Understanding the 3.6 Pentastar Parts Diagram

In the realm of automotive engineering, a comprehensive understanding of engine components is essential for effective maintenance and repair. This section delves into the intricate relationships and functionalities of various elements that work harmoniously within a specific engine design. By grasping these connections, enthusiasts and professionals alike can enhance their diagnostic and troubleshooting skills.

Visual representation plays a crucial role in simplifying complex systems. Through detailed illustrations, one can appreciate the layout and positioning of each component, facilitating a deeper insight into how these parts interact. Such depictions are invaluable for anyone looking to optimize performance or address potential issues.

As we explore this topic, the focus will be on identifying critical features and understanding their roles within the engine assembly. By familiarizing yourself with these essential elements, you will be better equipped to navigate the challenges that come with engine service and enhancements, ultimately leading to improved efficiency and longevity of the vehicle.

Understanding the 3.6 Pentastar Engine

The modern powerplant has become a cornerstone of automotive engineering, known for its impressive blend of efficiency and performance. This sophisticated unit delivers a seamless driving experience while maintaining a balance between power output and fuel economy. Its design reflects advanced technological principles, showcasing the evolution of internal combustion engines.

At its core, this engine features a V6 configuration that optimizes both space and weight distribution, contributing to the overall dynamics of the vehicle. Each component is meticulously crafted to enhance reliability and longevity, ensuring that drivers can enjoy a smooth ride for years to come. The integration of modern technologies, such as variable valve timing, plays a crucial role in maximizing performance across various driving conditions.

Moreover, the system is engineered for versatility, making it suitable for a wide range of applications–from sedans to SUVs. The adaptability of this engine allows manufacturers to offer enhanced features without sacrificing efficiency, appealing to a broad audience of drivers. Understanding the intricate workings of this powerhouse can provide valuable insights into its capabilities and advantages in the automotive market.

In conclusion, this cutting-edge engine exemplifies the fusion of innovation and practicality, solidifying its position as a favored choice among car enthusiasts and everyday drivers alike. Its continued evolution promises to shape the future of vehicle performance and efficiency.

Key Features of the Pentastar Engine

The modern powertrain has revolutionized the driving experience with its impressive performance and efficiency. This engine design is characterized by several innovative attributes that enhance overall functionality and reliability.

Power and Efficiency: One of the standout features is the remarkable balance between horsepower and fuel economy. The engineering behind this engine allows for substantial output while minimizing fuel consumption, making it ideal for both daily commuting and spirited driving.

Smooth Operation: The integration of advanced technologies contributes to a refined driving experience. With reduced vibration and noise, the operation is smooth, providing comfort for all occupants.

Durability: Constructed with high-quality materials and meticulous attention to detail, this engine offers impressive longevity. It is designed to withstand the rigors of various driving conditions, ensuring reliability over time.

Versatility: This powertrain is compatible with a wide range of vehicles, from sedans to SUVs. Its adaptability makes it a popular choice for manufacturers looking to provide a powerful yet efficient option across multiple models.

Innovative Technology: Featuring cutting-edge advancements such as variable valve timing and multi-point fuel injection, the engine optimizes performance across different driving scenarios, further enhancing its appeal.

Overall, the thoughtful design and engineering behind this powertrain deliver a compelling blend of power, efficiency, and reliability, making it a notable choice in today’s automotive landscape.

Common Applications of the 3.6 Engine

The modern powertrain has become a cornerstone in various vehicles, offering a blend of performance and efficiency. This versatile engine is commonly utilized in a wide array of applications, ranging from sedans to SUVs, reflecting its adaptability to different automotive needs.

One of the most prevalent uses of this engine can be found in family vehicles, where a balance of power and fuel economy is essential. These models often prioritize comfort and space, making this engine an ideal choice for those seeking reliable daily transportation.

In the realm of crossovers and larger SUVs, this power unit provides the necessary torque to handle both city driving and off-road adventures. Its robust nature allows these vehicles to perform well under diverse conditions, appealing to both adventure enthusiasts and everyday drivers.

Performance-oriented applications also benefit from this engine’s capabilities. Sports models and higher trims leverage its power for an exhilarating driving experience, enhancing responsiveness without sacrificing reliability.

Moreover, commercial vehicles have adopted this engine for its durability and efficiency, making it suitable for various business applications. Its ability to handle demanding tasks while maintaining economical fuel consumption is highly valued in this sector.

Overall, the widespread integration of this engine across multiple vehicle categories highlights its importance in the automotive industry, demonstrating a successful fusion of technology and engineering that meets a variety of consumer demands.

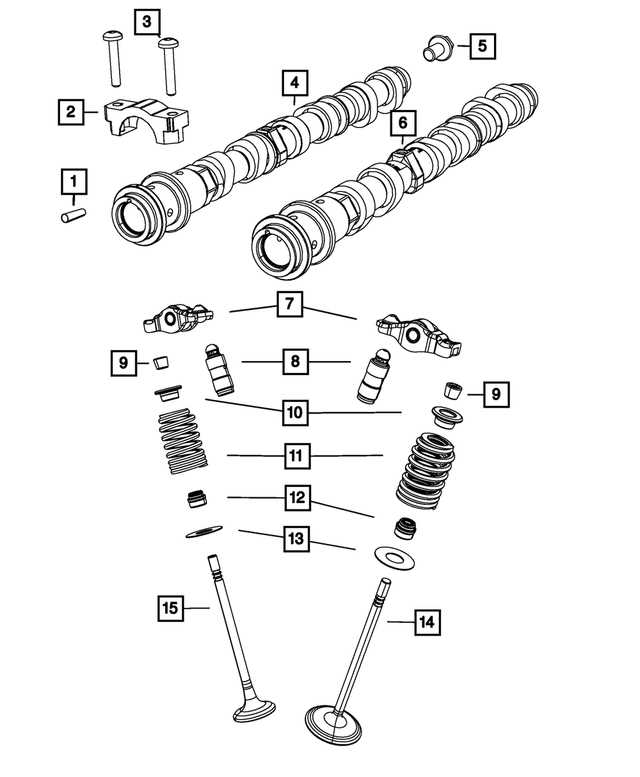

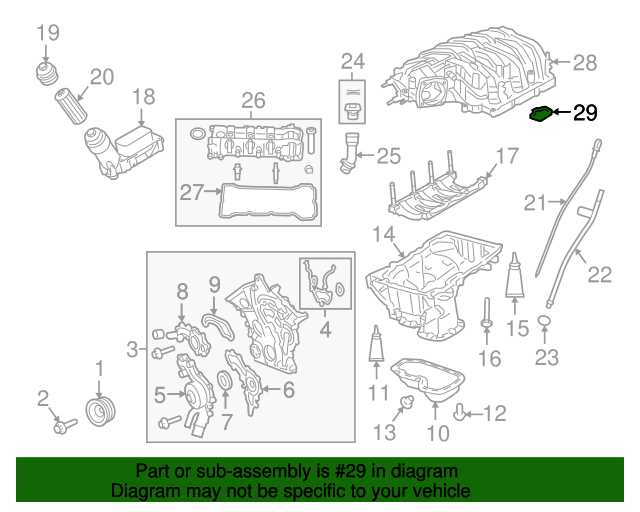

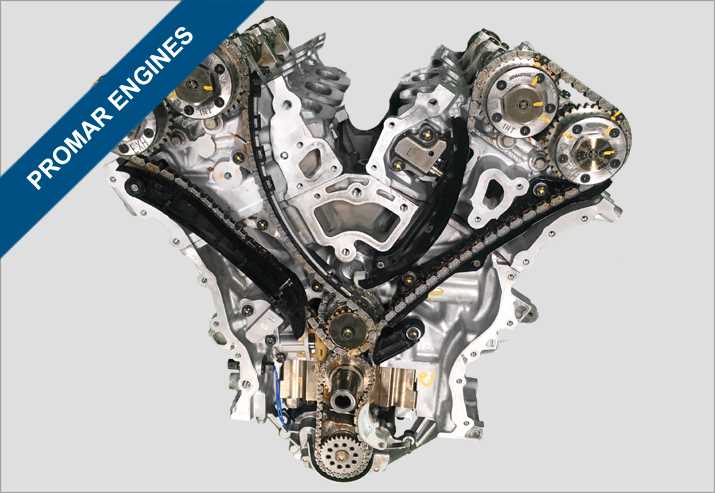

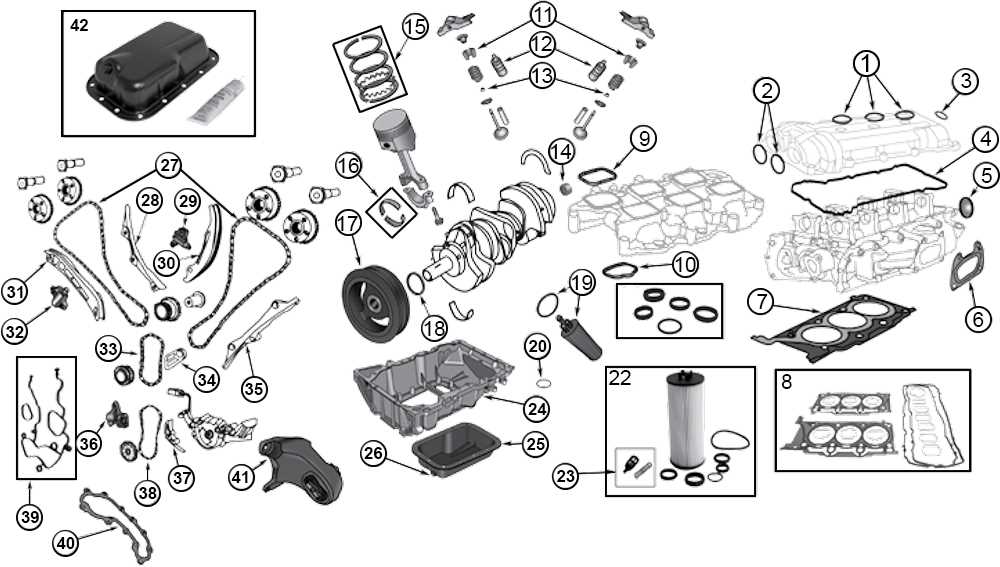

Parts Breakdown of Pentastar Engine

This section provides an overview of the components that make up a renowned powertrain. Understanding the various elements is essential for both maintenance and enhancement, ensuring optimal performance and longevity. Each segment plays a vital role in the overall functionality and efficiency of the engine.

Engine Block: The core structure houses the cylinders and supports all moving parts. It is engineered for durability and effective heat dissipation.

Cylinder Head: Positioned atop the block, this component contains vital elements such as the intake and exhaust valves, facilitating the crucial gas exchange process.

Pistons: These cylindrical units move within the cylinders, converting fuel energy into mechanical work. Their design impacts efficiency and power output.

Crankshaft: This rotating shaft transforms linear piston motion into rotational energy, driving the vehicle’s wheels.

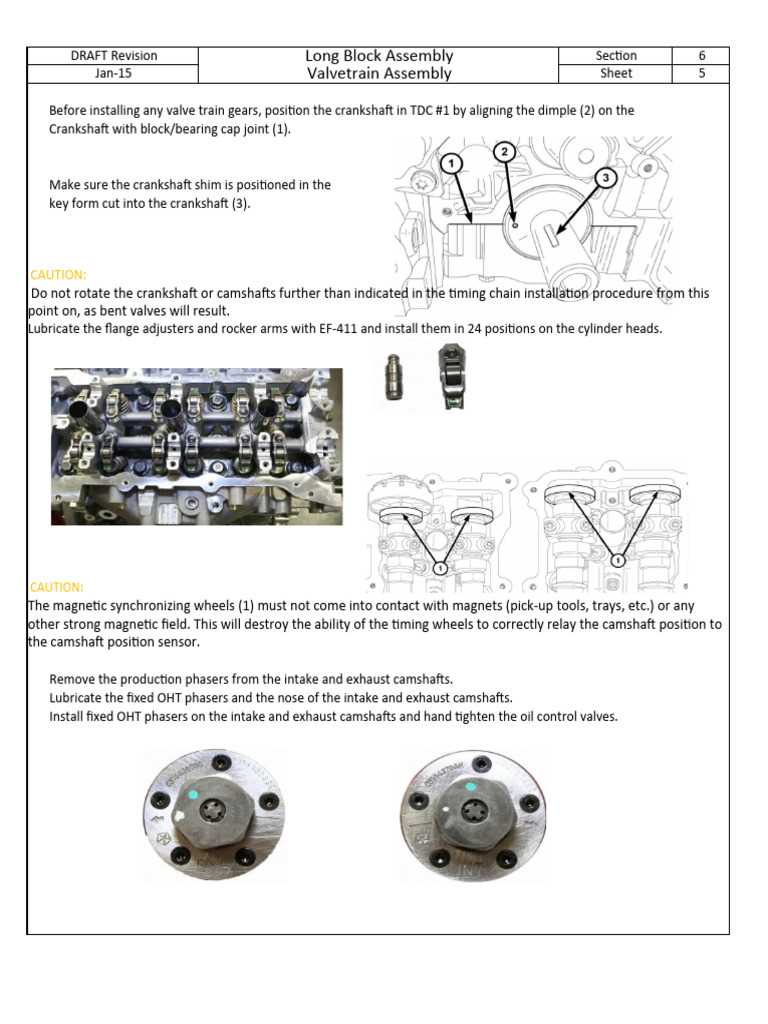

Timing Chain: An essential part that synchronizes the movement of the crankshaft and camshaft, ensuring precise timing for optimal performance.

Fuel Injectors: These devices atomize fuel, delivering it directly into the combustion chamber for efficient burning, impacting both power and emissions.

Exhaust System: This assembly directs waste gases away from the engine, minimizing back pressure and enhancing overall efficiency.

Each of these components contributes significantly to the overall system, and a thorough understanding can aid in troubleshooting and performance tuning. Regular inspections and maintenance can help in achieving maximum performance and reliability from this engine configuration.

Importance of Proper Maintenance

Maintaining your vehicle is crucial for ensuring its longevity and optimal performance. Regular care not only enhances efficiency but also helps in preventing unexpected breakdowns, saving you both time and money. By investing in consistent upkeep, you can identify potential issues before they escalate into costly repairs.

Benefits of Routine Care

Adhering to a routine maintenance schedule provides numerous advantages. It can improve fuel efficiency, extend the lifespan of key components, and enhance overall safety. Furthermore, regular inspections allow for timely replacements of worn-out elements, ensuring your vehicle operates smoothly and reliably.

Impact on Resale Value

A well-maintained vehicle often commands a higher resale value. Prospective buyers are more likely to invest in a car with documented service history, showcasing its reliability and care. This proactive approach not only benefits you during ownership but also secures better returns when it’s time to sell.

Identifying Common Issues and Solutions

In the realm of automotive maintenance, recognizing prevalent problems and their remedies is essential for ensuring optimal vehicle performance. Many drivers encounter similar challenges, which can often be addressed with straightforward solutions. This section aims to highlight some frequent concerns and provide effective strategies to resolve them.

Overheating is a common issue that can arise from various factors, including coolant leaks or a malfunctioning thermostat. Regularly checking the coolant levels and inspecting hoses can prevent this problem. If overheating occurs, it is crucial to stop the vehicle and allow it to cool before investigating the cause.

Engine Misfires can result from faulty spark plugs or issues with the ignition system. Symptoms may include rough idling or reduced power. To tackle this, routine maintenance, such as replacing spark plugs and inspecting ignition coils, is advisable. Addressing these components can restore engine efficiency and performance.

Oil Leaks often signify worn seals or gaskets. Noticing spots under the vehicle can indicate a need for inspection. Replacing these components promptly can prevent further damage and maintain engine integrity.

Finally, Fuel Efficiency Decline is a concern for many drivers. Factors such as dirty air filters or improper tire pressure can contribute to this issue. Regularly replacing air filters and ensuring tires are correctly inflated can significantly improve fuel economy.

By being proactive and addressing these common issues, vehicle owners can enhance their driving experience and prolong the life of their automobiles.

Aftermarket vs. OEM Parts Explained

When it comes to vehicle maintenance and repairs, consumers often face a crucial decision: whether to choose original equipment manufacturer components or alternatives produced by third-party vendors. Each option has its own set of advantages and disadvantages, influencing both performance and cost-effectiveness.

Understanding OEM Components

Original equipment manufacturer items are made by the same company that produced the vehicle’s initial components. This ensures a perfect fit and compatibility with the original specifications. Here are some key points about OEM items:

- Guaranteed quality and reliability.

- Often come with a warranty from the manufacturer.

- Typically more expensive due to the brand name and assurance of quality.

Exploring Aftermarket Alternatives

Aftermarket offerings are produced by companies other than the original manufacturer. They can provide a more affordable solution, but quality may vary widely. Consider the following:

- Cost-effective options, often significantly cheaper than OEM.

- A wide range of choices available, from budget to high-performance items.

- Quality can be inconsistent; it’s essential to research manufacturers.

In conclusion, the choice between OEM and aftermarket offerings ultimately depends on personal preferences, budget considerations, and the specific needs of the vehicle. Making an informed decision can lead to enhanced performance and satisfaction in the long run.

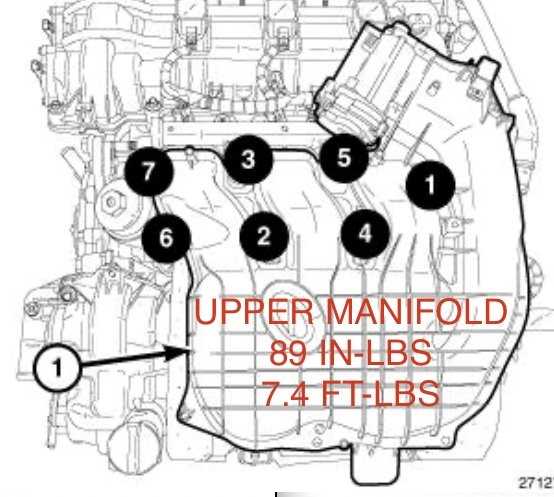

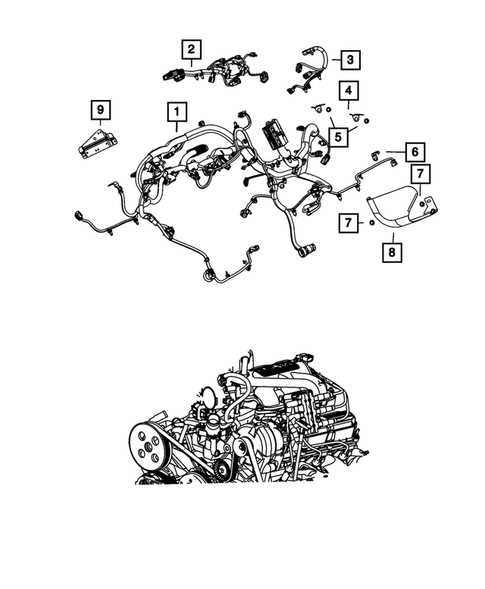

How to Read Engine Diagrams

Understanding the visual representation of an engine’s components is essential for anyone involved in automotive repair or maintenance. These illustrations serve as a roadmap, detailing the intricate relationships between various parts and how they interact within the system. Familiarity with these visuals can significantly enhance troubleshooting and repair efficiency.

Key Elements of Engine Illustrations

Engine visuals typically include various symbols and labels that indicate specific components. It’s crucial to identify these elements to grasp the overall function of the engine. Common features include:

- Component Labels: Clear markings that identify each part.

- Connection Lines: Arrows or lines showing how parts are linked and interact.

- Color Coding: Different colors may represent various systems, such as fuel or electrical.

Interpreting the Layout

To effectively analyze the layout, start by familiarizing yourself with the overall structure. Focus on the main assembly first, then delve into subcomponents. Understanding the flow of operations is vital; for instance, knowing how air and fuel move through the engine helps in diagnosing issues. Always refer to the key or legend, as it provides essential information on symbols and annotations used throughout the illustration.

Essential Tools for DIY Repairs

When it comes to tackling repairs on your own, having the right equipment is crucial for success. The right tools not only make the job easier but also ensure safety and efficiency. Whether you’re a novice or an experienced enthusiast, knowing what to have on hand can make all the difference in achieving quality results.

Here are some fundamental tools that every DIYer should consider:

- Wrenches: A variety of sizes, including adjustable wrenches, can handle different bolt and nut sizes.

- Screwdrivers: A set that includes both flat-head and Phillips-head options is essential for various tasks.

- Socket Set: A comprehensive socket set allows for easier access to tight spaces and provides better leverage.

- Pliers: Needle-nose and slip-joint pliers are versatile and helpful for gripping and twisting.

- Hammer: A good hammer is vital for driving nails and performing light demolition work.

In addition to the basic tools, consider the following items for more specialized tasks:

- Torque Wrench: Ensures that bolts are tightened to the correct specifications.

- Jack and Stands: Essential for safely lifting a vehicle for maintenance or repair.

- Multimeter: Useful for diagnosing electrical issues and checking circuits.

- Cutting Tools: Utility knives and wire cutters are important for precision cutting.

- Safety Gear: Goggles, gloves, and ear protection are crucial for personal safety during any project.

By investing in these tools, you’ll be well-equipped to handle a variety of repairs, ensuring your projects are completed successfully and safely.

Cost Considerations for Parts Replacement

When it comes to maintaining a vehicle, financial factors play a crucial role in decision-making. Understanding the expenses involved in replacing essential components can significantly influence the overall maintenance budget. Proper planning and assessment of costs ensure that vehicle owners can make informed choices, balancing quality with affordability.

Factors Influencing Costs

- Quality of Components: Opting for original equipment manufacturer (OEM) versus aftermarket options can greatly impact expenses. OEM parts typically come at a premium, but they often guarantee better compatibility and longevity.

- Labor Expenses: Professional installation can add to the overall price. It’s essential to consider whether to undertake the replacement as a DIY project or hire a skilled technician.

- Vehicle Type: The make and model can dictate the availability and pricing of components. Rare or luxury vehicles might incur higher replacement costs.

Strategies for Managing Costs

- Research Options: Thoroughly explore various suppliers and compare prices to identify the most cost-effective solutions.

- Consider Used Components: In some cases, gently used items can be a viable alternative, providing savings without sacrificing quality.

- Regular Maintenance: Preventative care can reduce the likelihood of needing premature replacements, ultimately saving money in the long run.

Upgrading Components for Performance

Enhancing the performance of your vehicle often involves a strategic approach to modifying various elements within the engine system. By focusing on specific components, you can achieve significant gains in power, efficiency, and overall driving experience. This section will explore several key areas where upgrades can make a notable difference.

When considering upgrades, it’s essential to identify the components that have the most impact on performance. Here are some areas to focus on:

- Intake System: Upgrading the air intake can improve airflow, resulting in better combustion and increased horsepower.

- Exhaust System: A high-performance exhaust system can reduce back pressure, enhancing engine efficiency and sound.

- ECU Tuning: Reprogramming the engine control unit can optimize fuel delivery and ignition timing for better performance.

- Turbochargers/Superchargers: Adding forced induction can dramatically boost power levels without sacrificing efficiency.

Each upgrade offers unique benefits and should be considered based on your specific performance goals. Prioritizing these modifications can lead to a more responsive and thrilling driving experience.

Before making any changes, it’s crucial to assess compatibility and potential impacts on vehicle reliability. Consider consulting with a professional to ensure that your upgrades align with your desired outcomes.

Resources for Further Learning and Support

When it comes to enhancing your knowledge and skills in automotive mechanics, a variety of resources are available to guide you. Whether you are a seasoned professional or a curious enthusiast, accessing quality information is crucial for mastering complex systems and components.

Online forums and communities offer a wealth of shared experiences and advice from fellow automotive aficionados. Engaging with these platforms allows you to ask questions, share insights, and stay updated on the latest trends in the industry.

In addition, manufacturer websites often provide technical manuals, troubleshooting guides, and other essential documentation. These resources can be invaluable when seeking detailed specifications and service procedures.

Finally, consider investing in reputable books and online courses that cover advanced topics and practical applications. These educational tools can deepen your understanding and enhance your ability to work on various vehicle models effectively.