Ultimate Guide to 7.3 Turbo Parts Diagram

In the world of automotive performance, the intricacies of enhancing engine efficiency and power are paramount. This section delves into the essential components that contribute to the optimization of engine functionality, particularly focusing on systems designed to amplify air intake and overall performance. A comprehensive understanding of these elements is crucial for enthusiasts and mechanics alike, enabling them to unlock the full potential of their vehicles.

By exploring the various elements involved in forced induction systems, readers will gain insights into how each component plays a vital role in achieving superior performance. From understanding the flow of air to recognizing the importance of specific mechanisms, this exploration will highlight the synergy between different parts and their contributions to an engine’s capability.

Whether you are a seasoned expert or a newcomer eager to learn, grasping the layout and operation of these critical components can significantly enhance your knowledge. This knowledge not only aids in maintenance and repair but also empowers you to make informed modifications that can elevate your vehicle’s performance to new heights.

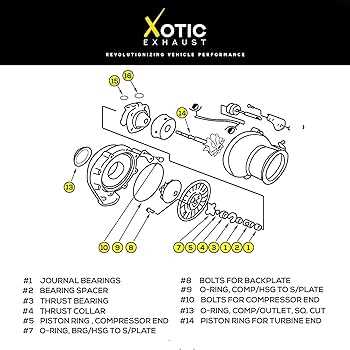

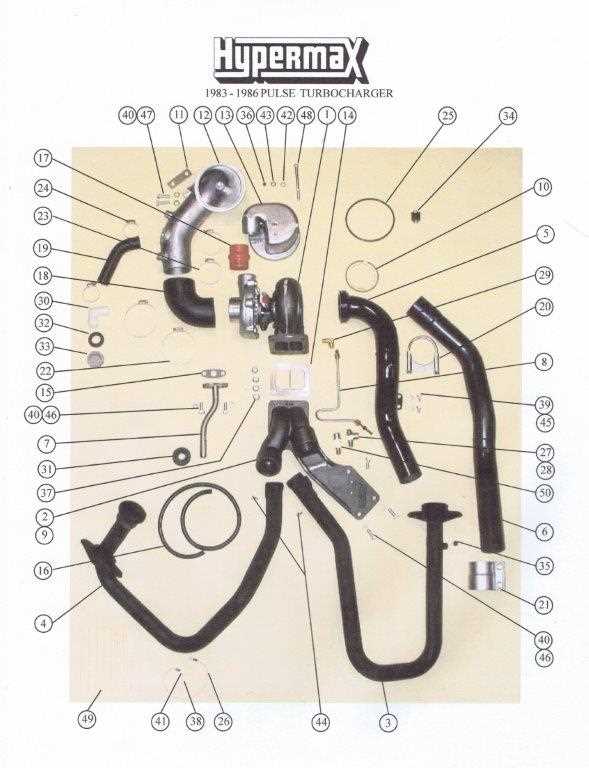

Understanding Turbocharger Components

In the realm of performance engineering, the efficiency of an internal combustion engine can be significantly enhanced through various mechanisms. One such mechanism involves a specialized device that forces more air into the combustion chamber, allowing for a greater fuel-to-air ratio and, consequently, improved power output. This section delves into the essential elements of this technology, exploring how they interact to elevate engine performance.

At the heart of this device is a turbine, which harnesses exhaust gases to create rotational energy. This energy is then transmitted to a compressor, which draws in ambient air and compresses it before it enters the engine. The interplay between these components is crucial, as it determines the overall effectiveness of the system in boosting engine power.

Additionally, various auxiliary components play vital roles in ensuring smooth operation and longevity. These include cooling systems designed to manage temperature fluctuations, as well as wastegate mechanisms that regulate pressure levels. Understanding the functionality of each part and their collaborative dynamics is key for anyone looking to optimize engine performance through advanced engineering techniques.

Ultimately, a thorough comprehension of these components not only aids in enhancing engine efficiency but also facilitates better maintenance and troubleshooting practices. By grasping the intricacies of this technology, enthusiasts and professionals alike can unlock the full potential of their vehicles.

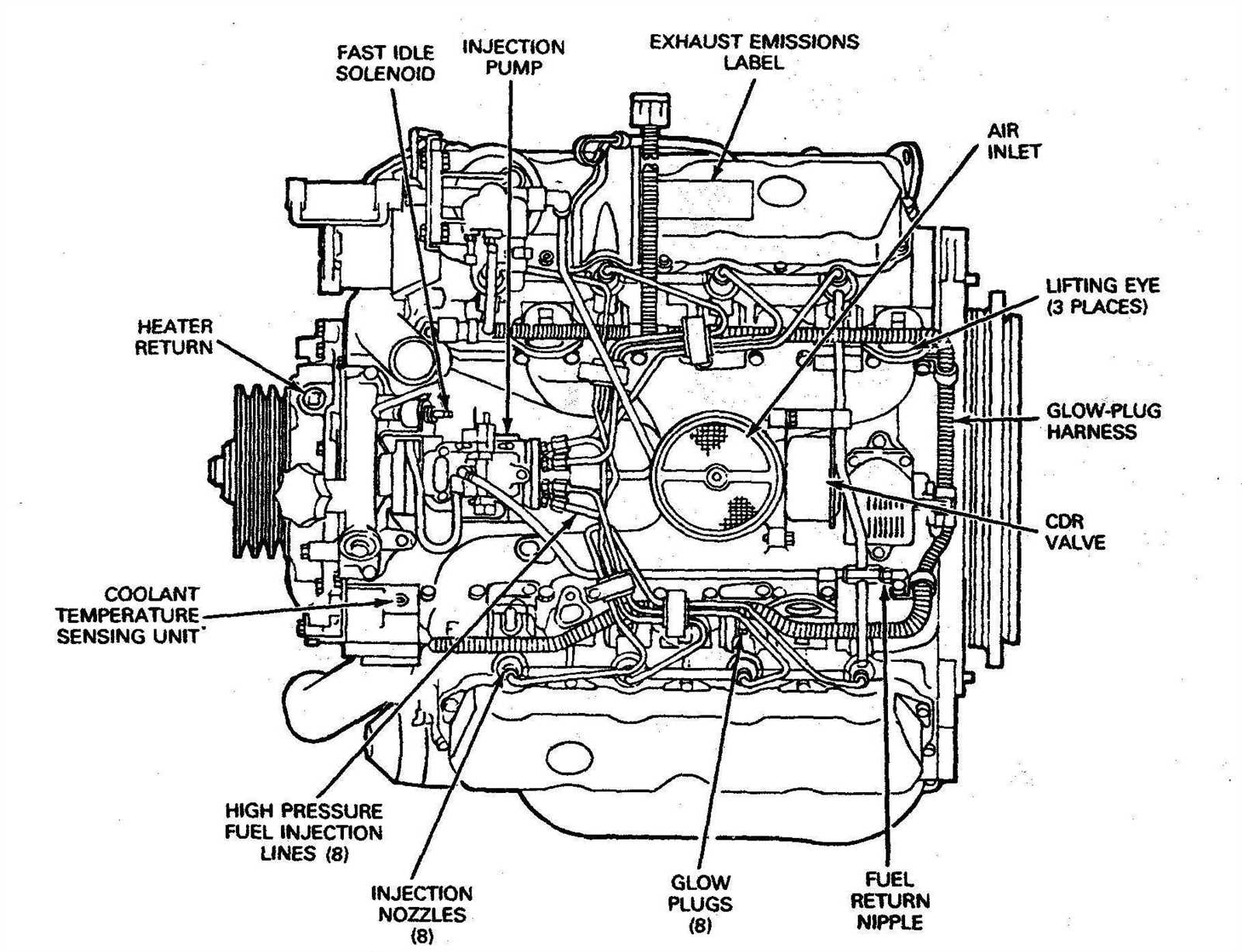

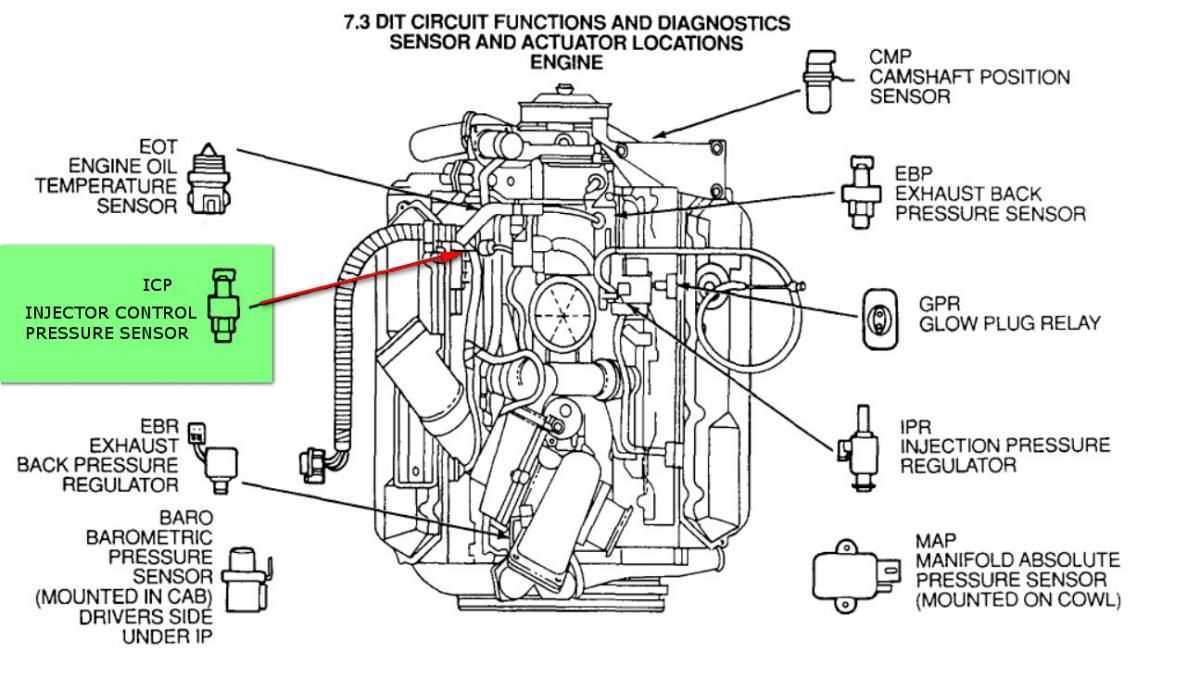

Key Parts of the 7.3 Turbo

This section explores the essential components that contribute to the performance and efficiency of the engine system. Understanding these elements is crucial for anyone looking to enhance their vehicle’s power and reliability.

Core Components

Among the most significant elements are the air intake system, which optimizes airflow, and the exhaust manifold, which ensures efficient gas expulsion. These components work in harmony to enhance overall engine output.

Supporting Elements

Additionally, the intercooler plays a vital role in cooling compressed air, while the fuel injectors are responsible for delivering the precise amount of fuel necessary for optimal combustion. Together, these parts form the foundation for an effective engine setup.

How Turbochargers Improve Engine Performance

Boosting the efficiency of internal combustion engines is essential for achieving higher power outputs and better fuel economy. Advanced mechanisms that enhance air intake allow engines to perform optimally under various conditions. This section delves into the benefits of these systems and their impact on overall performance.

Key Benefits

- Increased Power Output

- Improved Fuel Efficiency

- Enhanced Throttle Response

- Lower Emissions

How They Work

- Utilizing exhaust gases to spin a turbine.

- Compressing incoming air for better combustion.

- Creating a denser air-fuel mixture.

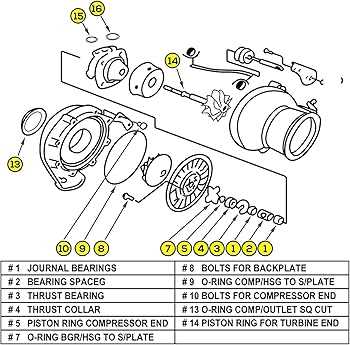

Diagram Analysis for 7.3 Turbo Parts

This section aims to explore the intricate layout and components that contribute to optimal performance in high-efficiency engines. Understanding the arrangement and function of these elements is crucial for effective maintenance and enhancement of engine capabilities.

| Component | Description |

|---|---|

| Compressor | Boosts air intake, increasing engine power. |

| Intercooler | Cools compressed air, enhancing density for better combustion. |

| Wastegate | Regulates exhaust flow to maintain optimal boost levels. |

| Turbocharger | Utilizes exhaust gases to increase air intake efficiency. |

Common Issues with Turbo Components

When it comes to forced induction systems, various challenges can arise, affecting overall performance and reliability. Understanding these common problems is crucial for maintaining optimal functionality and extending the lifespan of the system. This section delves into the frequent complications encountered in these setups, highlighting their potential impact on performance.

Boost Leaks are a prevalent issue, often resulting from damaged hoses or connections. These leaks can lead to a significant loss of pressure, diminishing the efficiency of the system and causing sluggish acceleration.

Oil Starvation is another critical concern. Insufficient lubrication can lead to severe wear or even catastrophic failure of the components. Regular maintenance and checks on oil levels and quality are essential to prevent this problem.

Overheating can occur due to excessive stress on the system, particularly during high-performance applications. Monitoring temperature levels is vital to avoid thermal damage, which can compromise various components.

Wastegate Issues can disrupt the regulation of boost pressure, leading to erratic performance. Ensuring proper operation of the wastegate is necessary to maintain consistent performance and prevent overboost conditions.

By being aware of these common challenges, enthusiasts and mechanics can take proactive measures to ensure longevity and efficiency in their systems, ultimately leading to enhanced driving experiences.

Maintenance Tips for Turbo Systems

Ensuring the longevity and optimal performance of forced induction systems requires a thoughtful approach to upkeep. Regular attention to specific components can prevent issues and enhance efficiency, ultimately leading to a smoother driving experience.

Regular Oil Changes

Frequent oil changes are crucial for maintaining lubrication and reducing wear on engine components. Using high-quality oil can significantly improve the system’s performance and reliability. Check the manufacturer’s recommendations for optimal intervals and oil specifications.

Cooling System Inspection

A well-functioning cooling mechanism is essential for preventing overheating. Regularly inspect hoses, radiators, and coolant levels. Address any leaks immediately to avoid potential damage, ensuring the system operates within safe temperature ranges.

Choosing the Right Turbo Upgrade

Selecting the ideal enhancement for your vehicle’s forced induction system is crucial for achieving the ultimate performance. With various options available, it’s important to consider multiple factors that influence both efficiency and output.

- Goals: Define your performance objectives, whether it’s daily driving or competitive racing.

- Compatibility: Ensure the selected upgrade fits seamlessly with your existing setup.

- Boost Level: Determine the desired level of pressure for optimal power gain.

- Fuel System: Evaluate if your current fuel delivery can support increased demands.

- Engine Health: Assess the condition of your engine to handle additional stress.

By delving into these aspects, you can make a more informed choice that aligns with your vehicle’s performance ambitions.

Fuel Efficiency and Turbochargers Explained

Understanding the relationship between performance-enhancing components and fuel consumption is essential for optimizing vehicle efficiency. These systems work by harnessing exhaust gases to boost air intake, leading to improved combustion and power output. By allowing engines to produce more power without significantly increasing fuel use, these technologies can enhance overall performance while maintaining economical operation.

The primary advantage lies in the ability to extract more energy from each drop of fuel. This not only translates to better acceleration and towing capacity but also results in reduced emissions and lower fuel costs. By utilizing advanced engineering, vehicles can achieve a balance between power and efficiency, making them more environmentally friendly and cost-effective over time.

As manufacturers continue to innovate, the incorporation of these systems becomes increasingly prevalent. Enhanced designs and materials contribute to reliability and longevity, ensuring that drivers benefit from both performance and savings. Ultimately, these developments represent a significant stride toward sustainable automotive technology.

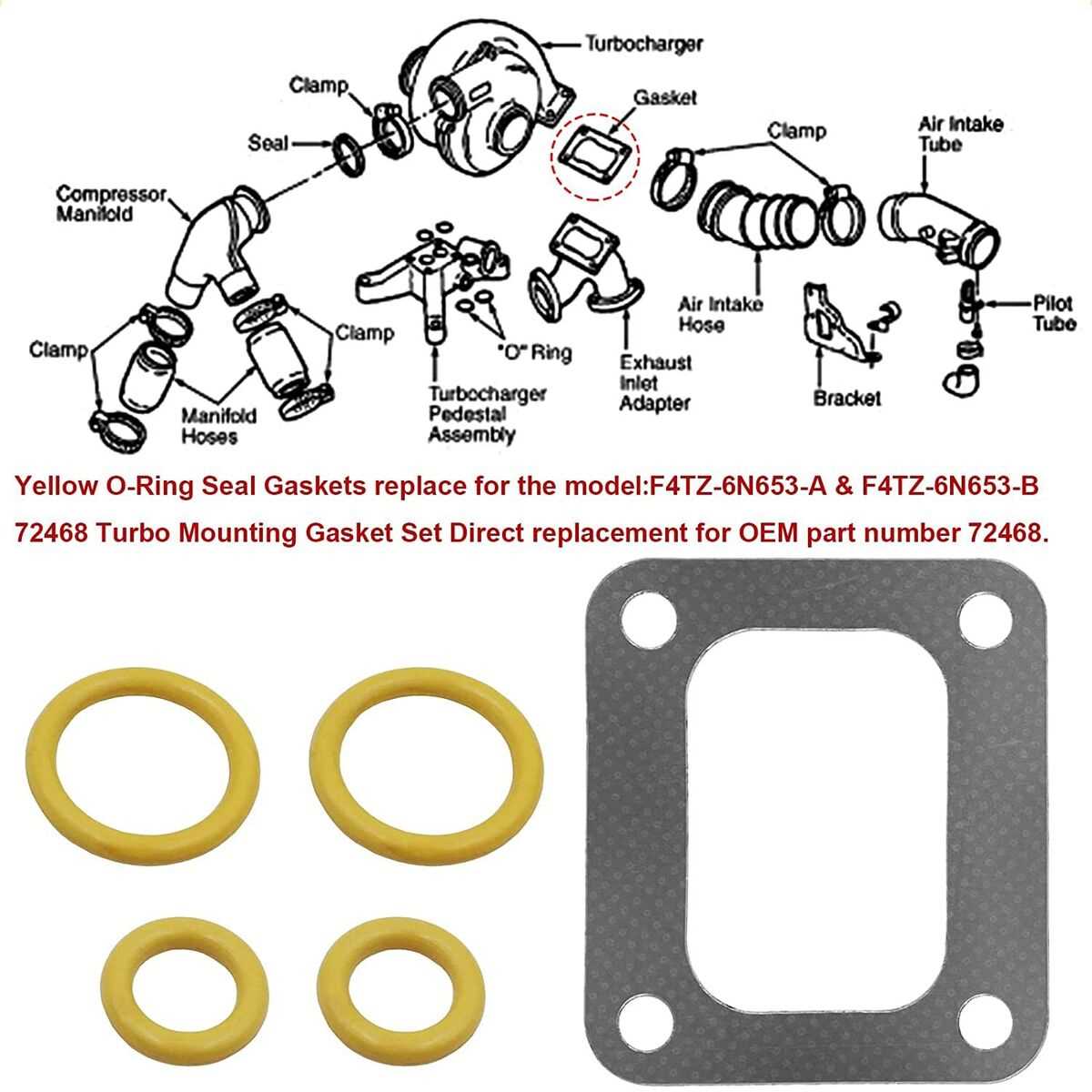

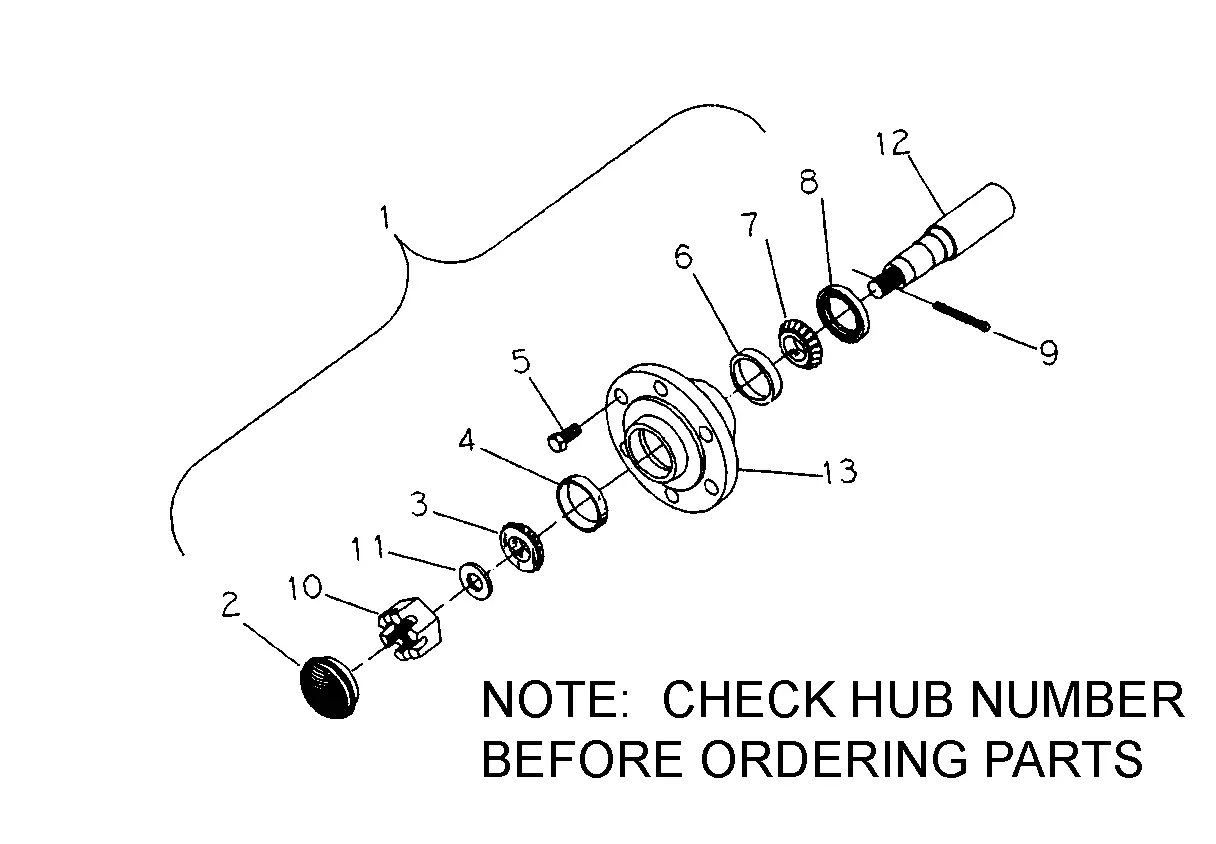

Installation Guidelines for Turbo Parts

When enhancing engine performance, proper installation of components is crucial for achieving optimal results. This section provides essential instructions to ensure that each element is fitted correctly, maximizing efficiency and reliability.

| Step | Description |

|---|---|

| 1 | Gather all necessary tools and components before starting the installation process. |

| 2 | Carefully read the manufacturer’s instructions to understand specific requirements and recommendations. |

| 3 | Begin with the removal of existing components that may obstruct the new installations. |

| 4 | Ensure all surfaces are clean and free of debris to facilitate a proper seal. |

| 5 | Install the new components methodically, following the outlined order and torque specifications. |

| 6 | Double-check connections and fittings to prevent any leaks or malfunctions. |

| 7 | Perform a thorough inspection after installation to confirm everything is secure and functioning correctly. |

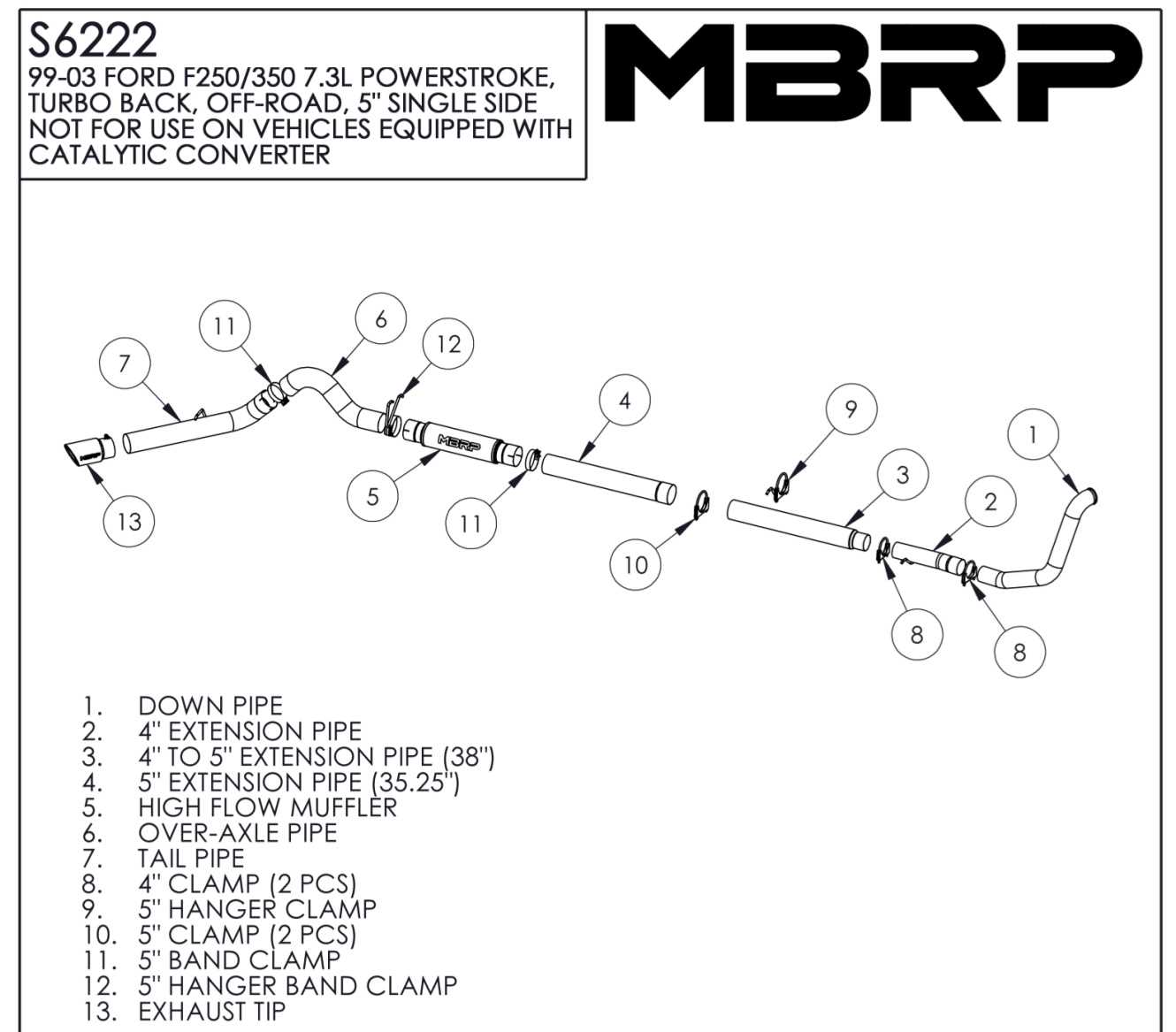

Aftermarket Options for 7.3 Turbo

Enhancing performance and efficiency is a common goal among enthusiasts looking to upgrade their vehicles. A variety of aftermarket solutions are available to optimize engine output and overall functionality. These enhancements can significantly improve driving experience and vehicle reliability.

Performance Enhancements

- High-Flow Exhaust Systems

- Upgraded Air Intake Kits

- Performance Tuners and Chips

- Intercooler Upgrades

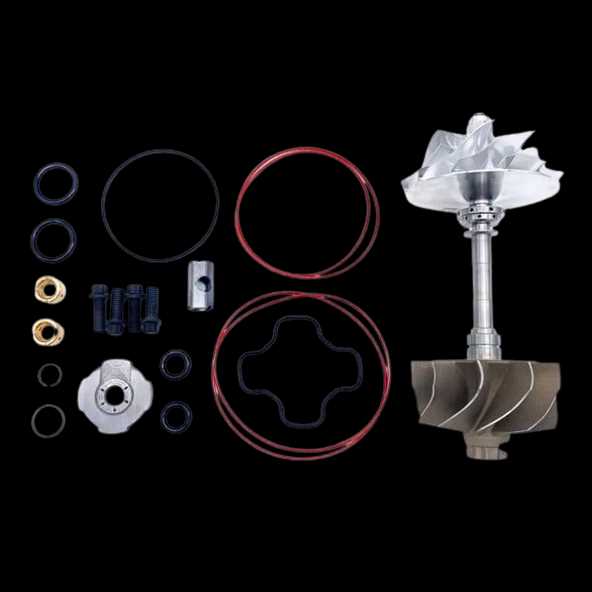

Durability and Reliability

- Reinforced Gaskets and Seals

- High-Performance Fuel Injectors

- Heavy-Duty Turbochargers

- Enhanced Cooling Systems

Choosing the right enhancements can lead to improved performance metrics and extend the lifespan of the engine. Careful consideration of options tailored to specific needs will yield the best results.

Impact of Turbo on Emissions Control

Enhanced forced induction systems have significantly transformed vehicle performance and efficiency. However, their influence on emissions management is equally critical. Understanding how these systems affect exhaust outputs can guide improvements in environmental standards and technology.

The integration of a forced induction system can lead to various outcomes regarding emissions:

- Improved Combustion Efficiency: By increasing the air supply, these systems allow for more complete fuel combustion, potentially reducing unburned hydrocarbons.

- Reduced Greenhouse Gas Emissions: More efficient combustion can lead to lower CO2 emissions, which is essential in the fight against climate change.

- Particulate Matter Control: Advanced designs can help in minimizing particulate emissions, aligning with stricter regulations.

- Optimized Fuel Usage: Enhanced air-fuel mixtures can lead to reduced consumption, further lowering harmful emissions.

However, challenges remain. The following factors must be considered:

- Heat Management: Increased temperatures can lead to higher nitrogen oxide (NOx) emissions if not adequately controlled.

- System Complexity: More components can introduce additional failure points, potentially impacting overall emissions performance.

- After-treatment Compatibility: These systems must work harmoniously with catalytic converters and other emission-reducing technologies to be effective.

In conclusion, while forced induction systems present opportunities for enhancing performance and reducing harmful outputs, they require careful integration and ongoing refinement to meet evolving environmental standards.