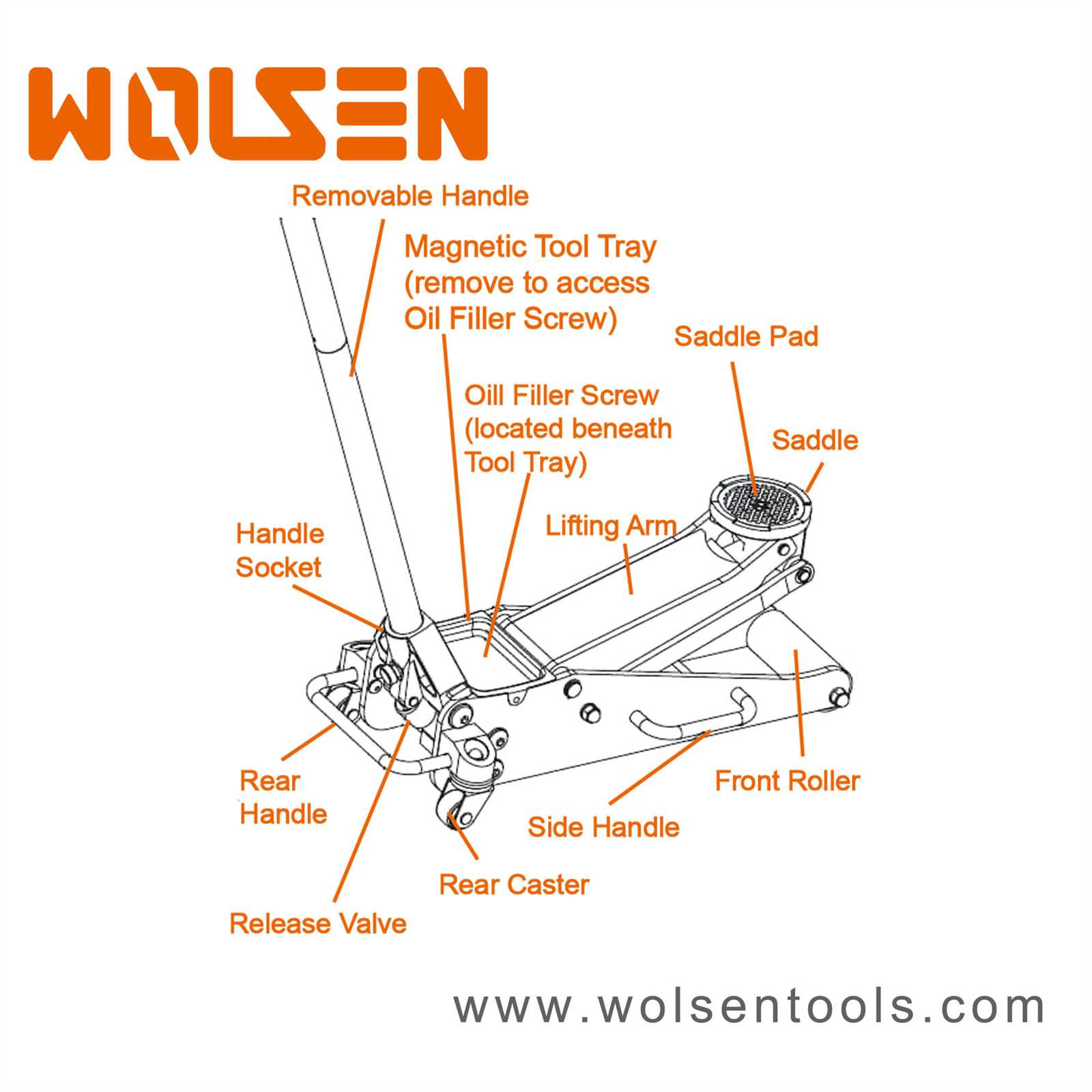

Allied Floor Jack Parts Diagram Overview

In the world of automotive repair and maintenance, having a clear understanding of lifting mechanisms is essential for both professionals and enthusiasts. These devices serve as invaluable tools, allowing users to safely elevate vehicles for inspections, repairs, or modifications. Familiarity with the components and their arrangement enhances the efficiency of any maintenance task.

By exploring the structure of these mechanisms, one can gain insights into their functionality and potential issues that may arise during use. This knowledge not only promotes safety but also aids in troubleshooting and repairs. With a comprehensive overview of the essential elements, users can better appreciate the intricacies of these devices.

Ultimately, understanding the configuration of these tools empowers users to make informed decisions, ensuring that maintenance tasks are performed with confidence and precision. Whether for personal use or professional applications, mastering the elements of these lifting aids is key to effective automotive care.

Overview of Lifting Equipment Components

This section provides a comprehensive look at the various elements that make up hydraulic lifting mechanisms commonly used in automotive and industrial settings. Understanding these components is essential for effective maintenance and troubleshooting, ensuring optimal performance during operation.

Key Components

The primary elements of these lifting devices include the hydraulic cylinder, release valve, and pump. Each component plays a vital role in the lifting process, allowing for efficient elevation and control of heavy loads. Familiarity with these parts can aid users in identifying issues and ensuring safe operation.

Maintenance Considerations

Understanding the Jack Mechanism

The lifting apparatus operates through a series of interconnected components that work together to elevate heavy objects with minimal effort. By leveraging mechanical principles, this system simplifies the process of raising and lowering loads safely and efficiently.

Key Components

- Piston: The central element that creates pressure to lift the load.

- Hydraulic Fluid: Transmits force throughout the system.

- Release Valve: Controls the lowering process by regulating fluid flow.

How It Works

- The operator engages the mechanism, causing the piston to compress the hydraulic fluid.

- This compression generates sufficient force to raise the load.

- When the load needs to be lowered, the release valve is opened, allowing fluid to escape and the load to descend smoothly.

Key Components of Floor Jacks

Understanding the essential elements of lifting devices is crucial for effective operation and maintenance. Each component plays a vital role in ensuring safety and functionality, contributing to the overall performance of the equipment.

| Component | Description |

|---|---|

| Chassis | The base structure that supports all other elements, providing stability and strength. |

| Hydraulic Cylinder | The mechanism responsible for generating lifting force through fluid pressure. |

| Pump | A device that moves hydraulic fluid, facilitating the lifting action. |

| Release Valve | A control mechanism that allows for the safe lowering of the load. |

| Handle | The lever used to operate the lifting mechanism, providing user control. |

Types of Allied Floor Jacks

When it comes to lifting equipment, there are various models designed for different applications and needs. Understanding the types available can help users select the most suitable option for their tasks.

Common Variants

Different variants of lifting devices can be categorized based on their design and functionality:

- Standard Models

- Low Profile Versions

- Heavy-Duty Options

- Portable Types

Usage Scenarios

Each type serves specific purposes, making them ideal for various situations:

- Standard models are great for general maintenance and repair tasks.

- Low profile versions are particularly useful for vehicles with minimal clearance.

- Heavy-duty options are designed for larger vehicles and demanding tasks.

- Portable types offer convenience for mobile applications and limited spaces.

Common Issues with Jack Parts

When working with lifting equipment, various challenges can arise that affect their functionality and safety. Understanding these common issues can help users maintain their equipment effectively and avoid potential accidents.

Leaks are a frequent problem, often caused by worn seals or damaged components. These leaks can lead to decreased lifting capacity and may pose safety risks if not addressed promptly.

Worn Out Components are another concern. Over time, various elements such as pistons and cylinders can wear down, resulting in reduced performance. Regular inspections can help identify these wear signs early.

Stability Issues may arise if the equipment is not placed on a level surface. This can lead to dangerous situations where the lifting apparatus may tip or fail. Ensuring a stable setup is crucial for safe operation.

Unresponsive Mechanisms can be frustrating and often indicate underlying mechanical problems. It’s essential to troubleshoot and identify the cause to ensure the device operates correctly.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your lifting equipment requires regular care and attention. By following a few essential maintenance practices, you can extend the lifespan of your apparatus and keep it functioning optimally.

- Regular Inspection: Conduct frequent checks for any signs of wear, damage, or leaks. Early detection can prevent more serious issues.

- Cleaning: Keep the components free from dirt and debris. Use appropriate cleaning agents that won’t harm the materials.

- Lubrication: Apply suitable lubricants to moving parts to reduce friction and wear. Follow the manufacturer’s recommendations for lubrication intervals.

- Storage: Store the equipment in a dry, clean environment when not in use to prevent corrosion and deterioration.

- Operating Instructions: Always adhere to the manufacturer’s guidelines for usage to avoid unnecessary strain on the equipment.

By implementing these practices, you will enhance the reliability and performance of your lifting tools, ensuring they serve you well for years to come.

Tools for Jack Repair and Maintenance

Proper maintenance and repair of lifting devices are crucial for ensuring their efficiency and longevity. Having the right tools on hand can simplify tasks and improve safety during service operations.

Essential Tools

- Socket Set: Useful for loosening and tightening bolts.

- Wrenches: Adjustable or fixed, essential for various nuts and bolts.

- Hydraulic Oil: Necessary for maintaining fluid levels and performance.

- Cleaning Supplies: Brushes and cloths help keep components free from debris.

Safety Equipment

- Gloves: Protect hands during repairs.

- Safety Goggles: Shield eyes from debris and splashes.

- Jack Stands: Provide stability while working on elevated equipment.

Safety Precautions When Using Jacks

Ensuring safety while operating lifting equipment is crucial to prevent accidents and injuries. Proper knowledge and adherence to guidelines can significantly enhance safety during use. It is essential to follow specific precautions to protect both the user and the equipment.

General Guidelines

Before engaging with lifting tools, familiarize yourself with the operational manual. Always inspect the equipment for any signs of wear or damage, and ensure that it is placed on a stable surface to avoid tipping.

Personal Protective Equipment

Wearing appropriate safety gear is vital. This includes gloves, safety glasses, and sturdy footwear to safeguard against potential hazards during operation.

| Precaution | Description |

|---|---|

| Check Stability | Ensure the equipment is on a level, solid ground before use. |

| Inspect Regularly | Conduct routine checks for any damage or wear before each use. |

| Clear Area | Keep the workspace free from obstructions to prevent accidents. |

| Use Proper Techniques | Follow correct procedures for lifting and lowering loads. |

How to Identify Worn Parts

Recognizing when components have become worn or damaged is crucial for maintaining equipment functionality. Regular inspections can help prevent further issues and ensure optimal performance.

Signs of Wear

- Visible cracks or chips on surfaces

- Unusual noises during operation

- Inconsistent movement or performance

- Excessive play or looseness in connections

Inspection Tips

- Perform routine checks during maintenance schedules.

- Use appropriate tools to measure tolerances and clearances.

- Compare worn components to new ones for visual reference.

- Consult manuals or guides for specific indicators of wear.

Replacing Faulty Jack Components

Maintaining optimal performance of your lifting device requires prompt replacement of any defective elements. Recognizing issues early can prevent further damage and ensure safety during operations. This section will guide you through the essential steps to effectively replace malfunctioning components.

Identifying Faulty Elements

Before proceeding with replacements, it’s crucial to identify which components are not functioning properly. Common indicators include unusual noises, leaks, or inability to lift loads. Regular inspections can help in spotting these issues early.

Replacement Procedure

Follow these steps for replacing damaged components:

| Step | Description |

|---|---|

| 1 | Disconnect the lifting apparatus from any power source. |

| 2 | Carefully remove the affected part using appropriate tools. |

| 3 | Install the new component, ensuring it fits securely. |

| 4 | Reconnect the system and conduct a test to confirm proper operation. |

Where to Purchase Replacement Parts

Finding suitable components for your equipment is essential for maintaining its functionality and ensuring safety. There are various avenues available to acquire the necessary items, each offering unique advantages. Whether you’re looking for OEM options or high-quality alternatives, knowing where to look can save time and money.

Online Retailers

Numerous online platforms provide a vast selection of components. Websites such as Amazon and eBay often feature both new and refurbished items, making it easy to compare prices and reviews. Additionally, specialty retailers may offer specific components tailored to your needs, ensuring you find the right fit.

Local Supply Stores

Visiting local supply stores can be advantageous for immediate needs. These establishments often carry a range of components and can provide helpful advice from knowledgeable staff. Furthermore, purchasing in person allows you to inspect the quality before committing to a purchase.

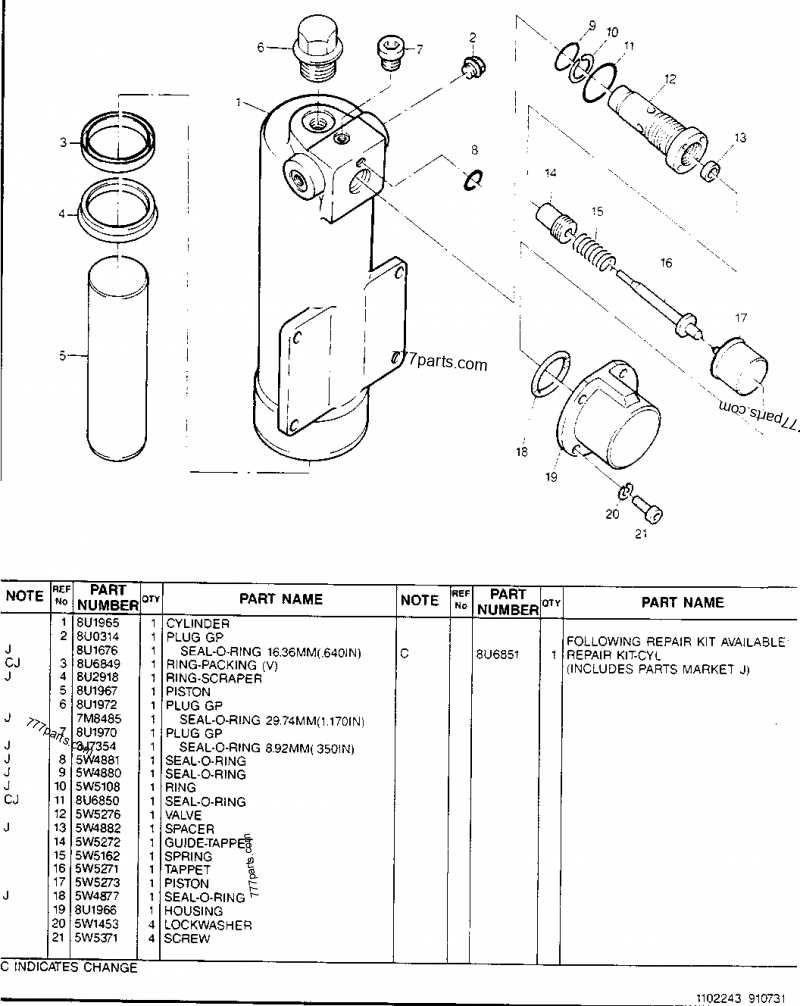

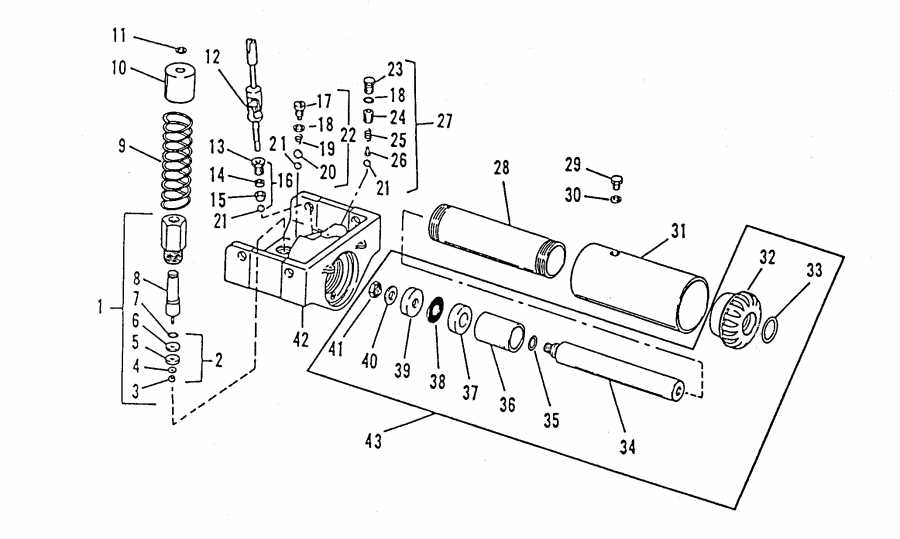

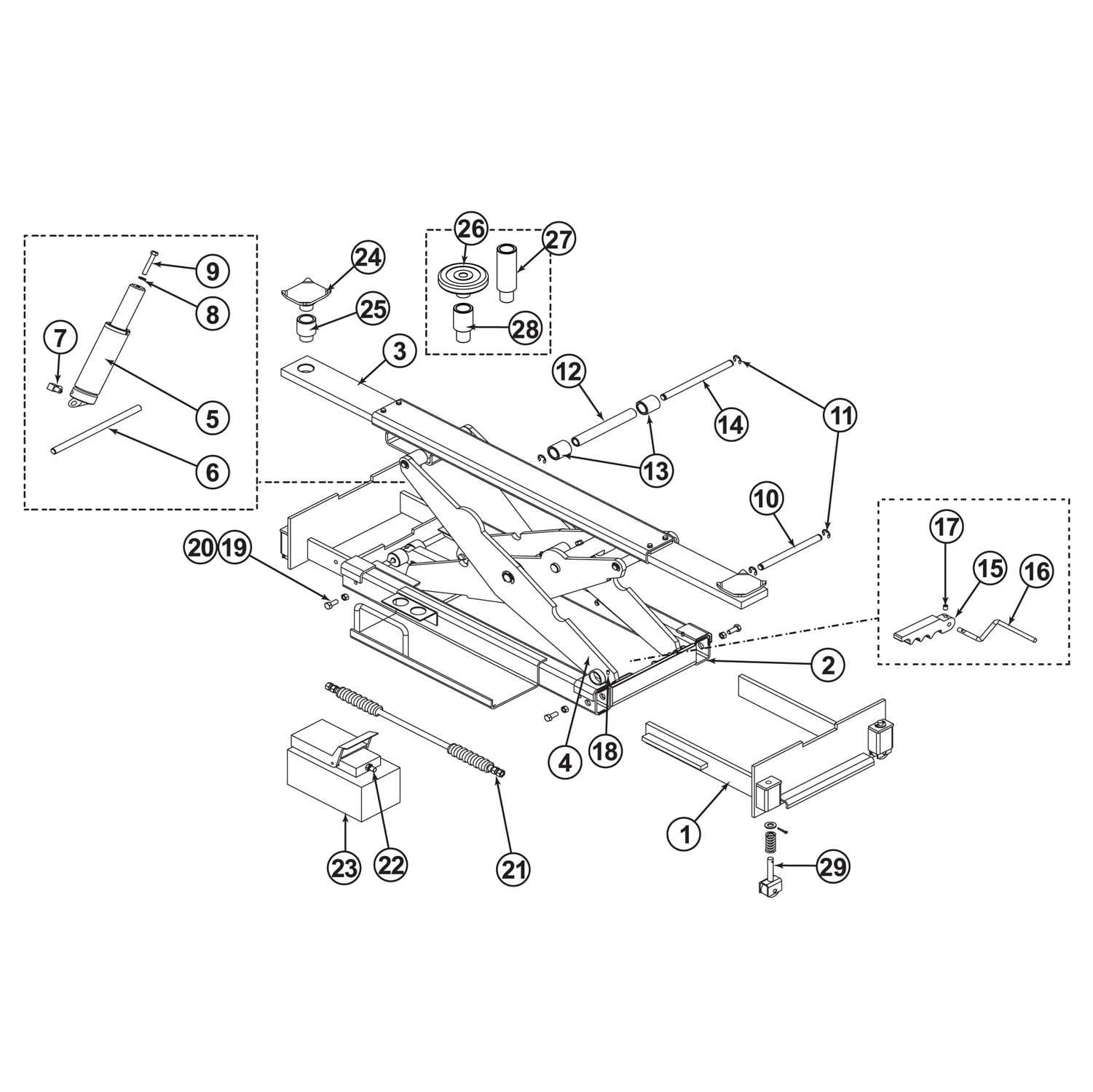

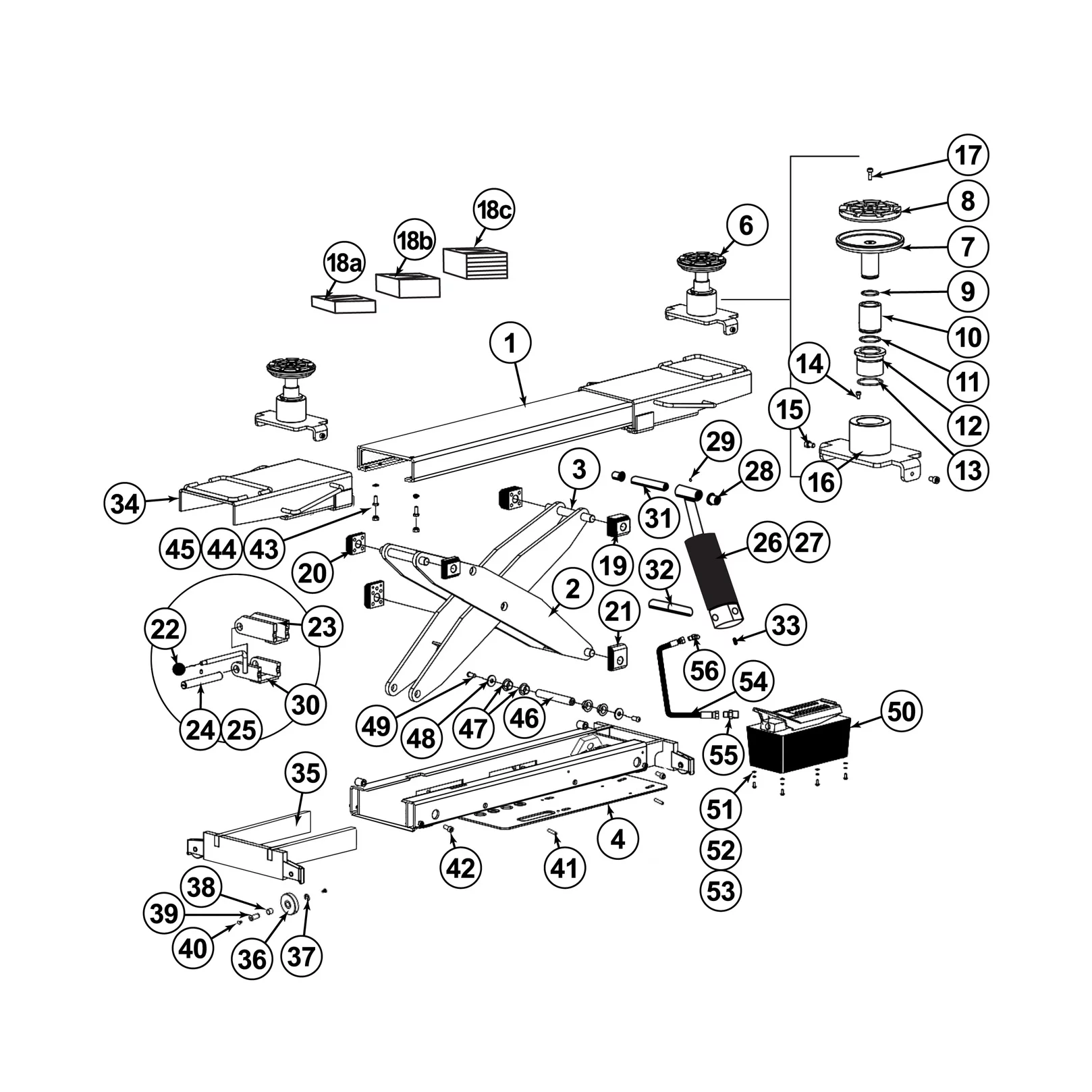

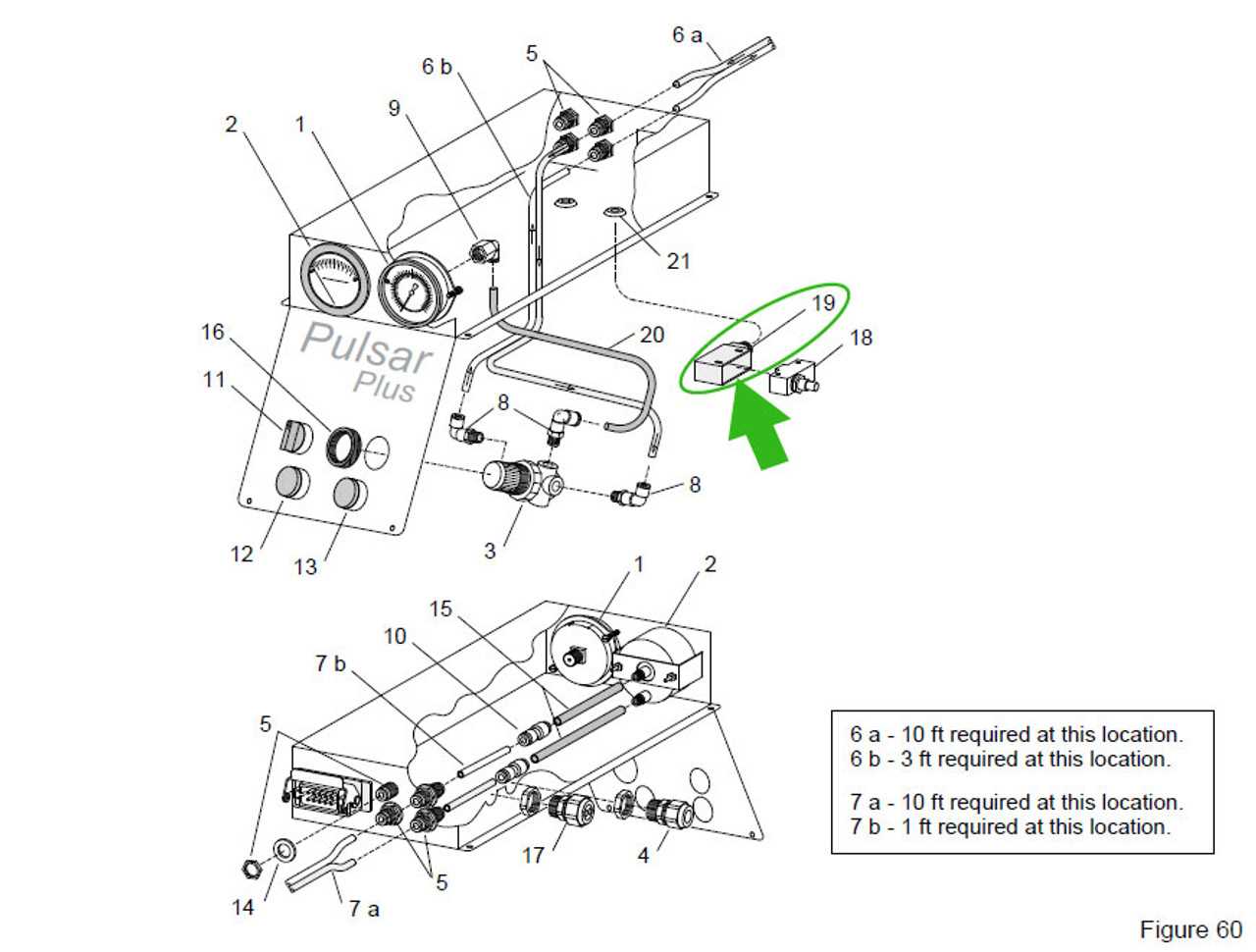

Reading Parts Diagrams Effectively

Understanding visual representations of components is essential for successful maintenance and repair tasks. These illustrations provide crucial information about each element’s function and placement, enabling users to identify and troubleshoot issues efficiently.

Identifying Key Components

When examining illustrations, focus on the labels and numbers assigned to each item. This information aids in pinpointing specific elements within the assembly, allowing for a clearer understanding of how everything fits together. Pay attention to the arrangement and connections, as these can reveal potential points of failure.

Utilizing Reference Materials

Consult additional resources such as manuals or online guides that complement the visuals. These documents often provide insights into assembly procedures and maintenance tips, enhancing your overall comprehension. By cross-referencing various materials, you can build a more comprehensive understanding of the entire system.