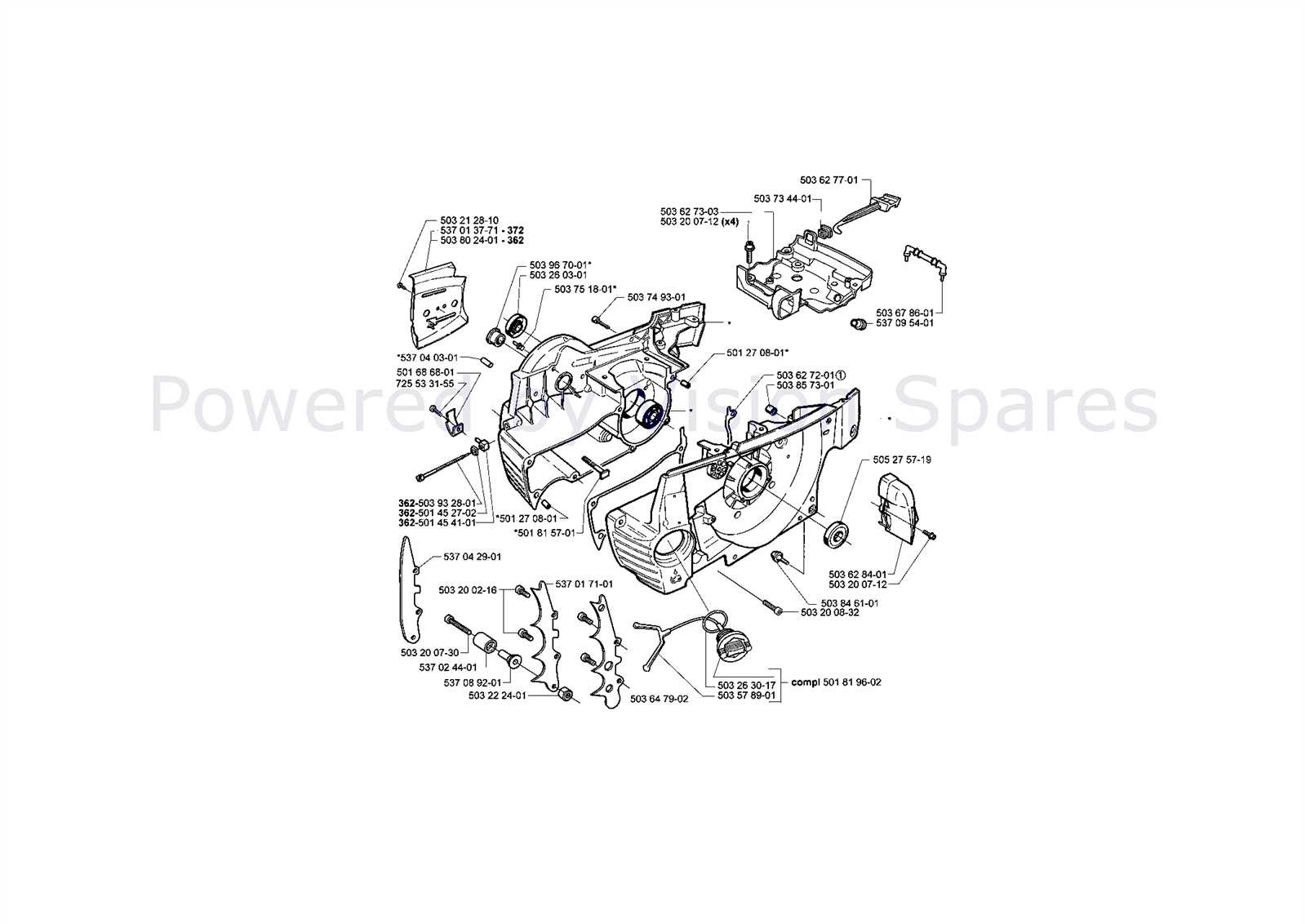

Exploring the 372xp Parts Diagram for Ultimate Understanding

In the realm of advanced machinery, a comprehensive grasp of each element’s role is essential for optimal performance. Every piece plays a critical part in the overall functionality, contributing to the effectiveness and reliability of the equipment. This section aims to shed light on the intricate assembly of such devices, revealing how each segment interconnects to achieve peak efficiency.

By examining the structure and configuration, one can appreciate the engineering behind the design. Each component, no matter how small, has its significance, and understanding their arrangement can enhance maintenance practices and operational insights. With a focus on clarity, this exploration invites you to delve into the specifics, empowering you with knowledge that supports both troubleshooting and performance enhancement.

The ultimate goal of this examination is to equip users with the tools to better comprehend their machinery. Recognizing how each individual part contributes to the whole not only facilitates repairs but also fosters a deeper connection to the equipment, enhancing overall proficiency in its use and care.

Understanding 372XP Components

Grasping the intricacies of a chainsaw’s structure is essential for effective maintenance and performance optimization. Each element plays a pivotal role in the overall functionality, ensuring a seamless operation and longevity of the tool. This section aims to provide a comprehensive overview of the various constituents, highlighting their significance and interconnections.

Key Elements of the Equipment

Among the critical components are the engine, cutting mechanism, and safety features. The engine serves as the powerhouse, converting fuel into mechanical energy. Meanwhile, the cutting mechanism, which includes the chain and bar, is vital for executing precise cuts. Safety features are equally important, as they protect the user during operation.

Interrelations and Performance

The interaction between these components determines the overall efficiency and reliability of the device. Understanding how each part influences performance can help users make informed decisions regarding upgrades, repairs, and regular upkeep, ultimately enhancing the tool’s efficacy in various tasks.

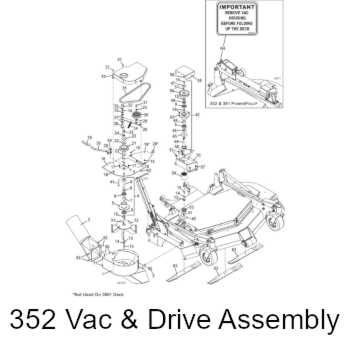

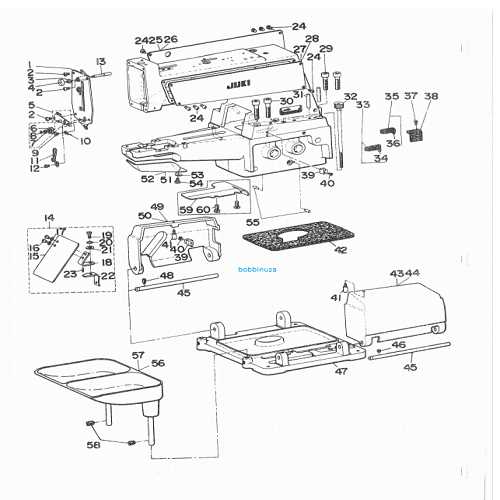

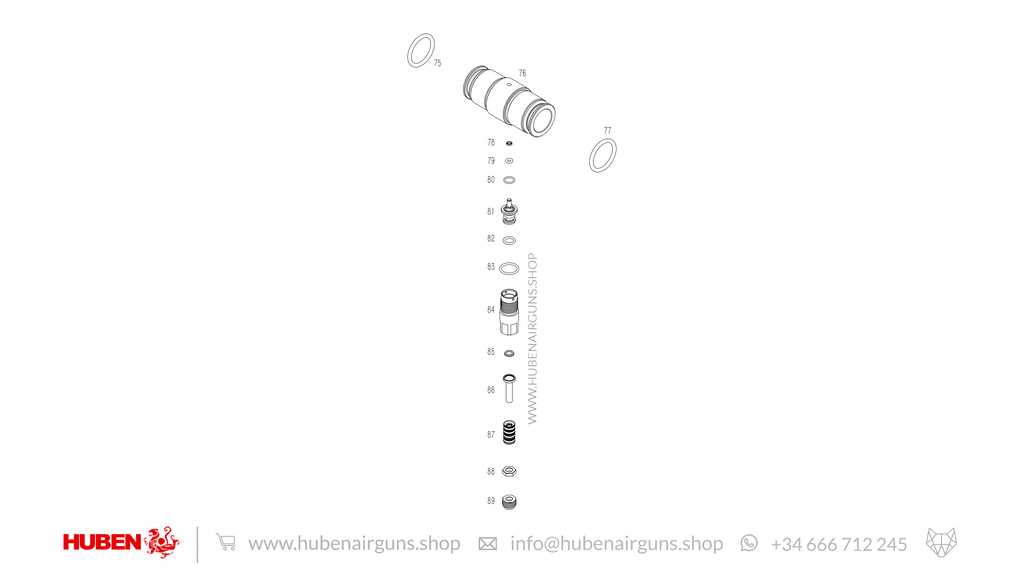

Importance of a Parts Diagram

Understanding the components of any mechanical system is crucial for effective maintenance and repair. A visual representation of these elements facilitates easier identification and organization, allowing users to navigate complex structures with confidence.

Firstly, such illustrations enhance troubleshooting efforts by providing clear insights into how individual pieces interact. This clarity minimizes errors and speeds up the diagnostic process.

Additionally, having a comprehensive layout aids in reassembly, ensuring that every part is correctly placed. This contributes to the longevity of the equipment and reduces the likelihood of future issues.

Moreover, a detailed visual reference can serve as an educational tool for both novice and experienced technicians, enabling them to deepen their understanding of the machinery and improve their skills.

In conclusion, leveraging an organized visual guide is essential for anyone involved in the maintenance or repair of mechanical systems, ultimately leading to more efficient operations.

Common Issues with 372XP Models

Many users encounter a range of challenges when operating these powerful machines. Understanding the frequent problems can help in effective maintenance and troubleshooting. Below are some of the typical issues faced by operators.

- Starting Difficulties: Machines may refuse to start due to fuel or ignition issues.

- Fuel Leaks: Users often report leaks that can affect performance and safety.

- Overheating: Excessive heat can lead to operational failures, often caused by clogged air filters or insufficient lubrication.

- Poor Cutting Performance: Dull chains or improper tension can result in ineffective cutting, leading to frustration.

Identifying these problems early can prevent more serious damage and enhance the longevity of the equipment.

- Check fuel lines and connections regularly to avoid leaks.

- Ensure proper air filter maintenance to prevent overheating.

- Regularly inspect and sharpen cutting chains to maintain performance.

By being aware of these common issues, operators can take proactive steps to ensure their machines run smoothly and efficiently.

How to Read the Diagram

Understanding a visual representation of components is essential for effective maintenance and repair tasks. This guide will help you navigate the intricacies of such illustrations, ensuring you can identify each element with confidence.

Start by familiarizing yourself with the layout. Each section typically contains numbered items corresponding to a list or legend. This makes it easier to pinpoint specific parts when needed. Below is a simplified example of how the information may be structured:

| Number | Description |

|---|---|

| 1 | Housing Assembly |

| 2 | Fuel Tank |

| 3 | Air Filter |

| 4 | Starter Motor |

Next, pay attention to the symbols and lines connecting the various components. These often indicate how parts interact with one another, such as airflow paths or fluid transfers. Understanding these connections can provide insight into how to troubleshoot issues or perform upgrades.

Finally, ensure you refer to the accompanying documentation for additional details, specifications, and maintenance tips. By combining your understanding of the visual layout with the provided information, you will be well-equipped to tackle any task related to these components.

Finding Replacement Parts Easily

Locating components for machinery can often be a challenging task. Understanding how to efficiently source these items can save time and ensure optimal functionality of your equipment. Whether you’re a seasoned professional or a novice, having a strategy in place is crucial.

Utilizing Online Resources

The internet offers a wealth of platforms dedicated to sourcing machinery elements. Websites specializing in industrial supplies typically provide detailed listings and specifications, allowing users to easily compare options. Forums and communities can also be valuable, as they often feature recommendations and experiences shared by other users.

Local Dealers and Workshops

Visiting local suppliers can be an effective approach for obtaining the necessary items quickly. Establishing a relationship with nearby vendors not only facilitates immediate assistance but also helps in acquiring tailored advice on which components best suit your needs. Networking within your community can yield insights that online searches might miss.

Maintenance Tips for 372XP

Proper upkeep of your equipment is crucial for optimal performance and longevity. Regular maintenance can prevent issues, ensuring that your tool remains reliable and efficient over time.

Routine Maintenance Practices

- Check and clean the air filter regularly to ensure proper airflow.

- Inspect the spark plug for wear and replace if necessary.

- Lubricate moving parts to reduce friction and prevent wear.

- Sharpen the cutting chain to maintain cutting efficiency.

Seasonal Care Tips

- Before winter, ensure the fuel system is clean and filled with fresh fuel.

- In spring, inspect all components for damage after storage.

- Check for any loose screws or bolts before starting regular use.

Tools Needed for Repairs

When it comes to maintaining and fixing machinery, having the right equipment is essential for efficient and effective work. A well-equipped toolbox ensures that you can tackle any issue that arises, minimizing downtime and extending the life of your device.

Essential Tools

To start, a good set of wrenches and sockets is crucial for loosening and tightening various components. These tools allow for precise adjustments and help prevent damage to sensitive parts. Additionally, screwdrivers of various sizes are necessary for accessing different fasteners.

Cutting and Prying Tools

In many cases, cutting tools like utility knives and prying tools are needed to remove old or damaged elements safely. These instruments facilitate clean removal, reducing the risk of injury or further harm to surrounding areas.

Measuring Equipment

Accurate measurements are vital for ensuring that replacement components fit correctly. Calipers and tape measures help guarantee that specifications are met, preventing costly mistakes during the repair process.

Protective Gear

Finally, do not overlook the importance of safety equipment. Gloves and goggles are necessary to protect yourself from sharp edges and debris, making the repair process safer and more comfortable.

Equipping yourself with the right tools not only simplifies repairs but also enhances the overall experience, allowing you to work with confidence and skill.

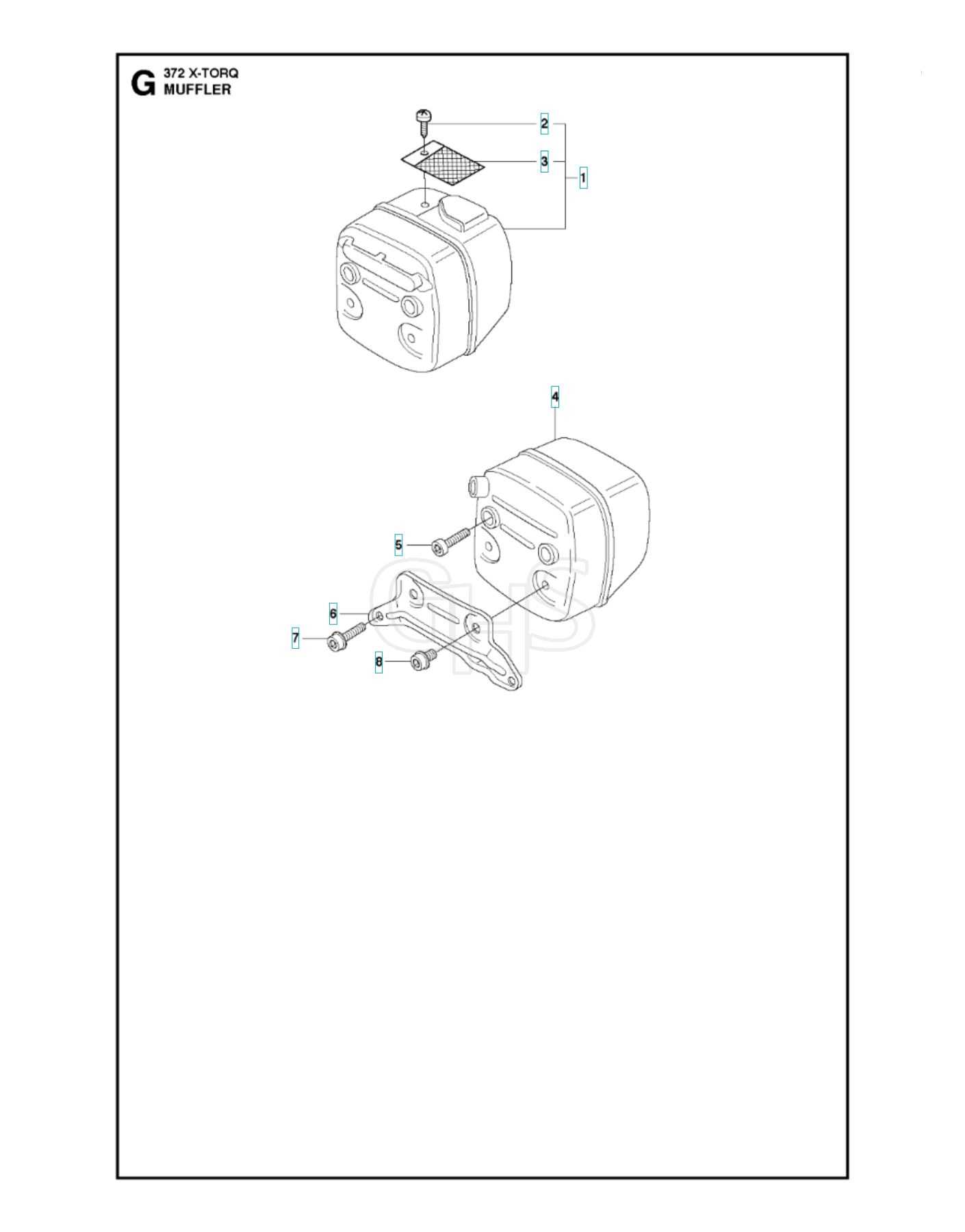

Upgrading Your 372XP Performance

Enhancing the capabilities of your chainsaw can significantly improve its efficiency and longevity. By focusing on key areas such as power, handling, and maintenance, you can achieve optimal results.

- Engine Upgrades:

- Consider a high-performance muffler to improve airflow.

- Upgrade the air filter for better filtration and airflow.

- Fuel System Enhancements:

- Use premium fuel for increased power and smoother operation.

- Install a high-flow carburetor for improved fuel delivery.

- Handling Improvements:

- Upgrade to a lighter guide bar for enhanced maneuverability.

- Consider anti-vibration handles for increased comfort during use.

- Maintenance Tips:

- Regularly clean and replace filters to maintain performance.

- Keep the chain sharp for efficient cutting and reduced strain on the engine.

By delving into these aspects, you can unlock the ultimate potential of your equipment, ensuring a more powerful and efficient experience every time you use it.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Understanding the necessary precautions can significantly reduce risks associated with handling tools and machinery. By being proactive and prepared, you can create a safer working environment.

Essential Safety Gear

Wearing appropriate protective equipment is vital during any repair process. This gear helps shield you from potential hazards and ensures that you can work effectively. Below are some recommended items:

| Type of Gear | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris and chemical splashes. |

| Gloves | Prevents cuts and abrasions while handling tools. |

| Ear Protection | Reduces noise exposure when using loud equipment. |

| Steel-Toed Boots | Protects feet from heavy objects and provides support. |

Workspace Organization

A well-organized workspace can greatly enhance safety during repair activities. Keeping tools and materials in designated areas minimizes the risk of accidents. Ensure that your working area is clean and free from clutter, and always store hazardous substances properly to avoid spills or leaks.

Where to Buy Authentic Parts

Finding genuine components for your equipment is essential for ensuring optimal performance and longevity. Authentic items not only guarantee compatibility but also enhance the overall efficiency of your machinery. Below are some reliable sources where you can acquire these quality items.

- Authorized Dealers: Always start with authorized distributors. They offer a range of genuine items backed by warranties.

- Manufacturer’s Website: Many manufacturers provide direct sales options. Purchasing directly from the source ensures authenticity.

- Reputable Online Retailers: Websites with a solid reputation often sell authentic items. Look for customer reviews and ratings.

- Local Specialty Shops: Visit local stores that specialize in your equipment type. They usually stock genuine items and can provide expert advice.

- Trade Shows and Expos: Attend industry events where manufacturers showcase their products. This is a great opportunity to purchase directly and network with suppliers.

By sourcing from these trusted avenues, you can ensure that you are getting the best quality components, ultimately benefiting the performance and durability of your machinery.