the system features a pressure regulator, which maintains the necessary pressure for optimal engine performance. This regulator ensures that the fuel reaches the engine at the correct pressure, enhancing efficiency and responsiveness. Understanding the layout of these components is vital for any maintenance tasks or modifications.

Understanding Steering System Components

The steering mechanism plays a crucial role in the overall functionality of a vehicle, allowing for precise navigation and control. It consists of various elements that work in harmony to ensure smooth movement and stability while driving. Each component contributes to the effectiveness of the steering process, influencing how the vehicle responds to the driver’s commands.

Key Elements of the Steering Assembly

At the heart of the steering assembly are several essential components. The steering wheel serves as the primary interface between the driver and the system, enabling the individual to dictate the direction of travel. Connected to the wheel is the steering column, which houses the necessary linkages and mechanisms that translate the driver’s input into movement.

The Role of Linkages and Joints

Linkages and joints form the connections between the steering column and the front wheels. These components are designed to facilitate smooth motion while minimizing play and enhancing responsiveness. A well-maintained linkage system ensures that the steering remains accurate and that the vehicle remains stable during various driving conditions.

Wiring and Connections Simplified

This section aims to provide a clear overview of the essential electrical components and their interconnections. Understanding these elements is crucial for efficient troubleshooting and maintenance.

Key Elements: The electrical system consists of various components such as switches, connectors, and wiring harnesses. Each part plays a vital role in ensuring the overall functionality of the vehicle’s electrical system.

Connections: Proper connections are fundamental for effective operation. Ensuring that all wires are securely attached and free from corrosion will enhance performance and longevity.

When examining the wiring setup, it is important to follow the established color codes and layouts. This attention to detail helps prevent confusion and facilitates easier repairs when issues arise.

Body Frame Structure and Materials

The construction of the frame is a fundamental aspect that contributes to the overall durability and performance of the vehicle. The framework serves as the backbone, providing essential support and stability, while its design influences handling characteristics and safety features. Understanding the materials and structural integrity involved in this component is crucial for maintenance and modifications.

Typically, the frame is constructed from a combination of robust metals and composites. Steel is commonly used due to its high tensile strength and resistance to deformation, whereas aluminum offers a lightweight alternative that enhances fuel efficiency. In some instances, reinforced plastics are incorporated for certain parts to reduce weight without compromising durability.

Material Type Properties Applications Steel High strength, durable, cost-effective Structural components, chassis Aluminum Lightweight, corrosion-resistant Body panels, support structures Reinforced Plastics Lightweight, moldable, impact-resistant Trim pieces, certain body components The choice of materials not only affects the weight and efficiency of the vehicle but also plays a significant role in its longevity and repairability. Proper maintenance of the frame ensures the vehicle remains safe and operational over time.

Transmission System Parts Identification

The transmission system plays a vital role in the functionality of any vehicle, facilitating the transfer of power from the engine to the wheels. Understanding the various components within this system is essential for maintenance and troubleshooting. This section focuses on identifying key elements of the transmission mechanism, ensuring optimal performance and longevity.

Main Components Overview

Various components collaborate within the transmission system to ensure smooth operation. Each element has a specific role, contributing to the overall functionality of the mechanism. Familiarity with these components aids in effective maintenance and repairs.

Component Name Description Gearbox Regulates the gear ratio, allowing for speed and torque adjustments. Driveshaft Transmits torque from the engine to the wheels, connecting the transmission to the differential. Torque Converter Allows for smooth acceleration by transferring engine power to the transmission fluid. Transmission Fluid Cools and lubricates the moving parts within the transmission, ensuring efficient operation. Importance of Proper Identification

Correctly identifying and understanding the various components is crucial for any maintenance task. It not only helps in diagnosing issues but also in making informed decisions regarding replacements and upgrades. Regular checks and familiarity with each element will significantly contribute to the reliability of the entire transmission system.